Patents

Literature

37results about How to "Guaranteed location consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

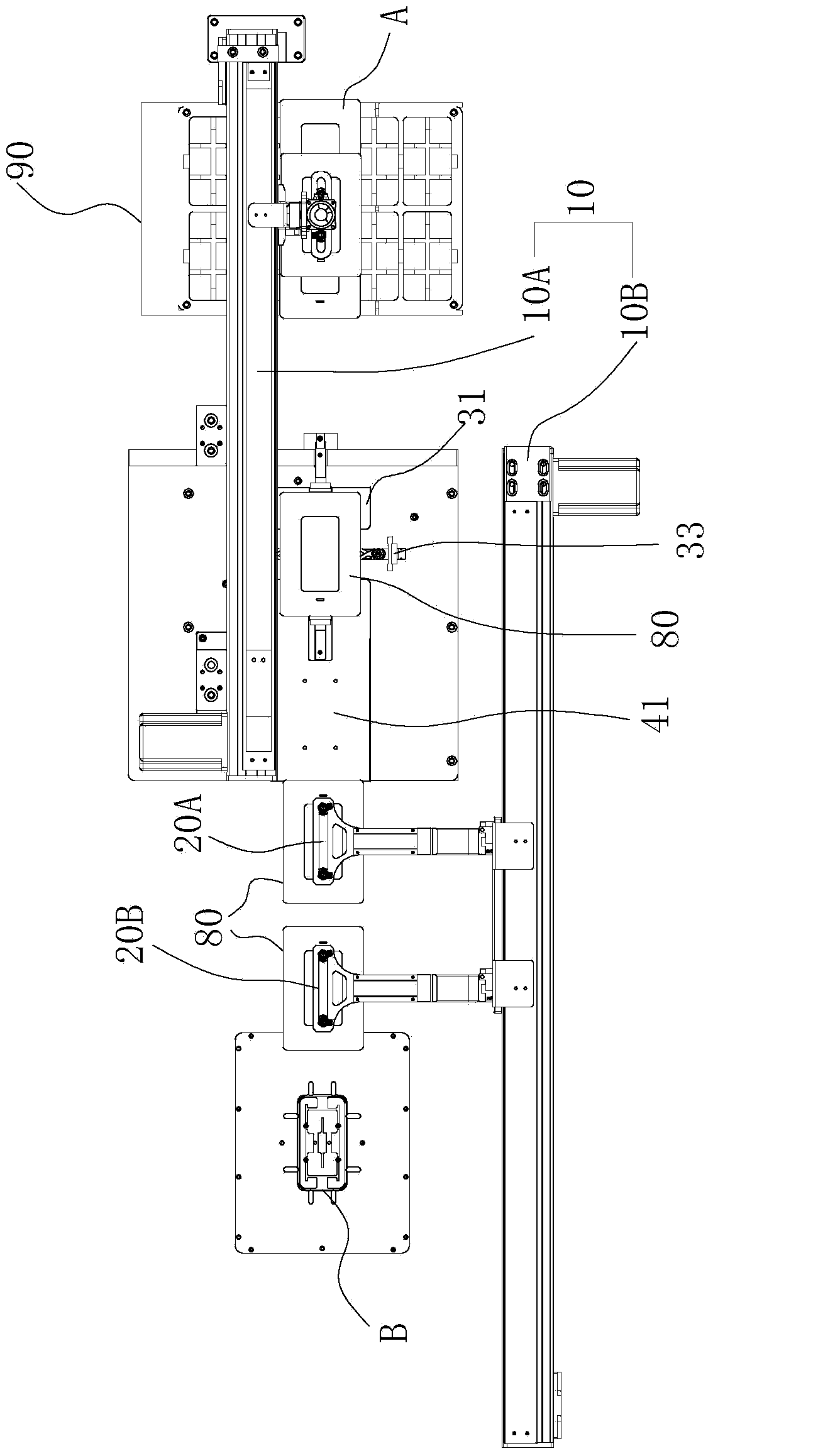

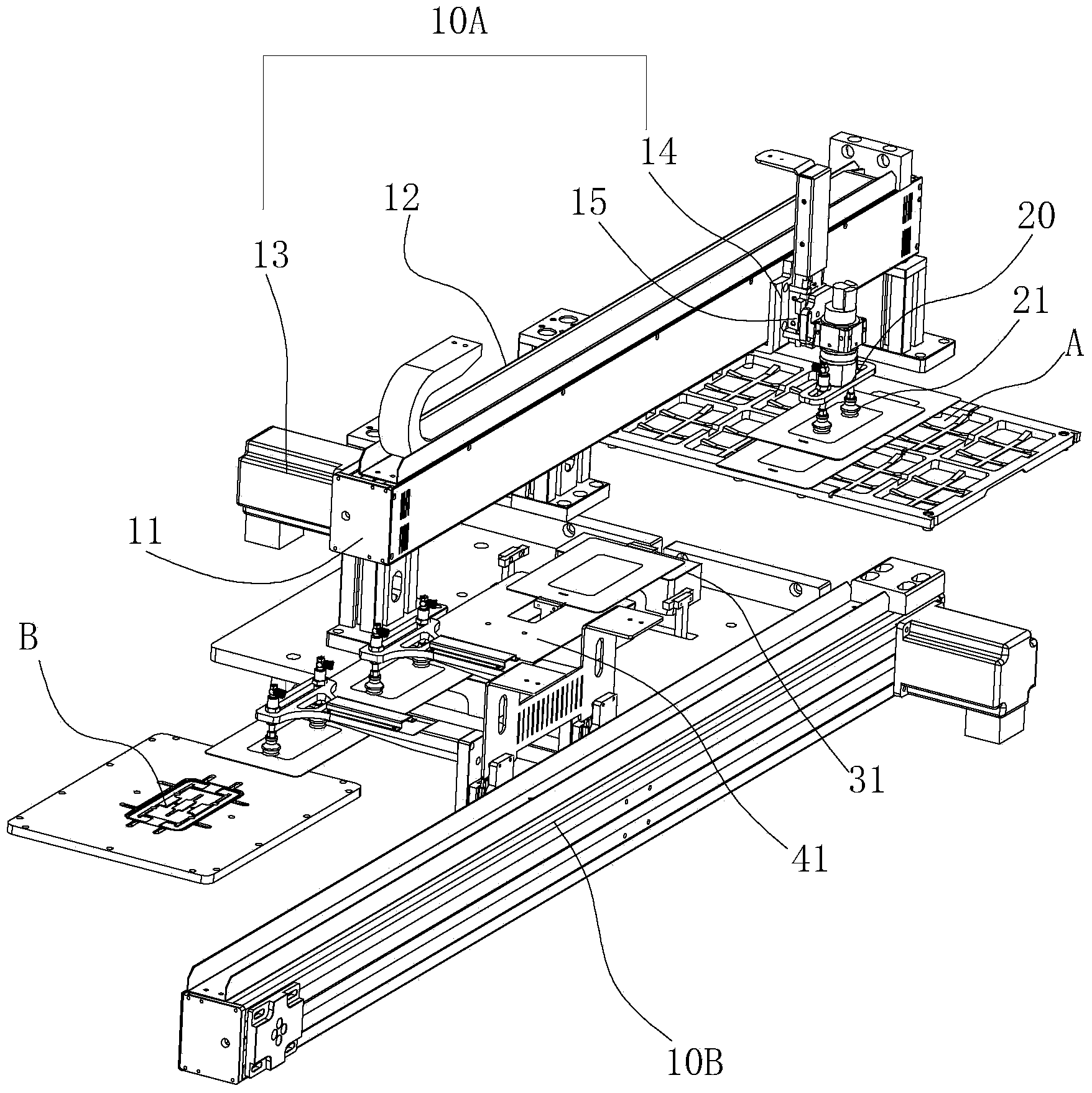

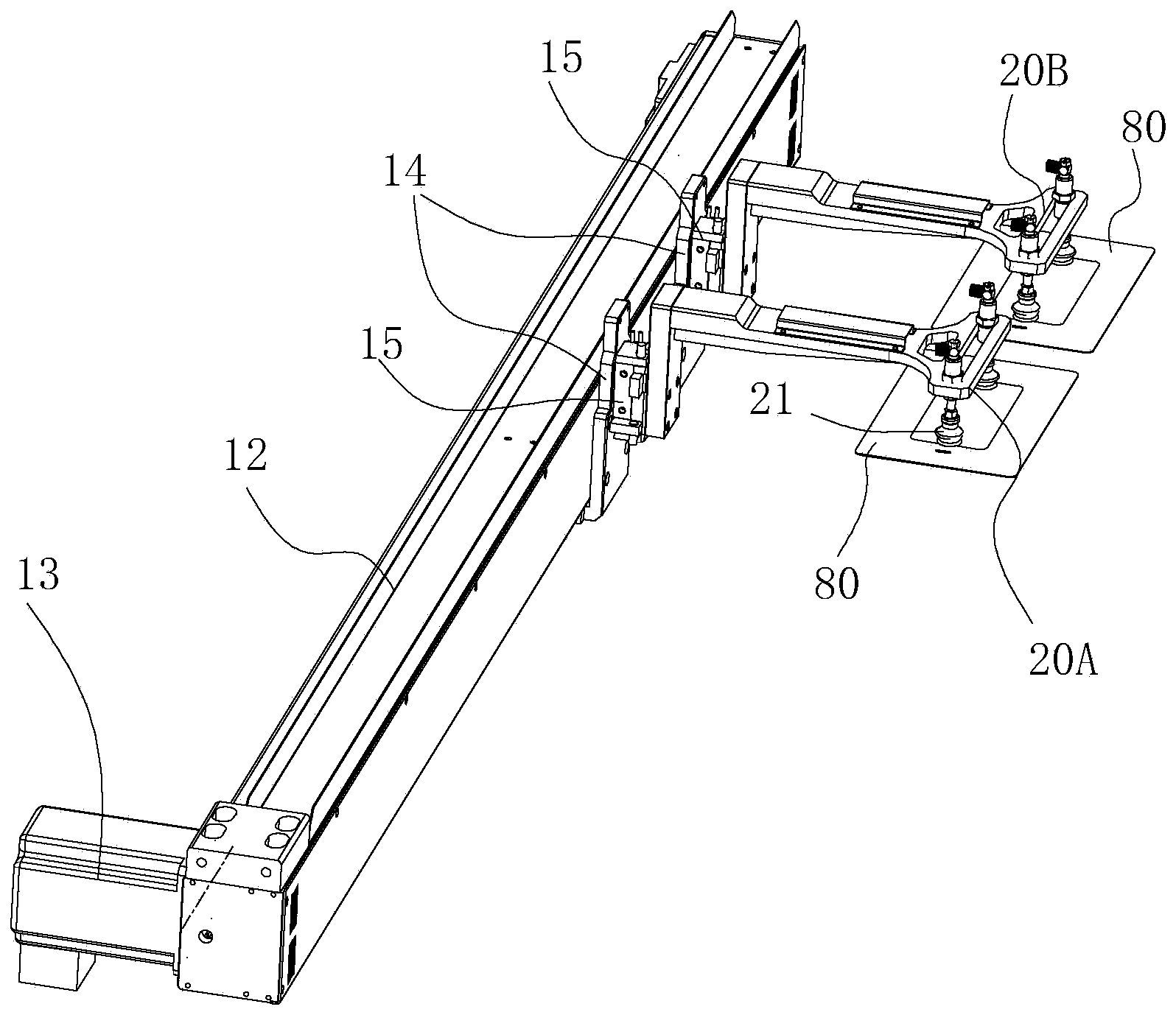

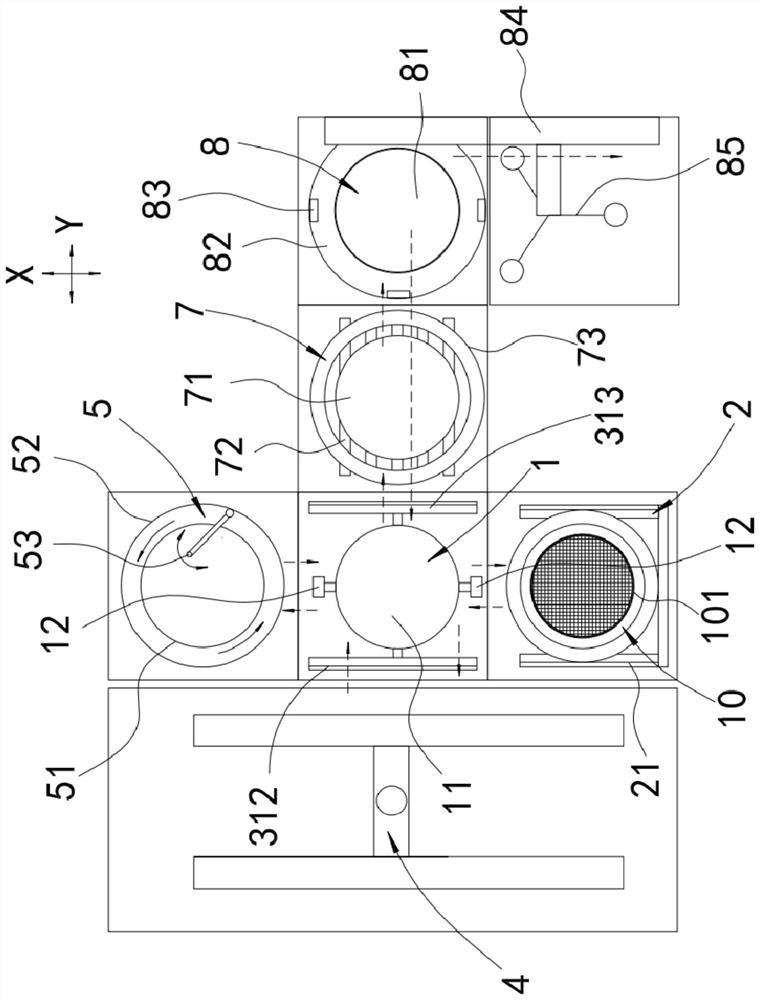

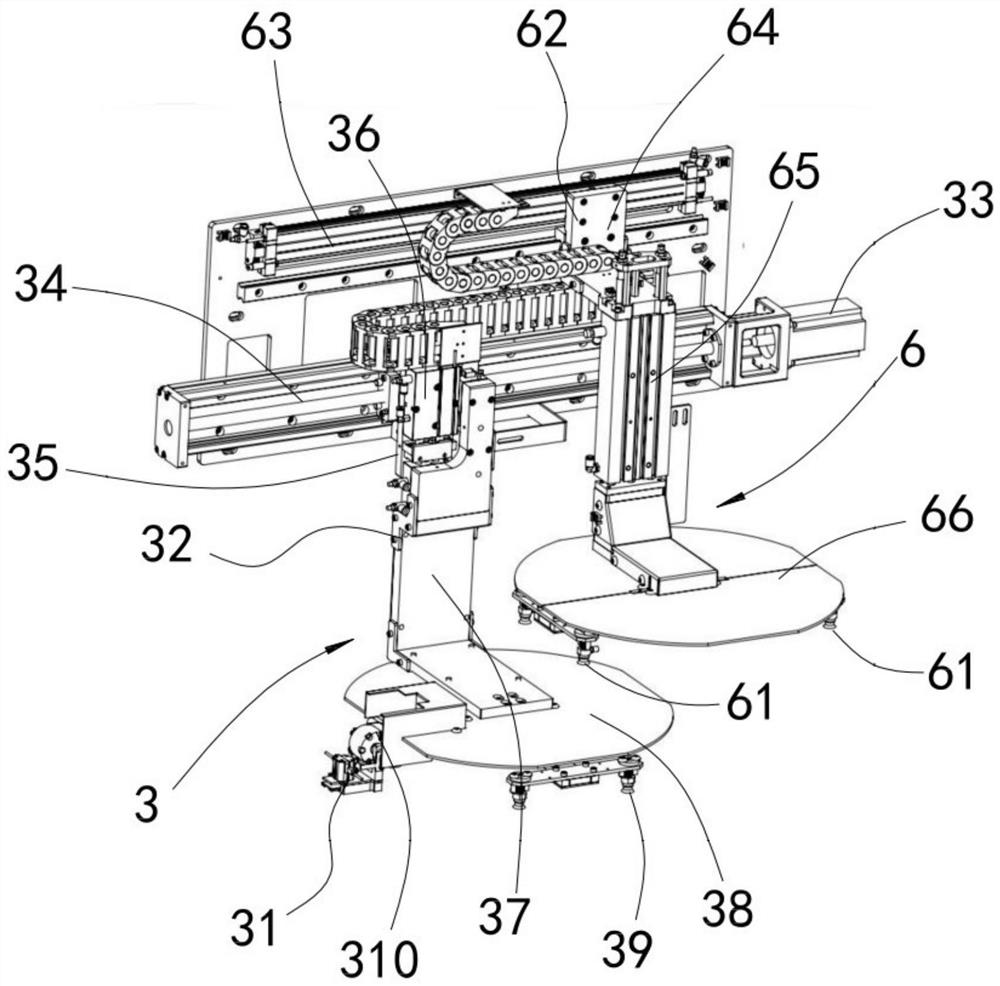

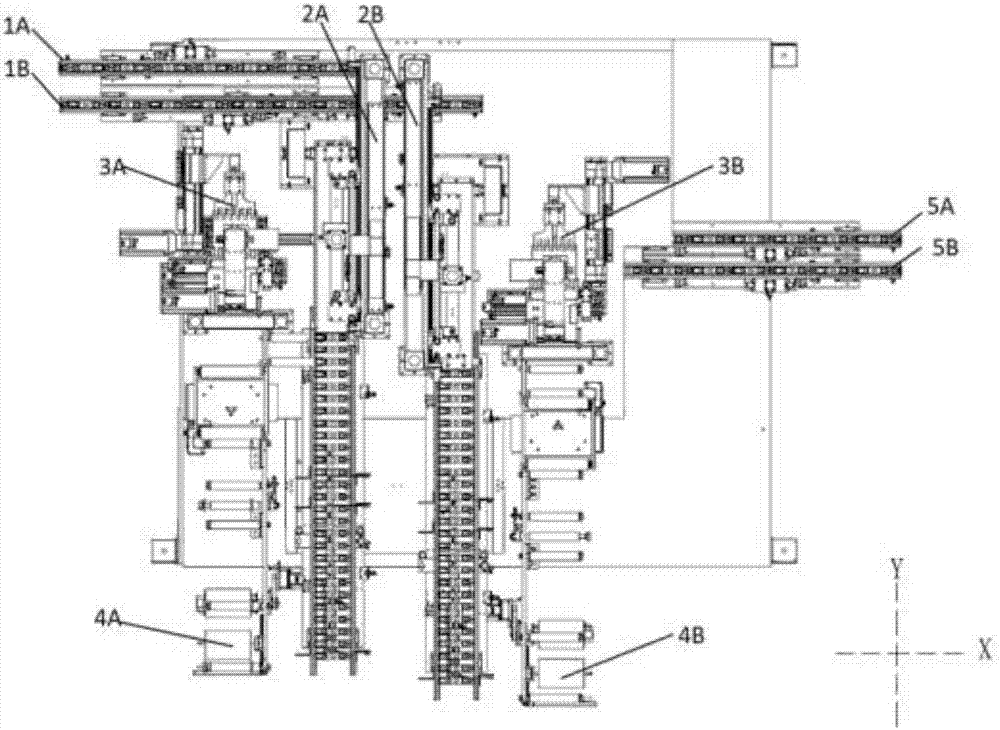

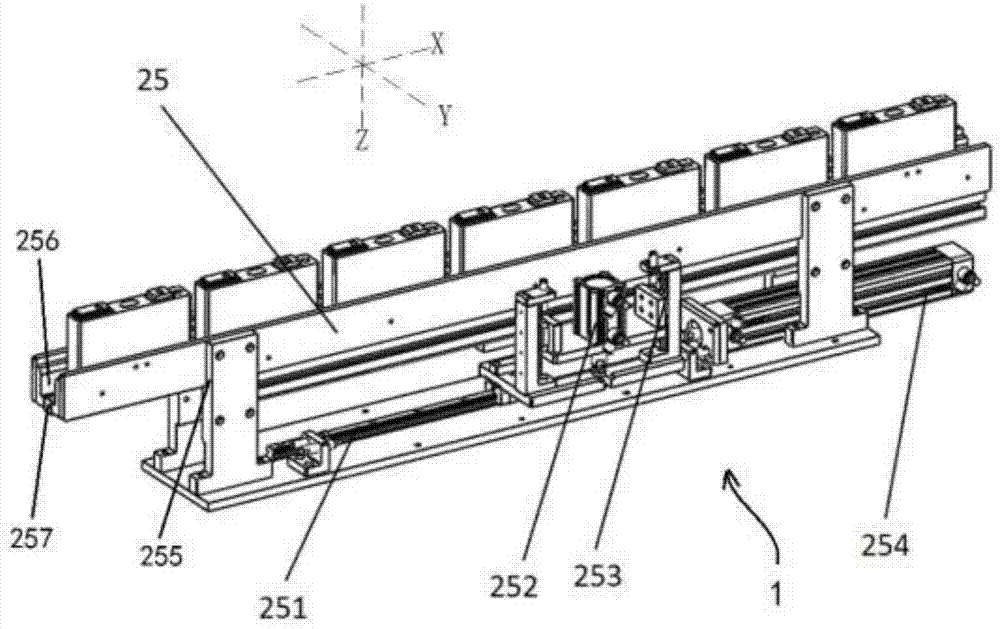

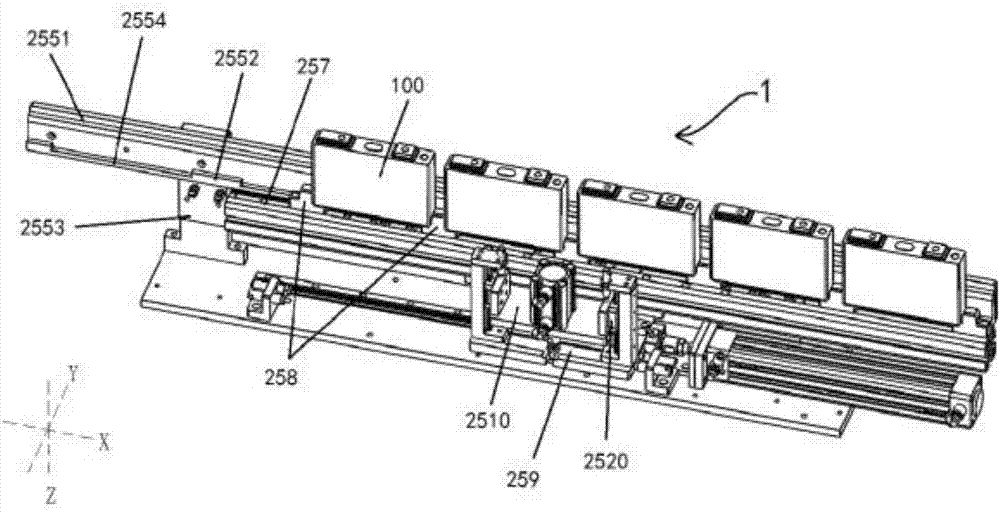

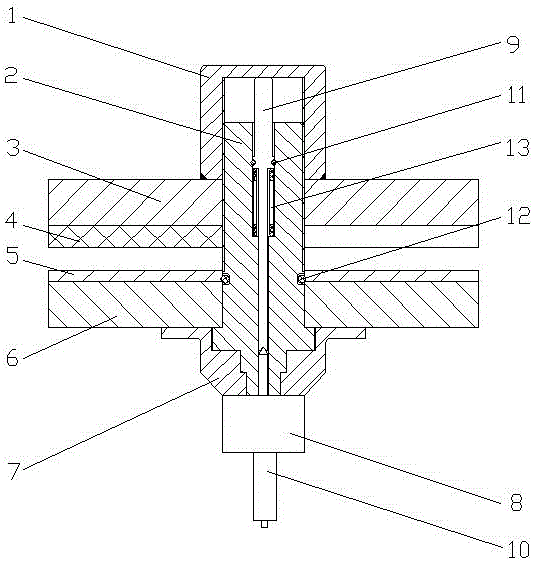

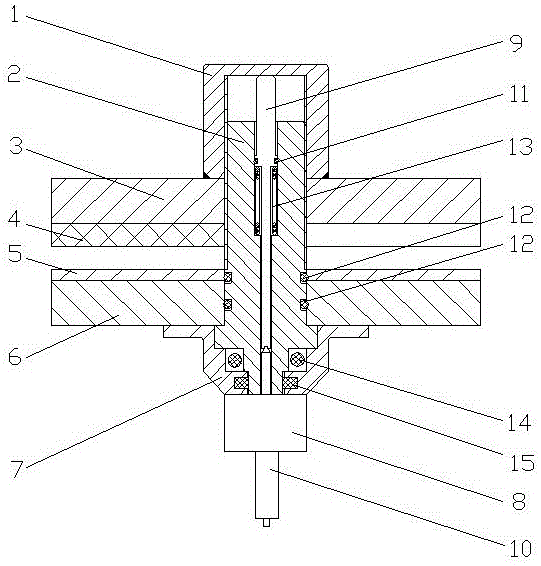

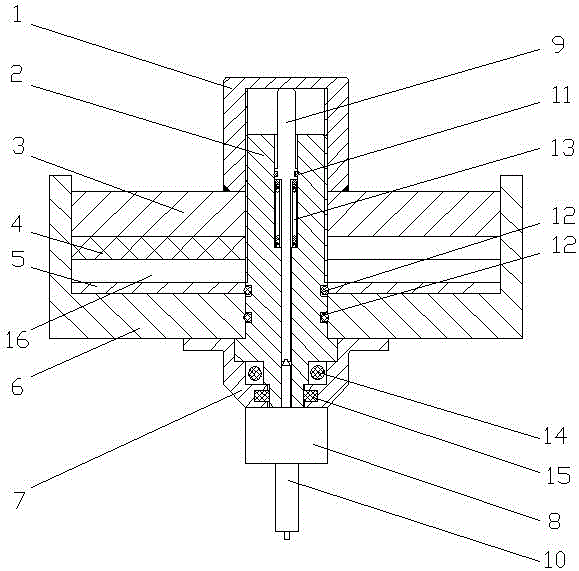

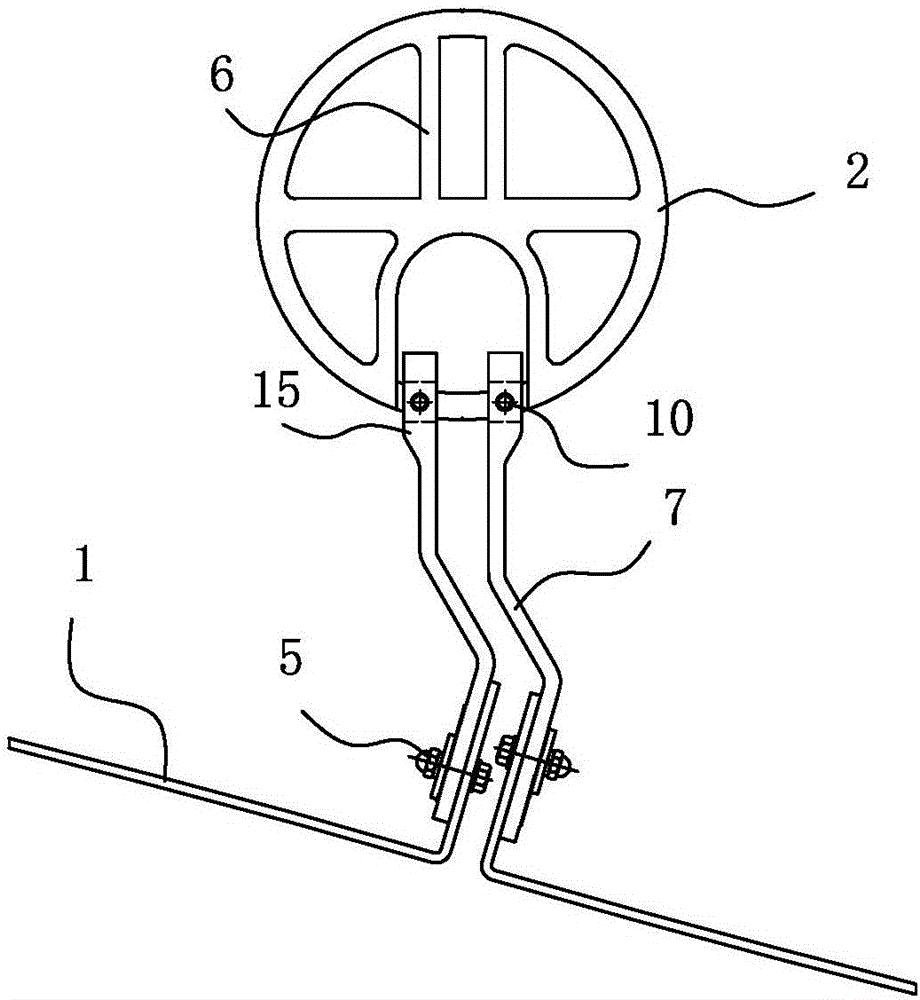

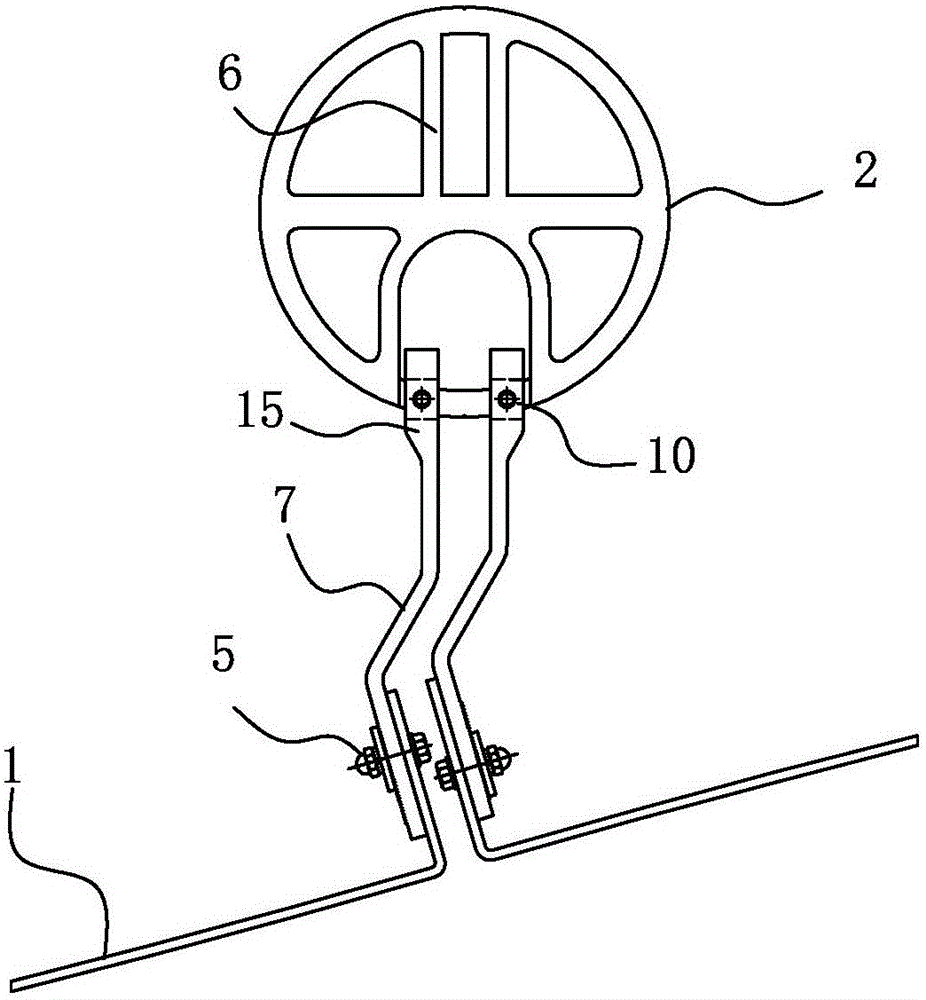

