Tripping device for breaker operation mechanism

A technology of operating mechanism and tripping device, applied in the direction of protection switch operation/release mechanism, etc., can solve problems such as miniaturization of circuit breaker volume, deformation and loosening of drawbar, and achieve simple assembly, saving fasteners, and eliminating deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Through the applicant's description of the following examples, it will be more helpful to understand the technical essence and technical effect of the present invention, but the examples do not constitute a limitation to the technical solution of the present invention.

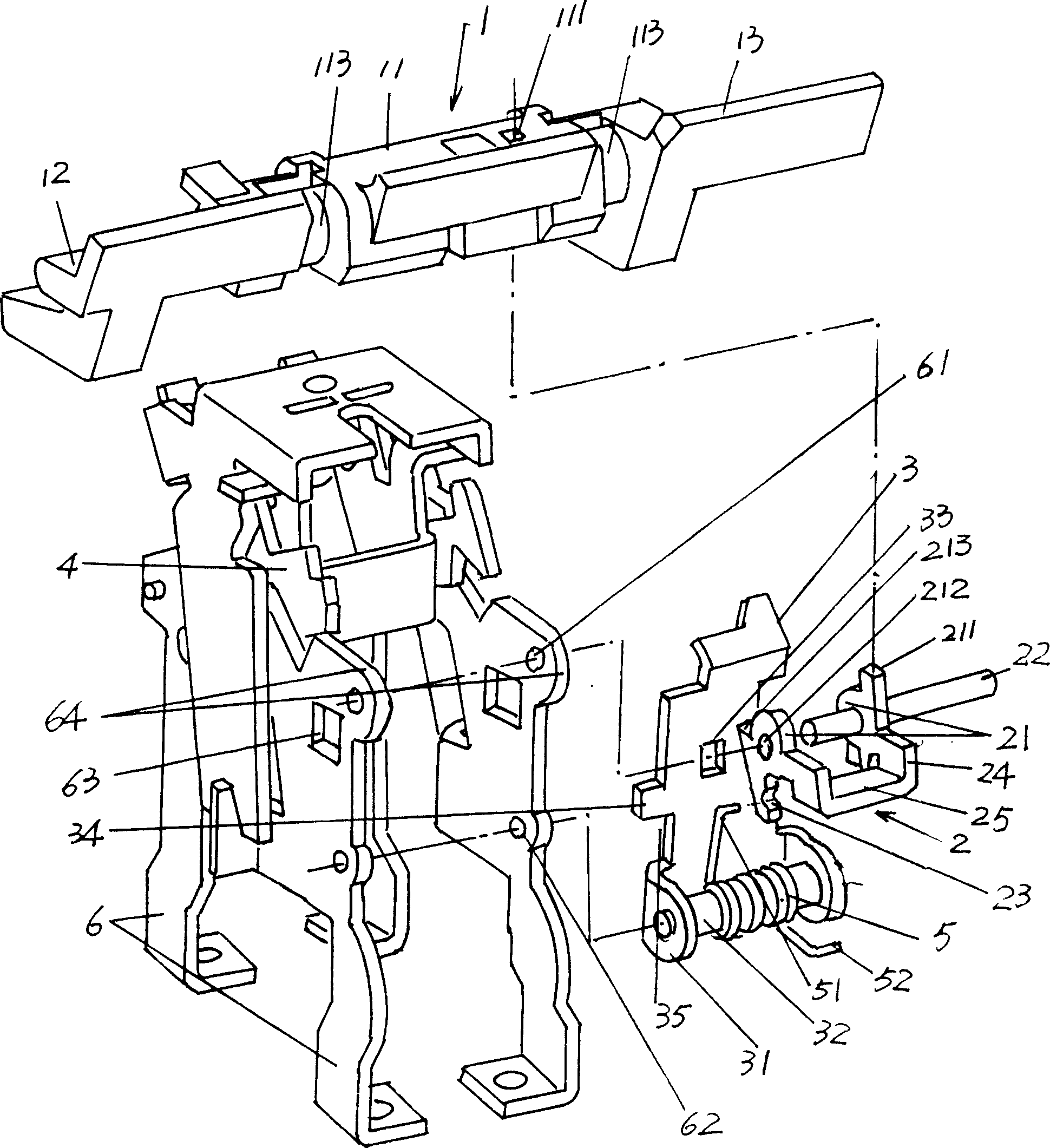

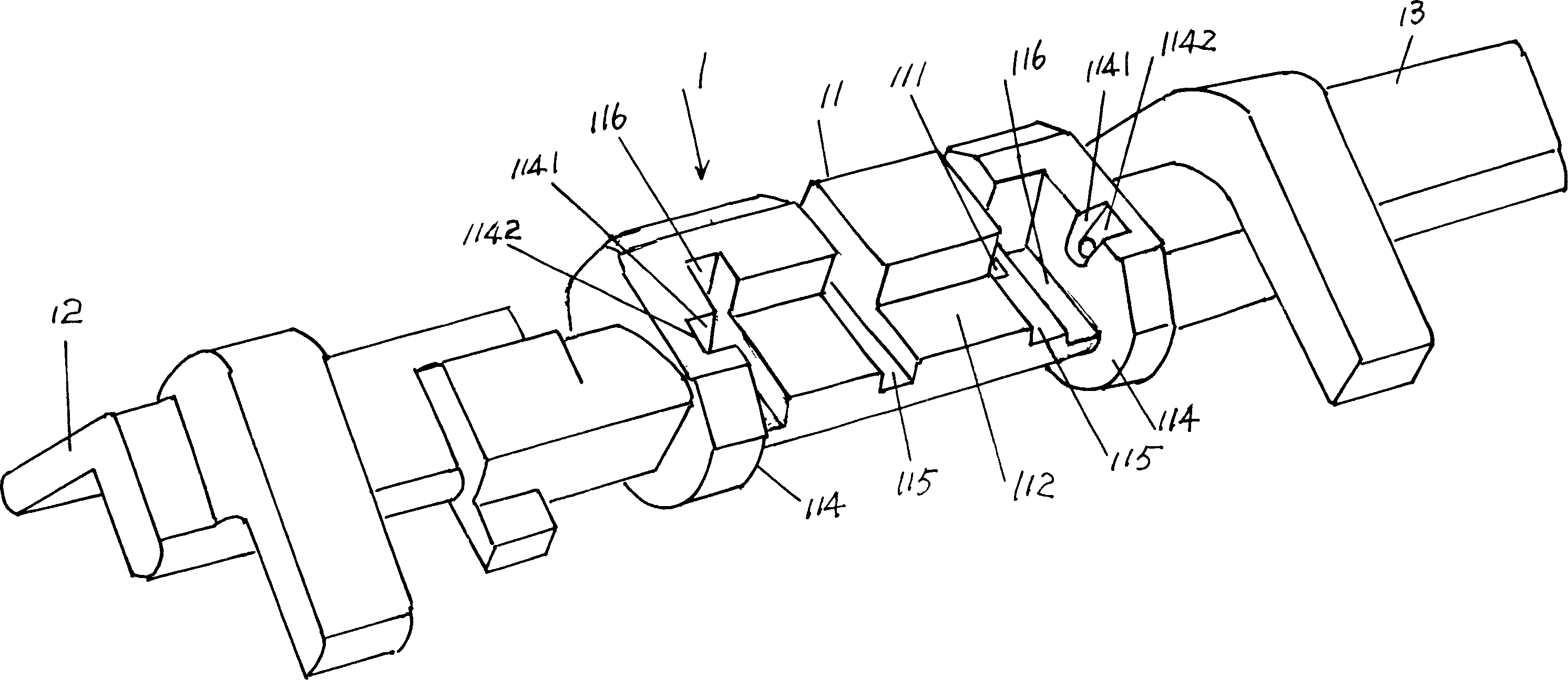

