Front plate unit of split air conditioner

An air conditioner and split-type technology, which is applied to the front panel device field of split-type air conditioners, can solve problems such as unclean appearance of indoor machines, and achieve the effects of beautiful appearance, quick and easy assembly operation, and easy disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, the implementation of the present invention is described as follows:

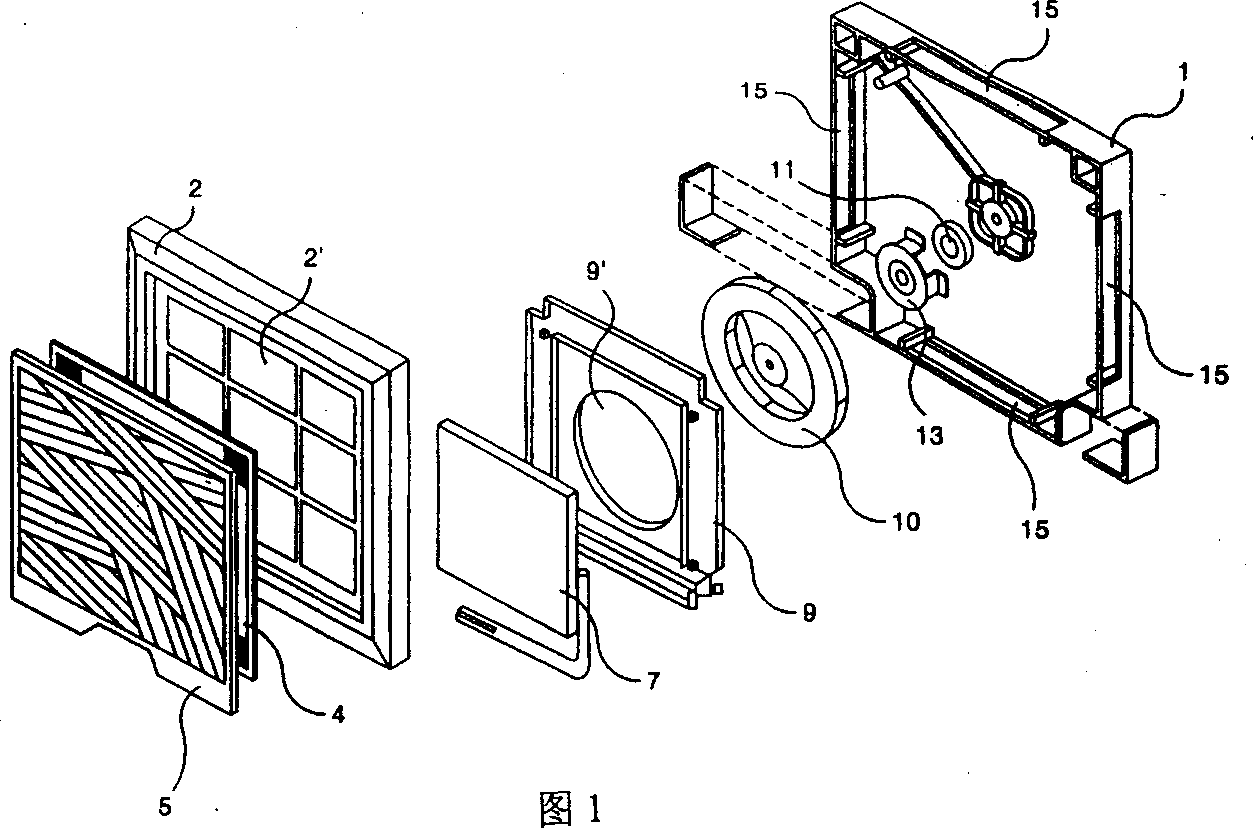

[0038] The description of FIG. 1 has been described in detail in "Background Technology", so it is omitted here.