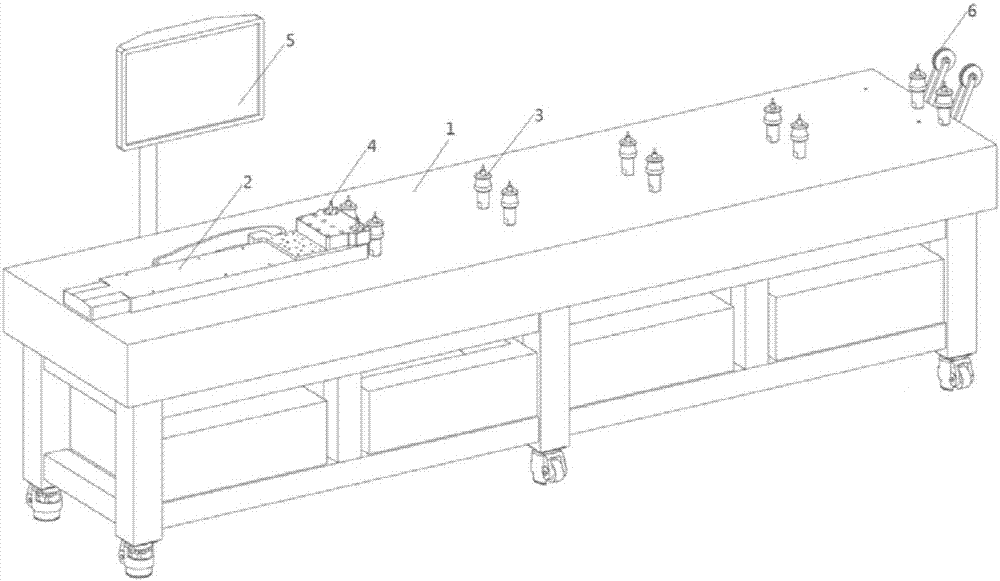

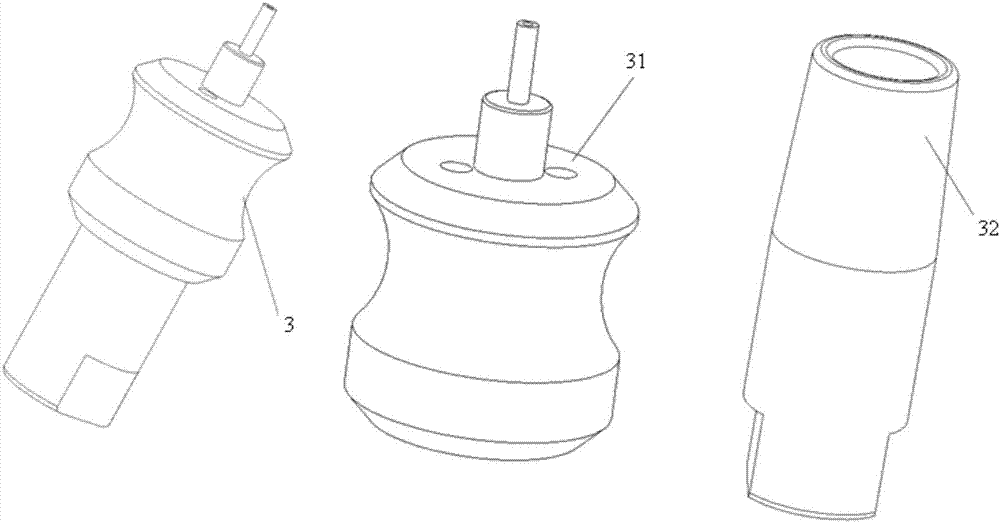

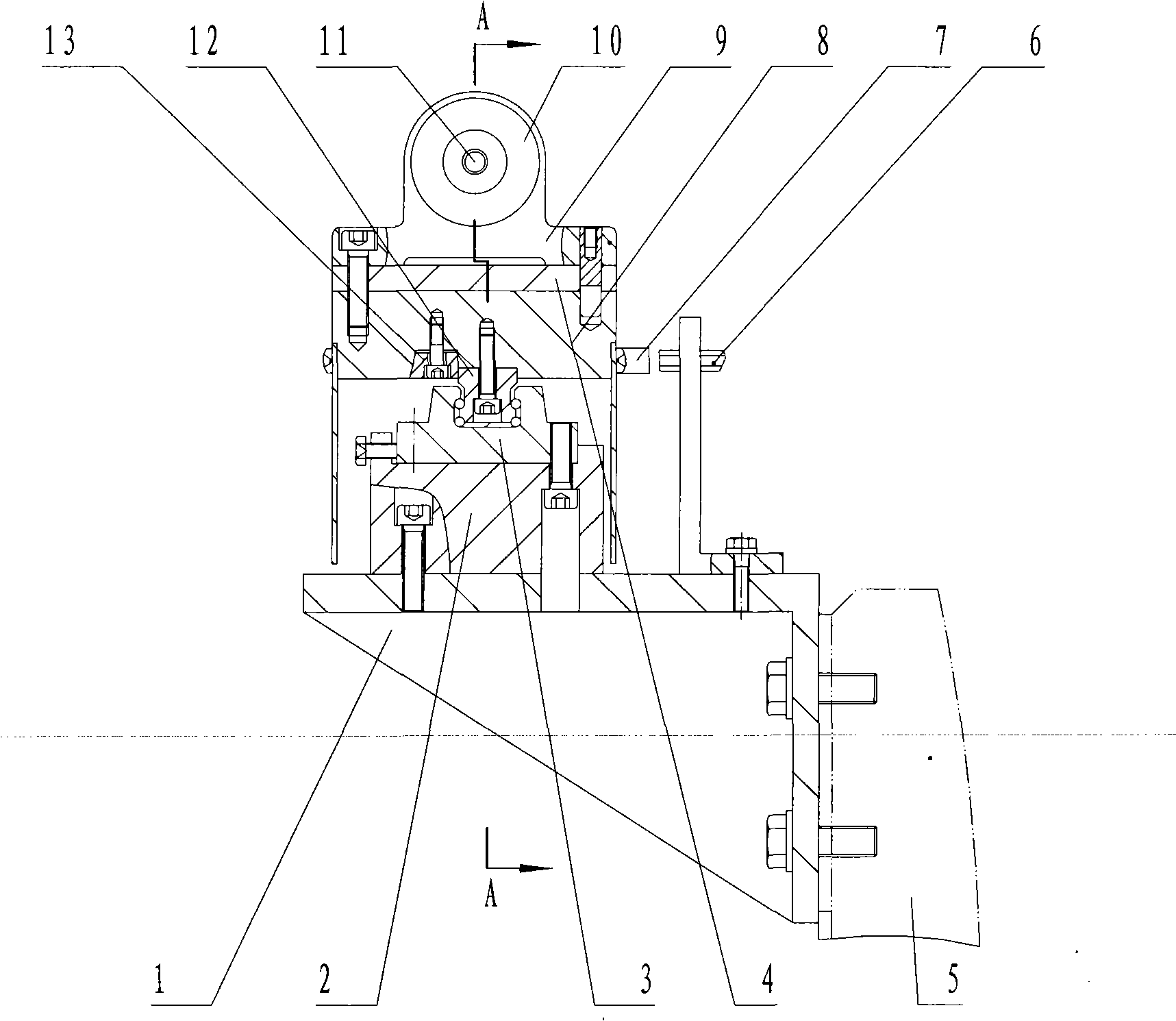

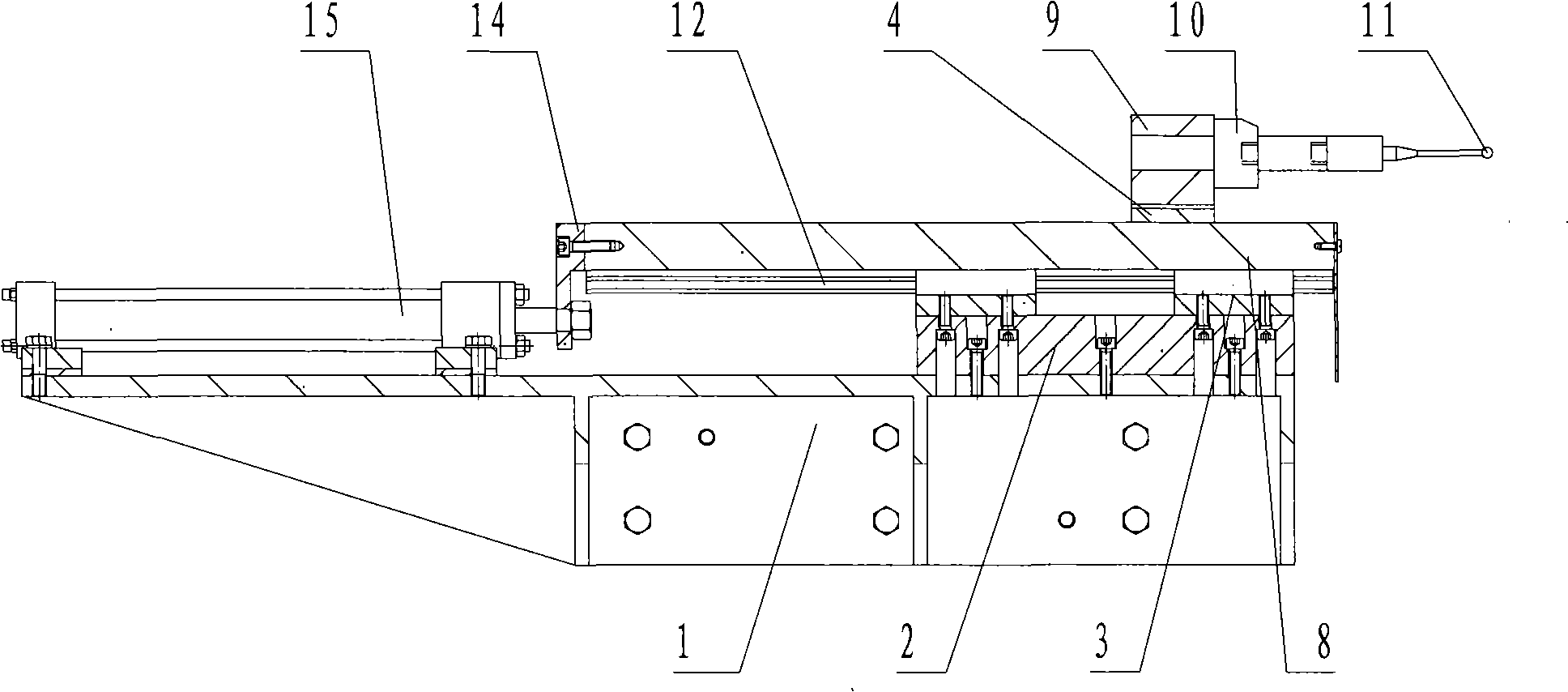

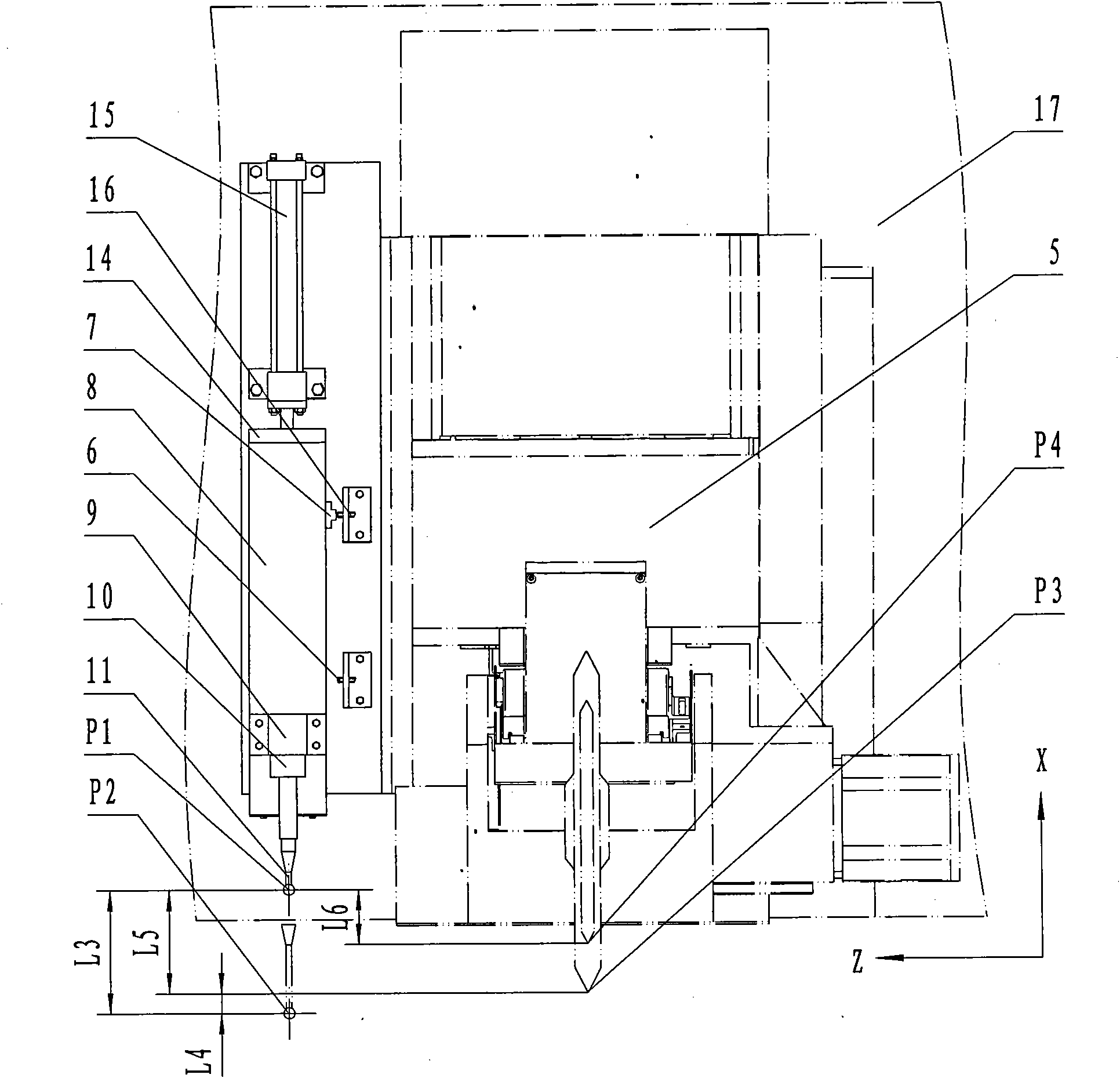

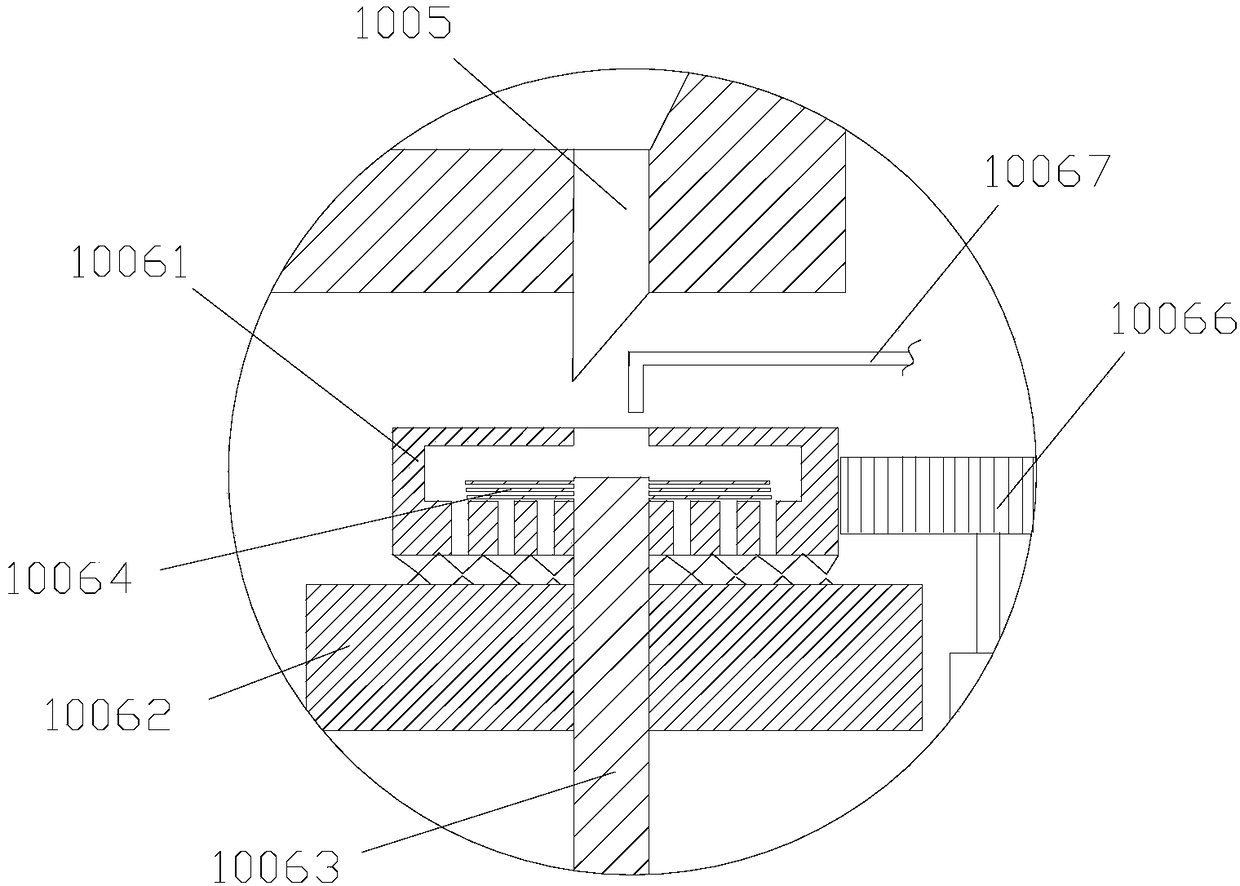

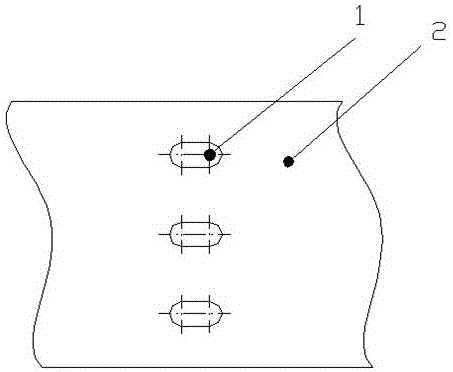

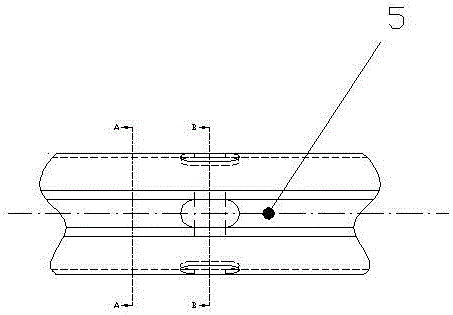

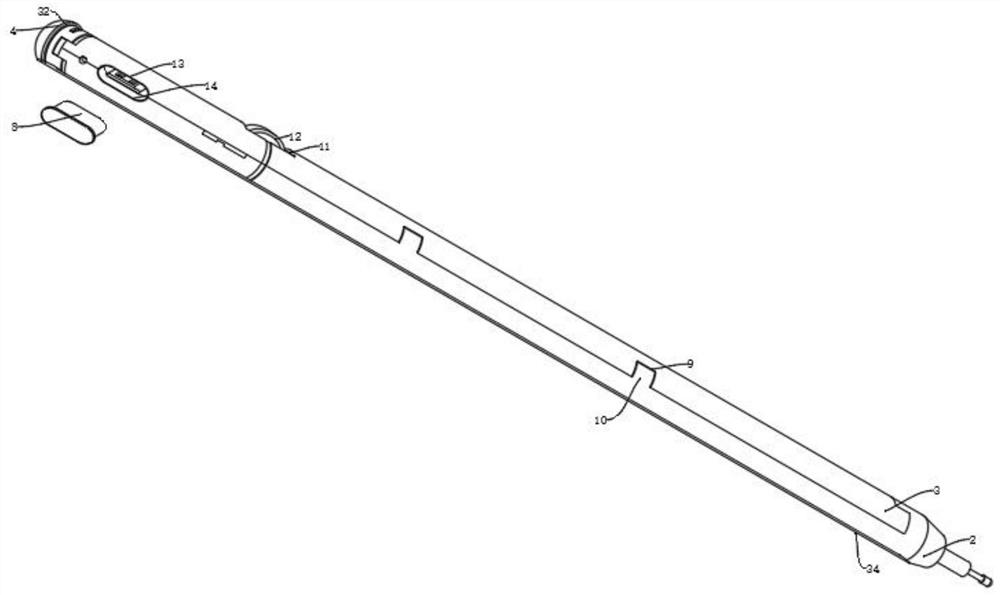

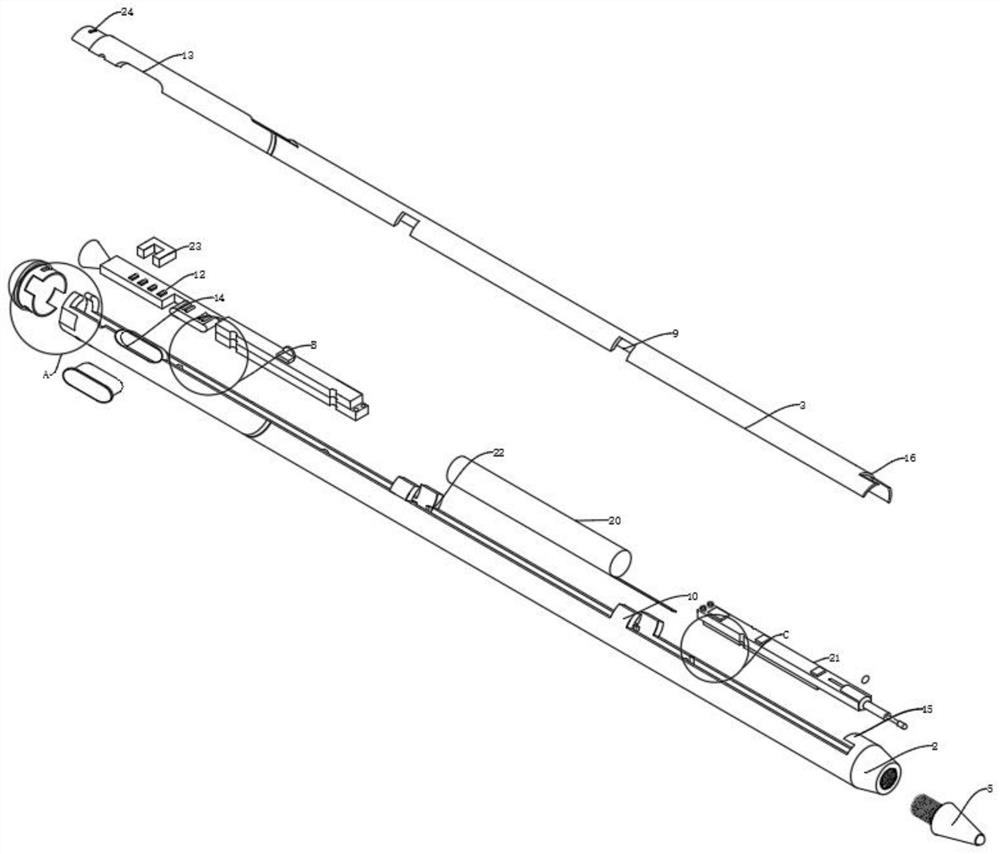

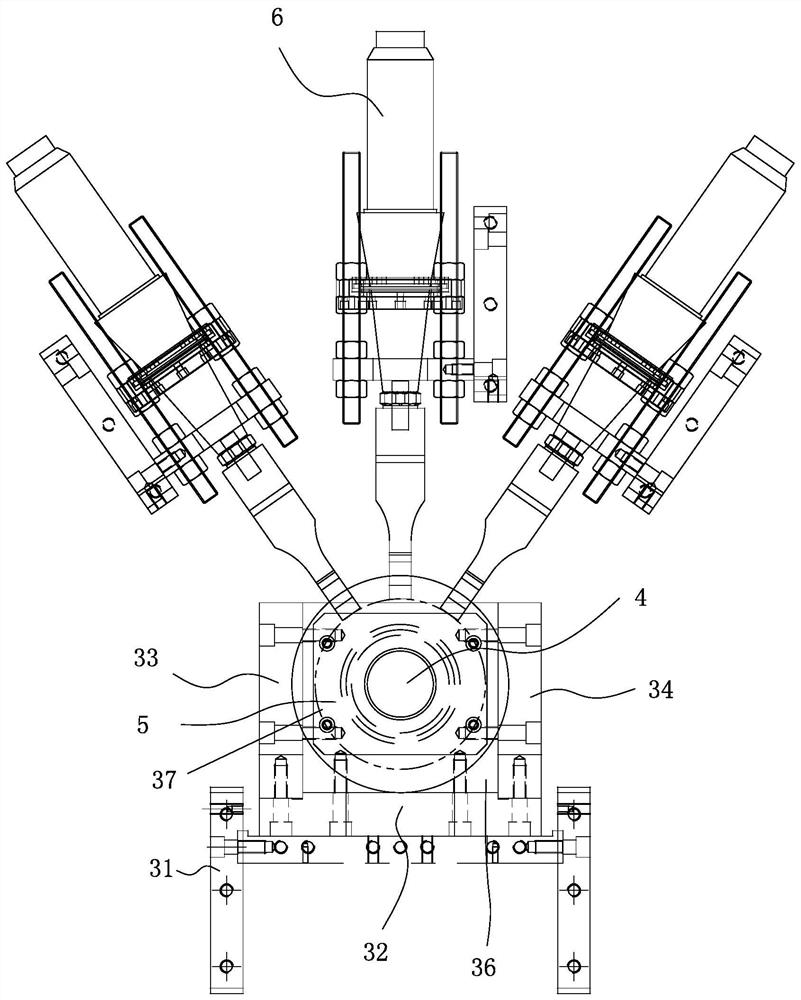

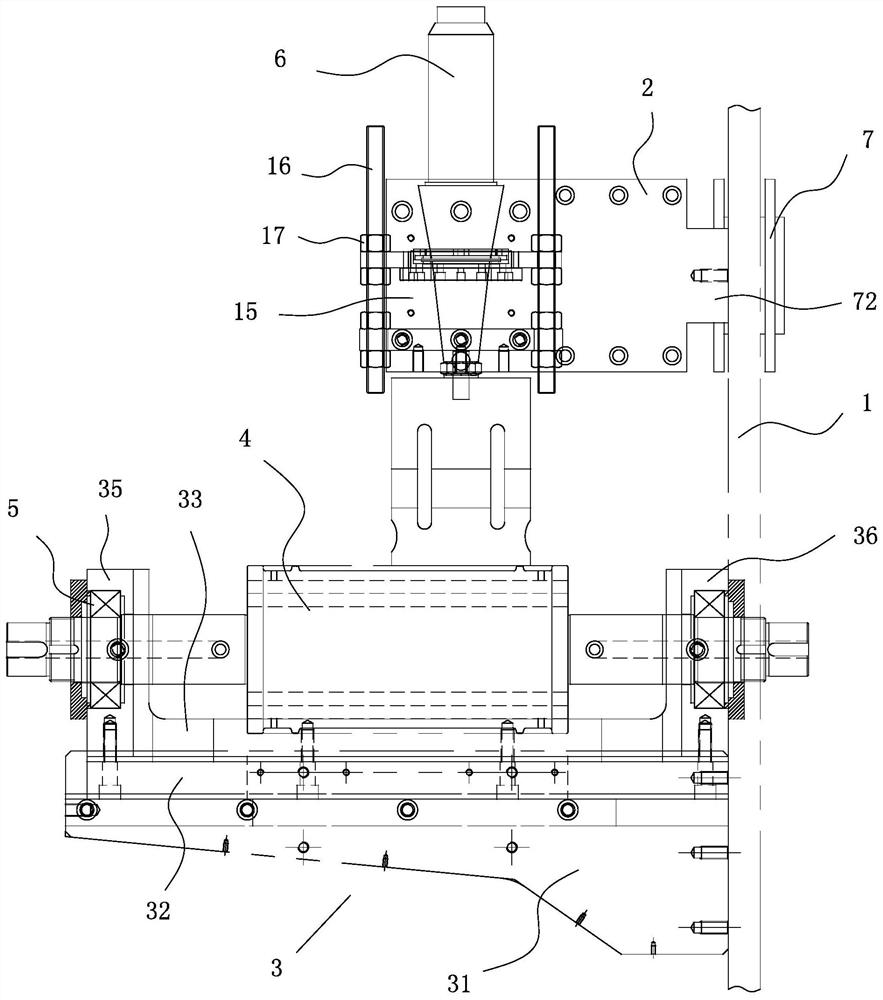

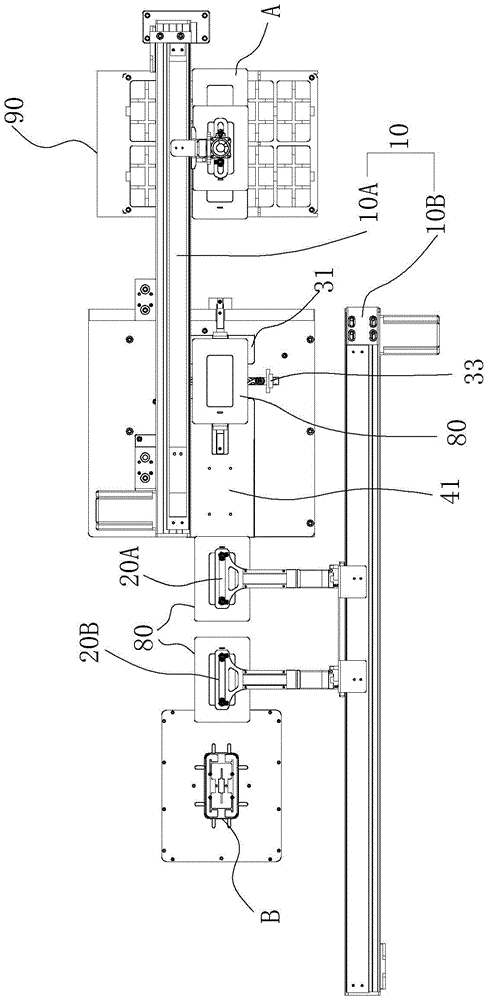

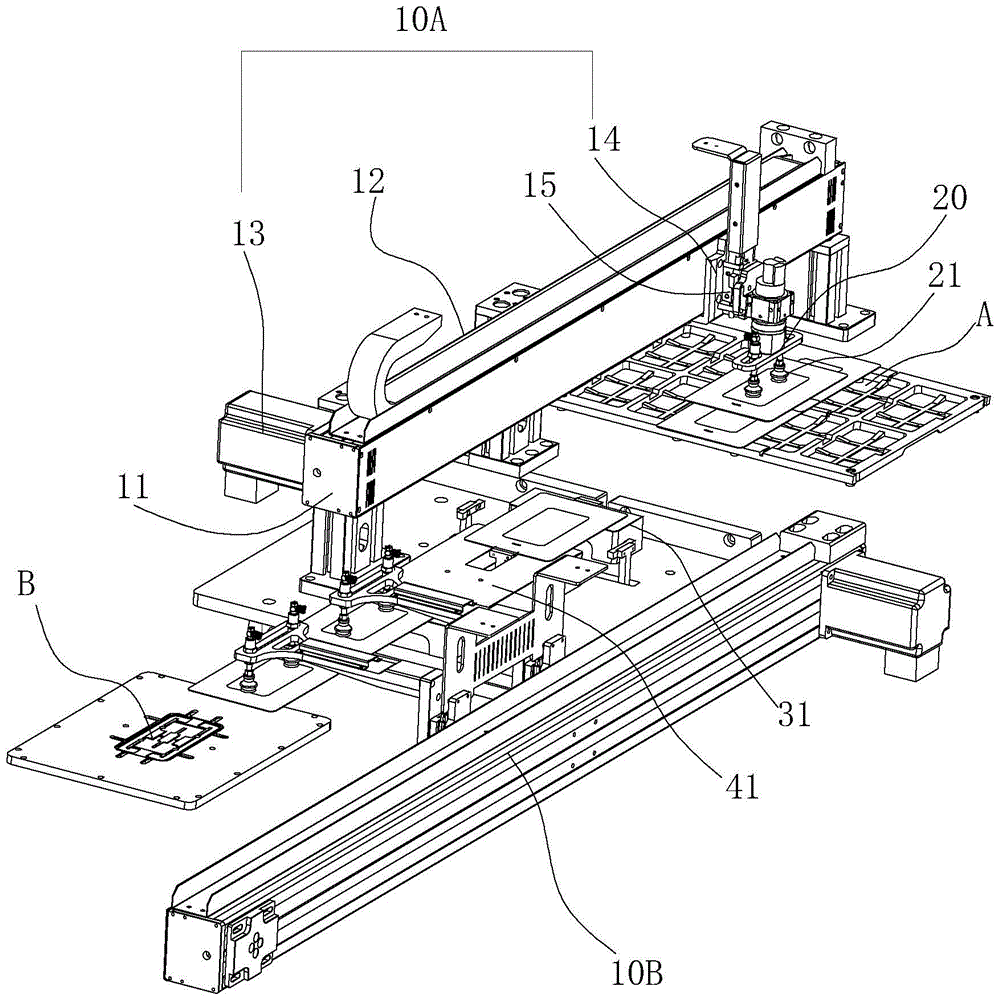

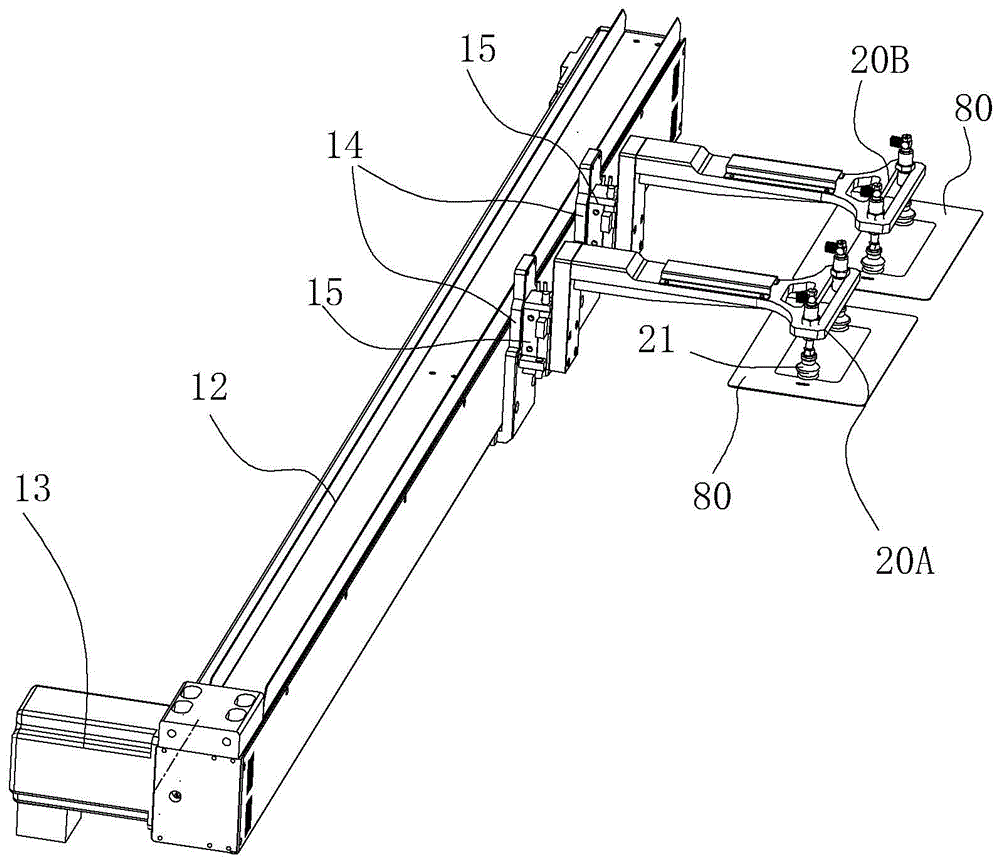

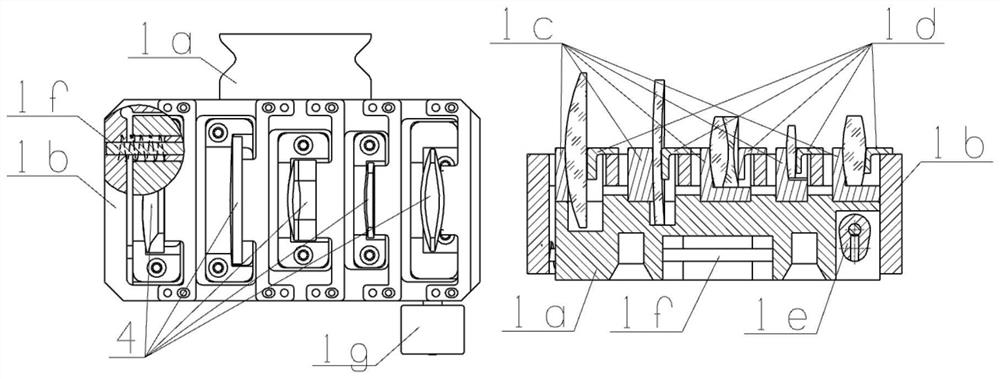

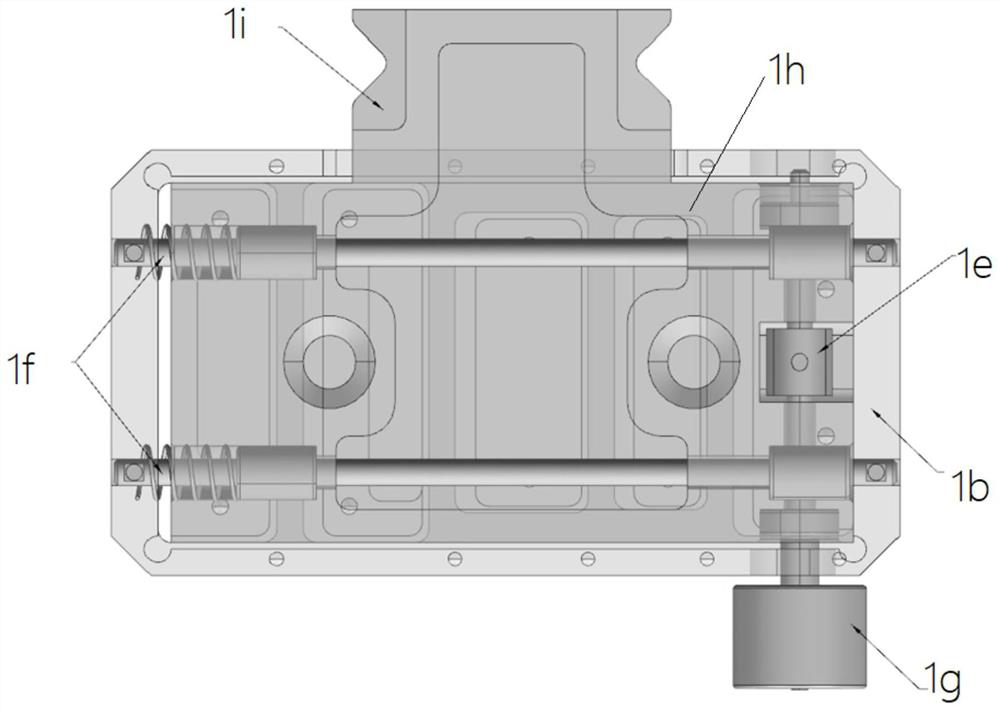