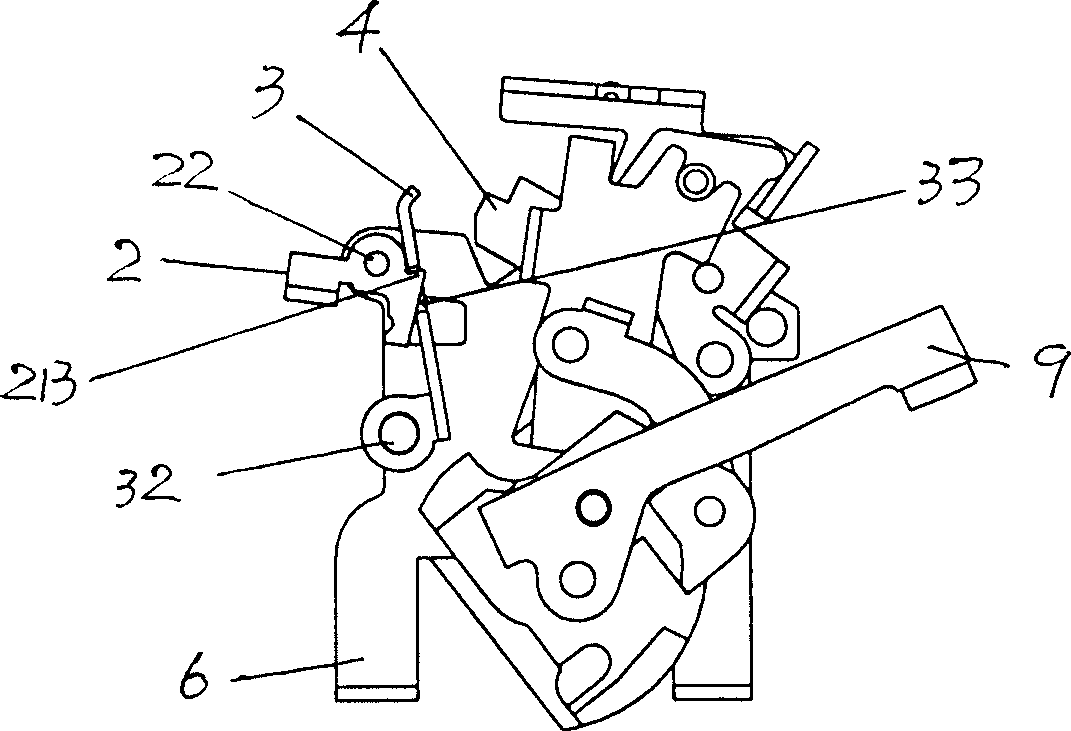

[0016] exist figure 1 and figure 2 Among them, the operating mechanism of the circuit breaker includes a bracket 6, which is used to set the first and second latches 2, 3 and jumper 4 of the tripping device of the present invention. The first lock 2 is pivoted on the first lock shaft 22 through a pair of first pivot holes 212 on a pair of first pivot flanges 21, and the two ends of the first lock shaft 22 are respectively pivoted. In the first pivot shaft hole 61 preset on both sides of the bracket 6 . Depend on figure 1 As shown, a spring stop protrusion 23 is extended on one side of the first buckle 2, and the spring stop protrusion 23 is used for leaning against the first spring foot 51 of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com