Attachment clip and attachment structure using same

a technology of attachment structure and attachment clip, which is applied in the directions of threaded fasteners, machines/engines, transportation and packaging, etc., can solve the problems of unsuitable attachment clip b>6/b> for components, and achieve the effect of suppressing the increase of manufacturing cost, easy rusting, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]Referring to the accompanying drawings, an embodiment of the present invention will be described below.

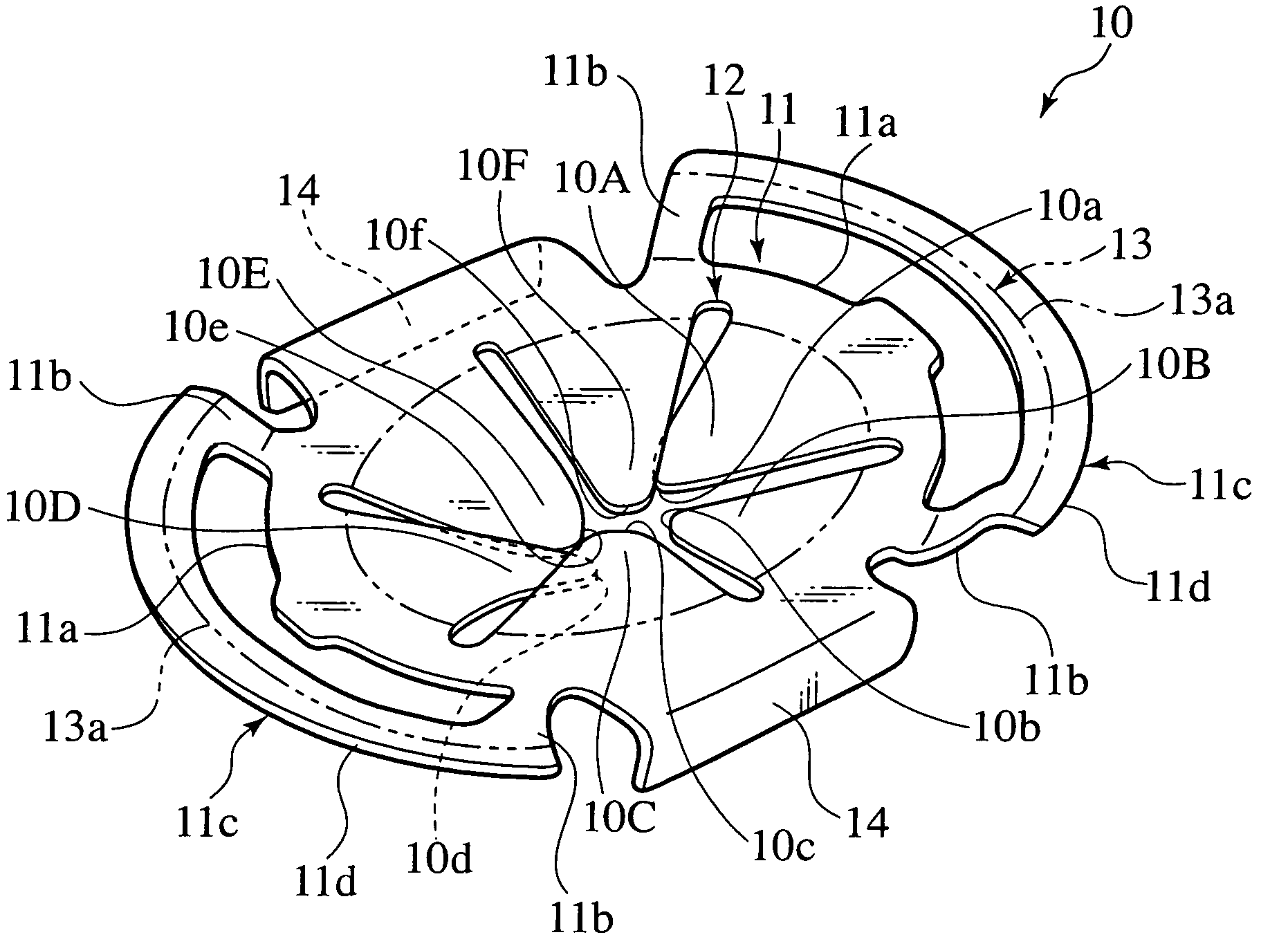

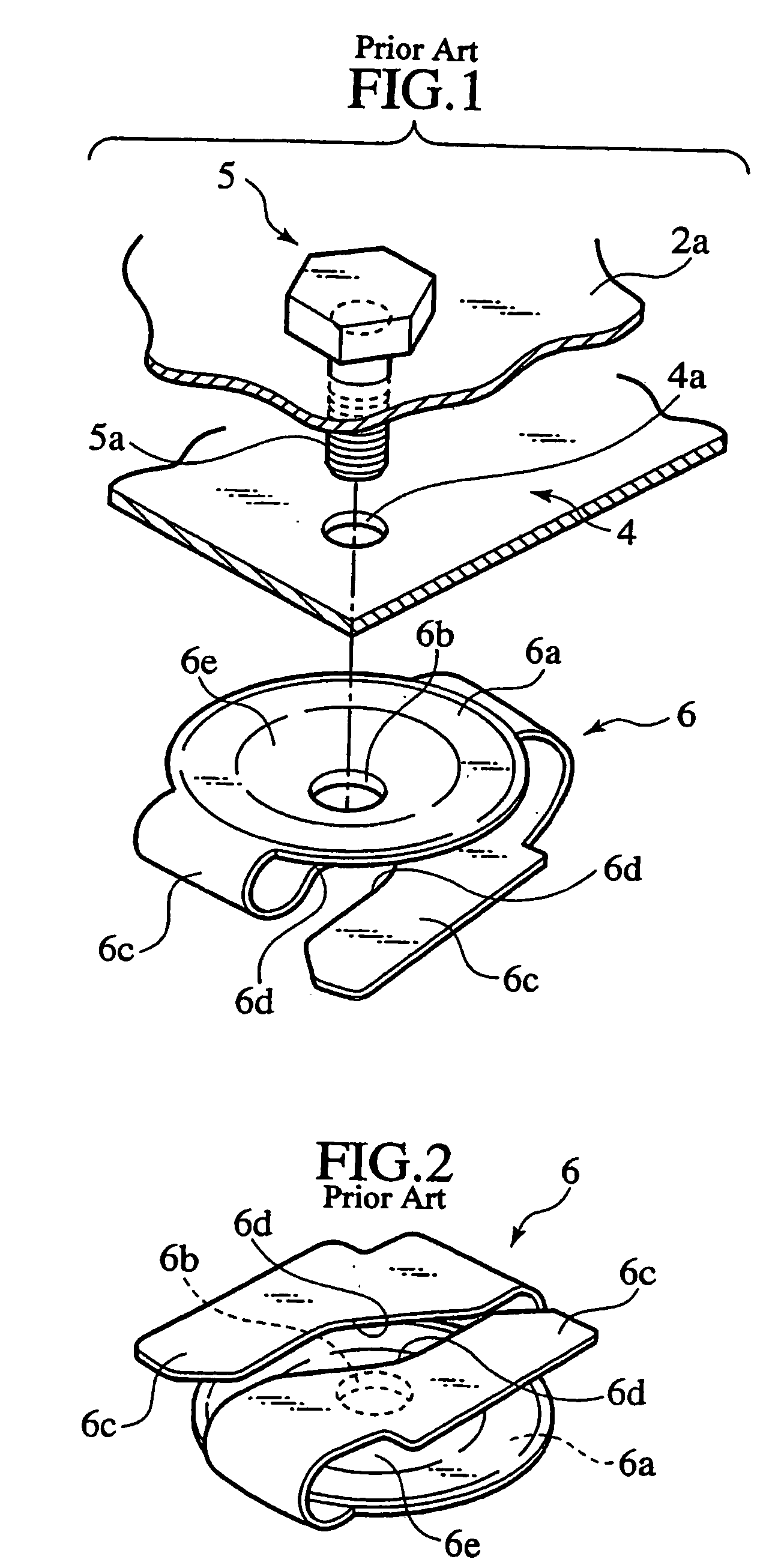

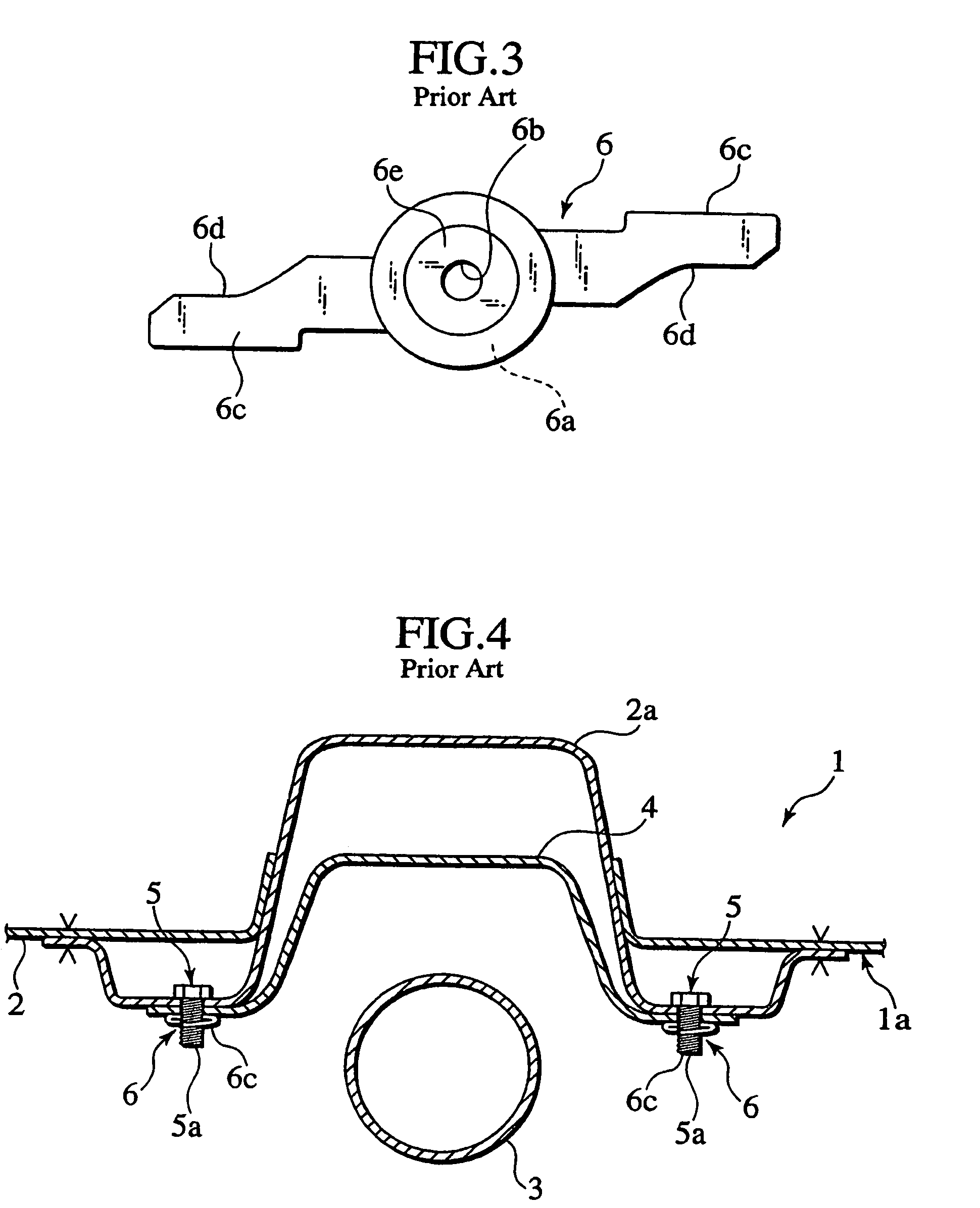

[0051]FIGS. 5 to 15 are views showing an attachment clip in accordance with the first embodiment of the present invention and an attachment structure using the above attachment clip.

[0052]Noted that elements similar to those of the afore-mentioned clip and attachment structure in earlier technology are indicated with the same reference numerals, respectively.

[0053]In these figures, FIG. 5 shows the attachment clip of the first embodiment, while FIG. 6 shows a pair of attachment structures each using the attachment clip of FIG. 5.

[0054]In FIG. 6, similarly, a vehicle body 1a is provided, on its underside 1a, with an under-panel 2 as an “attached” member (the second member).

[0055]In the under-panel 2, a floor tunnel 2a is formed so as to swell upward at a substantial center in the width direction of the vehicle, having a hat-shaped section.

[0056]Attached below the floor tunnel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com