Tail-tin-plated type plug power line detecting equipment

A technology for testing equipment and power cords, which is applied in the field of testing equipment for tail tinned plug power cords, can solve problems such as low production efficiency, inability to straighten the entire line, and irregular incoming materials, so as to save production costs and improve production. Efficiency and yield rate, the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended Figures 1 to 5 The detection equipment for the tail tinned plug power cord provided by the present invention will be described in detail.

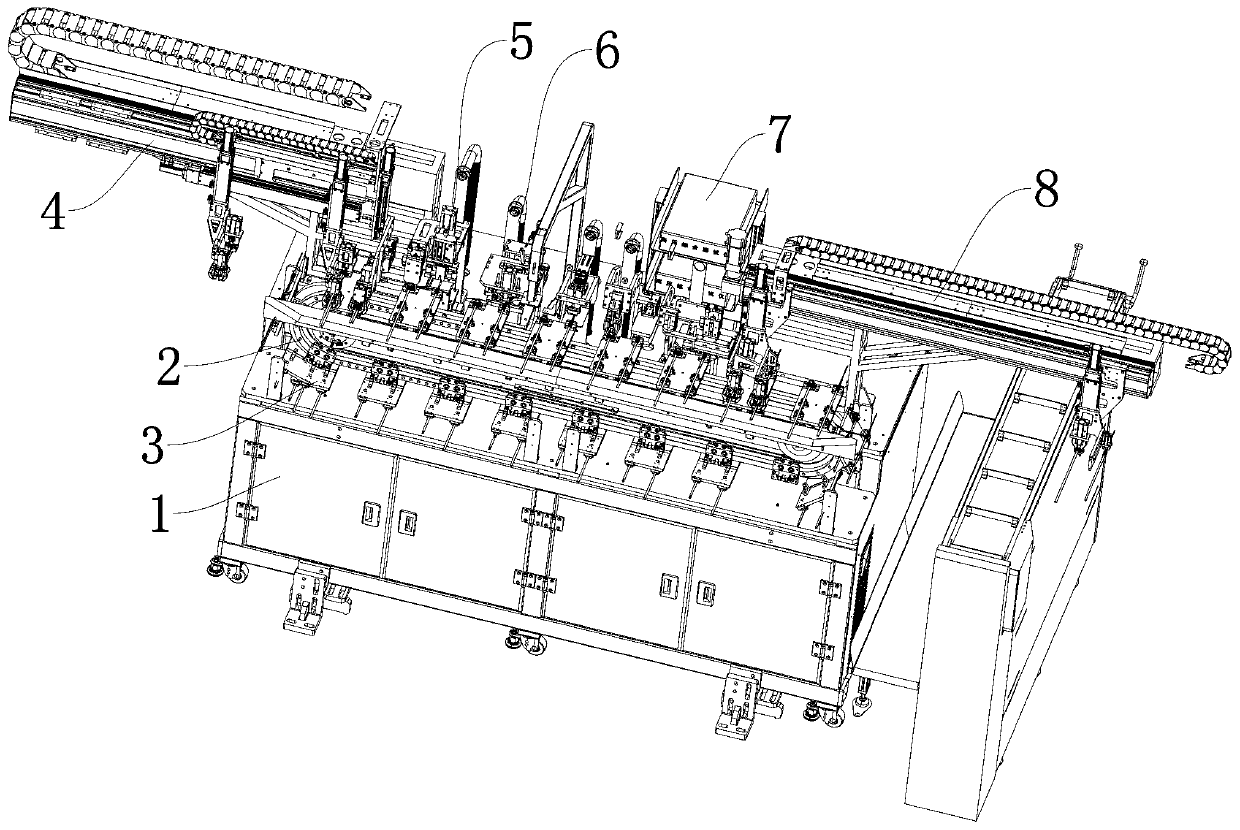

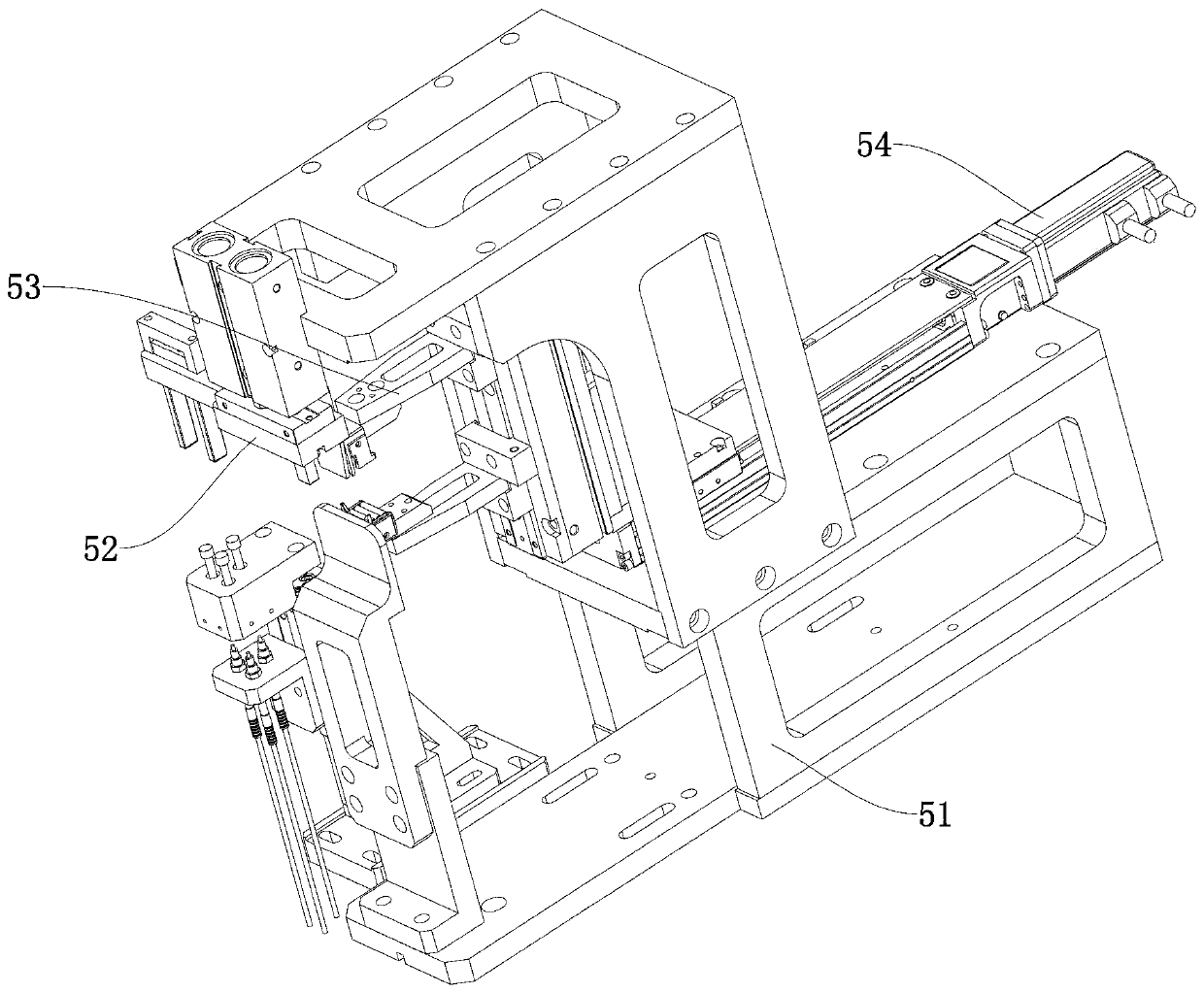

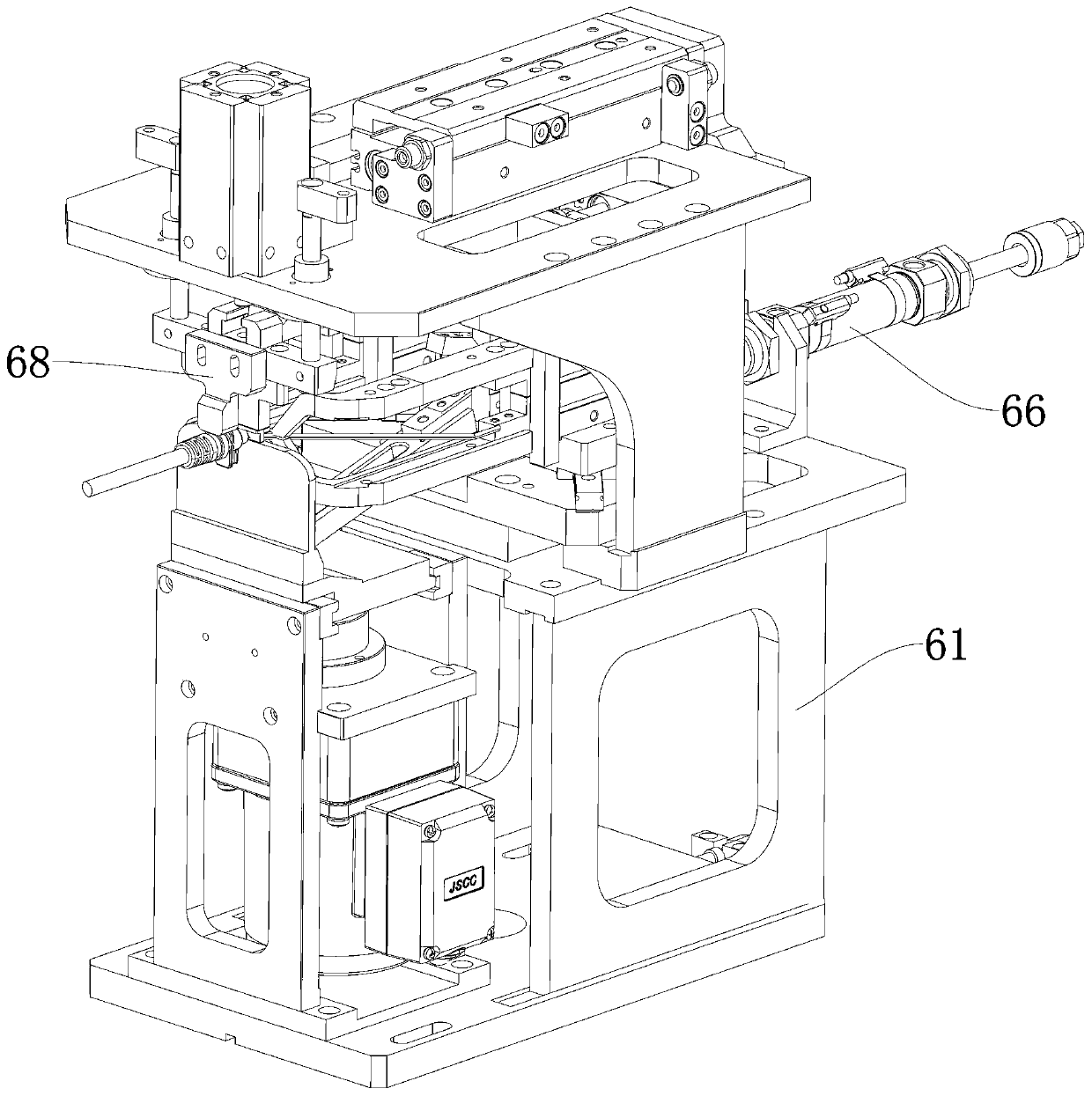

[0035] refer to Figures 1 to 5 The tail tinned plug power cord detection equipment provided by the present invention includes a frame 1, on which a circular conveying line 2 is arranged, and at least one jig 3 for arranging the plug wire is installed on the circular conveying line 2 ; along the conveying direction of the circular conveying line 2, a feeding mechanism 4 for transferring the plug wires from the previous process to the carrier, and a three-phase wire for exposing the tail ends of the plug wires are sequentially arranged on the frame 1 Tail shaping mechanism for shaping operation 5, tail branching mechanism for splitting the three-pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com