Rotary type hot blast drying device

A technology of rotating and blowing devices, which is applied in the direction of drying gas arrangement, heating to dry solid materials, drying, etc., which can solve the problem of failure to meet the requirements of the Ministry of Railways for the cleaning accuracy of vehicle parts, residual liquid of parts exceeding the standard, and drying treatment Unreasonable equipment structure design and other problems, to achieve the effect of saving air volume, good effect, and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

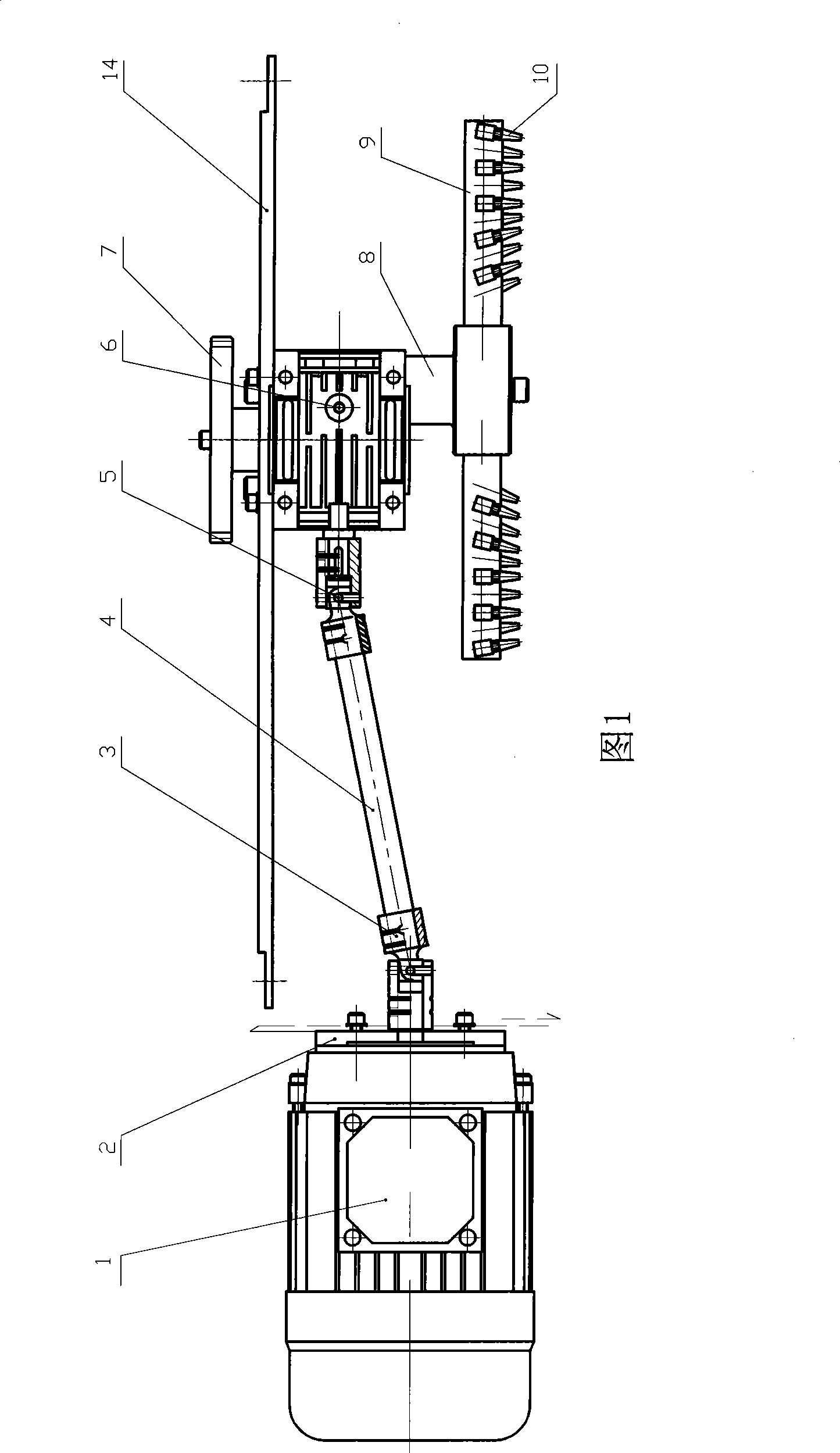

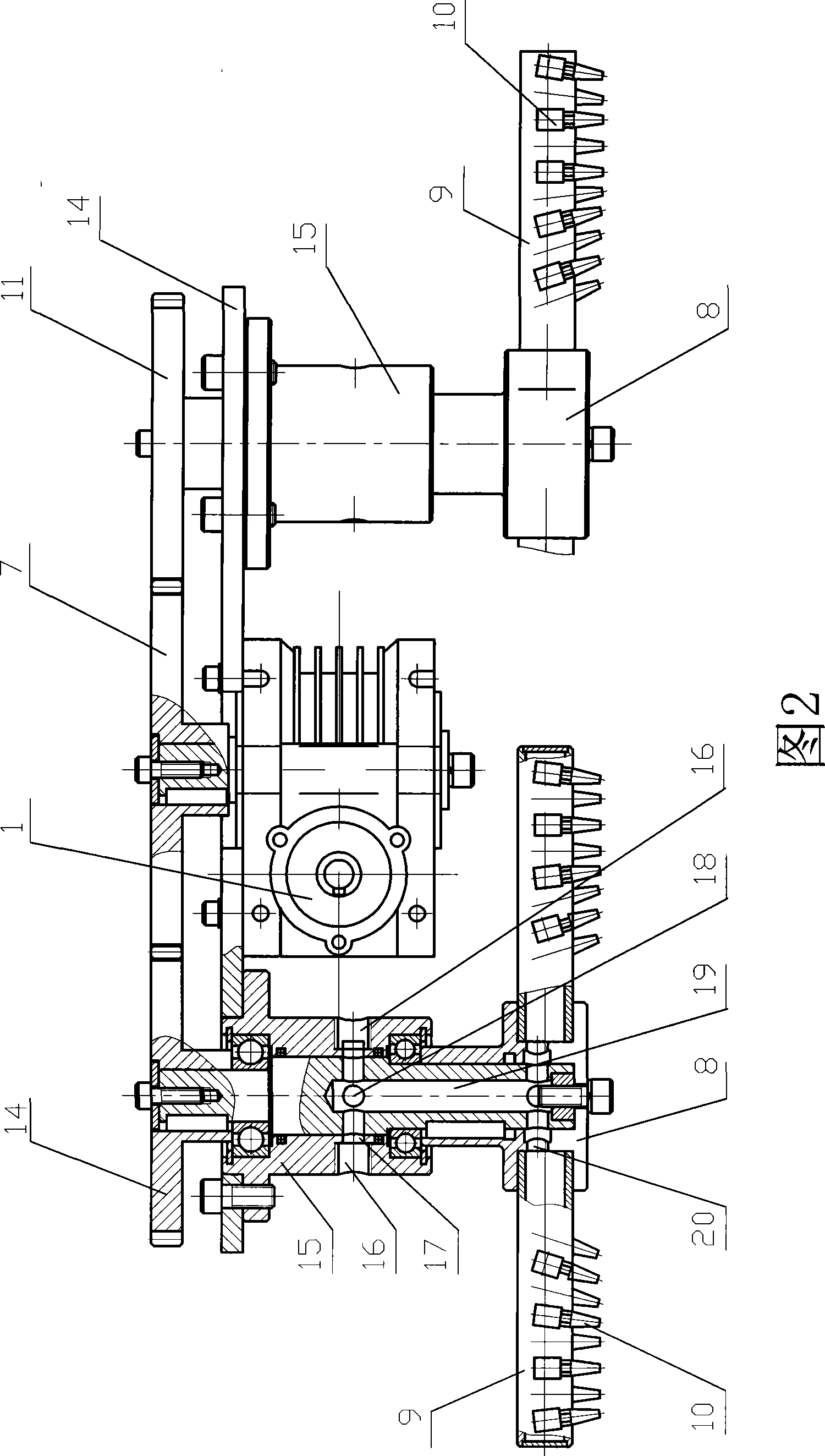

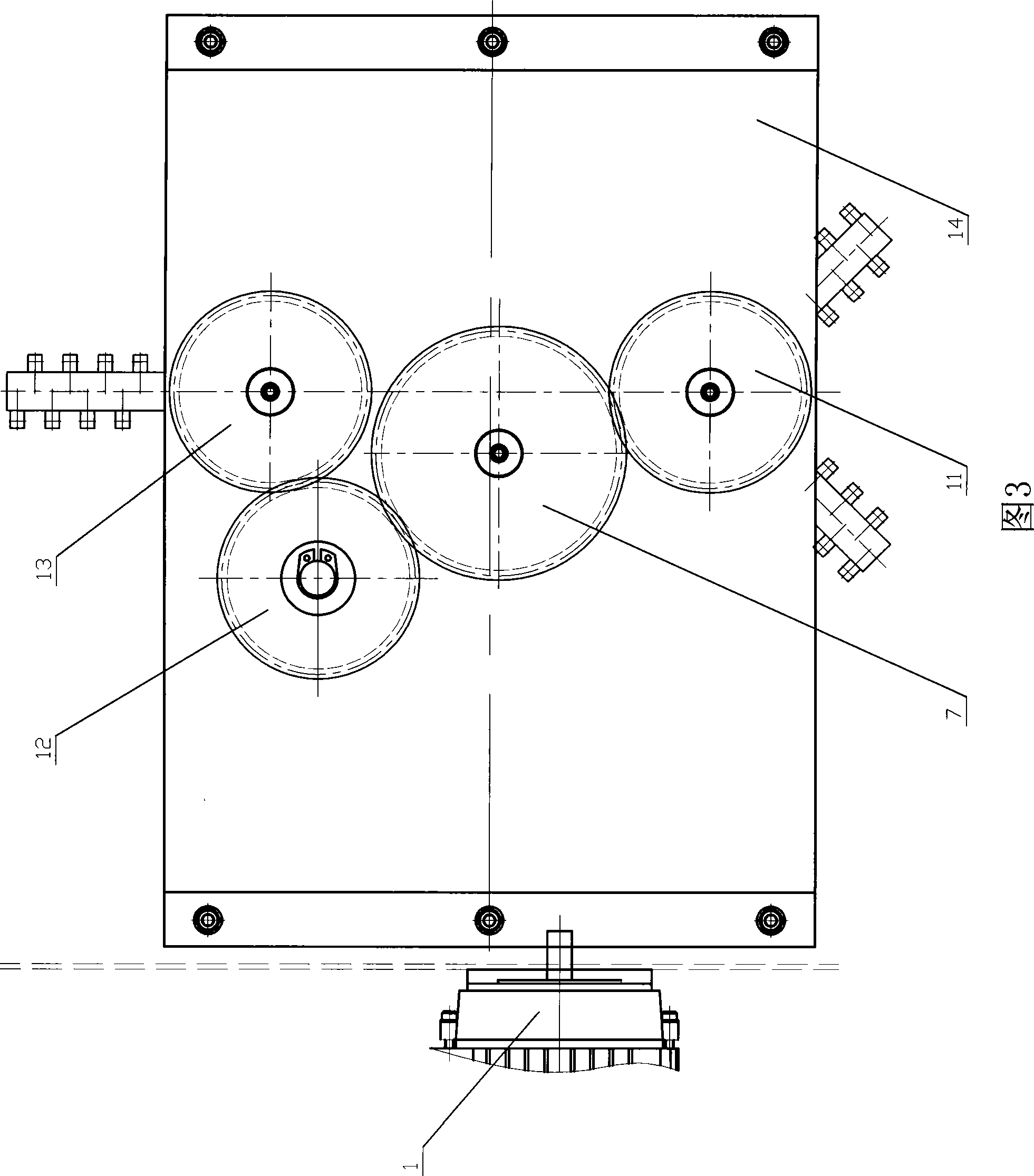

[0014] The specific embodiment of the present invention is as shown in accompanying drawing; Rotary hot air drying device is made up of wind source, hot air chamber, blowing device; Its structure blowing device is that rotary blowing device is by motor (1), motor output transmission device, Rotator 6, transmission gear, rotating head, air pipe 9, air nozzle 10; motor 1 is connected with motor output transmission device through motor output shaft 2; motor output transmission device is connected with rotator 6; in rotator 6 The output end is fixedly equipped with driving gear 7. There are three transmission gears meshing with the driving gear 7, namely transmission gear A, transmission gear B and transmission gear C. Each transmission gear is fixed on the input shaft of the corresponding rotating head body 15 fixed on the disc seat 14; there are three rotating head bodies 15 fixed on the disc seat 14, and there are rotating heads at the front end of the rotating head body 15. H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com