Long-pipe taper thread measurement device, taper plug gauge clamp and taper ring gauge clamp

A technology of measuring device and taper plug gauge, which is applied in the direction of measuring device, mechanical measuring device, angle/taper measurement, etc., can solve the problems of inconsistent pressing force, base surface gauge error, influence of measurement results, etc., to improve accuracy, eliminate The effect of easy guarantee of error and machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, a measuring device for long pipe-like tapered threads is provided. This measuring device can measure long pipe-like tapered threads, and can also measure common tapered threads. This measuring device can measure comprehensive parameters of tapered threads, such as base surface Pitch diameter, major diameter of base surface, minor diameter of base surface, pitch, cumulative error of pitch, profile angle, profile half angle, taper, etc. The measuring device can also measure the long tapered tube type smooth surface cone gauge.

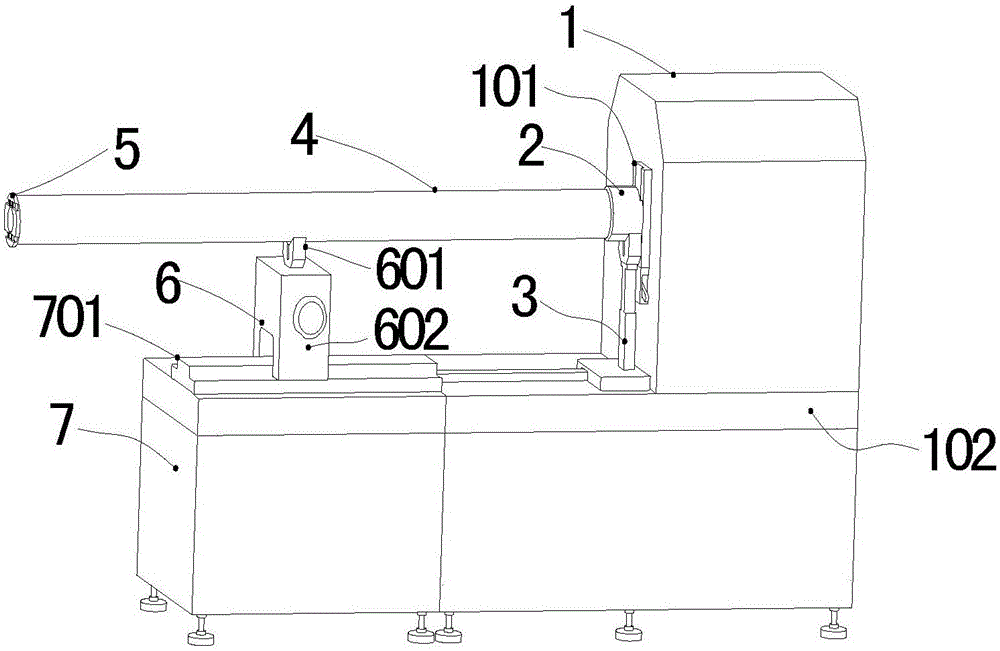

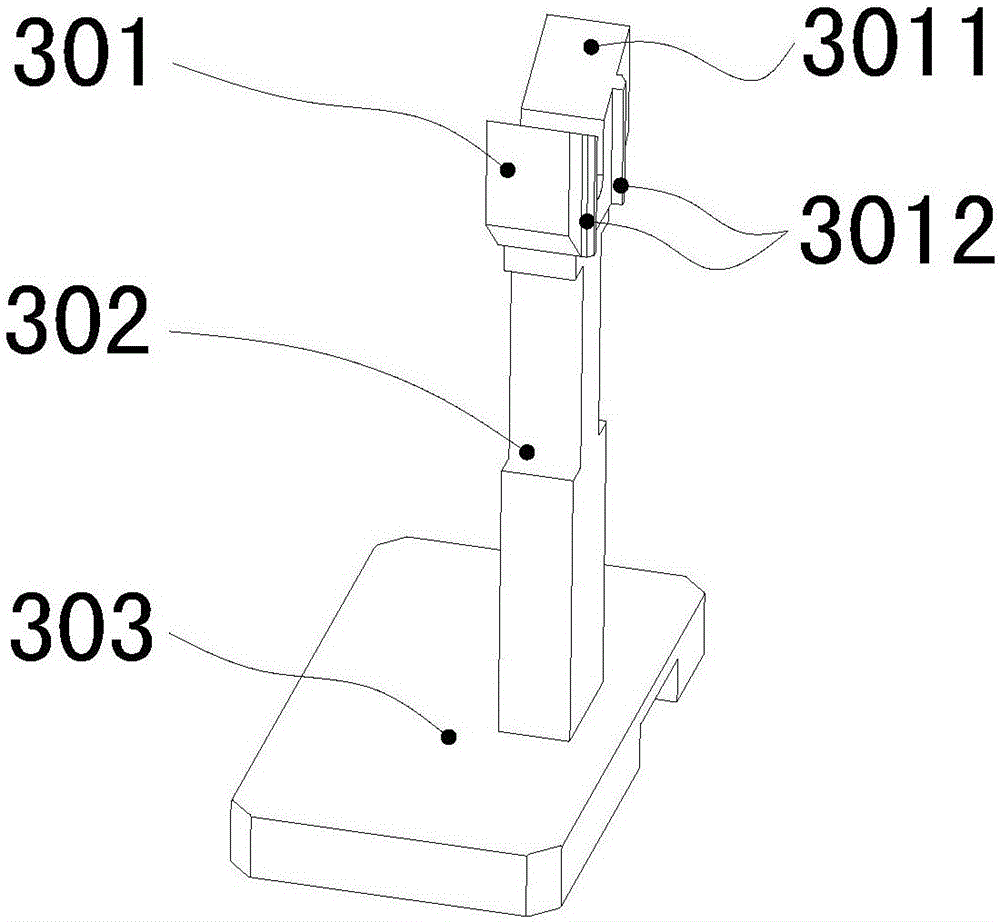

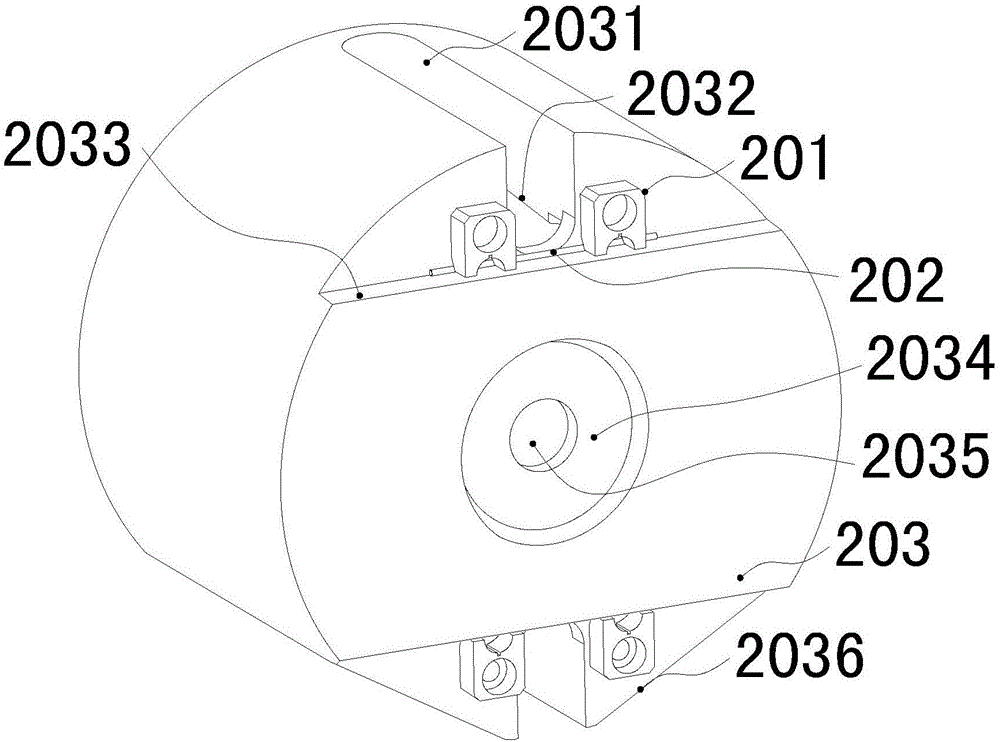

[0044] Such as figure 1 As shown, the measuring device mainly includes a support platform 7, a measuring mechanism 1, a first support fixture 3, a second support fixture 6, a first tapered sleeve fixture 2 and a second tapered sleeve fixture 5, wherein the support platform 7 is installed in existing equipment The base of the supporting table is grown, and the measuring mechanism 1 is consistent with the measuring mechanism of ...

Embodiment 2

[0060] This embodiment provides a tapered plug gauge fixture, and the tapered plug gauge fixture in this example is used to accurately measure the tapered plug gauge.

