Semi-automatic polishing machine

A kind of grinding machine, semi-automatic technology, applied in the direction of grinding machine, abrasive belt grinder, grinding/polishing equipment, etc., can solve the problems of manual operation difficult to control, the thickness of the metal conductive sheet becomes smaller, and affect the function of the metal conductive sheet, etc., to improve The effect of production efficiency and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

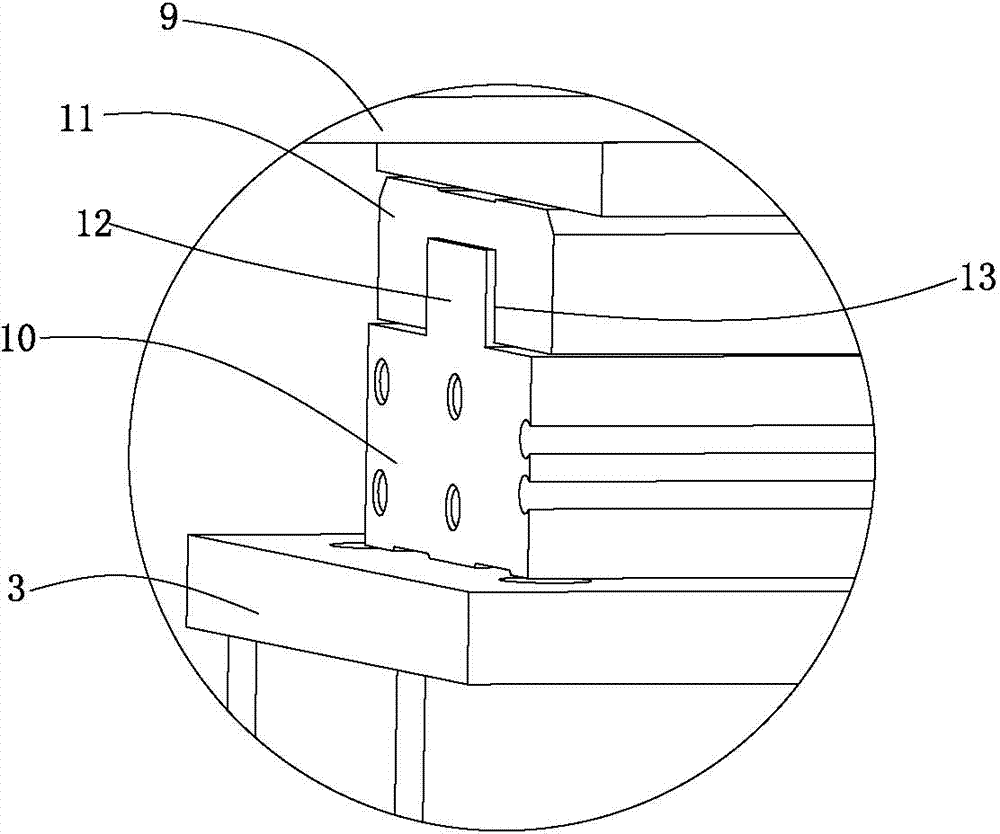

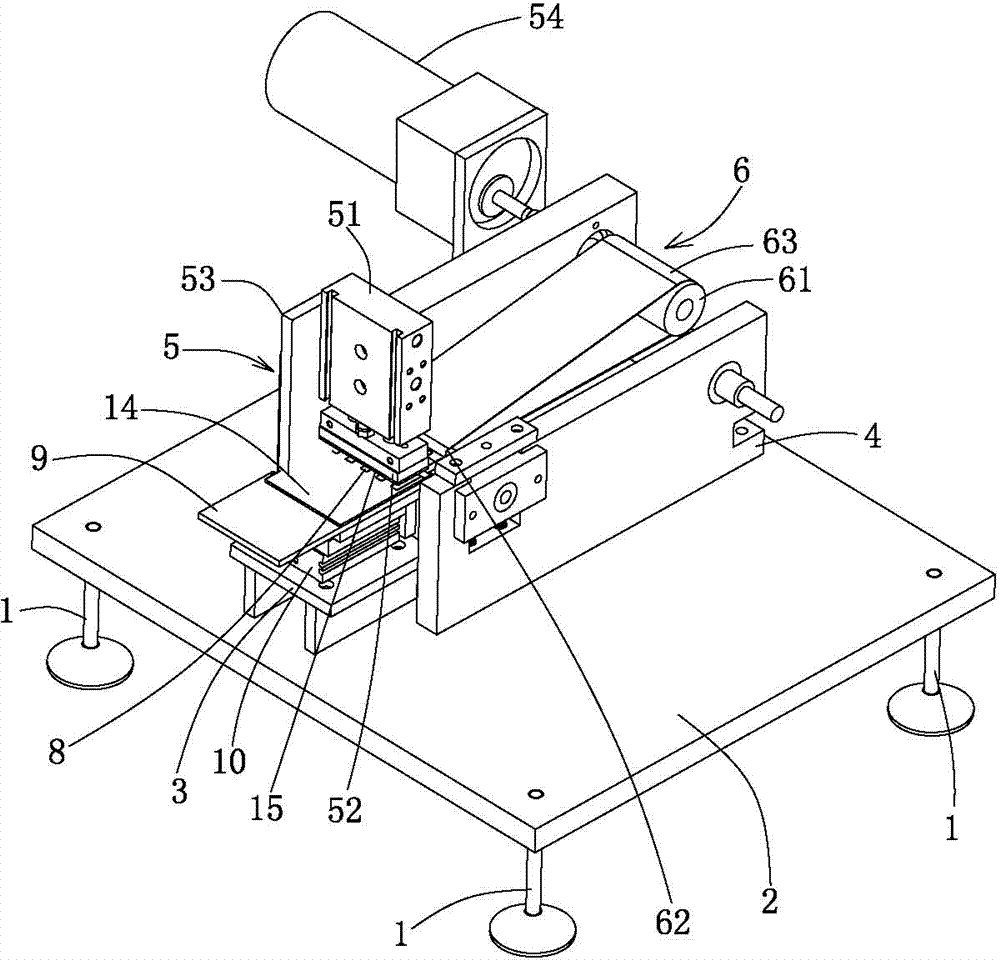

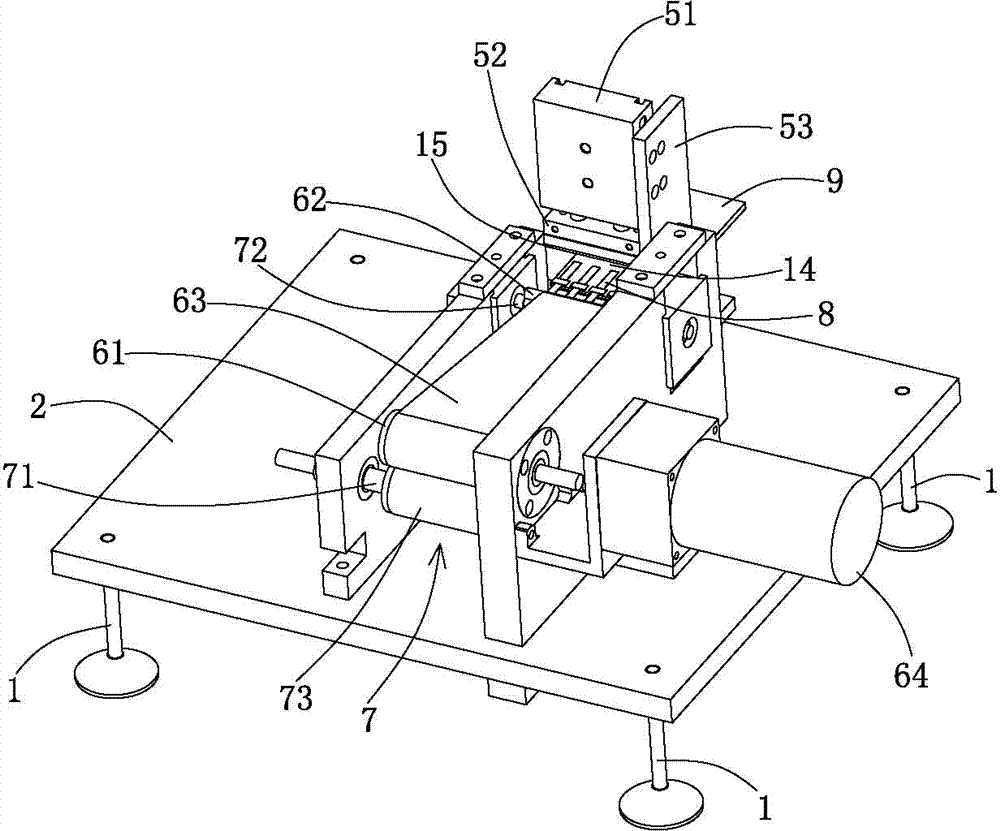

[0044] See Figure 1 to Figure 4 , a semi-automatic grinding machine, including a bracket 1 and a table 2, and also includes a first workbench 3 for fixing a workpiece to be polished and a second workbench 4 for grinding on the table 2, above the first workbench 3 A compacting device 5 for compacting the workpiece to be polished is provided, and the second workbench 4 is provided with an upper grinding device 6 and a lower grinding device 7 which can move cyclically, and between the upper grinding device 6 and the lower grinding device 7 is provided Grinding the gap where the workpiece protrudes, the size of the gap can be adapted and adjusted according to the thickness of the workpiece to be polished and the grinding pressure.

[0045] The upper grinding device 6 includes a driving roller 61, a driven roller 62, an upper sandpaper 63 and a driving device 64. The upper sandpaper 63 is set as a belt type, and the upper sandpaper 63 is sleeved on the driving roller 61 and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com