Combined integral assembly superposed box culvert and construction method

A box culvert, integrated technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of difficult quality control and high construction costs, and achieve easy quality assurance of components, low connection accuracy requirements, and short maintenance time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

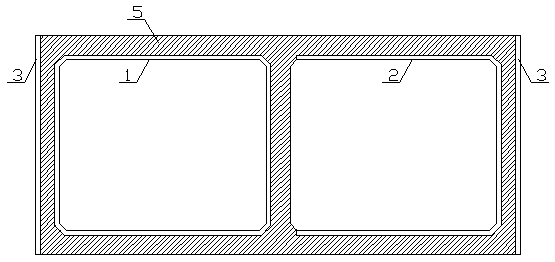

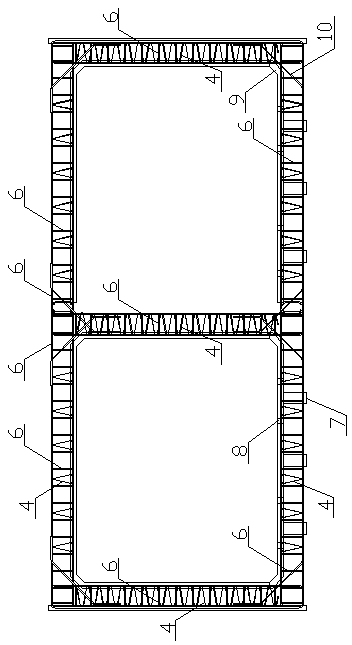

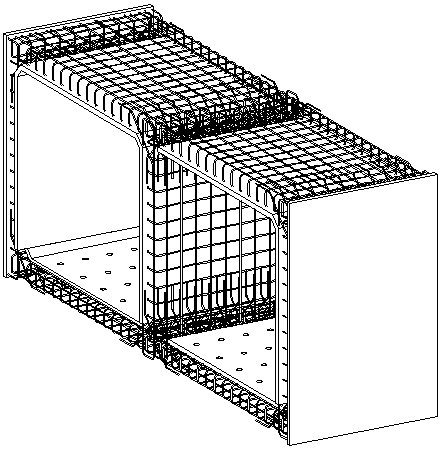

[0037] A combined integrally assembled superimposed box culvert, which is composed of: an annular inner wall 1, a C-shaped inner wall 2, a supporting outer wall 3, and a reinforcing steel frame. The annular inner wall, the C-shaped inner wall and the supporting outer wall are all A precast concrete layer, the steel frame is a box culvert steel frame, the box culvert steel frame is a double-layered two-way steel monolithic frame for the top plate, inner wall, outer wall and bottom plate of the box culvert. Between the supporting outer walls, the C-shaped inner wall and the supporting outer wall are connected by lattice steel bars 4, between the annular inner wall and the C-shaped inner wall, between the annular inner wall and the supporting outer wall , The cavity formed between the C-shaped inner wall and the supporting outer wall and the superimposed part of the top and bottom plates are poured in-situ concrete 5, the annular inner wall is connected to the C-shaped inner wall o...

Embodiment 2

[0039] According to the combined integral assembly stacking box culvert described in embodiment 1, the annular inner wall and the lower part of the C-shaped inner wall are provided with supports 7, and the supports are in the form of columns, and the annular inner wall, the An air vent 8 is provided on the precast concrete layer at the lower part of the C-shaped inner wall.

Embodiment 3

[0041] According to the combined integral assembly stack box culvert described in embodiment 1 or 2, the inner cavity of the annular inner wall and the C-shaped inner wall are square.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com