Production method of tightening device oil cylinder

A production method and tensioning device technology, applied in the field of construction machinery, can solve problems such as waste of aluminum billets, affect product performance, and high maintenance costs, and achieve reduced material costs and processing costs, dispersion distribution of inclusions, and dimensional accuracy after welding high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

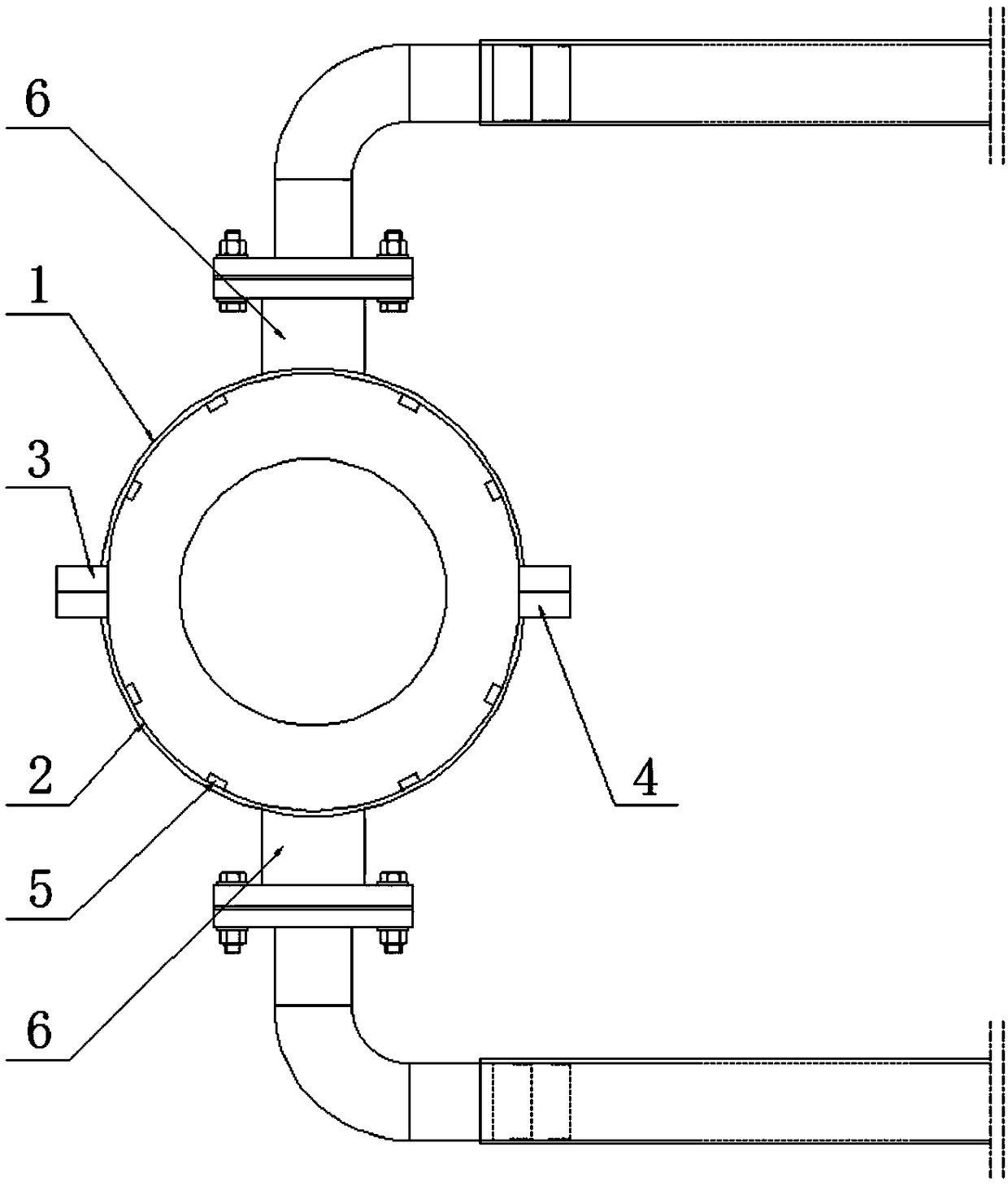

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0034] A kind of production method of tensioner oil cylinder in the present embodiment, it comprises the following steps:

[0035] Step 1. Prepare materials

[0036] According to the size of the cylinder, the blanks of the cylinder and flange are prepared in advance;

[0037] The welding surface of the cylinder blank is designed as a convex arc surface, and the corresponding area of the welding surface of the flange blank and the cylinder blank is designed as a concave arc surface. Coaxiality requirements;

[0038] Step 2, welding surface cleaning;

[0039] Step three, preheating;

[0040] Step 4. Friction welding

[0041] Clamp the cylinder and flange blanks on the friction welding equipment respectively, wherein the cylinder blank is clamped on the rotating fixture, the flange blank is clamped on the moving fixture, the welding speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com