Vent-blocking inflatable bladder assembly for a HVAC zone control system

a technology of hvac zone control and inflatable bladder, which is applied in the direction of ventilation system, space heating and ventilation details, heating types, etc., can solve the problem that the air tube cannot be removed from the assembly, and achieve the effect of convenient insertion, convenient and fast removal, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

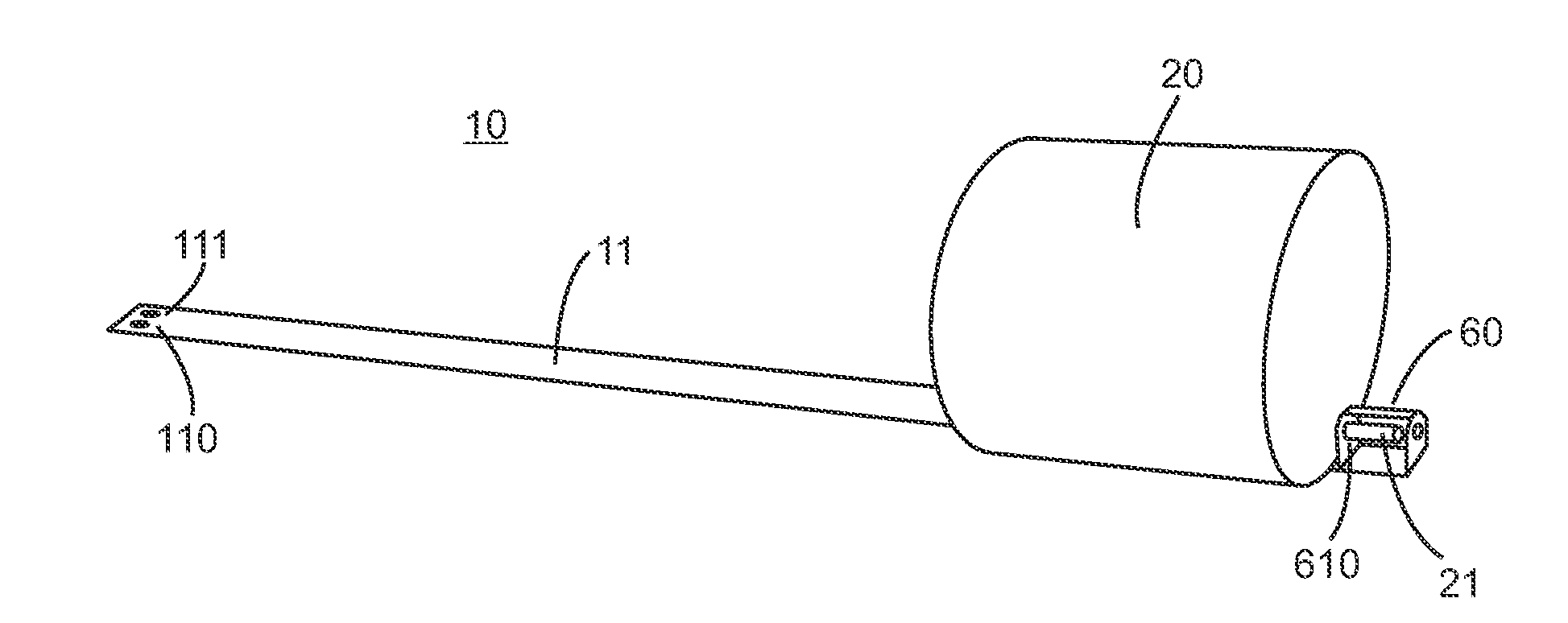

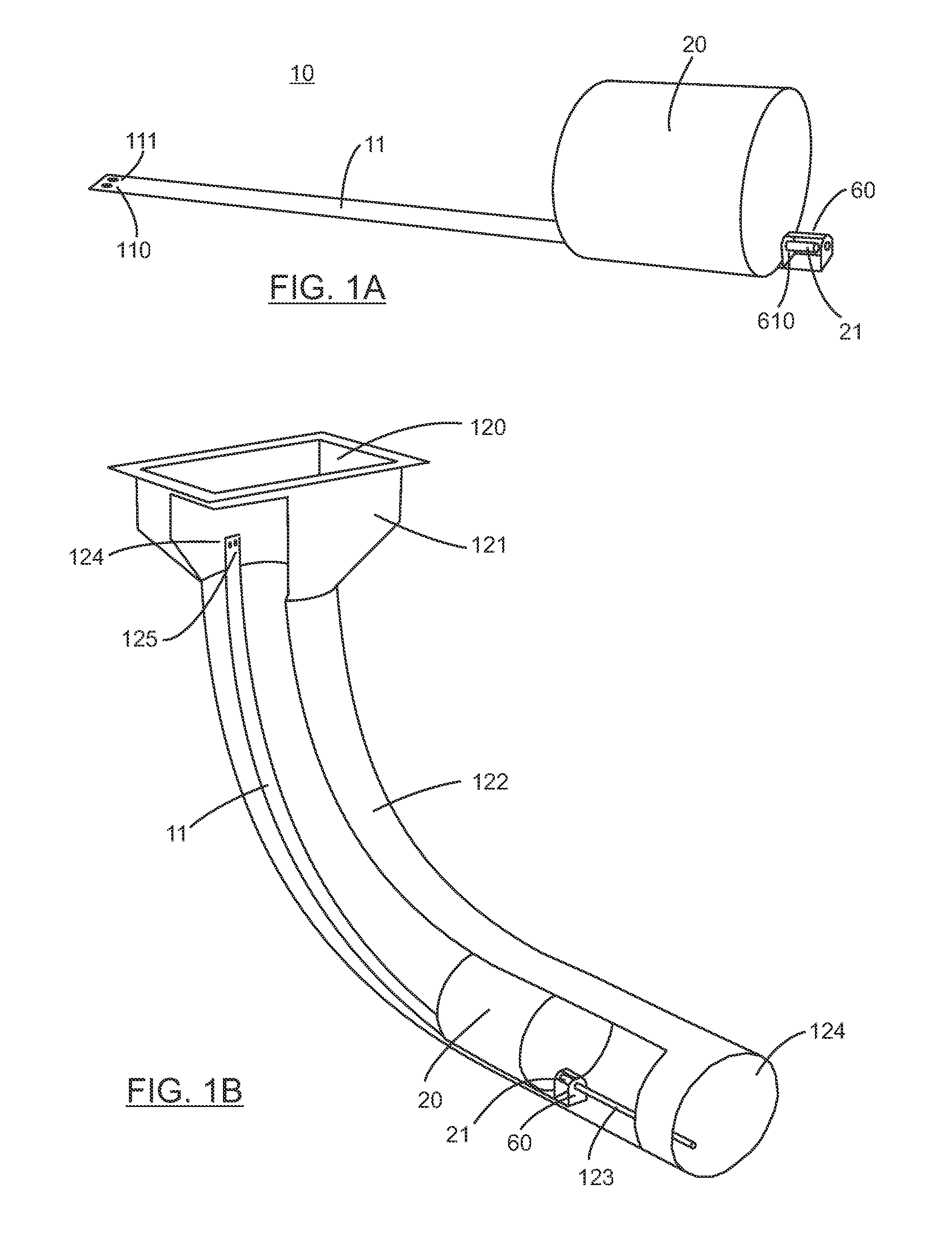

