Steel ball grinding crack detection method based on neighborhood gray level similarity

A technology of neighborhood grayscale and detection methods, applied in image data processing, instruments, calculations, etc., can solve problems such as large measurement errors, time-consuming and laborious, and achieve the effects of fast processing speed, wide application, and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

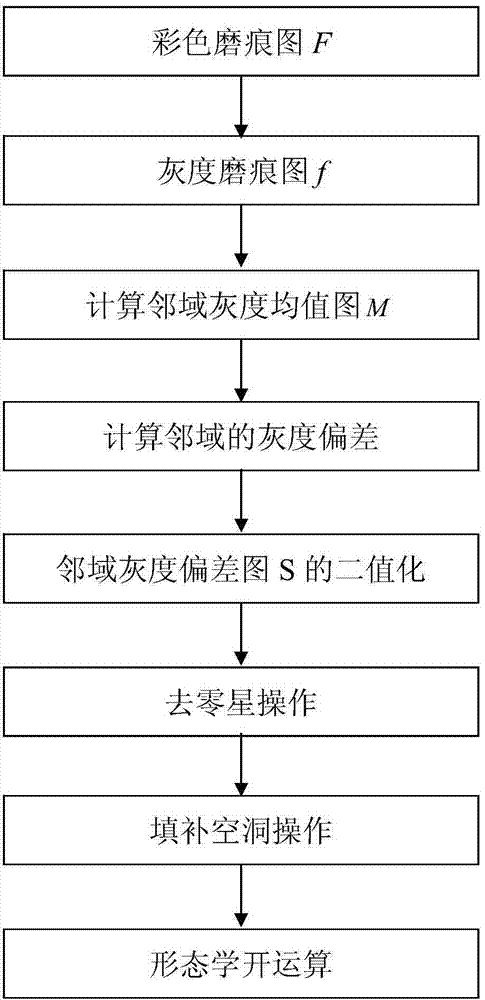

[0049] The wear scar detection method based on neighborhood gray similarity of the present invention specifically includes the following steps:

