Tap water separator lifting hole machining equipment and water separator lifting hole machining method

A water separator and hole processing technology, applied in the field of valve parts processing, can solve the problems of low production efficiency, complex process, copper scraps and other problems, and achieve the effect of improving production efficiency and yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

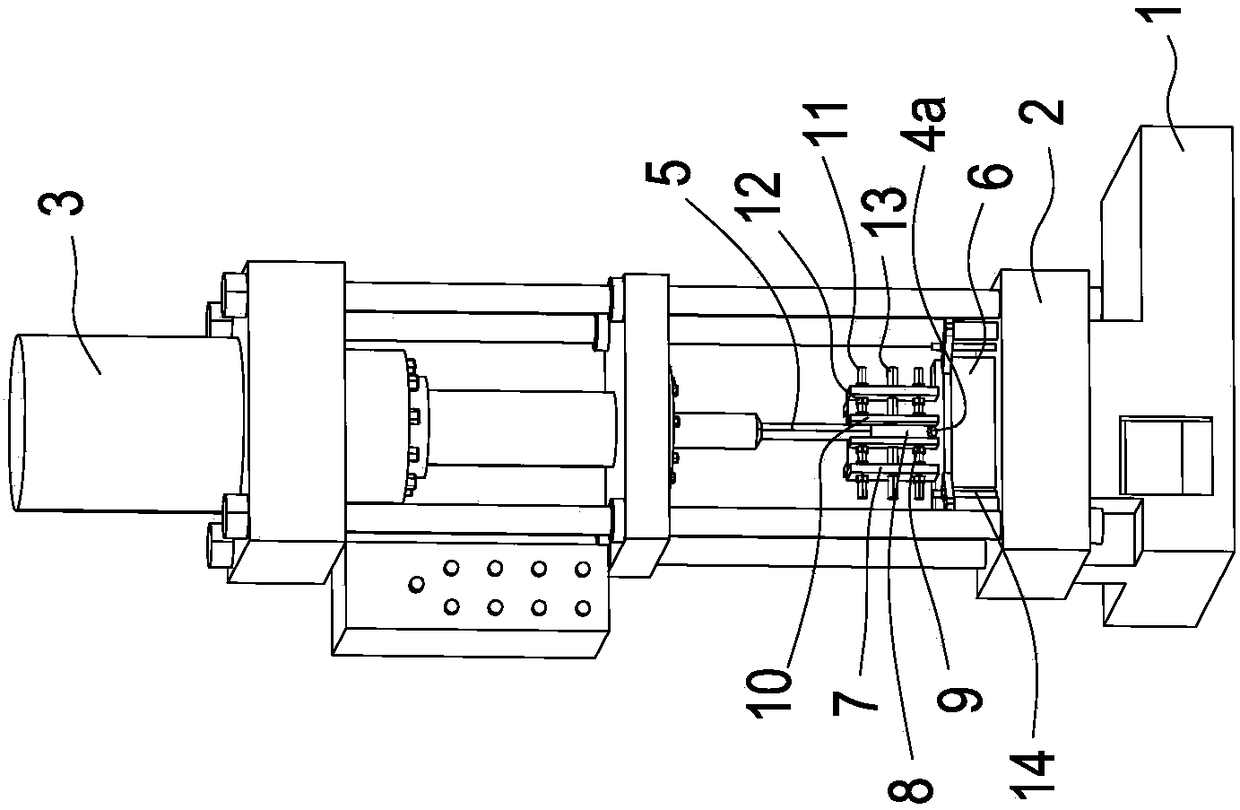

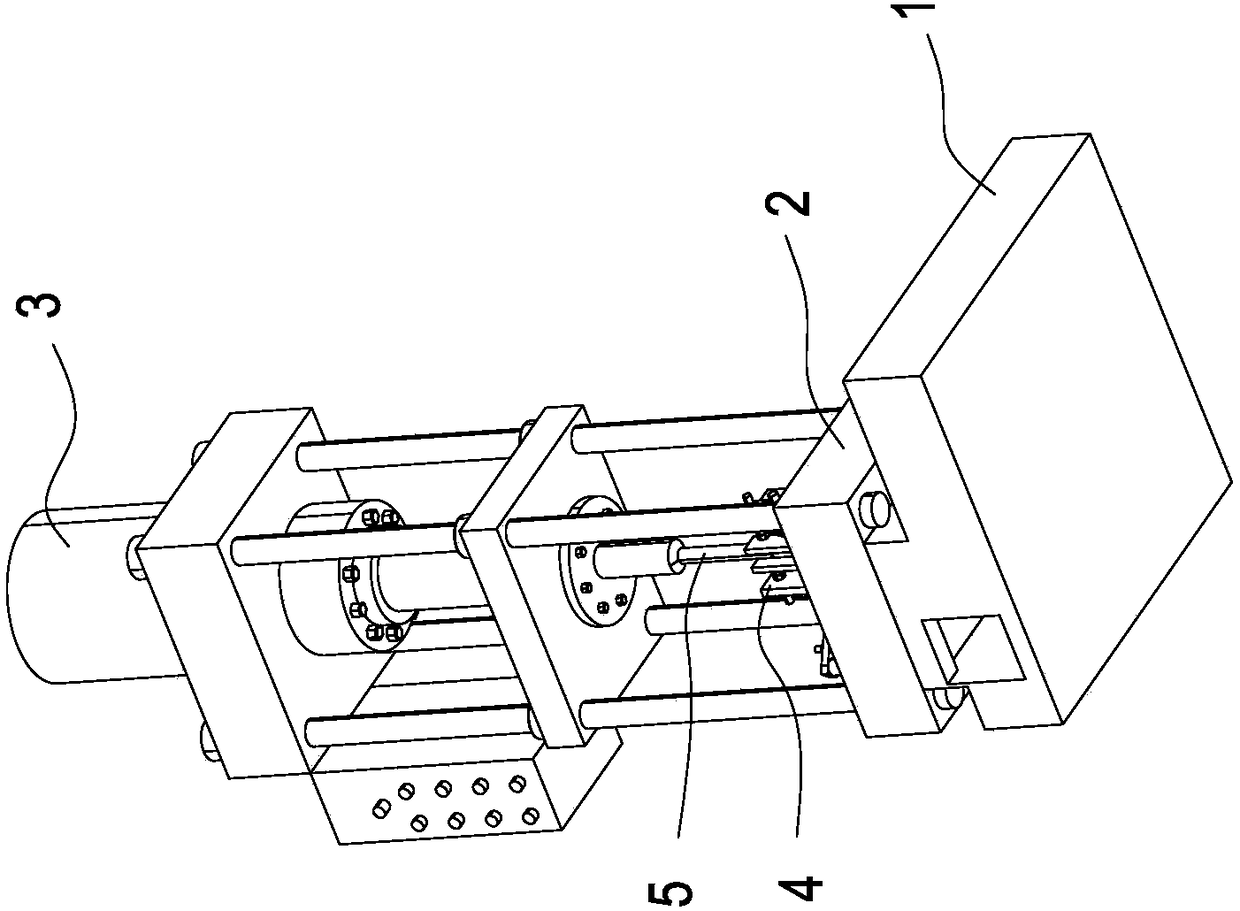

[0023] Such as Figure 1-3 As shown, a faucet diverter lifting hole processing equipment includes a machine base 1, and a pressing table 2 arranged on the machine base 1, and the pressing table 2 is provided with a The presser 3 of the output shaft of the presser 3 is detachably provided with a water divider fixing frame 4, and the output shaft of the presser 3 is connected with a cylindrical presser rod 5 , the position of the press rod 5 is corresponding to the water separator fixing frame 4, and also includes a steel ball, the diameter of the steel ball is greater than the aperture 2-6 wire of the water separator lifting hole, and the water separator fixing frame 4 is provided with There is a blanking hole 4a, and the aperture of the blanking hole 4a is not less than the diameter of the steel ball. Compressor 3 is an air cylinder or an oil cylinder.

[0024] When the present invention is in use, put the water separator into the water separator fixing frame 4, put a steel ...