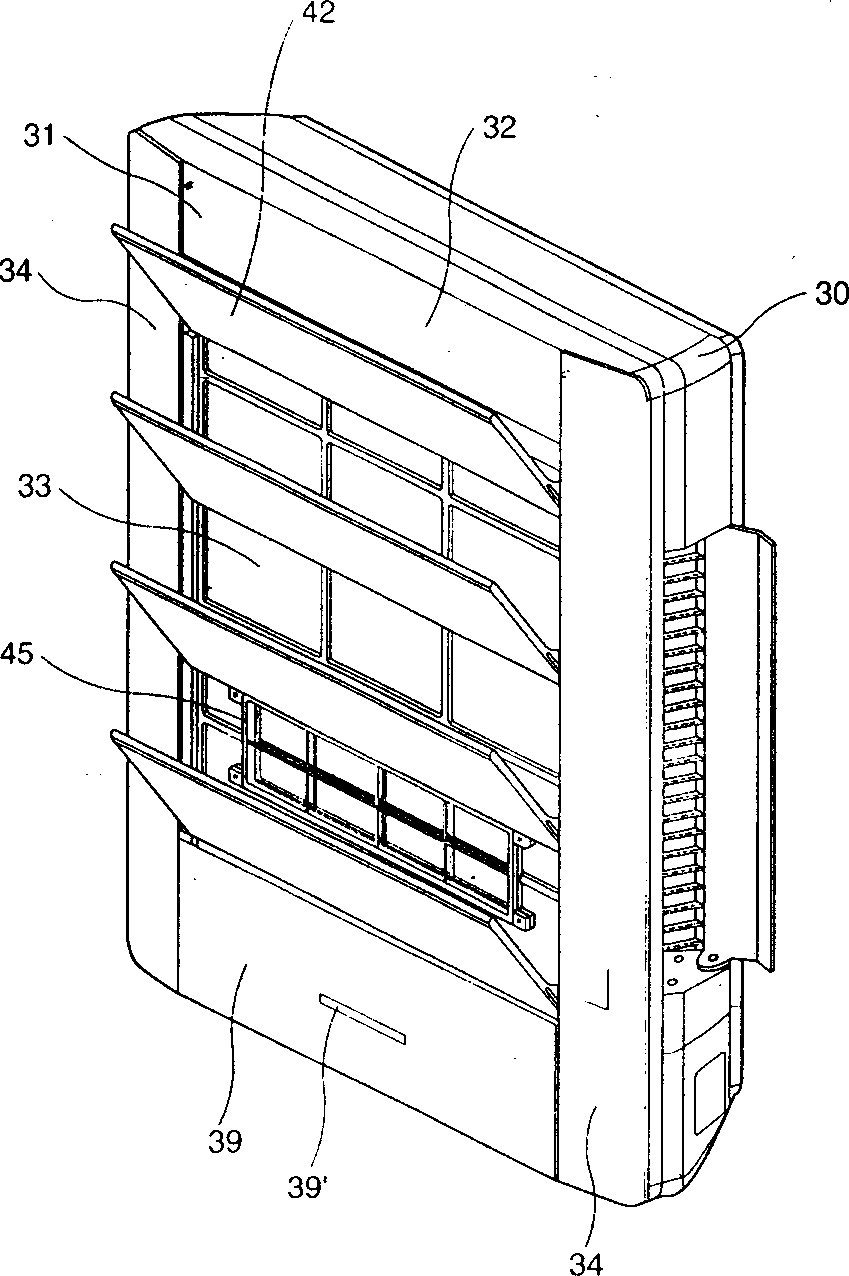

[0039] exist figure 2 , the internal structure of the split-type air conditioner using the split-type front panel device will now be described.

[0040] The casing (30) forms the exterior. The shape of the shell (30) is a very thin hexahedron. A front plate (31) is provided on the front of the casing (30) to shield the space inside the casing (30).

