Quick self-disassembled and assembled snap joint type furniture connector and assembling method

A buckle-type connector technology, which is applied in the direction of furniture connection, connection components, thin plate connection, etc., can solve the problems of high transportation cost, low component versatility, and difficult assembly, etc., to achieve fun and high mechanical strength and support ability, the effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

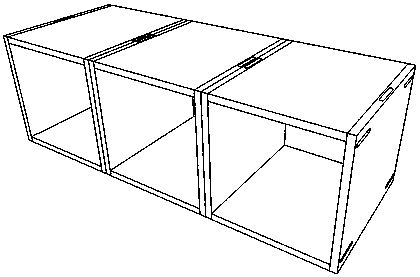

[0044] refer to Figure 5 It is a schematic diagram of an embodiment of the fast self-assembled and disassembled buckle-type furniture connector used for splicing furniture panels according to the present invention. The plate processing method and the connector assembly method include the following steps:

[0045] 1) Use a milling cutter to mill out elliptical tenons and grooves 14 on the joint end faces of plates A 12 and 13;

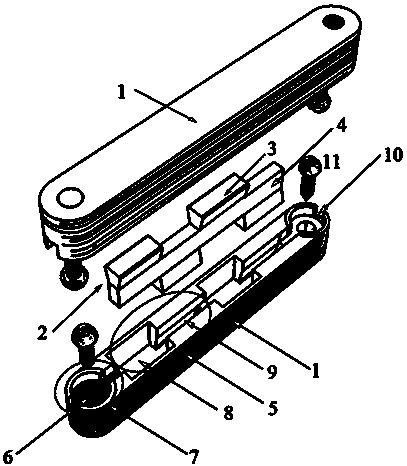

[0046] 2) Insert the groove part 1 into the oval mortise 14 pre-processed on the joint end surface of the A plate 12, use two screws 11 to pass through the screw holes 6, and insert them into the A plate 12 and tighten them to complete the groove part 1. Installation and fixing in A plate 12;

[0047] 3) Take another slotted piece 1, place its slotted surface opposite to the slotted piece 1, and then turn it over 180° in the horizontal direction, insert it into the pre-processed oval tenon groove 14 on the joint end surface of B plate 13, and use Tw...

Embodiment 2

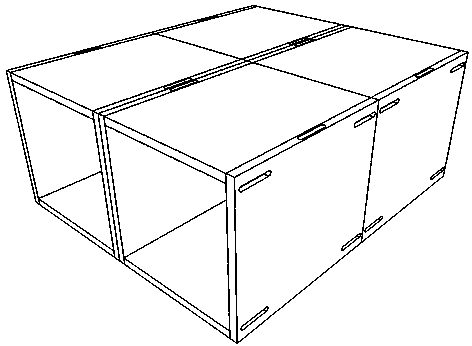

[0051] refer to Figure 6 It is a schematic diagram of the fast self-assembled and disassembled buckle-type furniture connector used in the L-shaped furniture joint of the present invention. The plate processing method and the connector assembly method include the following steps:

[0052] 1) At the corresponding joint positions of A horizontal plate 15 and A vertical plate 16, use a milling cutter to mill out elliptical tenons and grooves 14;

[0053] 2) Insert the slotted part 1 into the pre-processed elliptical mortise 14 of the A horizontal plate 15, use two screws 11 to pass through the screw holes 6, insert them into the A horizontal plate 15 and tighten them to complete the slotted part 1 installation and fixation in A horizontal plate 15;

[0054] 3) Take another slotted piece 1, place its slotted surface opposite to the slotted piece 1, and then turn it over 180° in the horizontal direction, insert it into the pre-processed elliptical tenon groove 14 on the joint en...

Embodiment 3

[0058] refer to Figure 7 It is a schematic diagram of jointing of the fast self-assembled and disassembled buckle-type furniture connector used for T-shaped furniture joints. The plate processing method and the connector assembly method include the following steps:

[0059] 1) At the corresponding joint positions of the B horizontal plate 17 and the B vertical plate 18, use a milling cutter to mill out the elliptical tenons and grooves 14 respectively;

[0060] 2) Insert the slotted part 1 into the pre-processed oval mortise 14 of the B horizontal plate 17, use two screws 11 to pass through the screw holes 6, insert them into the B horizontal plate 17 and tighten them, so as to complete the slotted part 1 installation and fixation in B horizontal plate 17;

[0061] 3) Take another slotted piece 1, place its slotted surface opposite to the slotted piece 1, turn it over 180° in the horizontal direction, and insert it into the pre-processed elliptical tenon groove 14 on the jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com