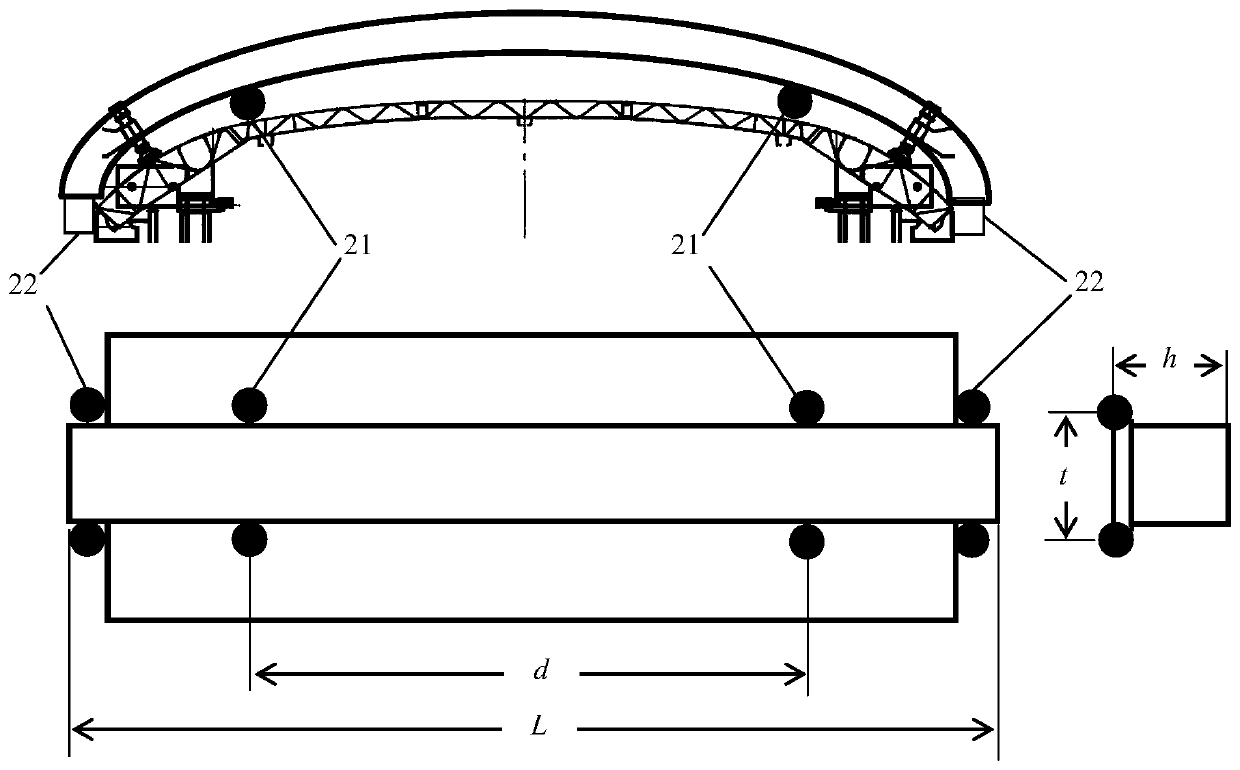

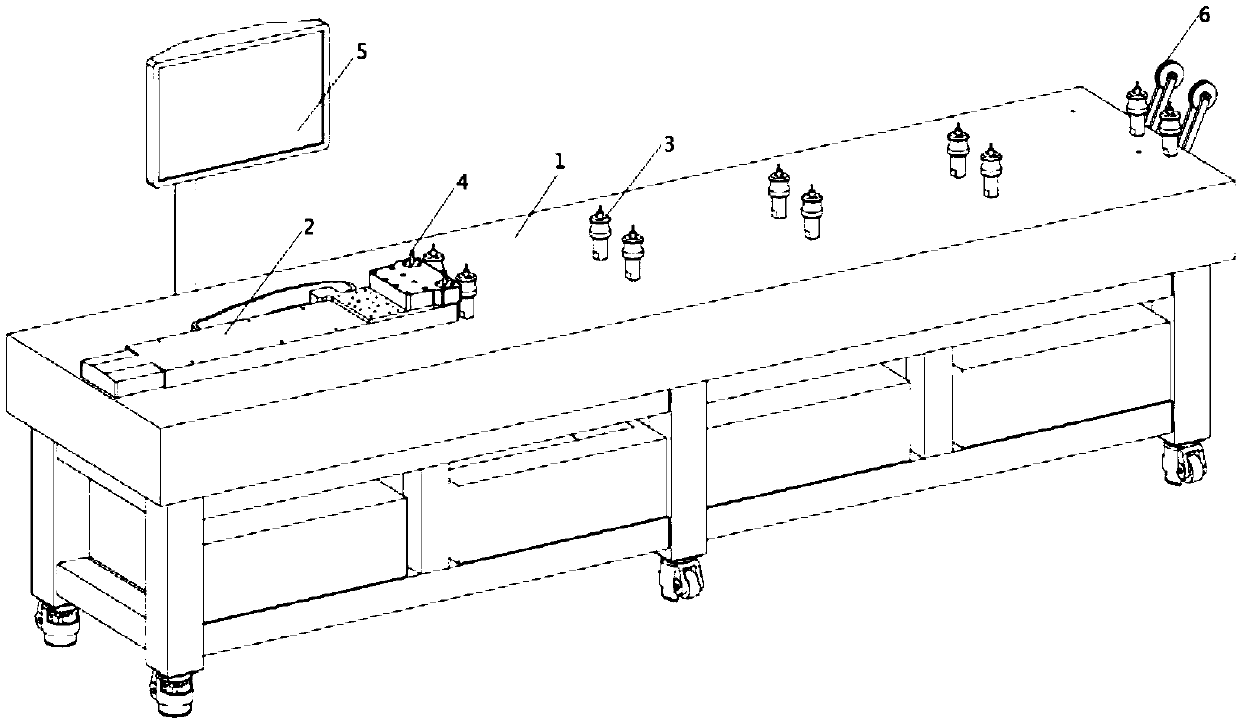

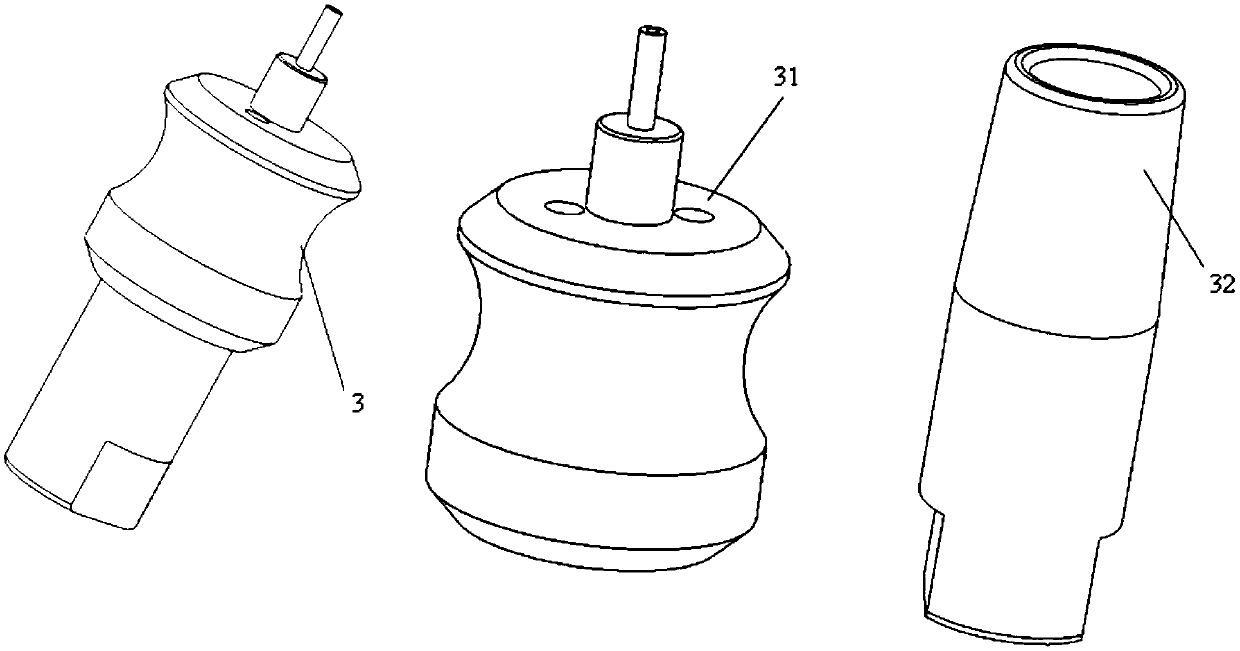

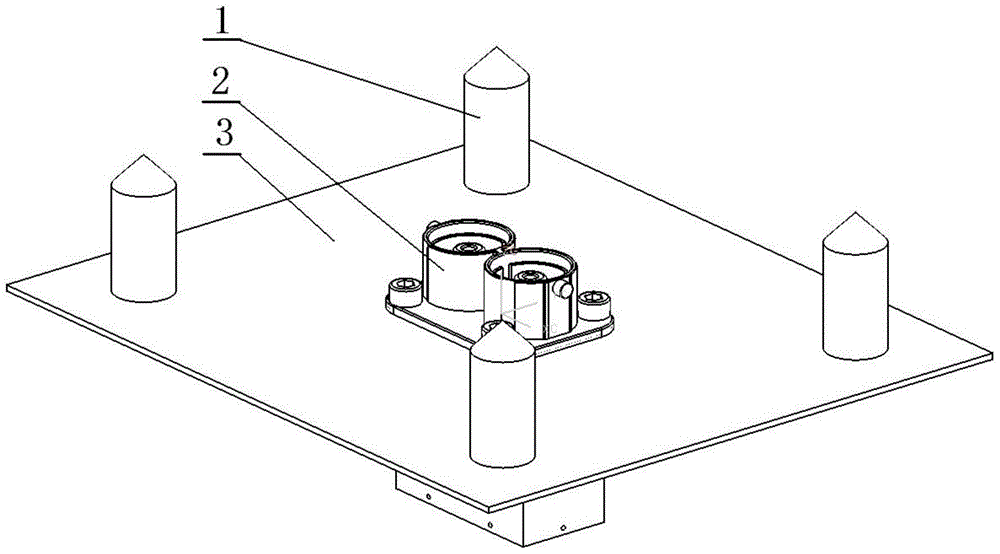

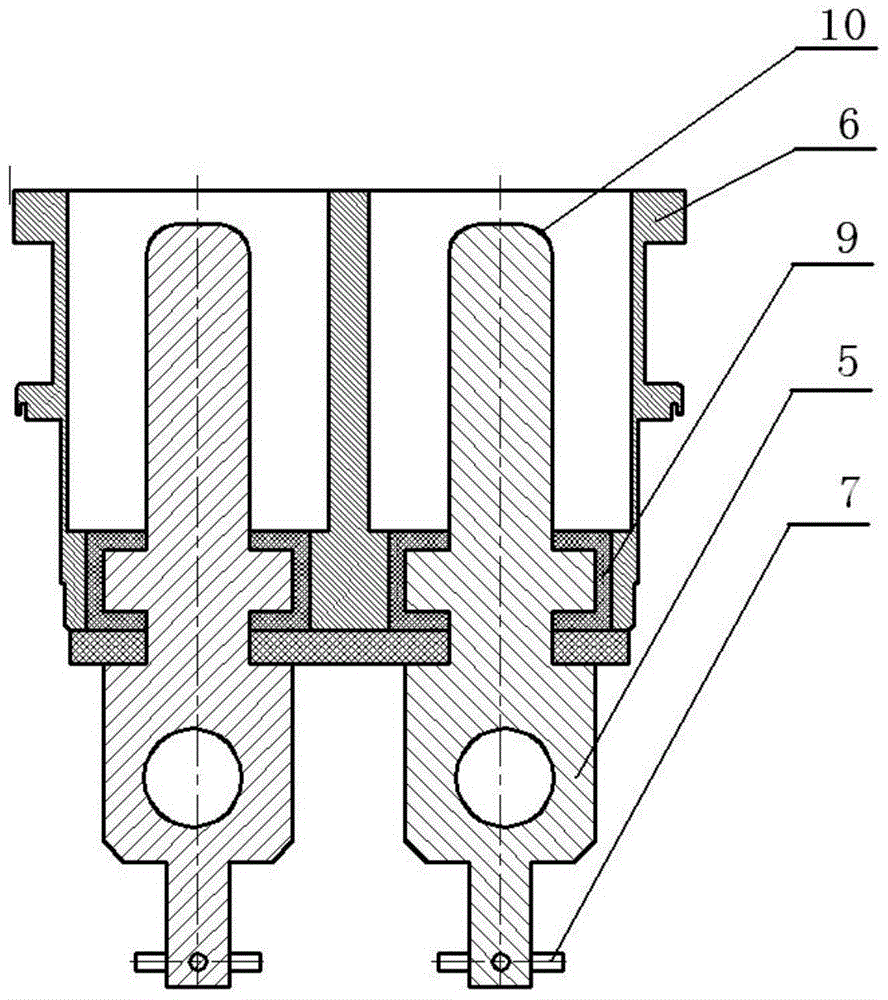

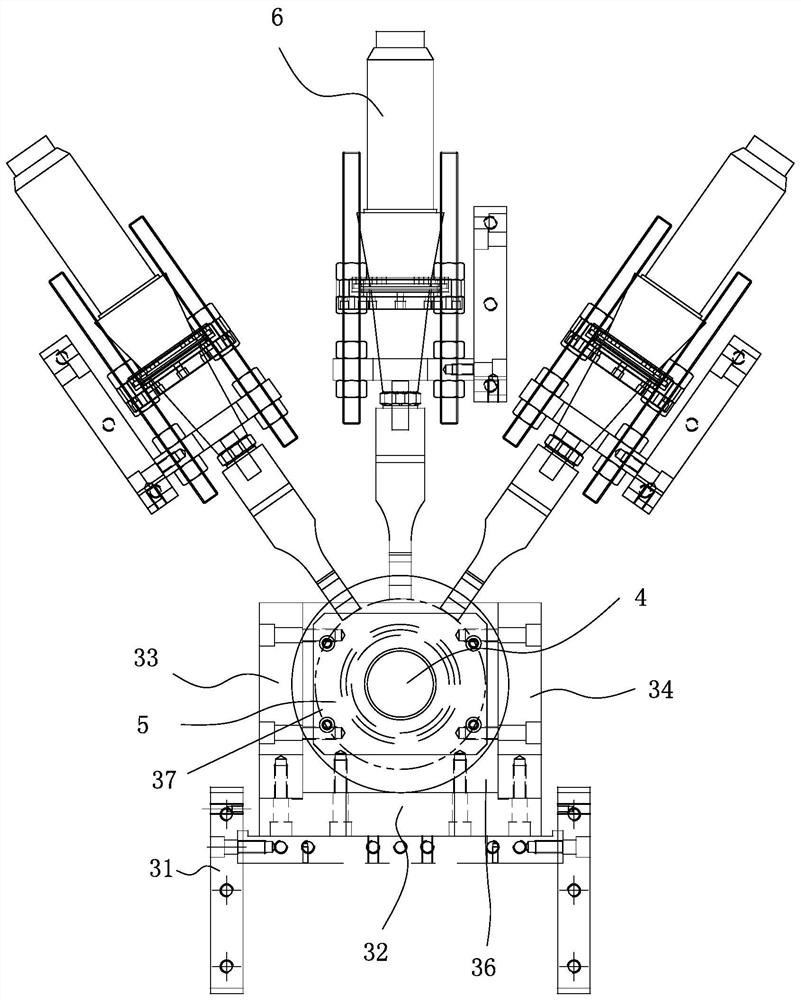

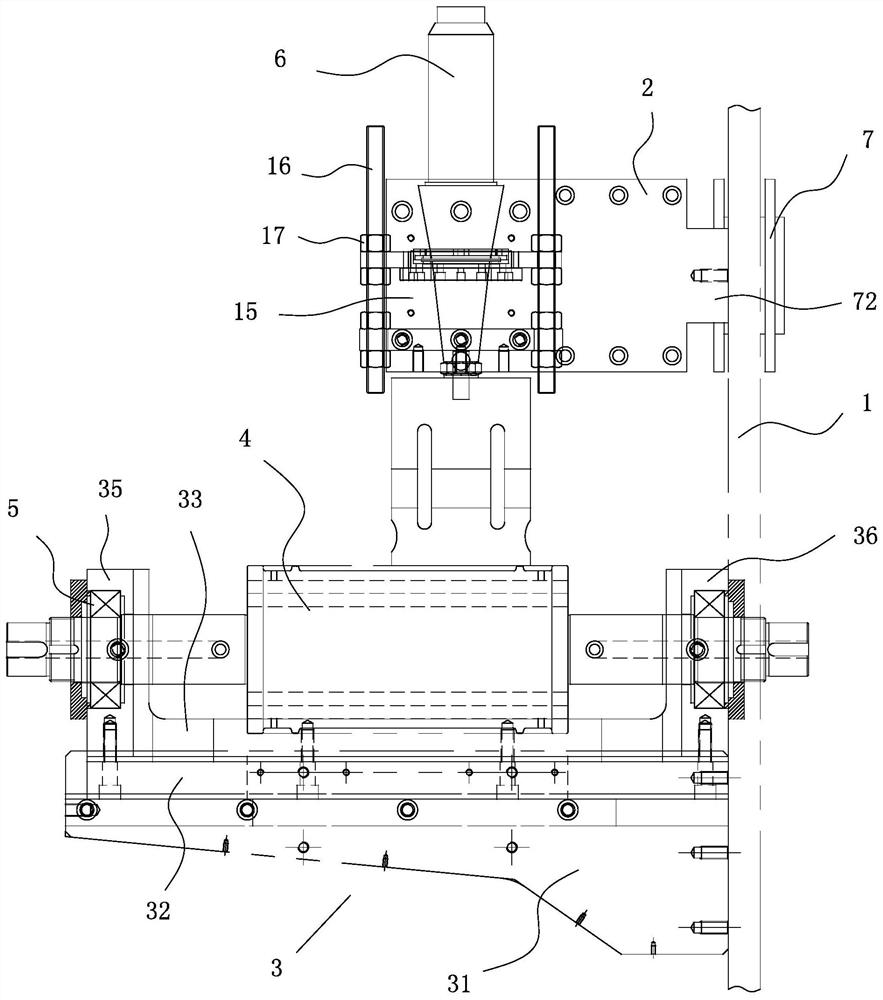

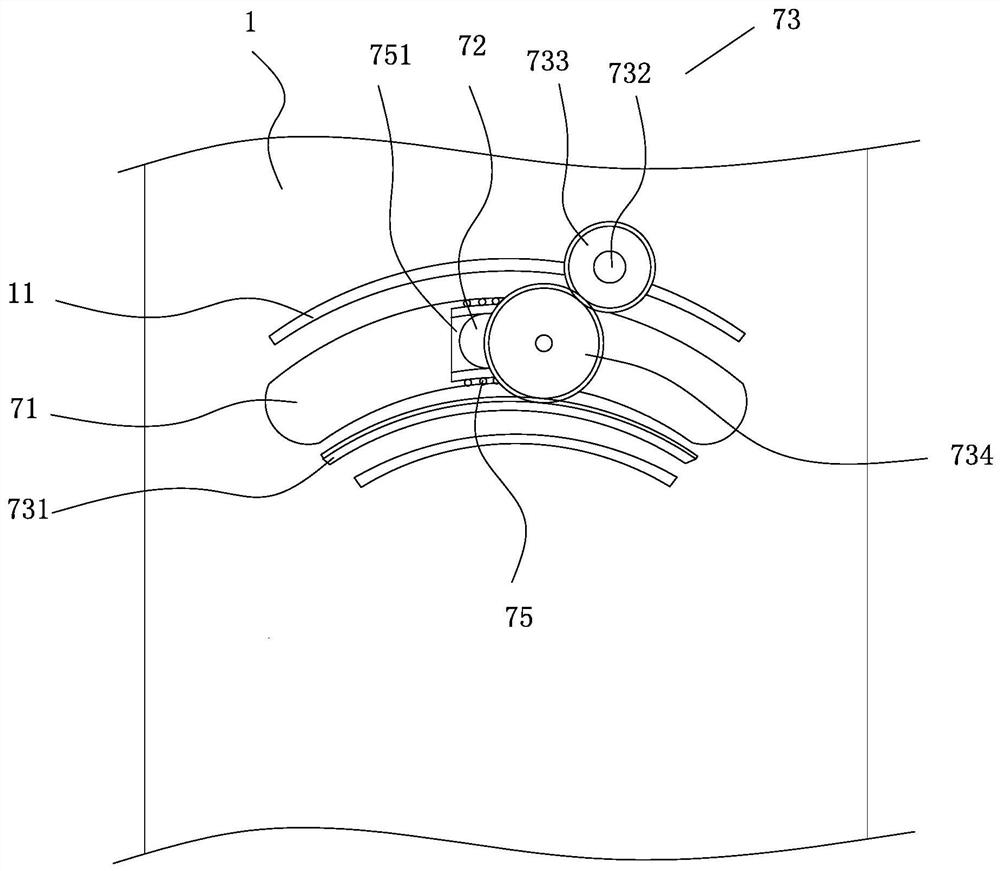

Material reciprocating transferring device and method

ActiveCN103863818AShorten the working cycleGuaranteed location consistencyCharge manipulationConveyor partsEngineeringLarge distance

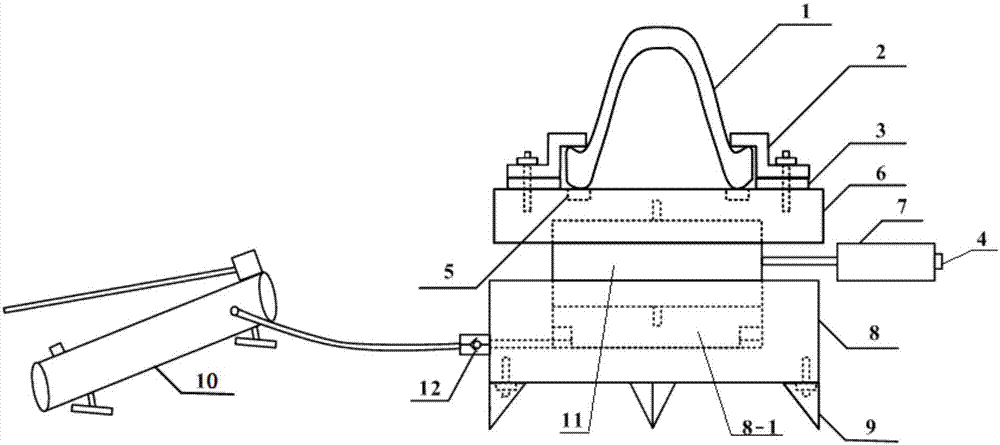

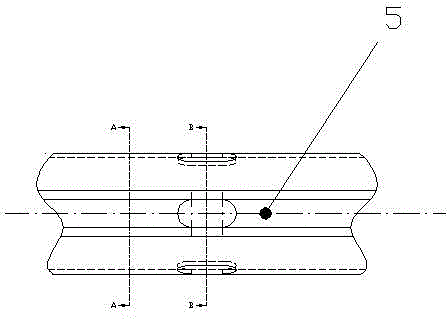

The invention discloses a material reciprocating transferring device and method. The material reciprocating transferring device comprises a transferring mechanism arranged between the material position of a material device and the machining position of a machining device. The transferring mechanism is movably connected with a downward fetching mechanism. The material reciprocating transferring device further comprises a primary locating mechanism located below the middle section of the transferring mechanism. Materials are fed for the first time and for the second time. When fetched for the first time, the materials move from the material position to the primary locating mechanism. When fetched for the second time, the materials move from the primary locating mechanism to the machining position. The primary locating mechanism is adopted, so that a work piece is roughly located at the material position; due to the locating function of the primary locating mechanism, the materials can be accurately placed at the machining position and can be accurately machined. The transferring mechanism adopts two mechanical arms moving linearly for feeding materials, so that the transferring period of the work piece is greatly shortened, and production efficiency is improved. The material reciprocating transferring device is suitable for the application environment with large distance between the material position and the machining position.

