Cam valve

A cam and camshaft technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of complex process, increased use cost and high use cost, and achieve simple processing technology, improved sealing performance, and easy processing and manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

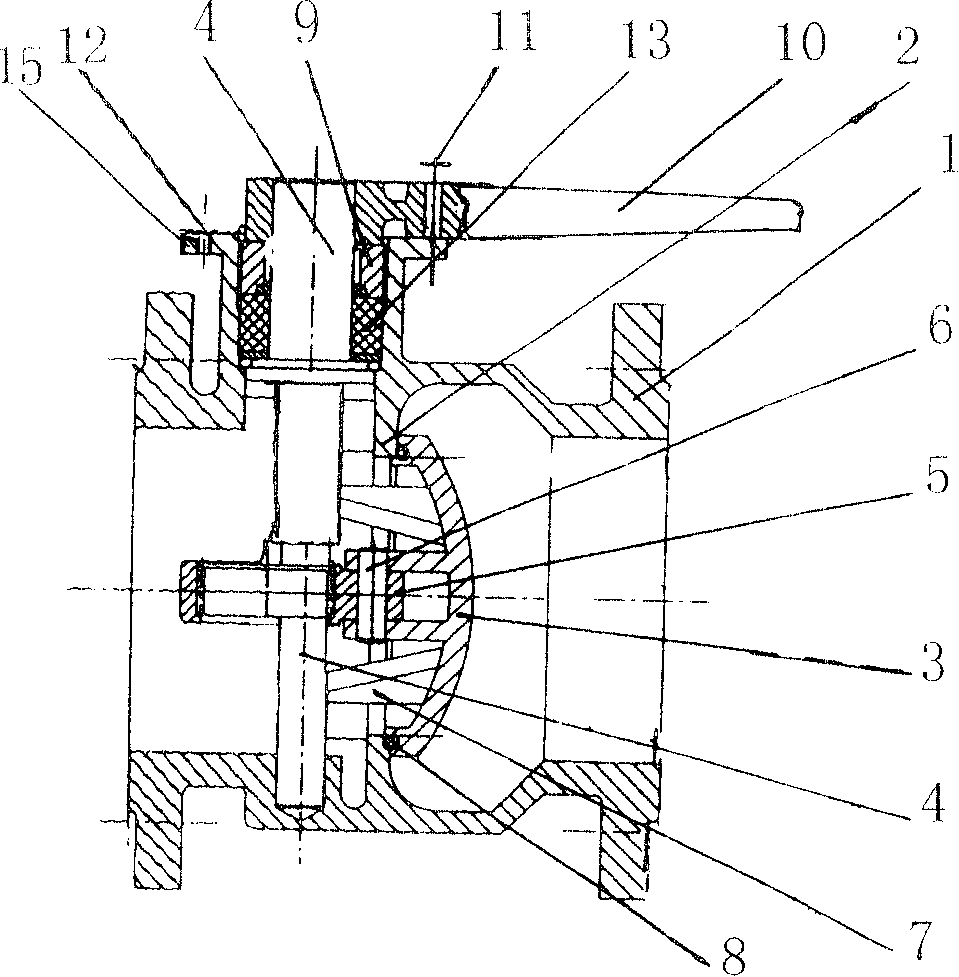

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

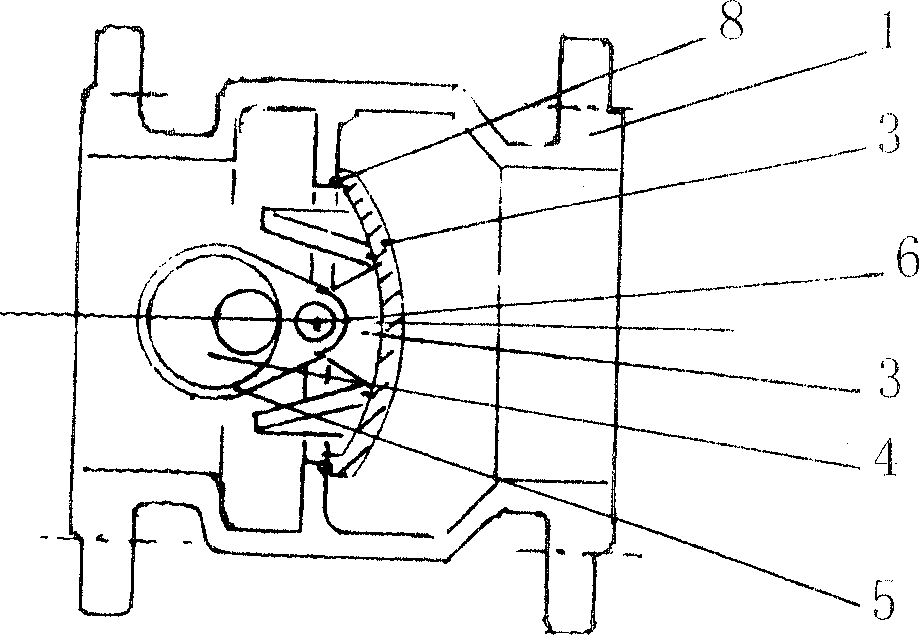

[0017] A cam valve, comprising a valve body 1, a valve seat 2, a valve disc 3, and a handle 10, the valve disc 3 is fixedly connected to one end of a coupling sleeve 5 through a connecting shaft 6, and the other end of the coupling sleeve 5 is