Ejection product taking-out device

A product take-out and position-connecting technology, which is applied in the field of injection product take-out devices, can solve problems such as poor product position, product slipping and falling off, product yield and production efficiency reduction, etc., to ensure position consistency and improve yield. The effect of rate and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical means and effects adopted by the present invention, a detailed description will be given below in conjunction with a preferred embodiment of the present invention and its accompanying drawings.

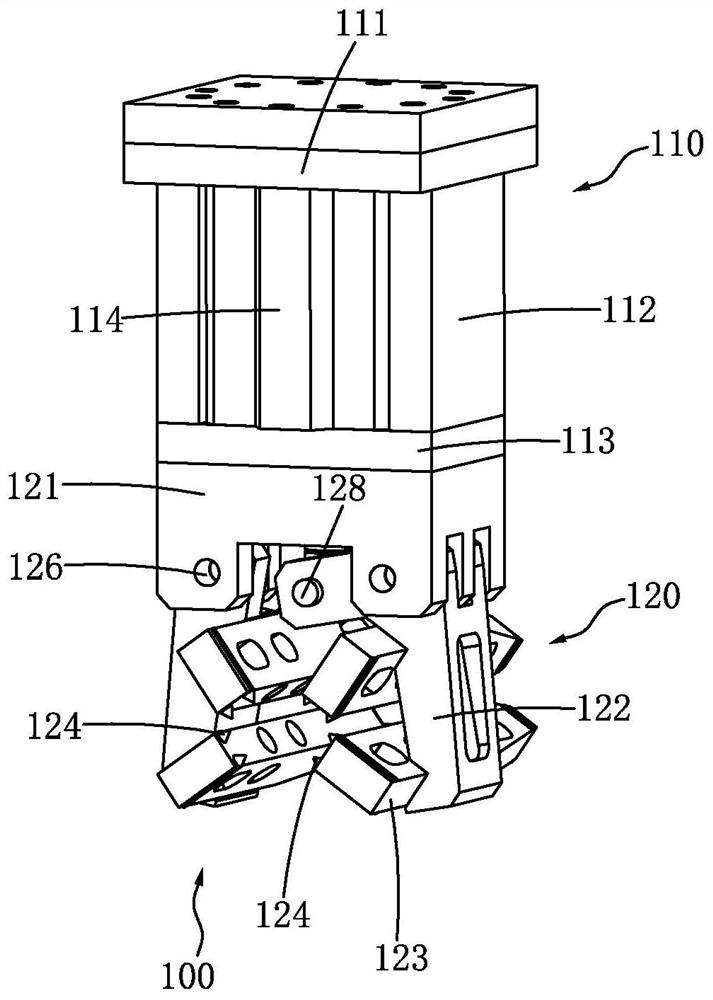

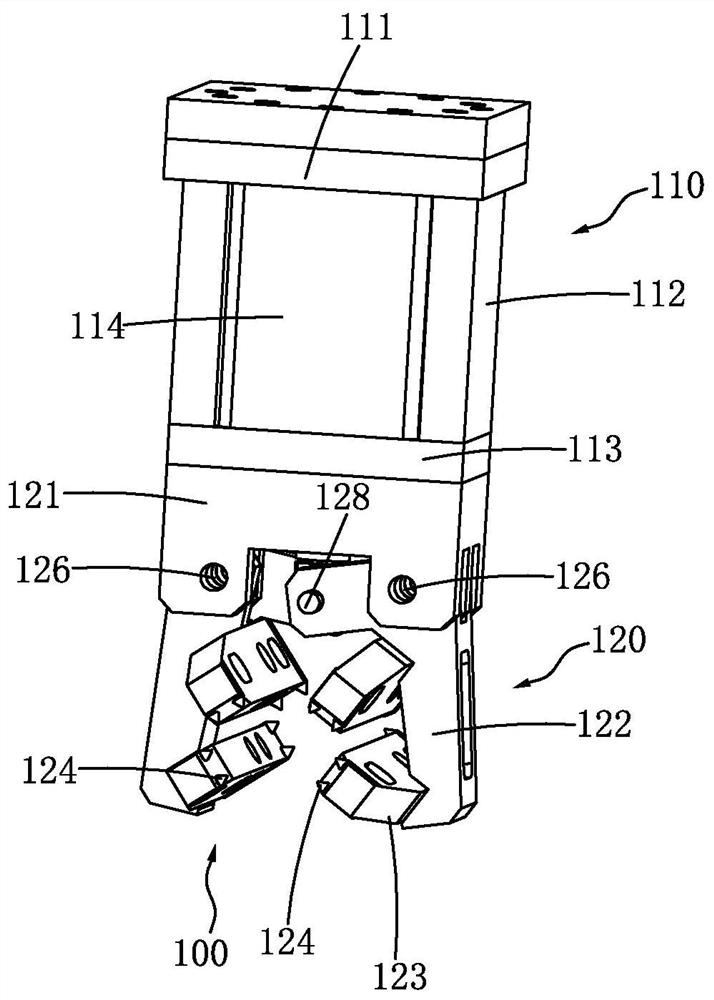

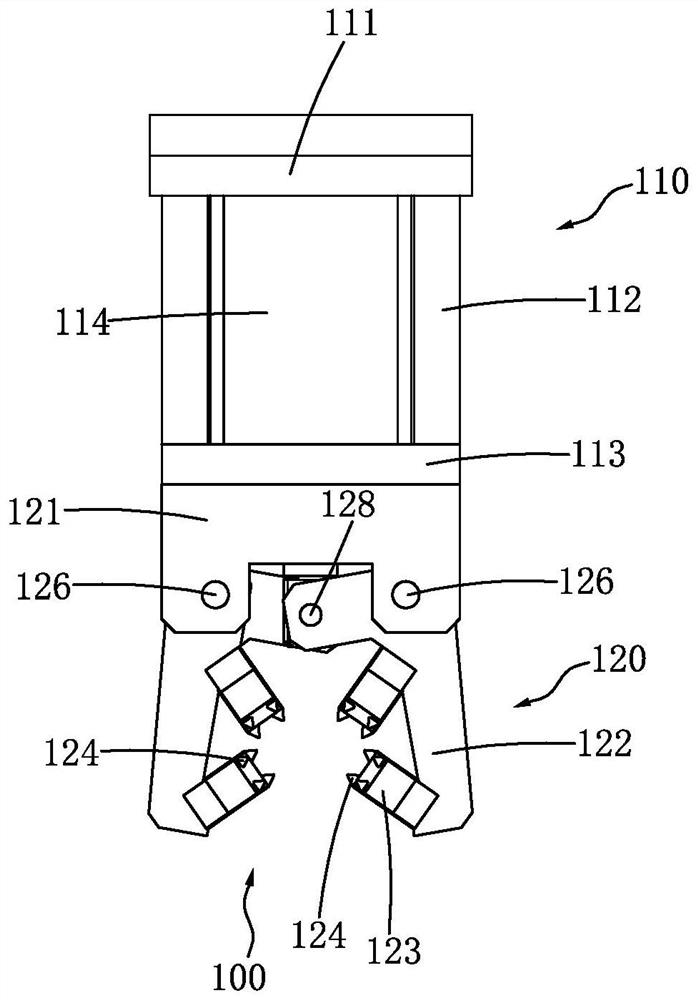

[0028] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 as shown, figure 1 is a schematic structural view of the ejection product take-out device of the present invention, figure 2 It is a structural schematic diagram of another angle of the ejection product take-out device of the present invention, image 3 is a front view of the ejection product take-out device of the present invention, Figure 4 It is a structural schematic diagram of the hinge structure of the injection product take-out device of the present invention, Figure 5 It is a structural schematic diagram of the clamping mechanism of the injection product take-out device of the present invention, Image 6 It is an exploded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com