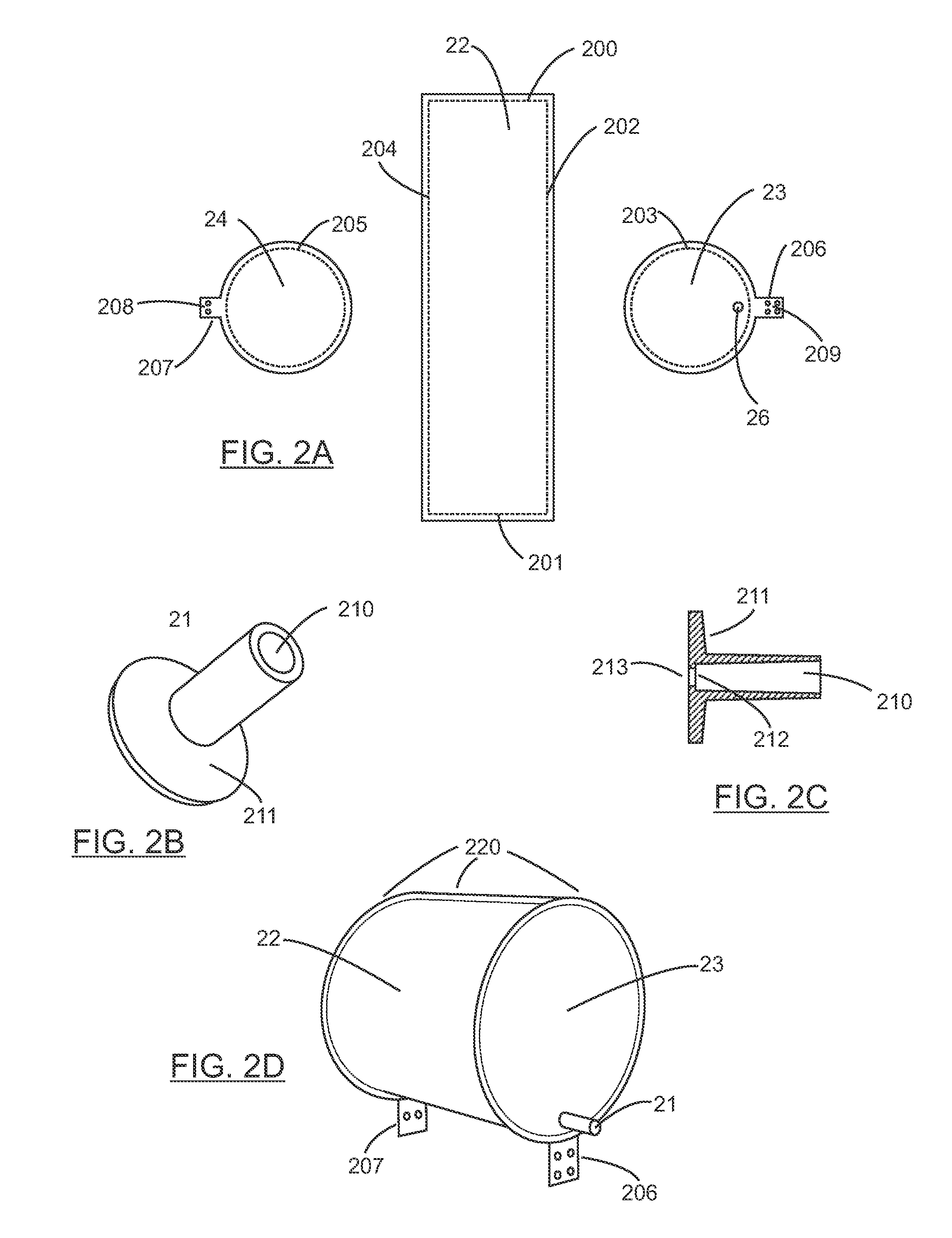

[0040]FIG. 1A shows a typical complete cylindrical bladder assembly 10 as prepared in a factory and supplied for use by an installer of the zone control system. The bladder 20 is made of flexible airtight fabric material. Its shape when inflated is a cylinder. The bladder has a nozzle 21 used to inflate or deflate the bladder. The nozzle is inserted into restraint fixture 60 through hole 610 which firmly grips the outside surface of the nozzle. Each end of the bladder is firmly attached to mounting strap 11. In the preferred embodiment, the strap is typically 1″ wide and 36″ long and made from 20 gauge (approximately 0.035″ thick) mild steel. This should not be taken to limit the scope of the invention since many other materials and dimensions can provide similar function. The requirements are the strap is flexible in one direction perpendicular to its long axis so the strap can easily follow bends in the duct system. The strap is rigid in the direction perpendicular to flexible dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com