Method for realizing conical roller bearing low friction and structure thereof

A tapered roller bearing and tapered roller technology, applied in the field of friction reduction, can solve the problems of large contact friction between the large retaining ring and the roller, affecting the normal operation of the equipment, and burning the large retaining edge, etc., so as to prolong the life of the bearing and improve the lubrication. situation and working conditions, improve the effect of anti-skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

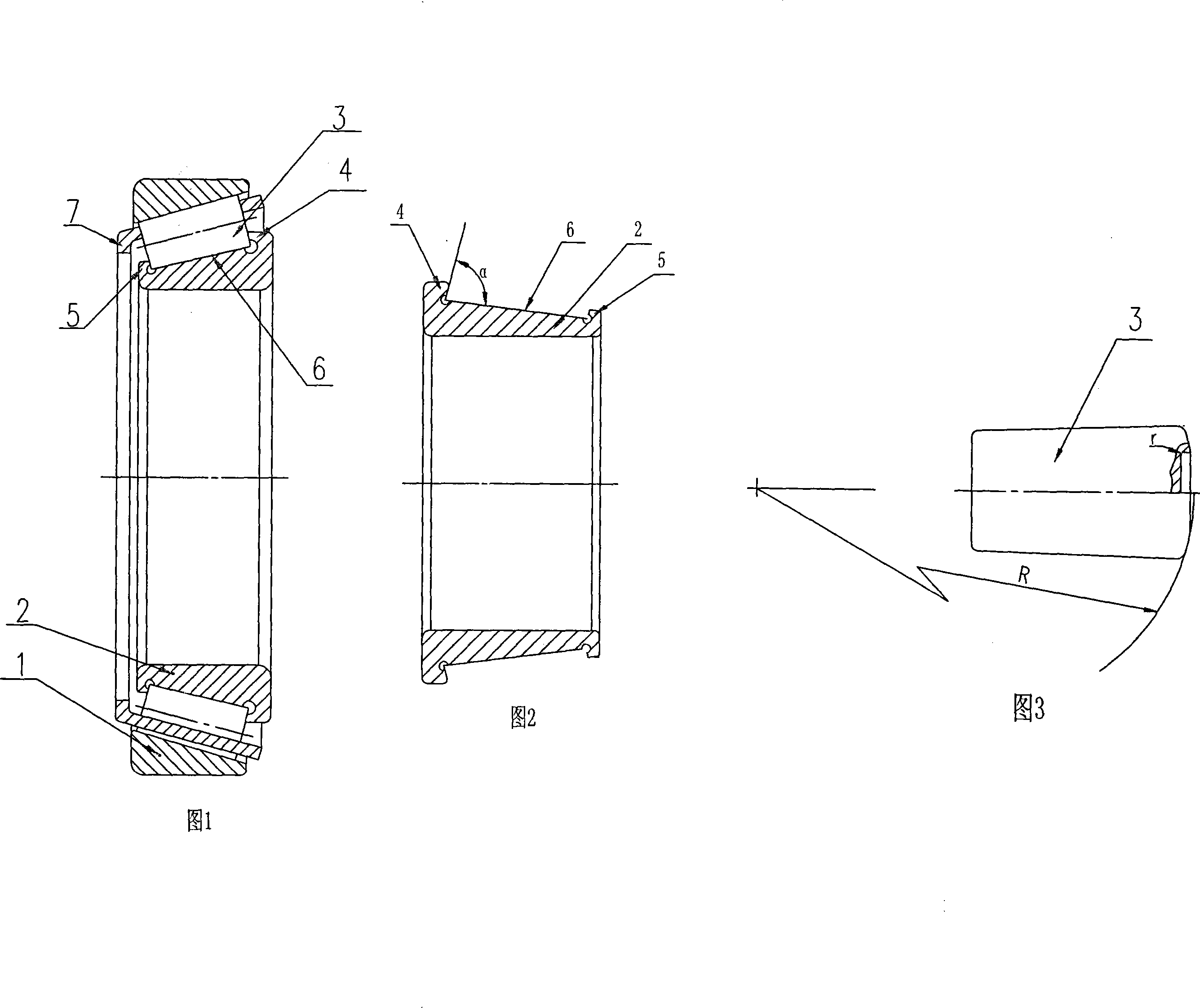

[0024] A method for realizing low friction of tapered roller bearings. First, the angle between the large retaining ring of the tapered roller bearing and the generatrix of the raceway is greater than 90 degrees; The contact between the roller spherical surface and the large retaining ring is changed from intersecting two-point contact to smooth one-point contact, thereby reducing the number of contact points, improving the contact condition between the two, reducing the friction between the large retaining ring and the spherical surface, and making the tapered roller rotate ability has been effectively improved. In addition, through the comprehensive application of the design principles of ball bearings, the anti-skew ability of the ribs to the tapered rollers is enhanced, and the high-speed and heavy-duty of the tapered roller bearings are realized. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com