Novel plastic welding equipment

A welding equipment and plastic technology, applied in the field of plastic welding equipment, can solve the problems of low degree of automation, melting and damage of plastic products, low production efficiency, etc., and achieve the effect of improving the yield and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

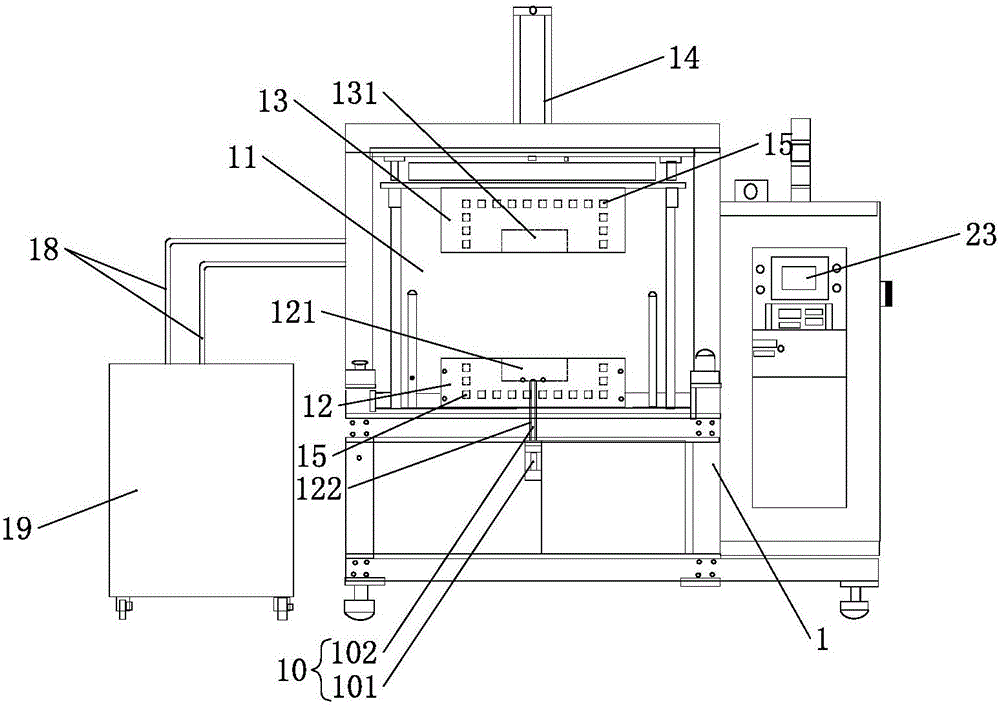

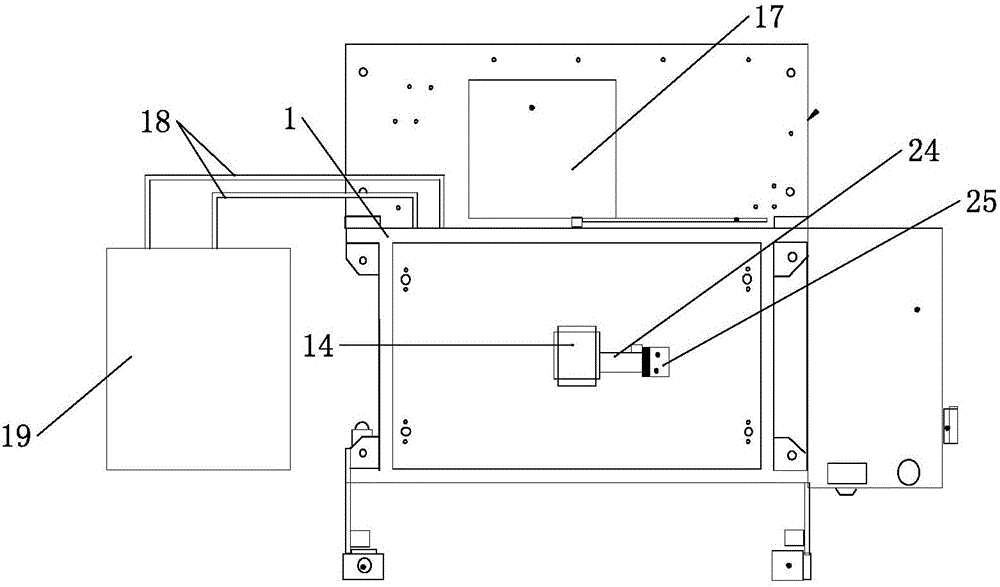

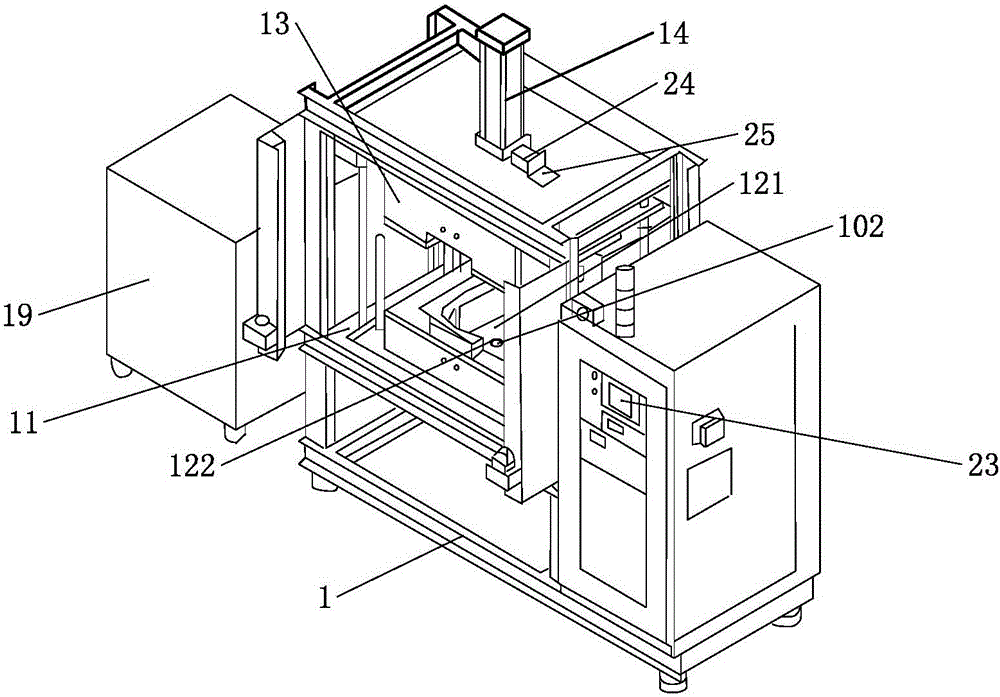

[0027] Such as Figures 1 to 8 As shown, the novel plastic welding equipment of the present invention is used for welding plastic products, and it includes a frame 1 and a control circuit 2, and the specific structure is as follows:

[0028] Described frame 1 is provided with a welding chamber 11, and the below of this welding chamber 11 is provided with positioning and supporting lower mold 12, and is provided with a positioning and pressing upper mold 13 connected with compression cylinder 14 above, and described positioning and supporting lower mold 12 and the positioning and pressing upper die 13 are installed on the welding chamber 11 using an easy-to-assemble and disassemble structure, and the positioning and supporting lower die 12 and the positioning and pressing upper die 13 can be replaced according to different products; the positioning and supporting lower die 12 A lower positioning die cavity 121 is provided, and the lower positioning die cavity 121 is correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com