Owner:湖南三兴精密工业股份有限公司

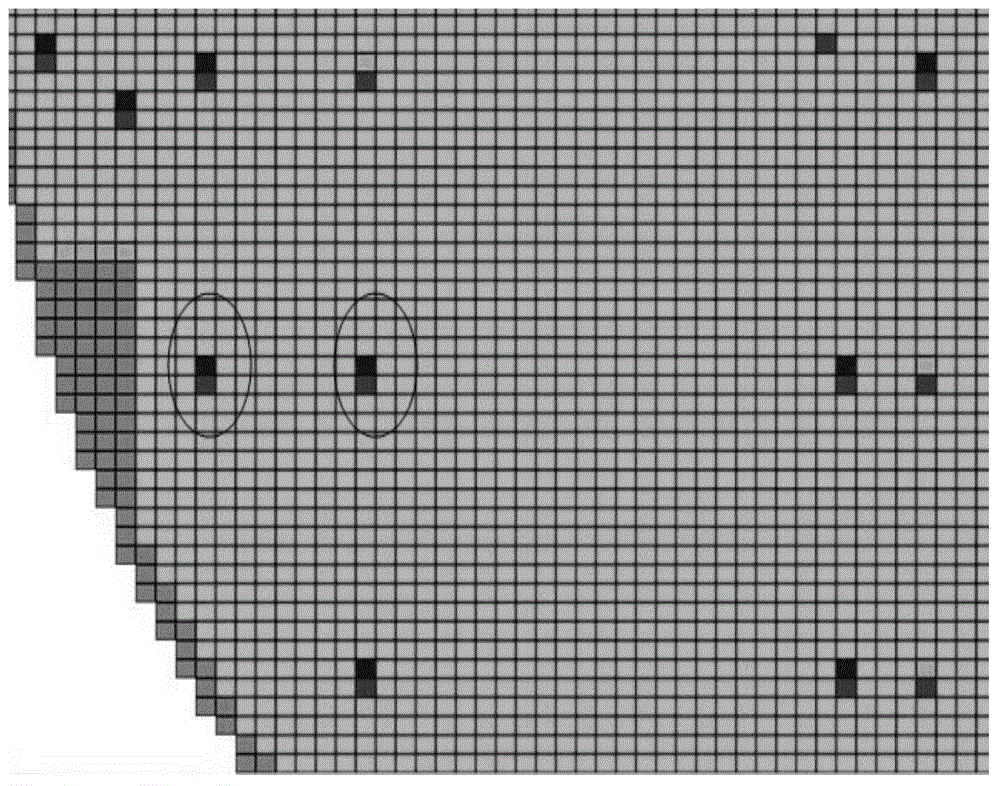

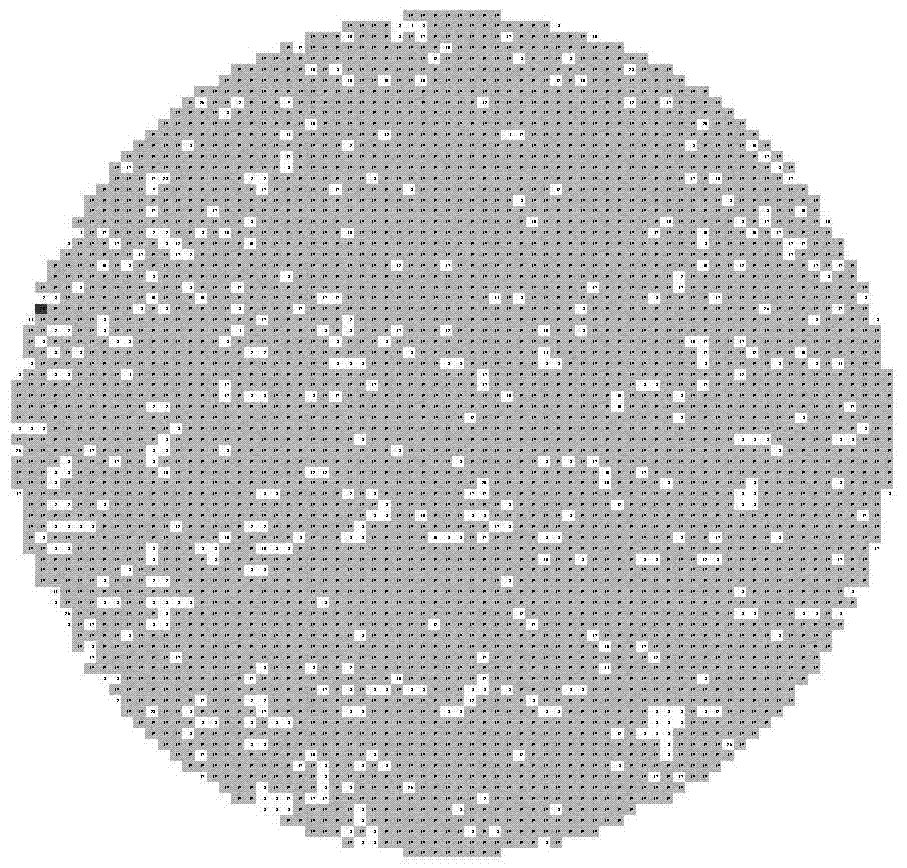

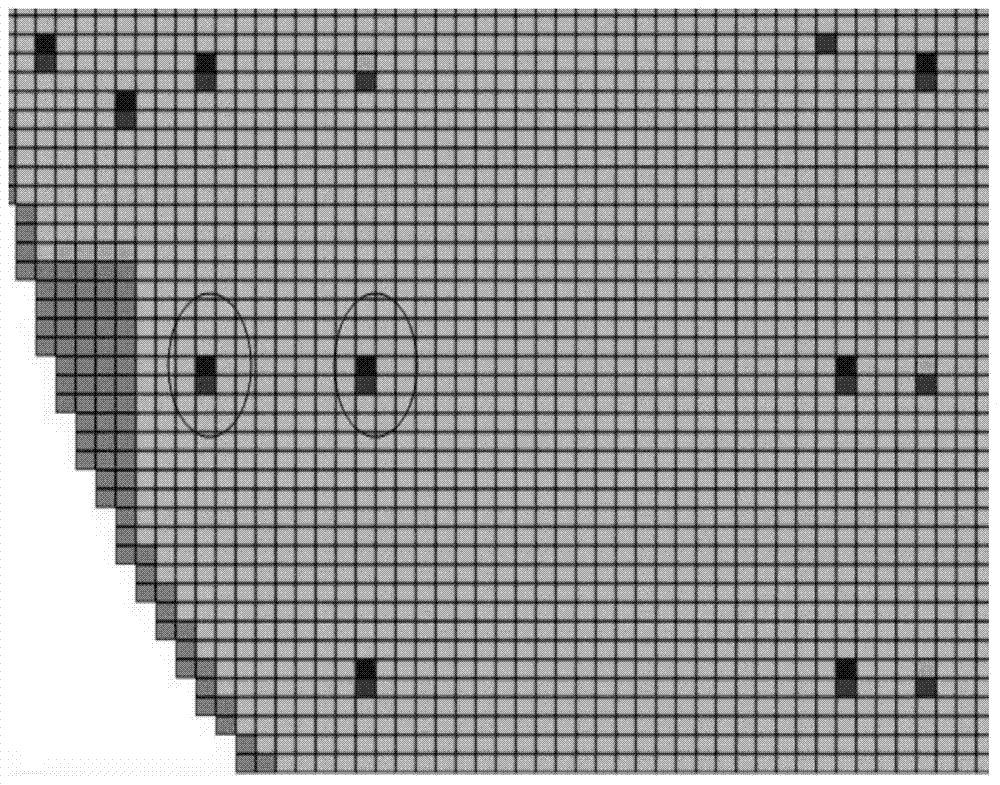

Method for confirming position alignment in wafer test

ActiveCN104422864AShorten test timeGuaranteed test qualityIndividual semiconductor device testingTester deviceTested time

The invention discloses a method for confirming position alignment in wafer test, comprising the following steps: (1) the position of an address Z in a chip memory area is specified as the position of storage mapping address, wherein a chip contains a chip status flag; (2) in the first test process, a tester reads information of a chip position A on a wafer from a prober system, and corresponding mapping relations are written into corresponding chips on the wafer through the tester; (3) in the second and subsequent process test, the chip position A read from the prober system is compared with a position A' read from a target chip, alarming is carried out through the tester if the two positions are not the same, and subsequent test continues if the two positions are consistent. Position alignment offset in multi-process test is avoided, the wafer test time is saved, and the quality of wafer test is guaranteed to the maximum.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

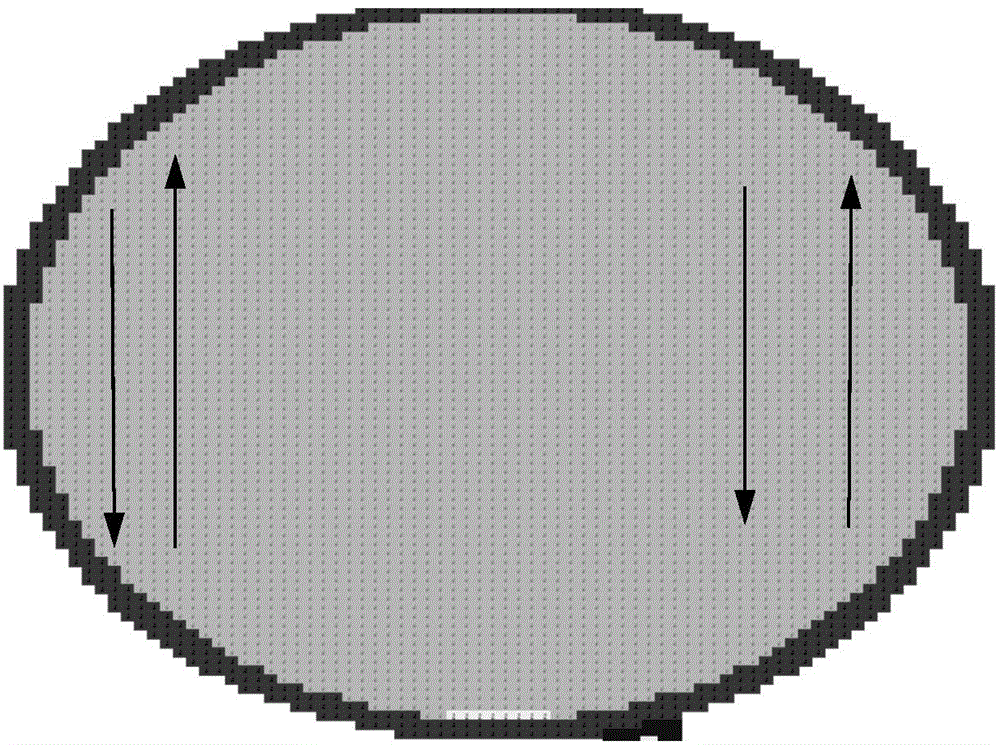

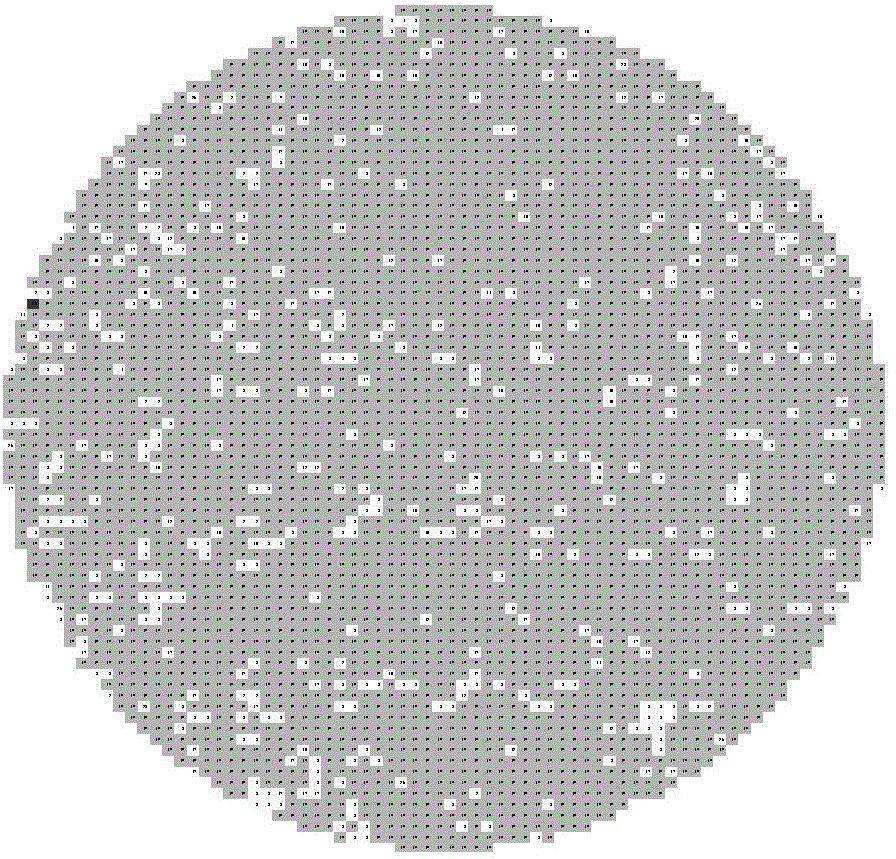

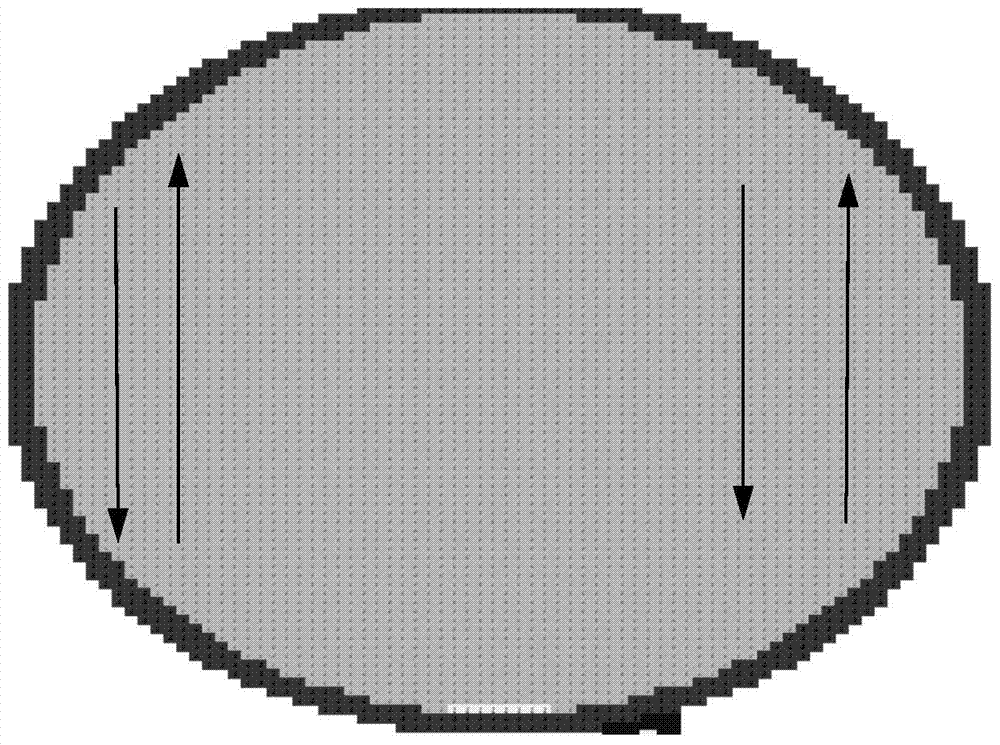

Wafer processing method and wafer processing device

ActiveCN114582713AGuaranteed positioning accuracyGuaranteed location consistencySolid-state devicesSemiconductor/solid-state device manufacturingWaferThin membrane

The invention discloses a wafer processing method and a wafer processing device.According to the wafer processing method, cleaning and UV dispergation are carried out on a wafer after girdling, the influence of cutting chippings and a glue layer on the surface of a thin film on subsequent ring taking can be effectively avoided, ring taking can be guaranteed, and before each action of girdling, UV dispergation and ring taking, ring taking can be carried out in a one-to-one manner; according to the technical scheme, the wafer is positioned through a set of centering mechanism, the position precision and consistency of the wafer at the positions of ring cutting, UV dispergation and ring taking can be effectively ensured, the ring cutting precision and the stable implementation of ring taking can be ensured, and the whole process of feeding, ring cutting, cleaning, UV dispergation, ring taking and discharging can be automatically realized through a set of automatic equipment, so that the production efficiency is improved, and the production cost is reduced. The automation degree is high, manual intervention is not needed, and continuous and efficient machining can be achieved.

