Vacuum brazing and thermal treatment composite process for stainless steel surgical instrument and application of process

A technology of vacuum heat treatment and surgical instruments, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of easy rust, decreased serviceability and anti-corrosion performance, deformation, etc., and achieves reduced process costs and high finished product qualification rate. , Reduce the effect of workpiece round trip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

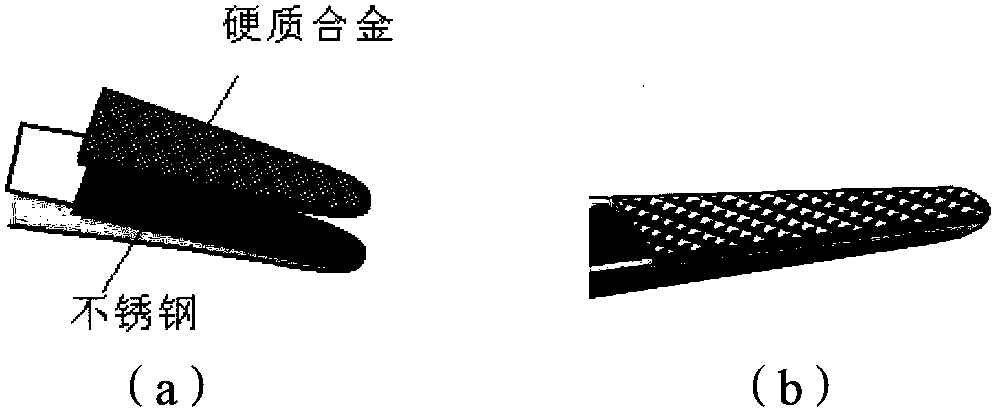

[0072] The vacuum brazing-heat treatment composite process of stainless steel surgical insert forceps is as follows:

[0073] (1) Carbide is inlaid into the working end of the stainless steel surgical instrument; the brazing surface of the stainless steel surgical instrument needs to be removed with metallographic sandpaper first, and the brazing surface of the cemented carbide needs to be ground with diamond first. The paste is polished; and the size of the nickel-based brazing material is required to be slightly larger than the brazing surface of the stainless steel surgical instrument. The joint gap between the two brazing surfaces is 0.02-0.10mm. The base material of the stainless steel surgical instrument workpiece is 20Cr13 stainless steel, and the hard alloy is For K40, the solder is made of the chemical composition and performance of Bni-2 solder shown in Table 3. The above-mentioned stainless steel surgical instruments are surgical forceps.

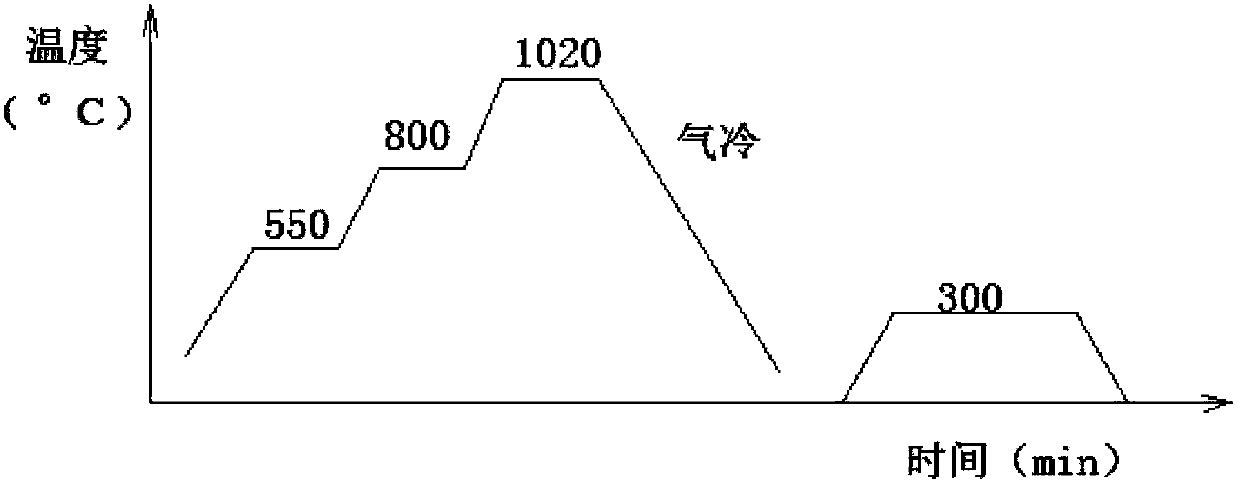

[0074] (2) The stainless...

Embodiment 2

[0077] The vacuum brazing-heat treatment composite process of stainless steel surgical insert forceps is as follows:

[0078] (1) Carbide is inlaid into the working end of the stainless steel surgical instrument; the brazing surface of the stainless steel surgical instrument needs to be removed with metallographic sandpaper first, and the brazing surface of the cemented carbide needs to be ground with diamond first. The paste is polished; and the size of the nickel-based brazing material is required to be slightly larger than the brazing surface of the stainless steel surgical instrument, the joint gap between the two brazing surfaces is 0.08mm, the base material of the stainless steel surgical instrument workpiece is 20Cr13 stainless steel, and the hard alloy is K40. The solder is made of the chemical composition and performance of Bni-2 solder shown in Table 3. The above-mentioned stainless steel surgical instruments are surgical forceps.

[0079] (2) The stainless steel su...

Embodiment 3

[0082] The vacuum brazing-heat treatment composite process of stainless steel surgical insert forceps is as follows:

[0083] (1) Carbide is inlaid into the working end of the stainless steel surgical instrument; the brazing surface of the stainless steel surgical instrument needs to be removed with metallographic sandpaper first, and the brazing surface of the cemented carbide needs to be ground with diamond first. The paste is polished; and the size of the nickel-based brazing material is required to be slightly larger than the brazing surface of the stainless steel surgical instrument, the joint gap between the two brazing surfaces is 0.03mm, the base material of the stainless steel surgical instrument workpiece is 20Cr13 stainless steel, and the hard alloy is K40. The solder is made of the chemical composition and performance of Bni-2 solder shown in Table 3. The above-mentioned stainless steel surgical instruments are surgical forceps.

[0084] (2) The stainless steel surg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com