A Preforming Die for Machining Straight and High Cylindrical Forgings

A pre-formed, high-tube technology, applied in the direction of manufacturing tools, metal processing equipment, engine components, etc., can solve the problems of increasing product costs, increasing the amount of forgings, etc., to improve the yield and production efficiency, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

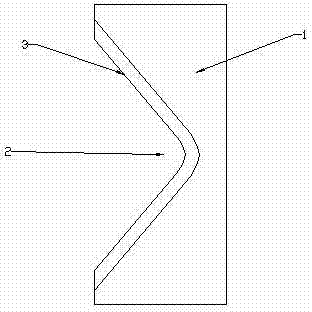

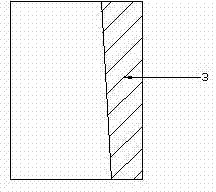

[0012] In order to gain an in-depth understanding of this preforming die for machining straight tall cylindrical forgings, combined with figure 1 , 2 described as follows:

[0013] It mainly includes: a base 1, a V-shaped opening 2 and a side slope 3. The front end of the base 1 is provided with a V-shaped opening 2, and the V-shaped opening 2 is composed of slopes 3 on both sides; the V-shaped opening 2 is 112°, and the inclination angle of the circular table The method of use is as follows: Put the mandrel in, then place the bearing ring flatly on the mold, the outer circle of the ring is in contact with the 3° inclined surface 3 of the abrasive tool, supported by the 112° V-shaped opening 2 , and then apply the gravity hammer of the air hammer to make the forging reach the height required by the process and form a conical forging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com