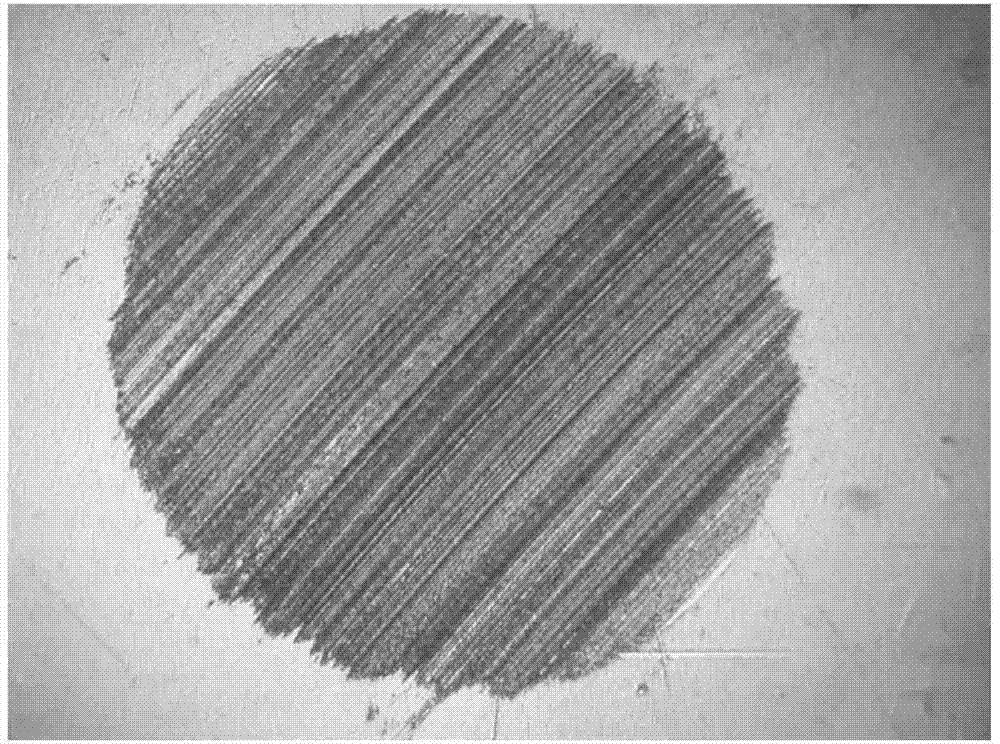

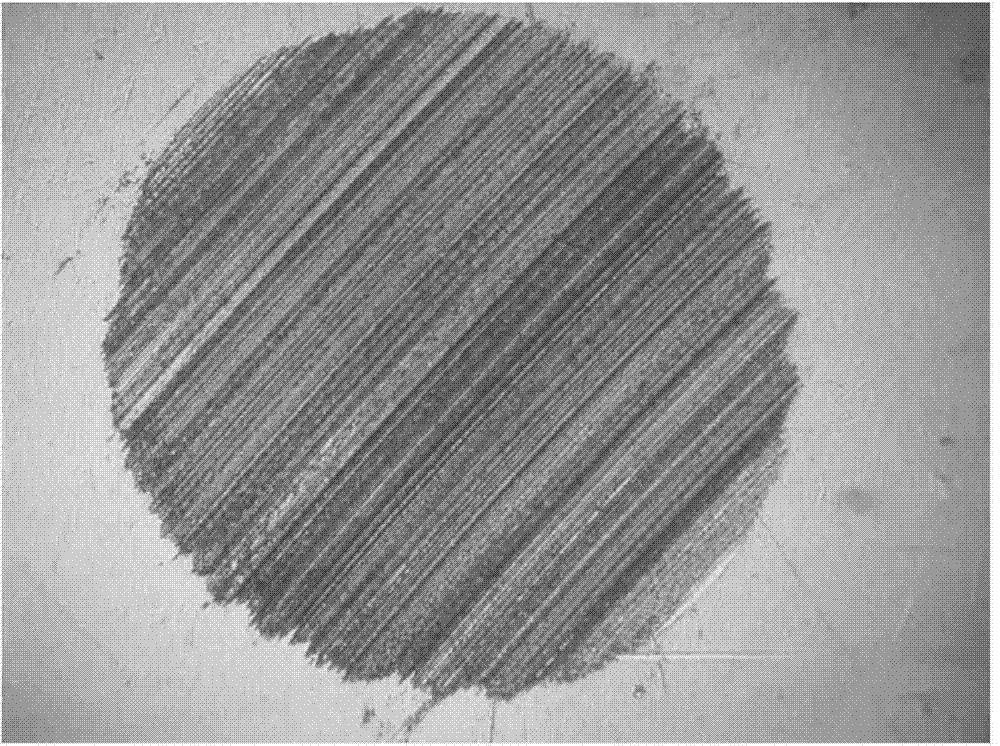

[0050] Step S1: Take out the steel ball after the four-ball friction test or extreme pressure test, use the electronic scanning mirror to collect the wear scar image of the steel ball, and read the wear scar image into the computer system;

[0051] Step S2: The collected wear scar image is a color wear scar image F of an RGB color model with a size of 768×1024;

[0052] Step S3: Grayscale the color image F. (R(p), G(p), B(p)) respectively represent the red R (Red, R) component value, green G (Green, G) component value and blue B (Blue, B) component of pixel p value; the grayscale of the color image F is shown in formula 1:

[0053] f(p)=0.3·R(p)+0.59·G(p)+0.11·B(p) (Formula 1)

[0054] Among them, f is the grayscale wear scar image, and f(p) is the grayscale value of pixel p.

[0055] Step S4: Calculate the neighborhood gray-scal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com