Transfer carrier assembly jig

A technology for assembling jigs and carriers, applied in manufacturing tools, workpiece clamping devices, etc., can solve problems such as affecting quality, and achieve the effects of simple operation, simple and rapid assembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0030] In the present invention, the so-called "locking" refers to a state or an action in which the object to be fixed cannot move under normal conditions by some means. The so-called "unlocking" refers to the state or action of making the fixed object break away from the locked state in some way and have the ability to move.

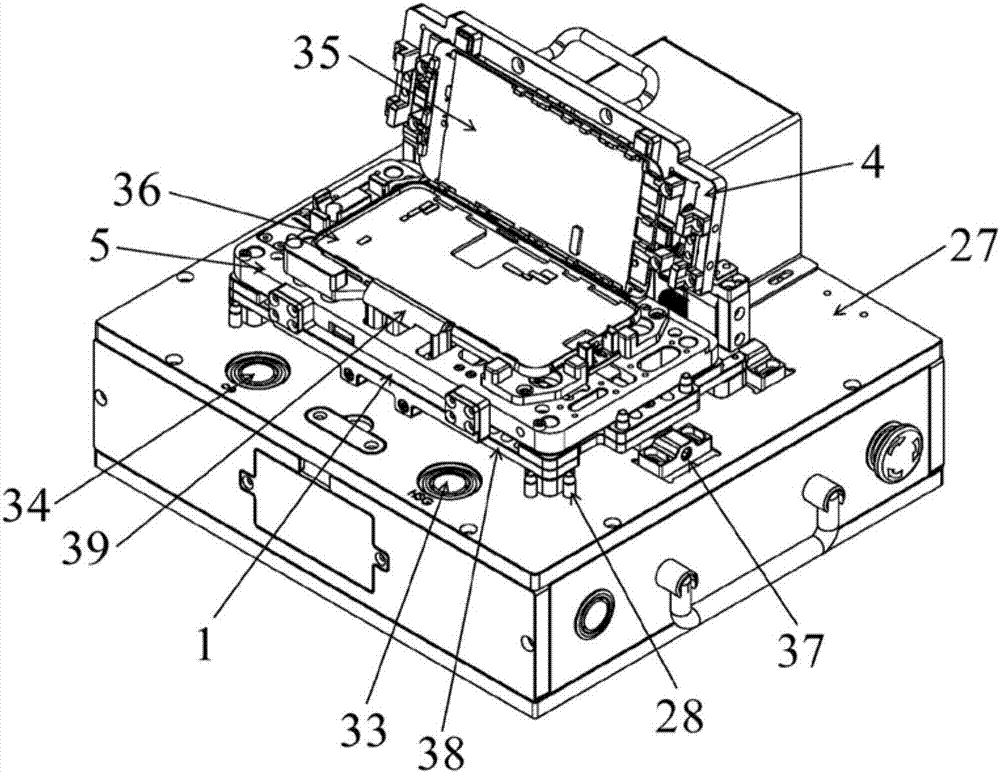

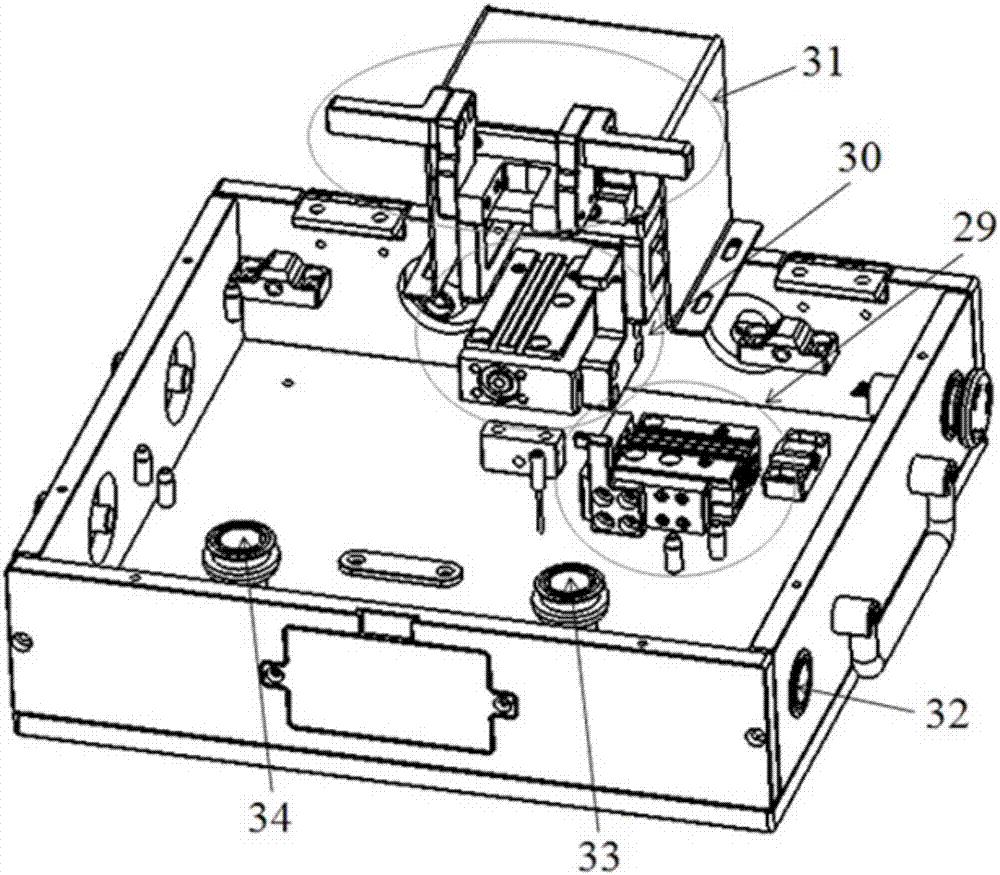

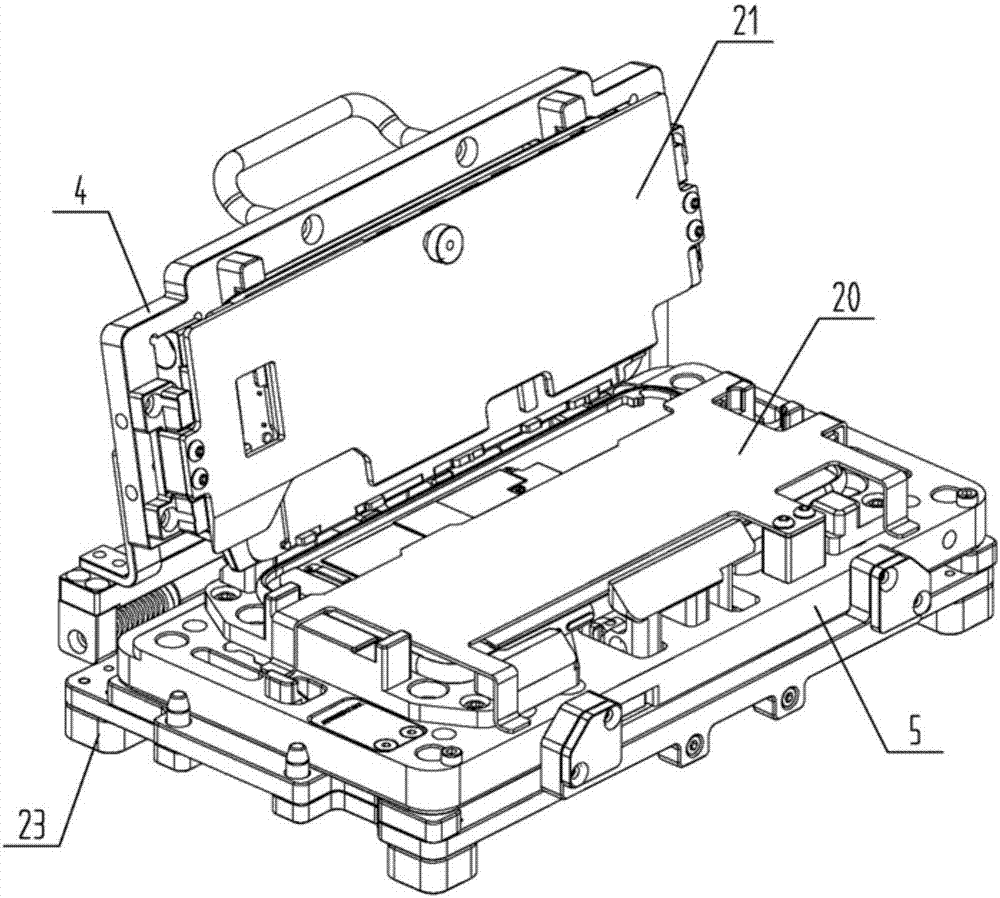

[0031] Such as Figures 1 to 10 As shown, a transfer carrier assembly jig includes an electrical cabinet 27, a transfer carrier 38 detachably mounted on the electrical cabinet, a housing module unlocking cylinder, a display screen unlocking cylinder and a housing unlocking cylinder. The transfer carrier 38 includes: a base plate 1, a positioning pad 23, a two-dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com