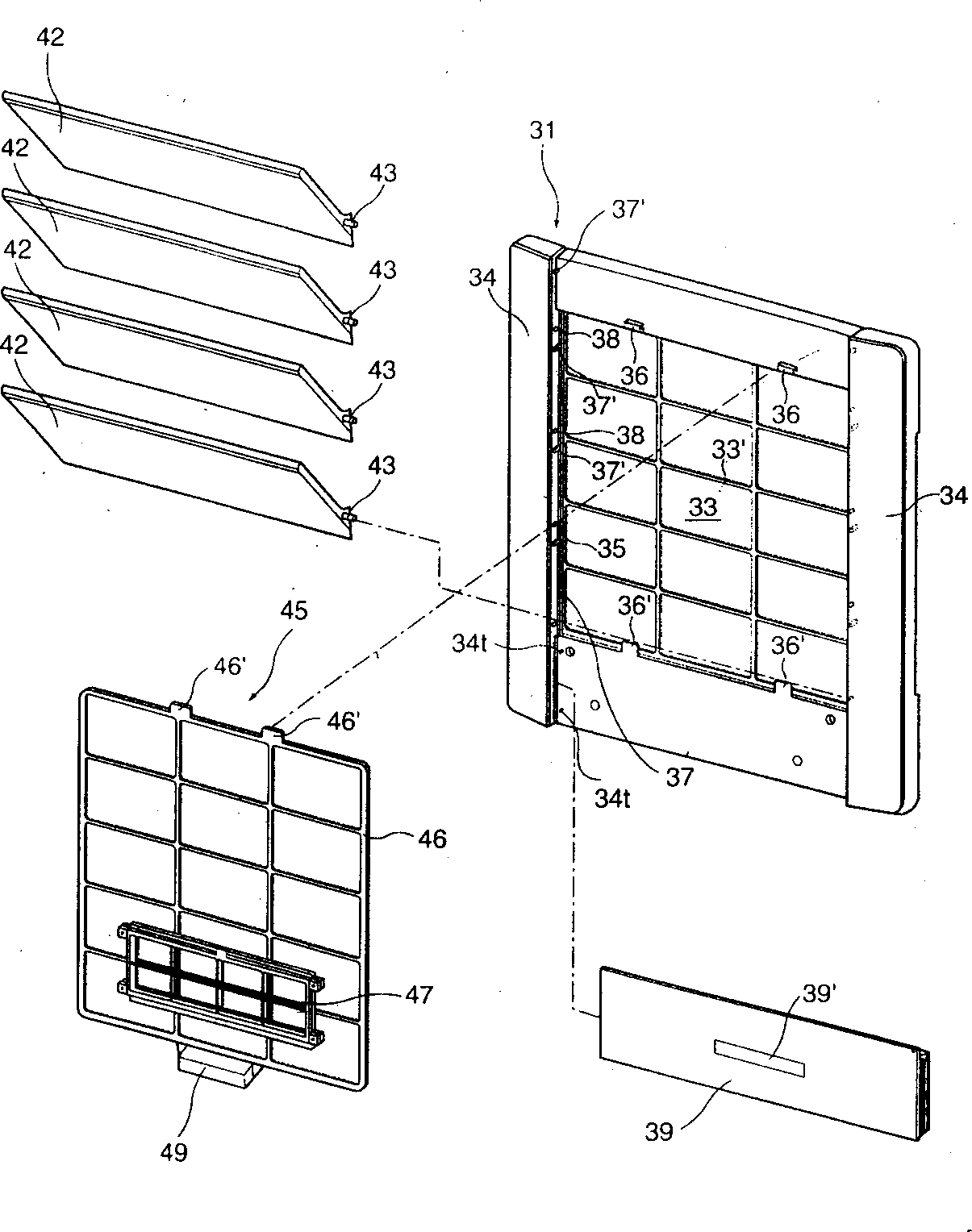

[0041] exist image 3 In, the detailed structure of front plate (31) is as shown in the figure. The front body (32) has a roughly square shape, and a square suction through-hole portion (33) is provided in the center thereof. The suction through hole portion (33) plays the role of a channel for sucking the space air to be regulated into the inside of the casing (30). Such suction through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com