Aluminum alloy, heat exchanger, aluminum alloy composite and preparation method of aluminum alloy composite

A composite material and aluminum alloy technology, applied in the field of aluminum alloy composite materials for brazing, can solve the problems of thinning thickness, inability to meet the strength requirements of brazing aluminum alloy composite materials, etc., to improve production efficiency, yield, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

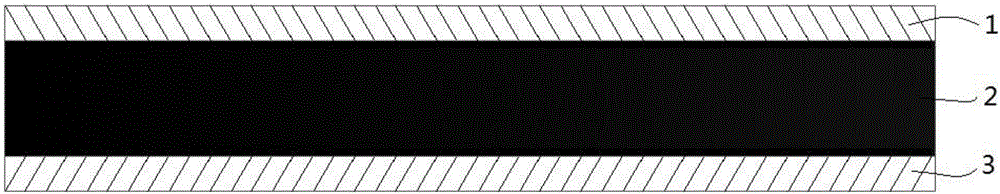

[0054] This embodiment provides a three-layer structure aluminum alloy composite material, the structure of which is as figure 1 Shown. The middle layer is AA3003Mod aluminum alloy, and the top and bottom layers are both AA4045 aluminum alloy. The mass percentage of each component in AA3003Mod aluminum alloy is as follows: Mn is 1.5%, Mg is 0.2%, Si is 0.1%, Fe is 0.32%, Cu is 0.76%, Ti is 0.02%, Zr is 0.1%, and the rest is Al and Impurities are inevitable.

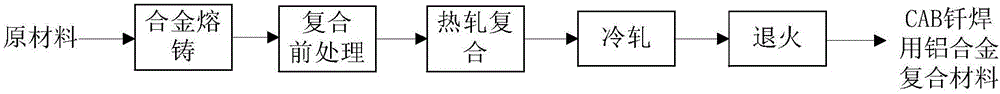

[0055] The preparation process is as figure 2 As shown, the details are as follows:

[0056] 1) Alloy casting: DC casting is used to cast AA4045 aluminum alloy and AA3003Mod aluminum alloy, and the ingot size is 450×1120×5100mm.

[0057] 2) Composite pretreatment: Surface treatment of AA4045 aluminum alloy, and milling treatment of AA3003Mod aluminum alloy to 419mm; AA4045 aluminum alloy after surface treatment is hot rolled to 42.5mm, and then evenly divided into 5100mm length.

[0058] 3) Hot-rolled composite: Stacked and fi...

Embodiment 2

[0063] This embodiment provides a three-layer structure aluminum alloy composite material, the structure of which is as figure 1 Shown. The middle layer is AA3003Mod aluminum alloy, the top layer is AA4045 aluminum alloy, and the bottom layer is AA7072 aluminum alloy. Among them, the mass percentages of each component in the AA3003Mod aluminum alloy are as follows: Mn is 1.36%, Mg is 0.18%, Si is 0.3%, Fe is 0.3%, Cu is 0.7%, Ti is 0.01%, Zr is 0.09%, and the rest is Al and unavoidable impurities.

[0064] The preparation process is as figure 2 As shown, the details are as follows:

[0065] 1) Alloy casting: DC casting is used to cast AA4045 aluminum alloy, AA7072 aluminum alloy and AA3003Mod aluminum alloy, and the ingot size is 450×1120×5100mm.

[0066] 2) Composite pre-treatment: surface treatment of AA4045 aluminum alloy and AA7072 aluminum alloy, and milling of AA3003Mod aluminum alloy to 420mm; after surface treatment, AA4045 aluminum alloy and AA7072 aluminum alloy are hot ...

Embodiment 3

[0072] This embodiment provides a three-layer structure aluminum alloy composite material, the structure of which is as figure 1 Shown. The middle layer is AA3003Mod aluminum alloy, and the top and bottom layers are both AA4045 aluminum alloy. Among them, the mass percentages of the components in the AA3003Mod aluminum alloy are as follows: Mn is 1.8%, Mg is 0.15%, Si is 0.7%, Fe is 0.4%, Cu is 0.2%, Ti is 0.02%, Zr is 0.13%, and the rest is Al and unavoidable impurities.

[0073] The preparation process is as figure 2 As shown, the details are as follows:

[0074] 1) Alloy casting: DC casting is used to cast AA4045 aluminum alloy and AA3003Mod aluminum alloy, and the ingot size is 450×1120×5100mm.

[0075] 2) Composite pre-treatment: surface treatment of AA4045 aluminum alloy, and milling treatment of AA3003Mod aluminum alloy to 422mm; after surface treatment, AA4045 aluminum alloy is hot rolled to 41.5mm, and then evenly divided into 5100mm length.

[0076] 3) Hot-rolled composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com