[0061] Such as Figure 11 As shown, the taper plug gauge fixture includes a plug gauge fixture 10 for clamping, and also includes a datum 9 for determining the reference plane of the taper plug gauge. When measuring the taper plug gauge 11 , the benchmark 9 is installed on the V-shaped groove 1001 of the plug gauge fixture 10 , the taper plug gauge 11 is placed on the V-shaped groove 1001 of the plug gauge fixture 10 , and the end is attached to the benchmark 9 .

[0062] The plug gauge fixture 10 is provided with a V-shaped groove 1001 for installing the taper plug gauge 11, and the bottom of the V-shaped groove 1001 is provided with a groove for avoiding the measurement of the scanning needle 15. The plane on which it rests is provided with a slot for avoiding the measurement of the probe. The benchmark 9 i...

Embodiment 3

[0074] This embodiment provides a taper ring gauge clamp, and the taper ring gauge clamp in this example is used for accurately clamping the taper ring gauge.

[0075] Such as Figure 14 As shown, it includes a ring gauge fixture 13 for clamping, and also includes a datum 12 for determining the reference plane of the taper ring gauge. When measuring the taper ring gauge 14 , the ring gauge fixture 13 is installed on the fixture base 101 , the taper ring gauge 14 is installed on the reference device 12 , and the reference device 12 is installed on the ring gauge holder 13 .

[0076] Such as Figure 15 As shown, the reference device 12 is an annular body 1202 with a panel on one side. The annular body 1202 has an annular cavity 12022 that matches the taper ring gauge 14. A mounting hole 12021 is provided in the center of the panel. There are two installation grooves symmetrical to the center, and an avoidance hole for avoiding the measurement of the scanning needle 15 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com