Plastic toilet pan without water tank

A toilet and no water tank technology, which is applied to the field of plastic toilets without a water tank, can solve the problems of low processing yield, heavy finished product weight, fragile cost, etc., and achieves the effects of light weight, simple structure and low cost of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The plastic toilet without a water tank will be described in further detail below in conjunction with the drawings.

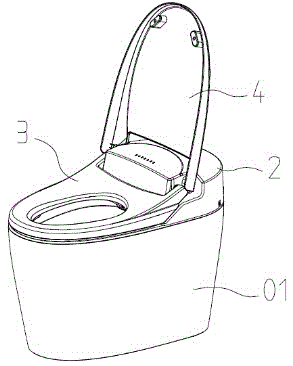

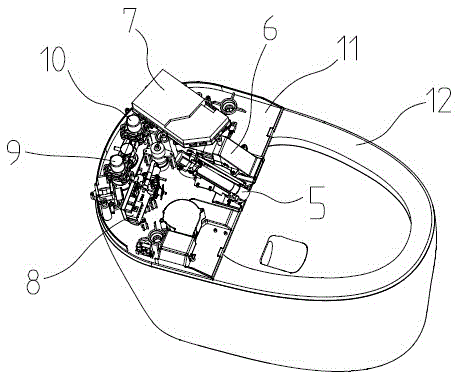

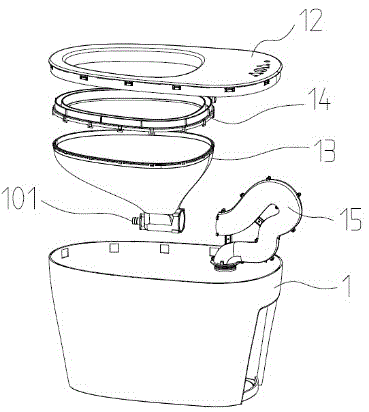

[0019] Such as Figure 1~8 As shown, the plastic toilet without a water tank of the present invention includes a plastic base 01, a seat ring 3, a flip cover 4, an upper cover 2, a base 11, a water temperature heater 8, a water spray rod 5, and a warm air heater. Component 6, control circuit board 7, flushing solenoid valve 9 and 10, plastic base 01 consists of base cover 12, base shell 1, inner tank 13, water channel frame 14, siphon 15, water inlet connection hose 17, scrubbing connection hose 18. The strong punching connecting hose 16 is assembled.

[0020] Furthermore, the main structural parts in the plastic base 01, the base cover 12, the base shell 1, the inner tank 13, the water channel frame 14, and the siphon 15 are all made of plastic. Screws, glue, buckles or welding can be used between the various parts. The way is fixed connection.

[0021] Fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com