Owner:JIANGSU JCA ELECTRONICS TECH CO LTD

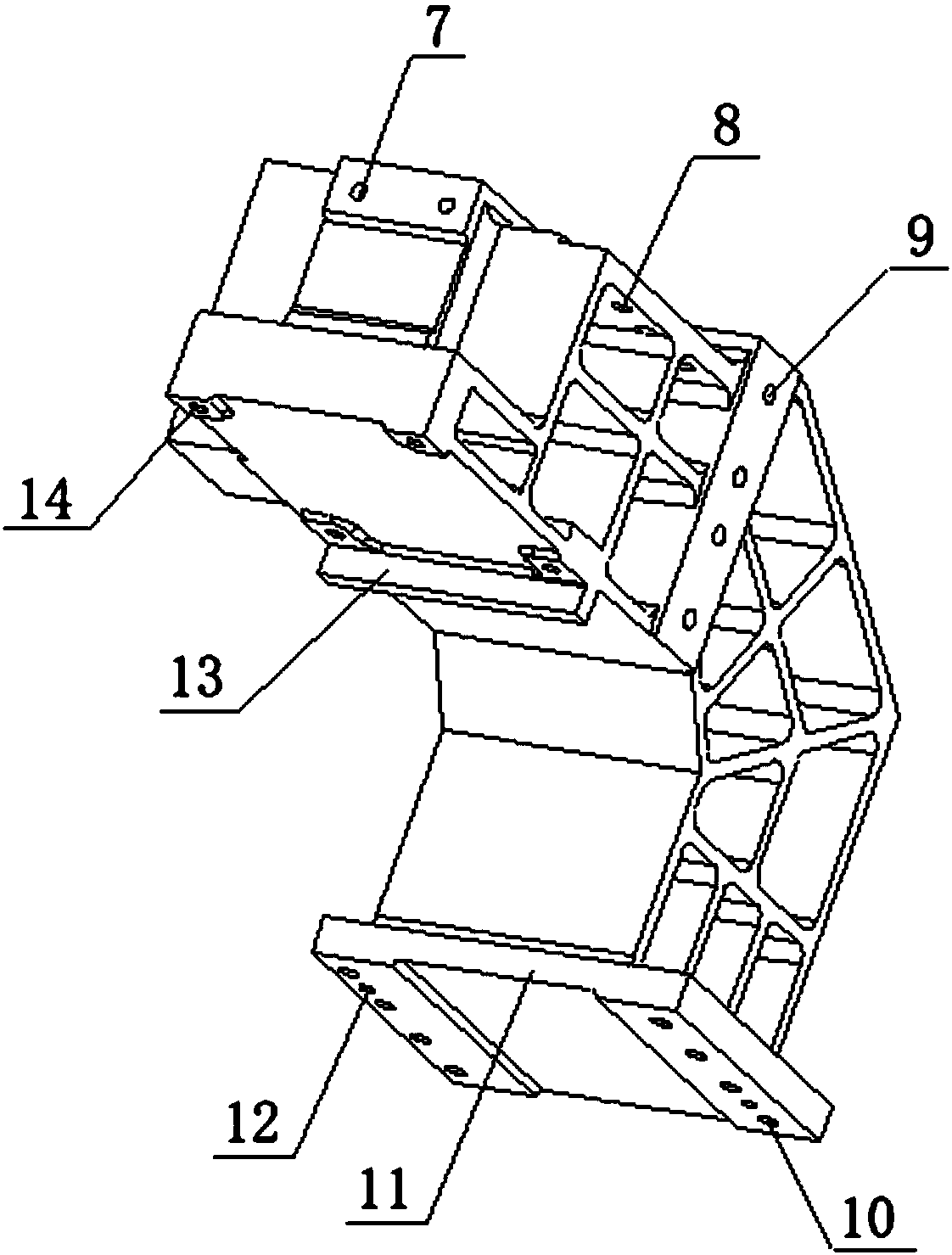

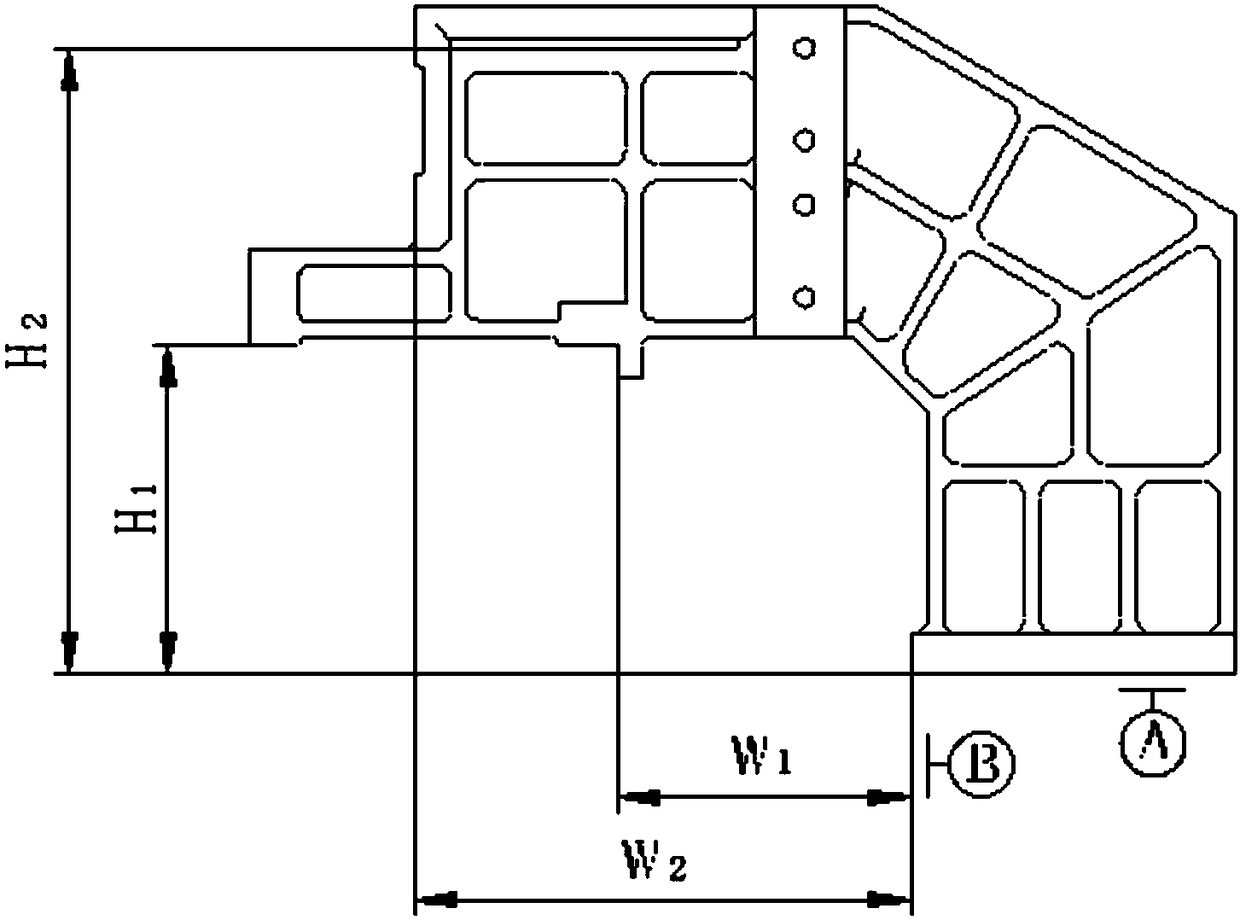

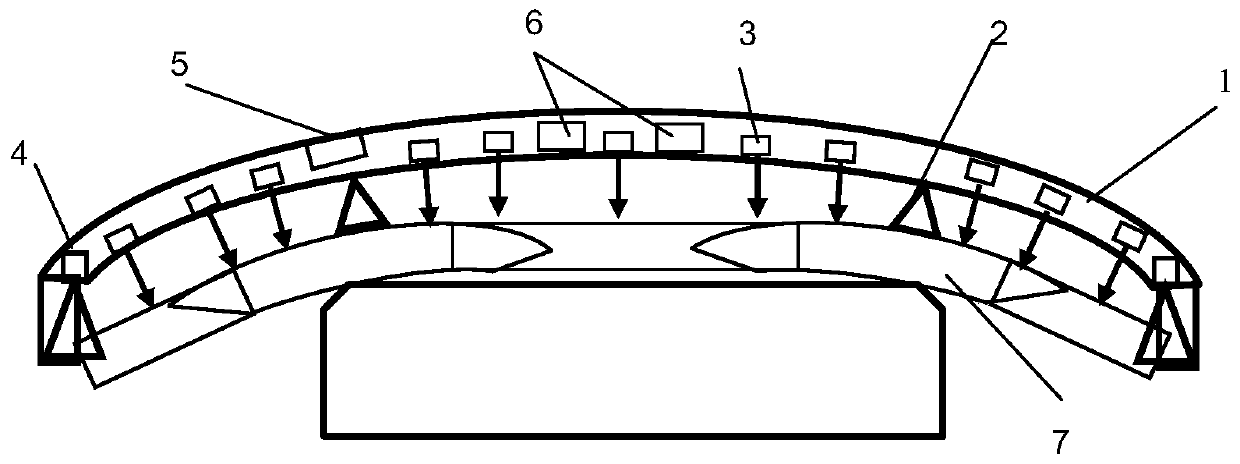

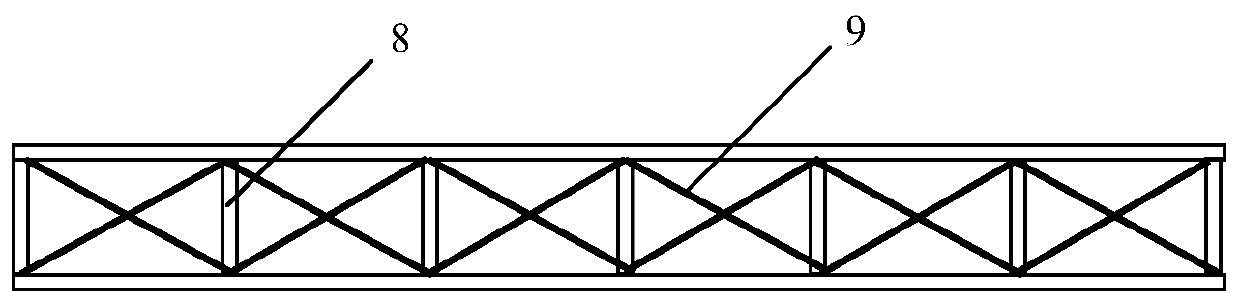

Magnet and motor integrated module of middle-low speed maglev train

InactiveCN108382263ASimplify the assembly processGuaranteed positional accuracy and consistencyRailway vehiclesElectric propulsionMagnetLow speed

The invention relates to a magnet and motor integrated module of a middle-low speed maglev train. The magnet and motor integrated module comprises a linear motor assembly, a suspension magnet assembly, a motor longitudinal beam and a pair of supporting arms which are integrated into a whole module, wherein the pair of supporting arms are each in an inverted-L shape. The motor longitudinal beam isconnected with the pair of supporting arms along the two ends of a longitudinal beam body of the motor longitudinal beam to form a supporting structure. The linear motor assembly is hung and mounted at the tops of the supporting arms. The bottoms of the supporting arms and the suspension magnet assembly are mounted in a matched mode. Compared with the prior art, the magnet and motor integrated module is advantageous in that the linear motor assembly and the suspension magnet assembly are integrated through the supporting arms and the motor longitudinal beam, the enough position dimension accuracy is ensured through positioning datum and the fine-adjusting function among all parts, in addition, the integrated whole module participates in overall integration and overhaul of a vehicle, the integration and overhaul process of the vehicle is simplified, the assembly quality is ensured, a basic guarantee is provided to commissioning and operation control of the vehicle, and great convenienceis also brought for vehicle maintenance and overhaul.

Owner:TONGJI UNIV

Vertical conveying machine for cells, vertical cell film coating machine, and film coating method of vertical cell film coating machine

ActiveCN108001962AMove preciselySimple structureConveyorsFinal product manufactureStart stopControl signal

The invention discloses a vertical conveying machine for cells, a vertical cell film coating machine, and a film coating method of the vertical cell film coating machine. The vertical conveying machine comprises two brackets, and further comprises a lifting and forward moving device, wherein the brackets are symmetrically arranged in a spacing manner; main rods of the brackets extend along the first axis direction and are matched to form a supporting groove used for the placement of cells; and the lifting and forward moving device is used for driving all the cells in the supporting groove to rise synchronously, move forward by a certain distance after the cells are separated from the bottom of the supporting groove, and then fall back to the bottom of the supporting groove. The vertical conveying machine disclosed by the invention has the advantages that through the supporting groove, the cells can remain vertical and can be prevented from toppling; an air cylinder is adopted for the conveying of the cells, the start-stop control based on the combination with a sensor is not needed, and the circuit structure is simplified; meanwhile, the vertical conveying machine is prevented frombeing influenced by the delay of a control signal, so that the cells can be correctly moved to a target position, the influence of a cell position error on the follow-up machining precision can be avoided, and the machining precision can be guaranteed; and furthermore, the position consistency of all to-be-machined cells can be guaranteed, and then the final film coating quality consistency can be guaranteed.

Owner:HEFEI JUYI POWER SYST CO LTD

Fracture simulation adjusting mechanism of grouting expansion testing device

ActiveCN105842125ASpeed up the flowReal-time reflection of crack width changesDiffusion analysisInternal pressureSlurry

The invention discloses a fracture simulation adjusting mechanism of a grouting expansion testing device, and belongs to the technical field of grouting expansion testing equipment. The fracture simulation adjusting mechanism comprises adjusting parts and measuring parts, wherein the adjusting parts comprise a fastening screw nut, an adjusting bolt, an upper pressing plate, a visible plate, a lower pressing plate, a bottom plate, a gland and a servo motor; the fastening screw nut is fixed on the upper pressing plate; one end of the adjusting bolt is connected with the fastening screw nut; the other end of the adjusting bolt is connected with the servo motor; the gland is fixedly connected with the bottom plate; the measuring components comprise a displacement measuring rod and a displacement sensor; the displacement measuring rod is arranged inside the adjusting bolt; a first sealing ring is arranged on the displacement measuring rod; a second sealing ring is arranged on the adjusting bolt; a spring is mounted on the displacement measuring rod; the displacement sensor is connected with the servo motor. By adoption of the fracture simulation adjusting mechanism, multiple functions of balancing inner pressure, adjusting fracture width and measuring width are achieved, accurate basis can be provided for grouting construction and establishment of slurry expansion models, and the grouting effect can be ensured.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Arc-shaped perforated decoration aluminum plate system

The invention discloses an arc-shaped perforated decoration aluminum plate system, which comprises a base layer framework, a plurality of connecting assemblies and an aluminum plate, wherein the aluminum plate is arranged on the base layer framework through the connecting assemblies. The arc-shaped perforated decoration aluminum plate system is characterized in that the aluminum plate is an arc-shaped aluminum plate with a circular arc radian; the base layer framework consists of a plurality of upright posts; a plurality of hanging and connecting holes are separately formed in the upright posts; the connecting assemblies comprise at least one pair of hooks and a plurality of connecting screw bolts; the hooks have the bending angles; the bending angle adapts to the bending radian of the arc-shaped aluminum plate, so that one end of each hook is hooked and buckled in the corresponding hanging and connecting hole formed in the upright posts; the other end of each hook is fixedly connected with the arc-shaped aluminum plate through screw bolts. The arc-shaped perforated decoration aluminum plate system has the advantages that through the connection via the hooks with the bending angles, the hanging installation of the arc-shaped aluminum plate is realized; the three-dimensional effect is added to the wall surface decoration; meanwhile, the hanging installation is simple; the arc-shaped perforated decoration aluminum plate system is suitable for the installation of various wall surfaces.

Owner:苏州苏明装饰股份有限公司

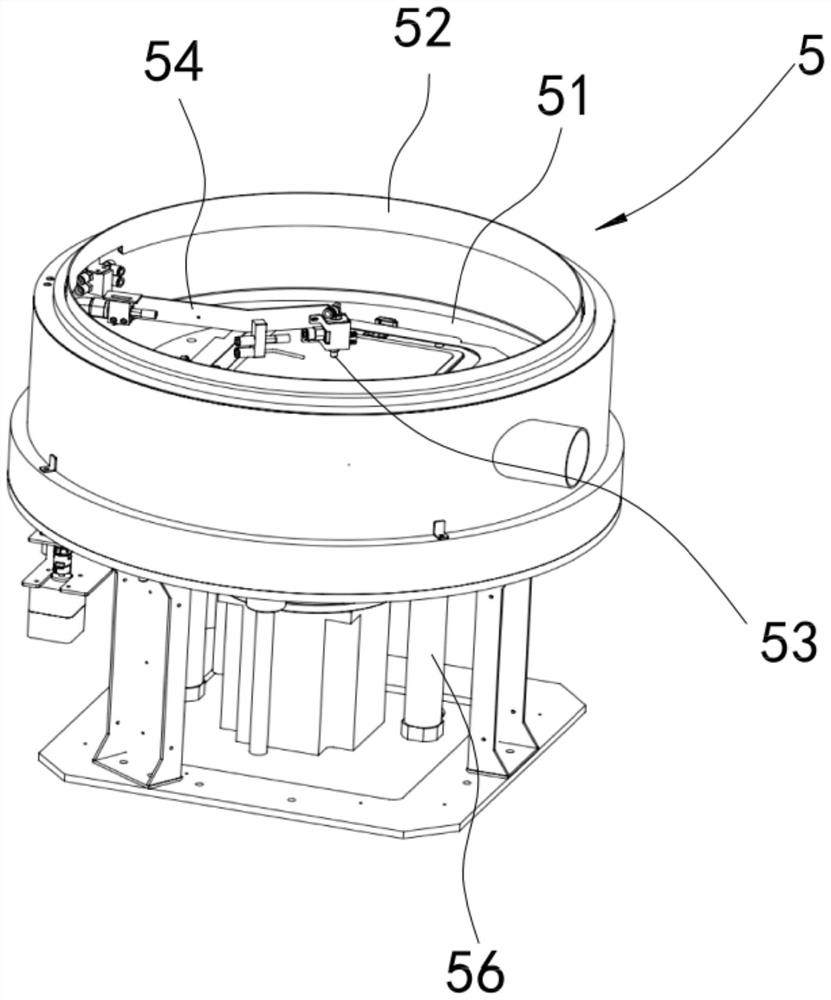

Material transfer system

InactiveCN111573276AGuaranteed location consistencyAccurate placementConveyorsControl devices for conveyorsPhysicsRotational axis

The invention discloses a material transfer system. The material transfer system comprises a first conveying device and a second conveying device which are arranged in a spaced mode, and further comprises a grabbing and releasing device used for transferring products from the first conveying device onto the second conveying device. The grabbing and releasing device comprises a rotating device anda lifting device. The rotating device comprises a first driving device. A rotary shaft of the first driving device is fixedly connected with a fixed plate. The fixed plate is provided with a pluralityof suction cup assemblies used for grabbing and releasing the products. The material transfer system provided by the invention can stably and effectively transfer the products from the first conveying device onto the second conveying device through the set steps and facilitates achievement of mechanized production of the products.