Embodiment 2

[0038] This embodiment adopts the equipment of Embodiment 1, and provides a method for processing the lifting hole of the water separator of the faucet. Specifically, the water separator is placed in the water separator fixing frame (4), and the Put a steel ball, the diameter of the steel ball is 2-6 wires larger than the inner diameter of the inner hole of the water separator, start the compactor (3) to push the pressing rod (5) to push the steel ball into the inner hole of the water separator and finally from the Pass through the inner hole of the water separator.

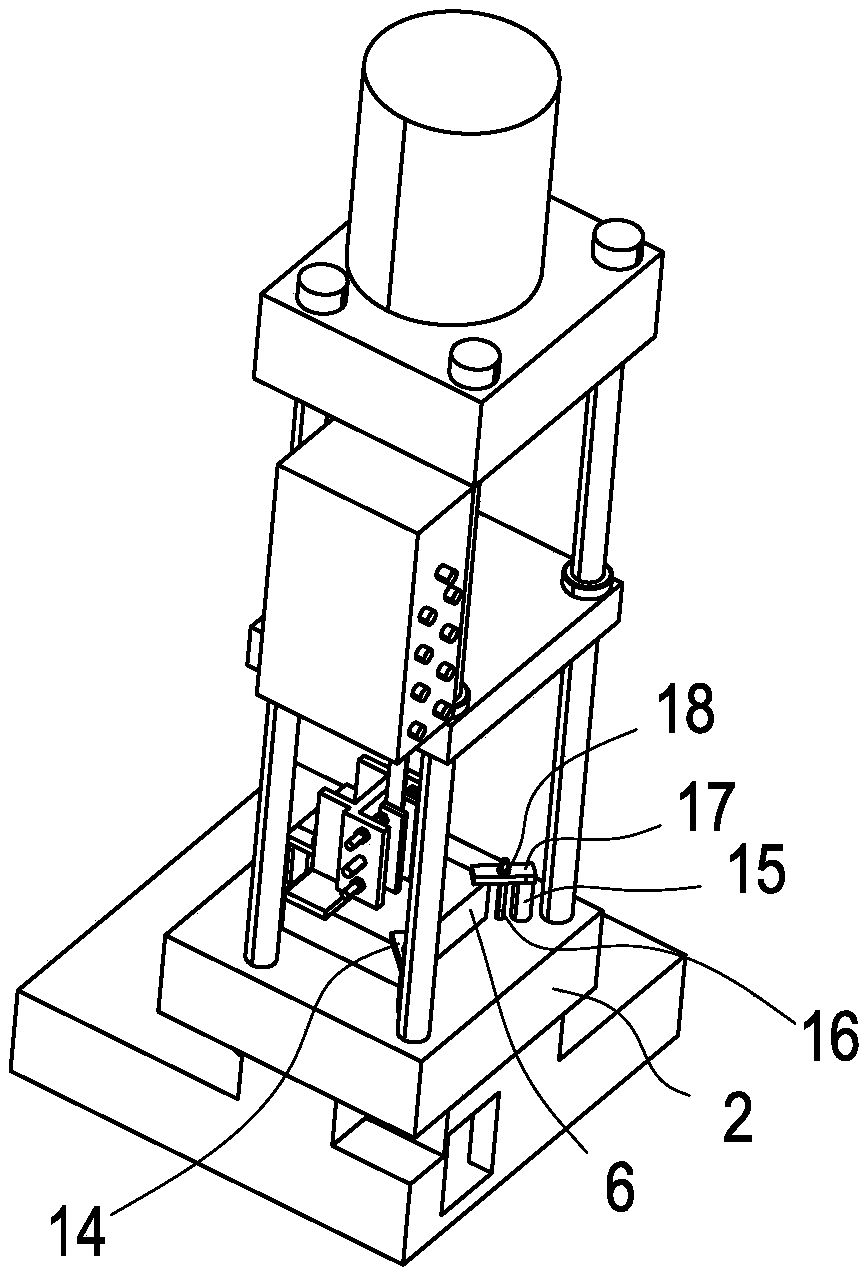

[0039] To be more specific, select the steel ball whose diameter is the diameter of the water separator lifting hole after processing, place the water separator fixing frame 4 on the pressing table 2, adjust the position so that the fixing groove 8 is aimed at the bottom of the pressing rod 5, and use the pressing The material plate 17 cooperates with the pressing nut 18 to press the fixing seat 6, the water sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com