High-strength plate rolling and on-line cutting method

A high-strength, plate-rolling technology, applied in the field of high-strength plate rolled profiles processing technology, can solve the problems of easy breakage of cutters and large incision deformation of rolled profiles, so as to improve production efficiency, reduce cutting stress, and improve production efficiency. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

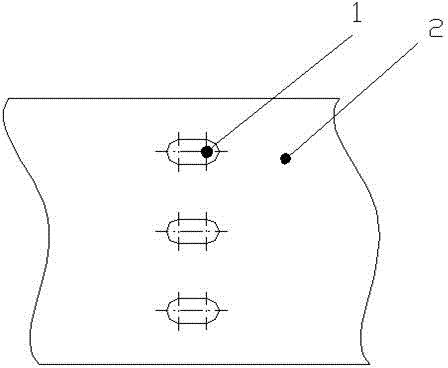

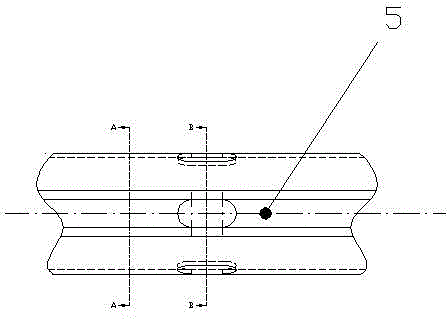

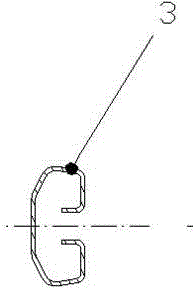

[0023] The invention discloses a high-strength plate rolling online cutting method. The process steps include coil uncoiling, coil leveling, roll forming, profile straightening, and online cutting; the coil leveling and roll forming steps are Add an automatic punch punching step for punching a row of holes on the sheet (such as figure 1 ), to roll-formed profiles (such as Figure 2-4 ) when cut off at the punched position (eg Image 6 ), the cut-off force point is reduced by more than 1 / 3, thereby reducing the cut-off stress and reducing the cut-off deformation.

[0024] After this roll forming, profile straightening step and before the in-line cutting step, a locating pin (e.g. Figure 5 ), an adjustable distance photoelectric sensor is installed on the supporting platform of the cutting machine to detect the position of the tail end of the profile; when the front end of the profile passes through the photoelectric sensor during the rolling process (such as Figure 7 ), th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com