Sound barrier unit plate

A unit board and sound barrier technology, applied in construction, noise absorption devices, etc., can solve the problems of reduced sound absorption effect, reduced sound absorption effect, etc., and achieve the effects of convenient transportation, improved noise reduction effect, and simple assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

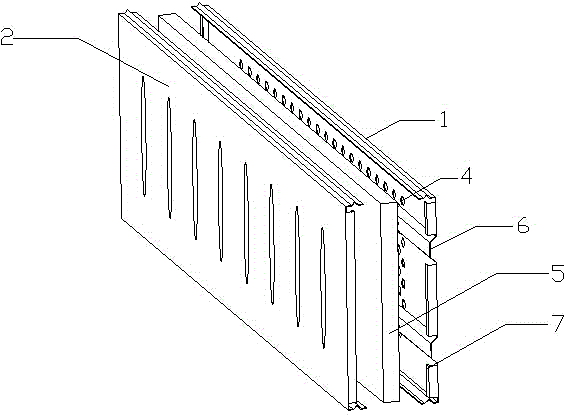

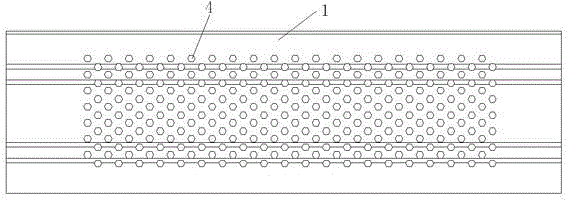

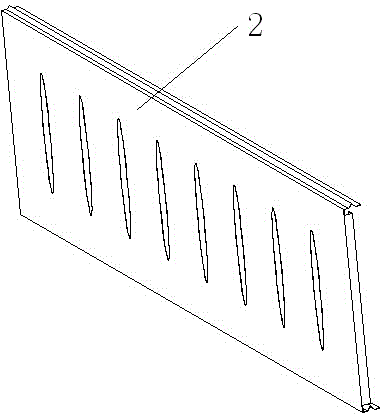

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the sound barrier unit board is composed of a sound-absorbing board 1, a foamed cement board 5, and a sound-insulating board 2. The cavity formed between the sound-absorbing board 1 and the sound-insulating board 2 is provided with a foamed cement board 5, and the sound-absorbing board 1 is provided with a sound-absorbing hole 4, and the axial direction of the sound-absorbing hole 4 is at an angle of 30° to the front of the sound-absorbing panel. 70%, the sound insulation board 2 includes the front and two sides, the two sides form an angle of 85° with the front, and the front is provided with a convex cone 3. The sound-absorbing panel 1 includes a front and two sides. The two sides form an angle of 85° with the front. Each side is divided into three small sides. The front is provided with two grooves 6. The cross-section of the bottom is a triangle without a bottom. This triangular structure can coopera...

Embodiment 2

[0023] It is basically the same as the first embodiment, except that the axial direction of the sound-absorbing hole 4 is at an angle of 45° to the front of the sound-absorbing panel, and the sound-absorbing hole 4 is in the shape of a regular hexagonal star, and the diameter of its circumscribed circle is 5mm. The two sides of the sound insulation board 2 form an angle of 89° with the front, and the two sides of the sound-absorbing board 1 form an angle of 89° with the front.

Embodiment 3

[0024] Embodiment 3: It is basically the same as Embodiment 1, except that the axial direction of the sound-absorbing hole 4 forms an angle of 60° with the front of the sound-absorbing panel, and the sound-absorbing hole 4 is in the shape of a regular five-pointed star, and the diameter of its circumscribed circle is 8mm , The opening rate is 90%, the two sides of the sound insulation board 2 form an angle of 87° with the front, and the two sides of the sound-absorbing board 1 form an 87° angle with the front.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com