Compound blue crystal underlay substrate and method for producing the same

A substrate substrate and crystal technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high substrate price, high cost, high hardness, etc., and achieve improved scribing yield, low cost, and good thermal performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

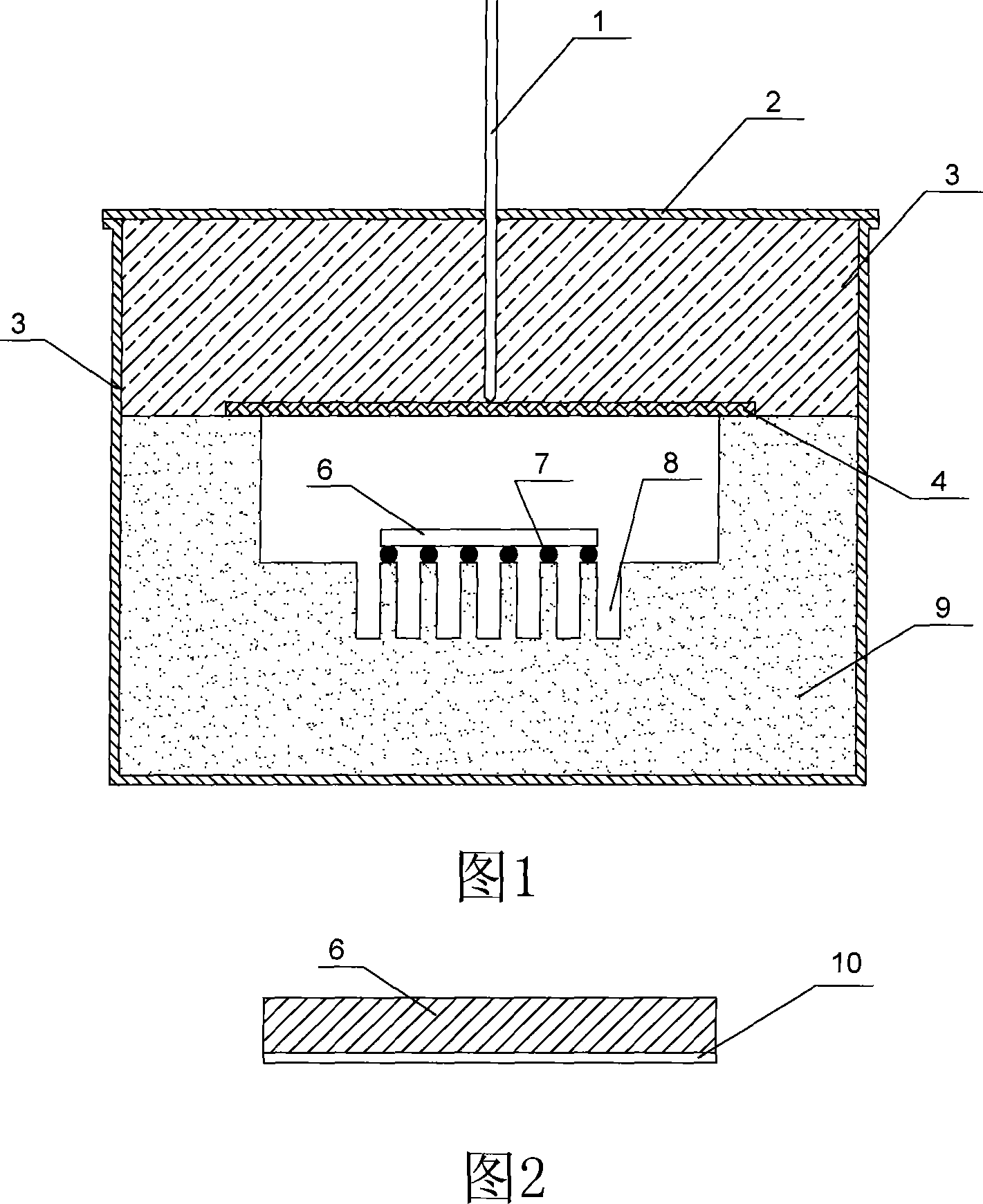

[0019] The schematic diagram of the gas phase transport equilibrium (VTE) experimental device used in the present invention is as figure 2 Shown, in the platinum crucible 5, be placed with air hole 8, the Li of the same certain ratio 2 SiO 2 and Li 2 O compound block 9, platinum wire 7 is placed on the compound block 9, and the blue crystal wafer 6 of fine grinding or polishing is placed on the platinum wire 4 through rough grinding, and the platinum sheet is placed on the compound block 9, and also covered Li 2 SiO 2 and Li 2 O the mixture block 3, the thermocouple 1 is inserted into the mixture block 3, and finally the crucible 5 is sealed with a platinum cover 1.

[0020] Vapor transport equilibrium (VTE) technique is a mass transport process, so there should be enough Li in the crucible 2 O supply. And the gas phase transport balance depends on the Li 2 O keeps flowing from Li 2 SiO 2 and Li 2 O is maintained by volatilization in the mixed material, in order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com