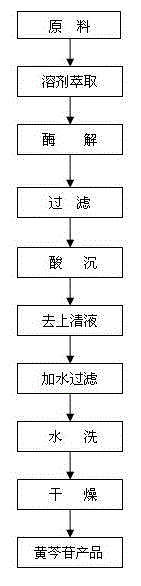

Extraction method for producing baicalin with biological enzyme method

An extraction method and a biological enzymatic technology are applied in the field of extracting baicalin, which can solve the problems of low baicalin yield, complex process and high cost, and achieve the advantages of improving yield, strong anticancer reaction, and scavenging oxygen free radicals. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] Example 1: Take 1 kg of black rice, crush it into fine powder, add 8 times the amount of water, adjust the pH to 5.0 with hydrochloric acid, add amylase, keep it at 70°C for 4 hours, filter, pass the filtrate through AB-8 macroporous adsorption resin, and pour the column liquid Concentrate to a density of 1.30 to obtain 821 g of black rice syrup. The resin was washed with 5 times of purified water, and then analyzed with 80% ethanol. The analyzed solution was concentrated under reduced pressure at 50°C to a density of 1.10, and spray-dried to obtain black rice anthocyanins, 11.2g, with a content of 25.8%. Add 4 times the amount of water to the filter residue, adjust the pH to 4.8 with citric acid, keep it at 50°C for 4 hours, filter, add 8 times the amount of 4% sodium hydroxide solution to the filter cake, keep it at 70°C for 2 hours, filter, and adjust the pH of the filtrate to 3.5 with hydrochloric acid , heated to 85°C, let stand, filter, filter cake, and dry at 70-...

example 2

[0033] Example 2: Take 1 kg of black rice dregs, grind it into fine powder, add 5 times the amount of water, adjust the pH to 4.5 with citric acid, add glucoamylase, keep it at 90°C for 2 hours, filter, and the filtrate passes through XDA-6 macroporous adsorption resin. The lower column liquid was concentrated to a density of 1.32 to obtain 546 g of black rice syrup. The resin was washed with 5 times of purified water, analyzed with 60% ethanol, concentrated under reduced pressure at 60°C to a density of 1.15, and freeze-dried at -40°C to obtain 13.4g of black rice anthocyanins with a content of 27.2%. Add 8 times the amount of water to the filter residue, adjust the pH to 4.8 with citric acid, keep it at 50°C for 4 hours, filter, add 6 times the amount of 4% sodium hydroxide solution to the filter cake, keep it at 70°C for 1 hour, filter, adjust the pH of the filtrate to 5 with hydrochloric acid, and heat to 98°C, let stand, filter, filter cake, add 10 times the amount of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com