Band laser welding tool for laser welding equipment

A jig and radium welding technology, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of unfavorable use of automatic radium welding equipment, manual opening and placing of products, cumbersome positioning of radium welding jigs, etc. Achieve the effect of solving monitoring and traceability problems, satisfying some shape changes, and simple and fast assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

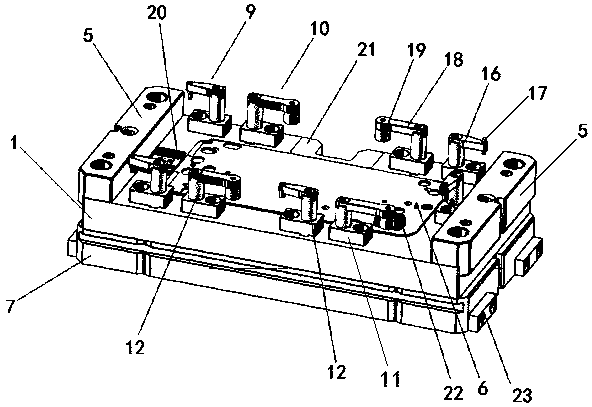

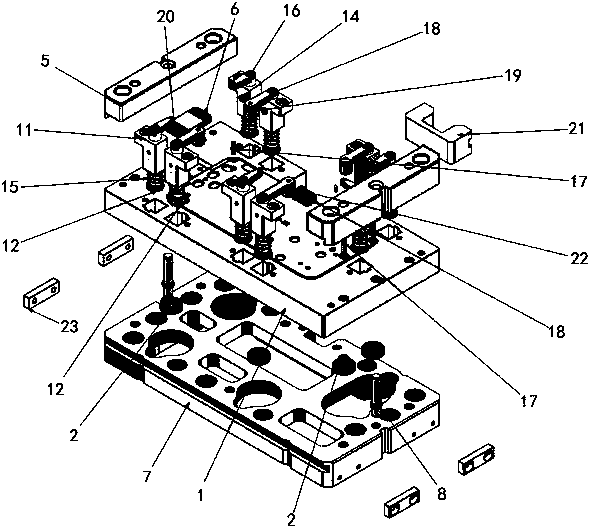

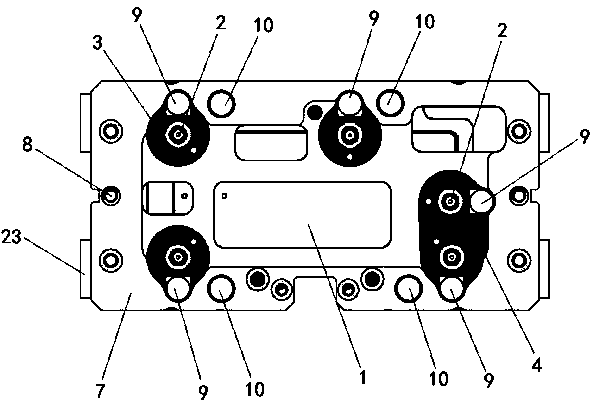

[0029] see Figure 1-3 As shown, a Band radium welding jig used on radium welding equipment includes an integrally formed jig substrate 1, and the lower surface of the jig substrate 1 is provided with three single welding positions 9 and one double welding position 10 , one copper sleeve 2 is provided in each of the three single welding positions 9, and two copper sleeves 2 are provided in the double welding positions 10; five NUT rotation compressions are provided in the jig substrate 1 Mechanism 3, three of the NUT rotary pressing mechanisms 3 are located on the edges of the three single welding positions 9, and the remaining two NUT rotating pressing mechanisms 3 are located on the edges of the double welding positions 10; The jig substrate 1 is also provided with four product rotary pressing mechanisms 4, three of which are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com