Steel galvanized group corner combining piece

A technology of steel and angle assembly, which is applied to building components, windows/doors, buildings, etc., can solve the problems of unsuitable high-temperature welding and inconvenient assembly, and achieve the goals of reducing material and labor costs, simple and fast assembly, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

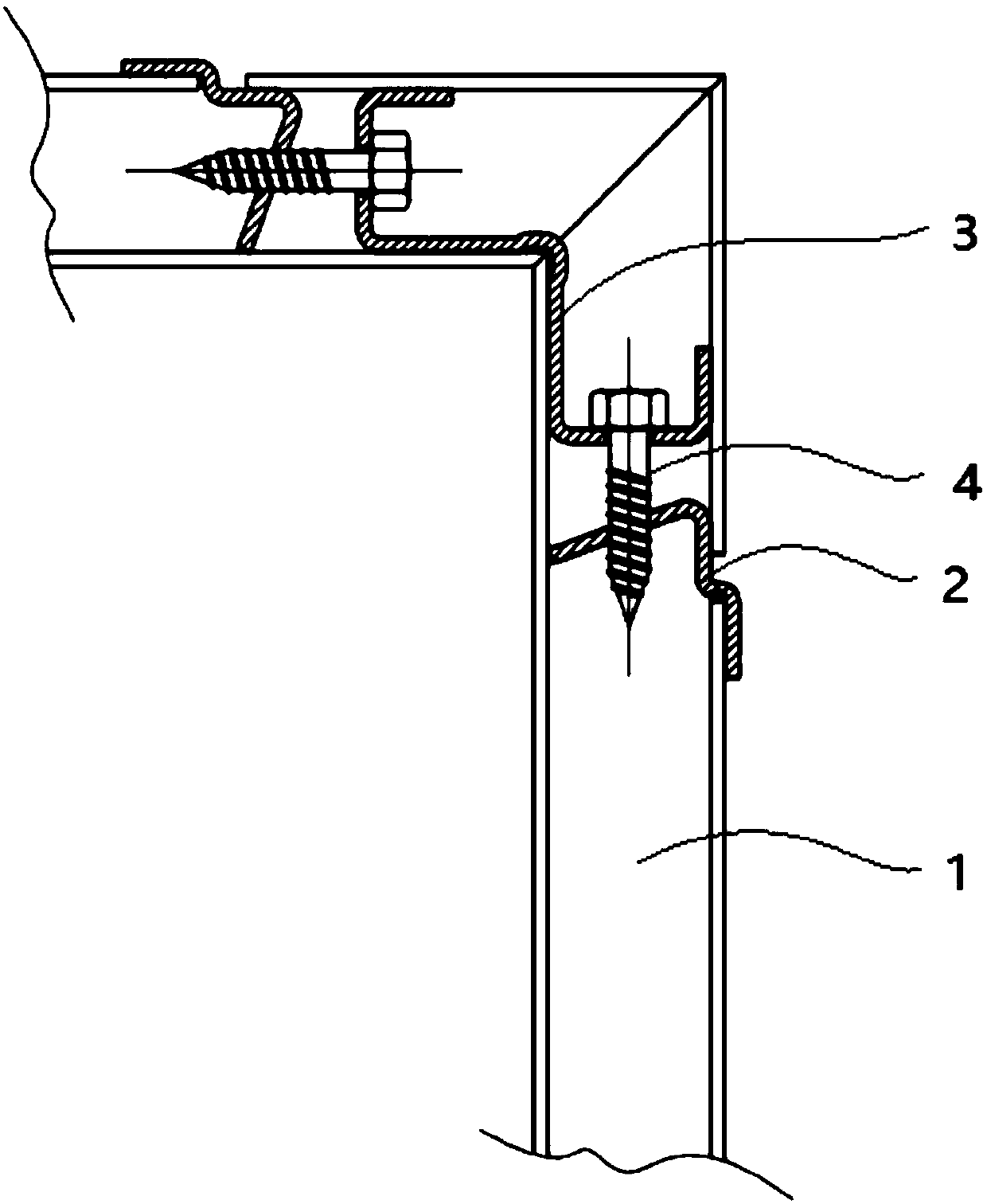

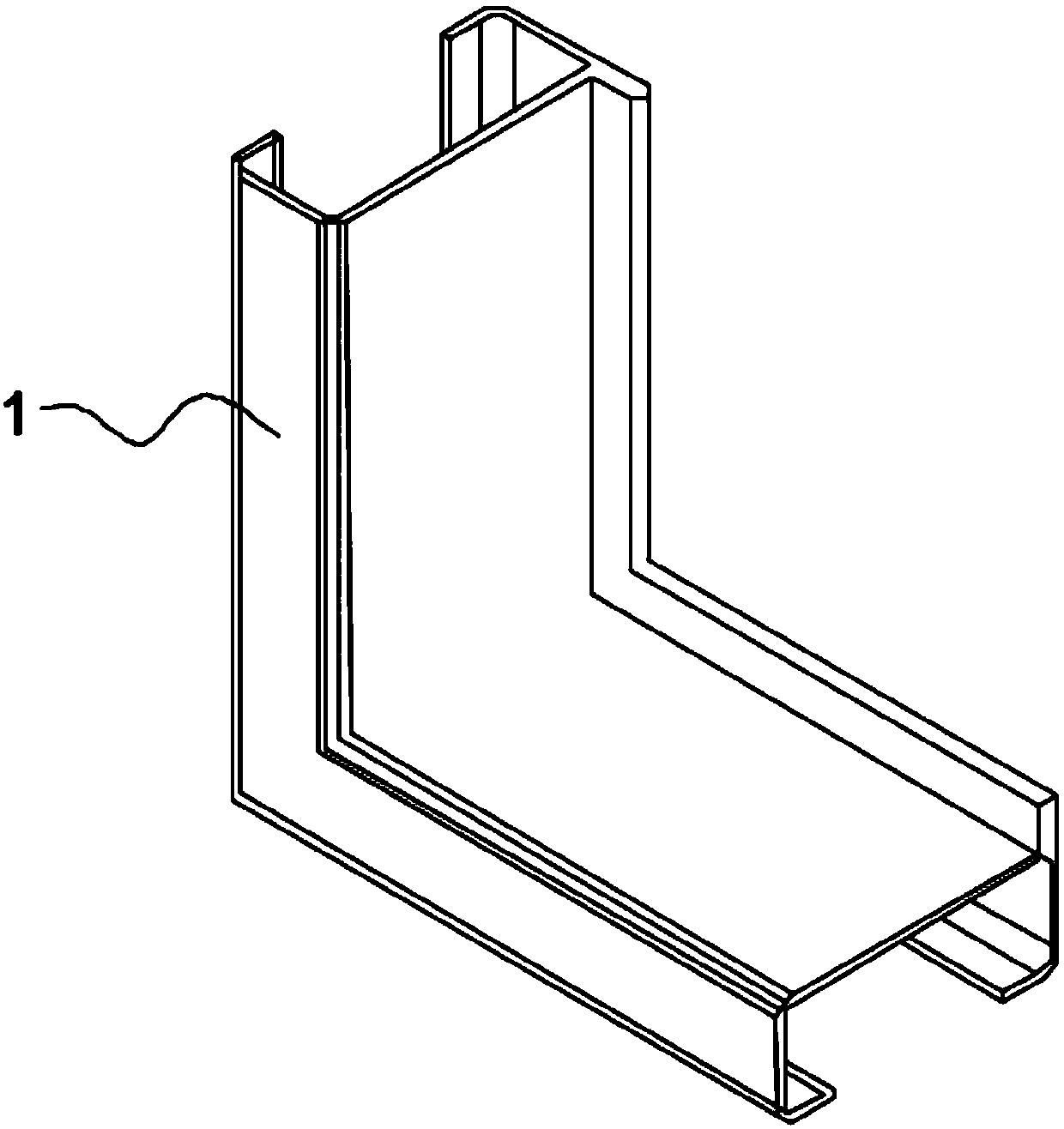

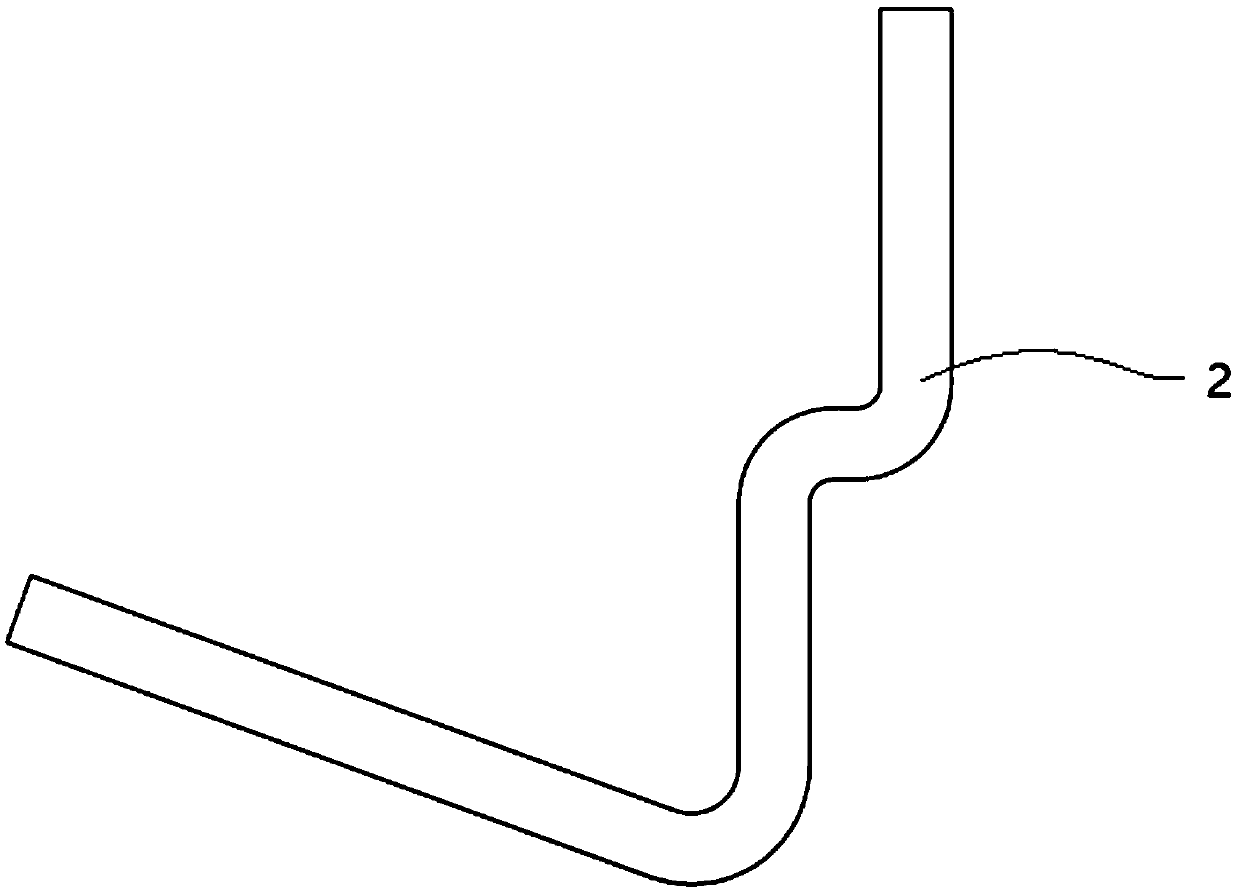

[0025] Such as figure 1 As shown, in the embodiment of the present invention, a steel galvanized corner assembly includes a steel subframe 1, an intermediate group corner profile plate 3 is arranged at the corner of the steel subframe 1, and the two sides of the middle group corner profile plate 3 A side corner profile plate 2 is provided respectively, and the side corner profile plate 2 and the middle corner profile plate 3 are fixed by screws 4 .

[0026] Further, the material of the steel sub-frame 1 is hot-dip galvanized steel. The steel sub-frame 1 is L-shaped. The sub-frame 1 is equipped with a notch groove in cooperation with the side corner profile plate 2, and the notch groove and the groove body are vertically distributed. The inner surface of the steel sub-frame 1 is provided with a convex edge, and the convex edge and the steel sub-frame 1 are integrally fixed. .

[0027] Furthermore, the combination of the side corner profile plate 2 and the middle corner profil...

Embodiment 2

[0029] A steel galvanized corner fitting, such as Figure 1~4 As shown, the embodiment of the present invention is further limited on the basis of embodiment 1.

[0030] Further, the side corner profile plate 2 and the middle corner profile plate 3 are equipped with fixing holes with screws 4, the fixing holes are threaded holes, and the cross section of the middle corner profile plate 3 is W-shaped.

[0031] Further, the side corner group profile plate 2 and the middle corner group profile plate 3 are made of the same material as the steel sub-frame 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com