connected to a camshaft 4, The camshaft 4 drives the valve disc 3 to move axially, and the camshaft 4 is fixedly connected with the handle 10 .

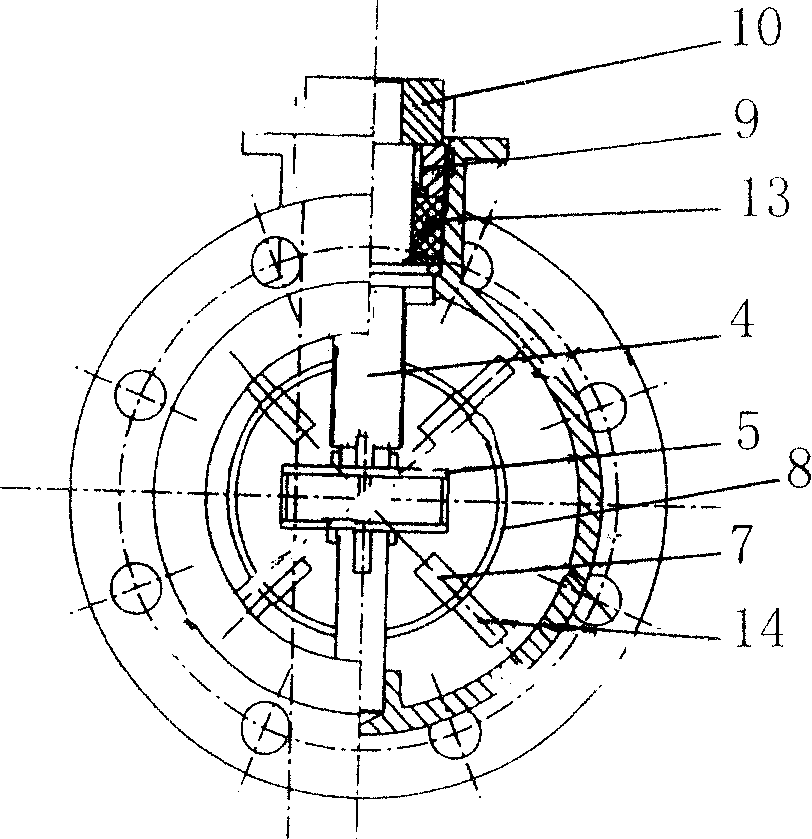

[0018] The valve flap 3 is provided with a slide block 7, and the valve seat 2 is provided with a support block 14 corresponding to the slide block 7, and the support block 14 is in the same body as the valve seat 2.

[0019] The slider 7 is in the same body as the disc 3, and there are 4 sliders 7, and the 4 sliders are arranged vertically and symmetrically. There are four supporting blocks 14, and the four supporting blocks are vertically symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com