Owner:GUANGDONG MINGLIDA TECH

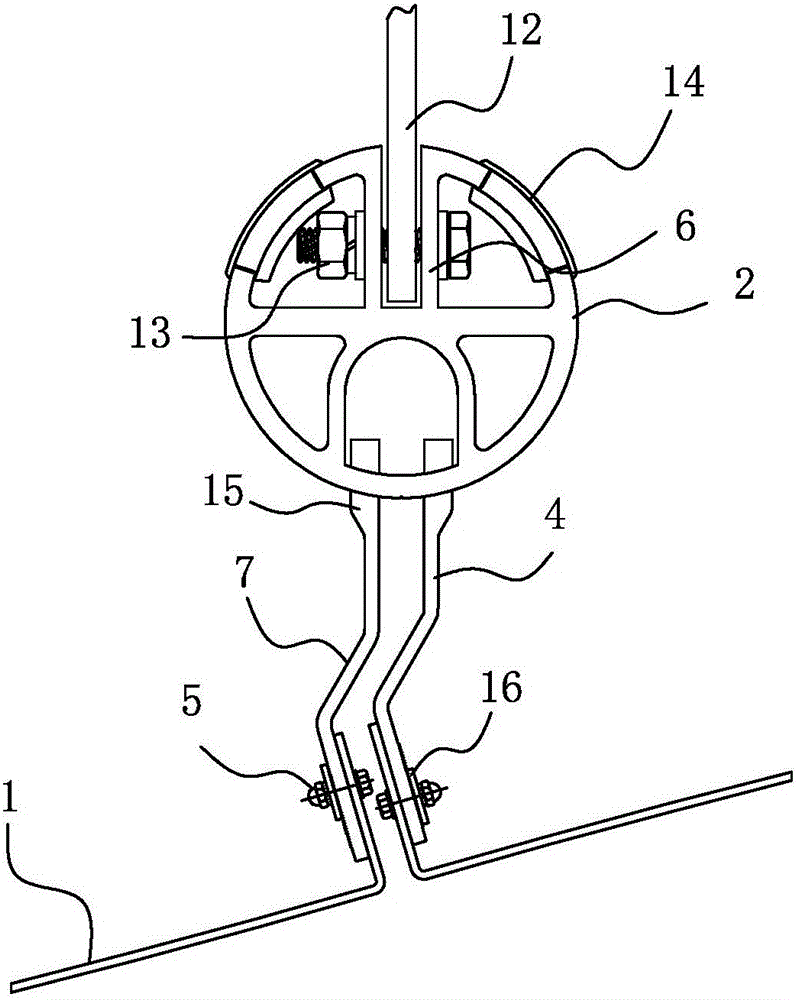

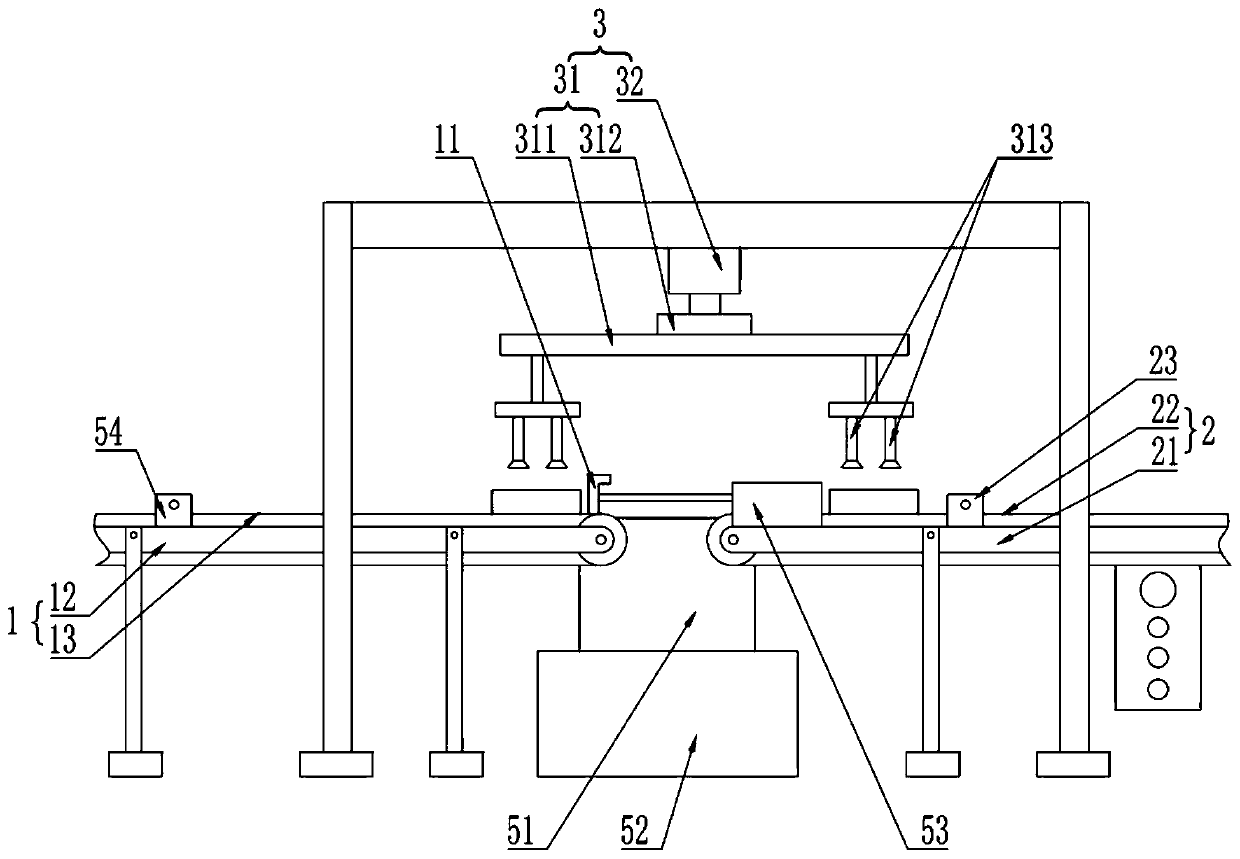

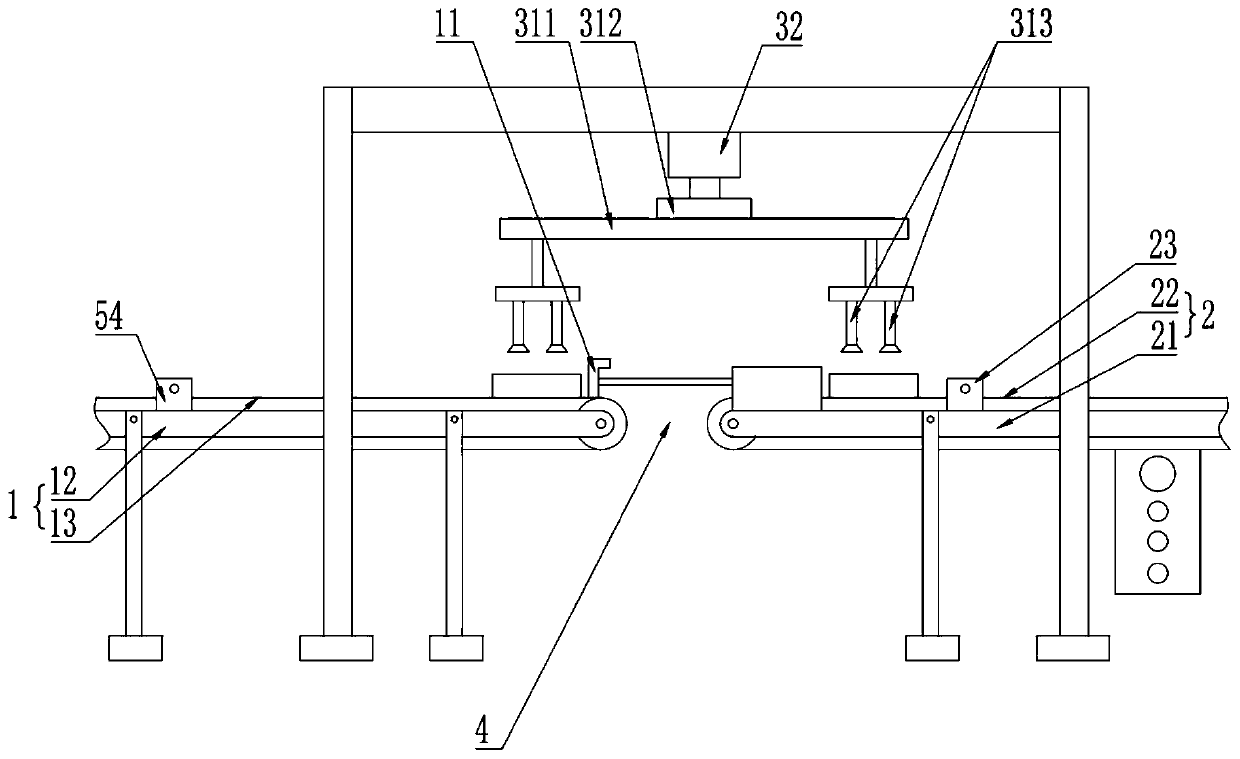

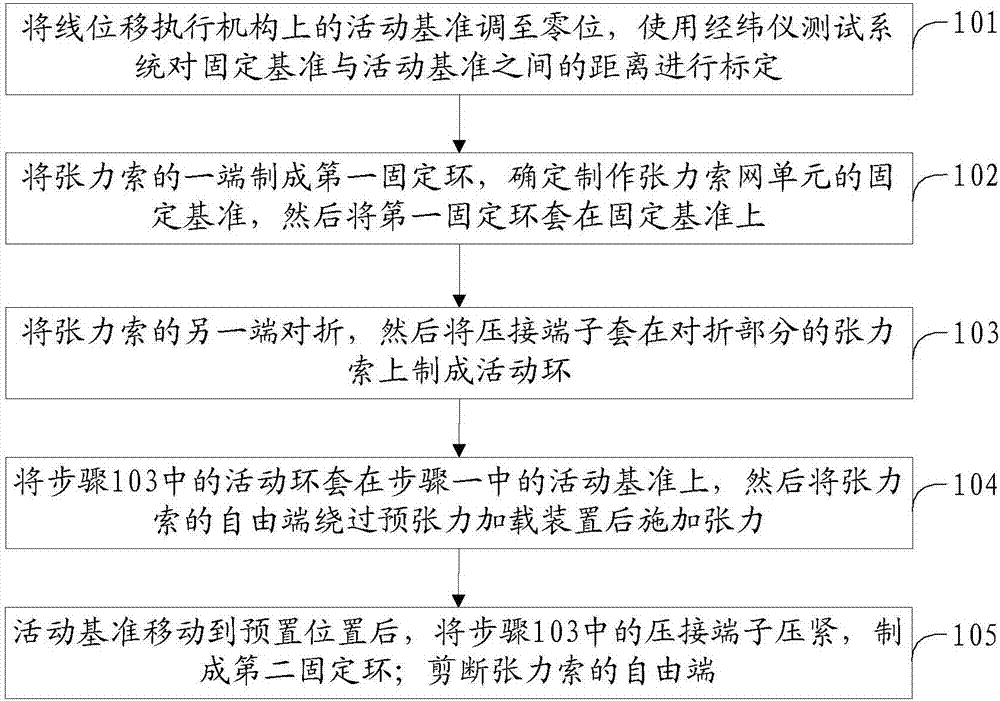

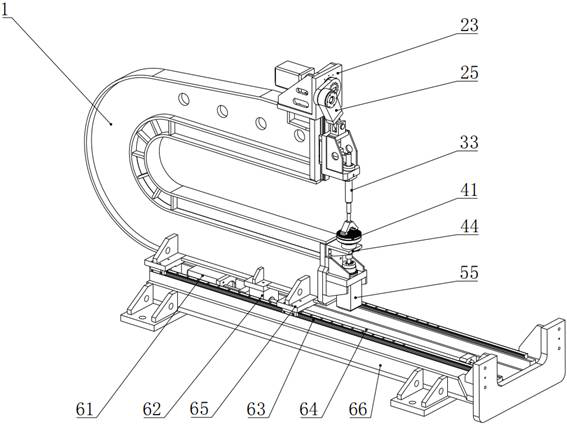

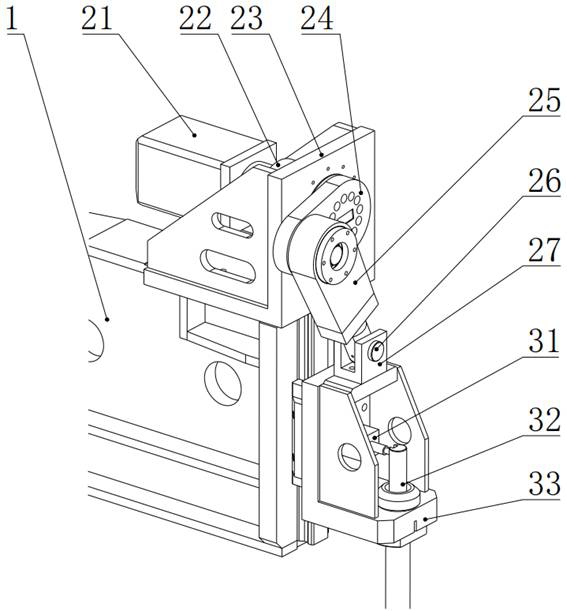

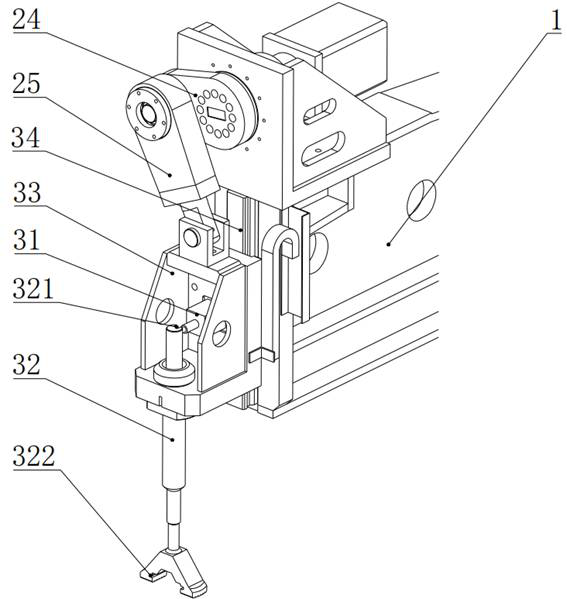

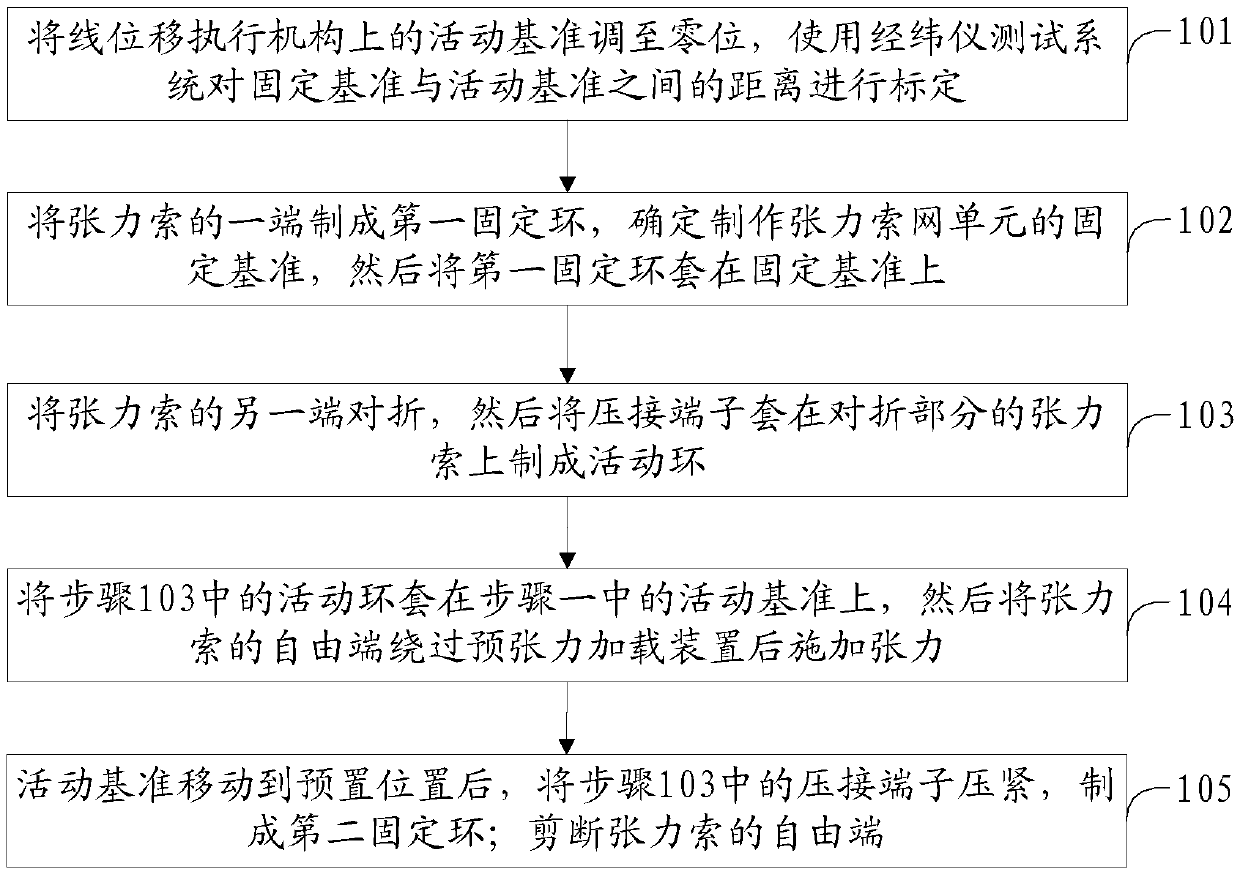

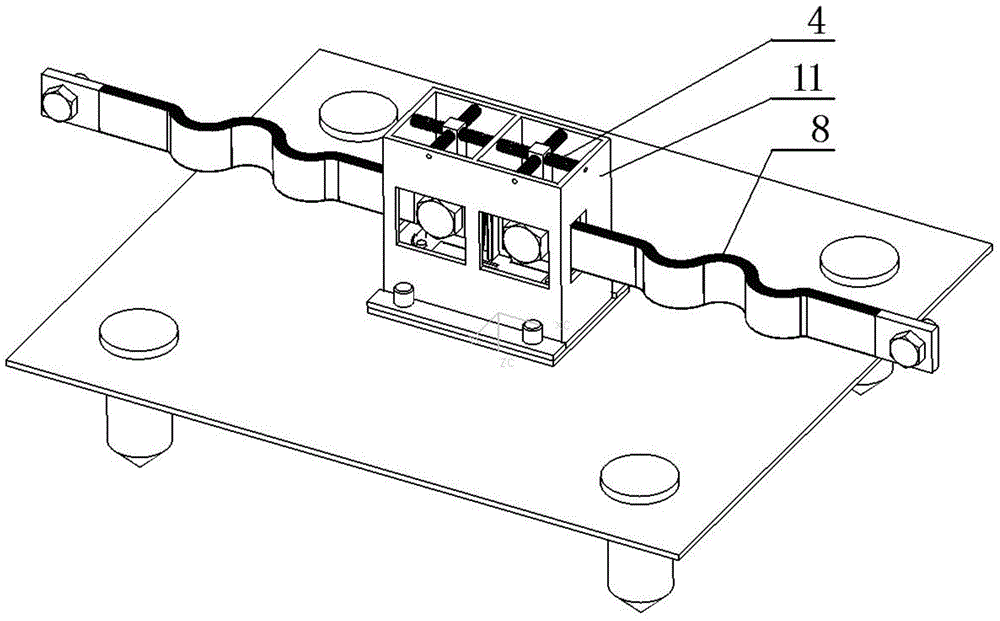

Manufacturing method of high-precision tension cable net unit of mesh antenna

ActiveCN107986115AEasy to makeGood operation consistencyAntenna supports/mountingsWire toolsLinear displacementTheodolite

A manufacturing method of a high-precision tension cable net unit of a mesh antenna comprises the following steps that firstly, a moving datum (4) on a linear displacement executing mechanism (2) is adjusted to be zero, and the distance between a fixed datum (3) and the moving datum (4) is calibrated through a theodolite test system; secondly, one end of a tension cable is manufactured to be a first fixed ring, and the fixed datum (3) is sleeved with the first fixed ring; thirdly, after the other end of the tension cable is used as a free end and folded in two, the part, folded in two, of thetension cable is sleeved with a compression connection terminal, and a moving ring is manufactured; fourthly, the moving datum (4) obtained in the first step is sleeved with the moving ring obtained in the third step, the free end of the tension cable is wound around a pretension loading device (6), and then tension is applied; fifthly, the linear displacement executing mechanism (2) is controlledto move, after the linear displacement executing mechanism (2) drives the moving datum (4) to move to a preset position, the compression connection terminal in the third step is tightly pressed, anda second fixed ring is manufactured.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Automatic tool setting device for numerical control external thread grinder

ActiveCN101898316BHigh precisionImprove efficiencyAutomatic control devicesFeeding apparatusAutomatic controlZ-Coordinate

The invention discloses an automatic tool setting device for a numerical control external thread grinder. The automatic tool setting device can realize the thread tool setting motion by a machine tool numerical control system, a numerically controlled grinding carriage transverse motion mechanism, a planker longitudinal motion mechanism, a probe motion mechanism of the invention and embedded special software. A planker doing the motion in the Z-coordinate direction is mounted on a longitudinal guide rail at the rear part of a machine tool, and a grinding carriage doing the motion in the X-coordinate direction is mounted on a planker transverse guide rail. The probe motion mechanism consists of a support, a base, sliding blocks of a linear guide rail pair, the linear guide rails, a slidingplate, a support saddle, a probe with a multi-point sensor and an oil cylinder, and is used for completing the extension and the resetting motion of a probe; and the embedded special software sequentially implements a tool setting program. The device can automatically measure and calculate the coordinate value of the tool setting position of a threaded workpiece, automatically control the tool setting motion, leading the tool setting process to have no need of human intervention, be precise and fast, improve the tool setting precision and the efficiency of the external thread grinder, be conductive to safety protection and solve the deficiencies of manual tool setting.

Owner:陕西汉江机床有限公司

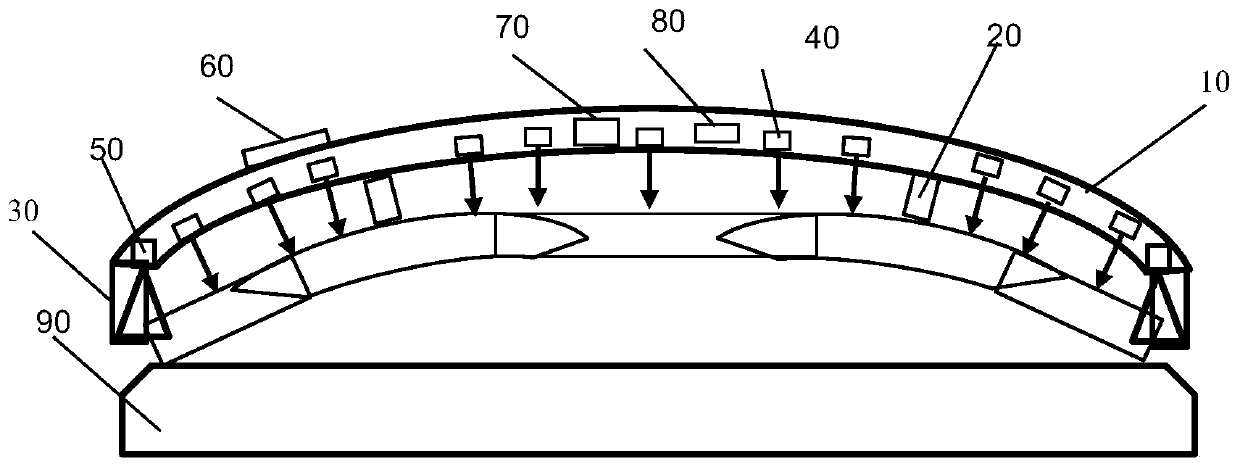

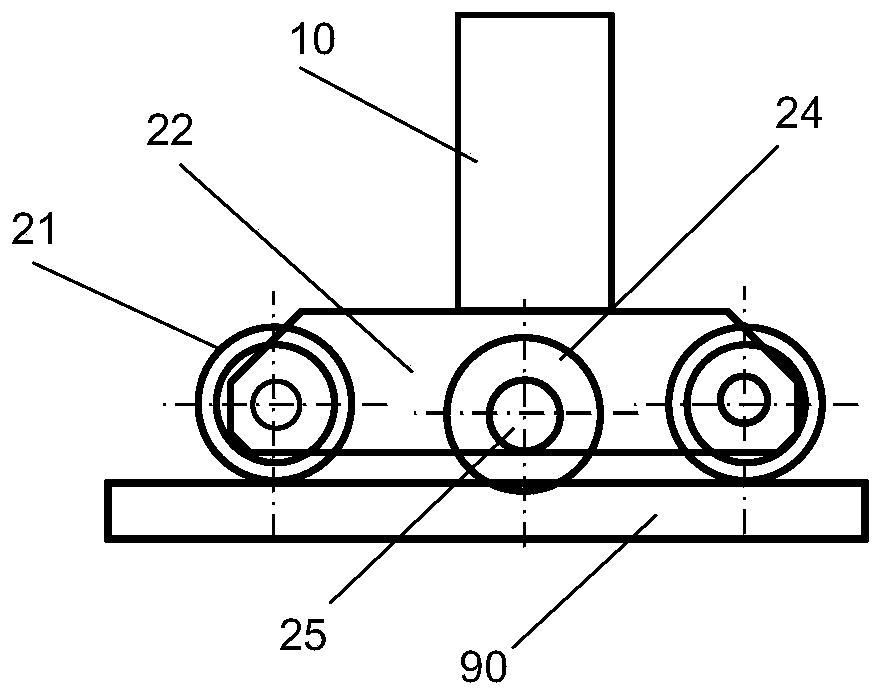

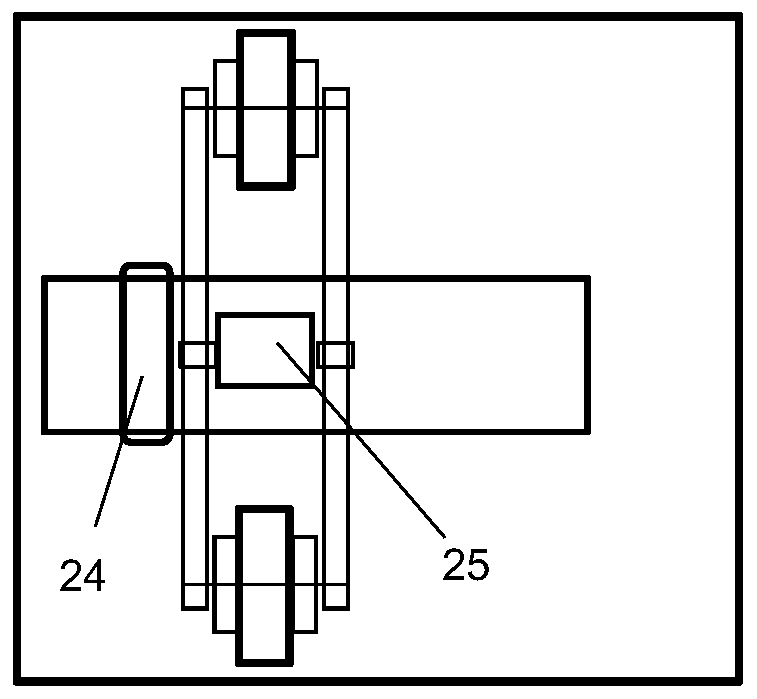

Mobile digital pallet and its measuring method for measuring vehicle body contour deviation

ActiveCN109307479BStable and reliable relative position relationshipGuaranteed location consistencyUsing optical meansElectricityMeasurement point

The invention provides a movable type digital clamping plate for measuring outline deviation of a vehicle body and a measuring method of the movable type digital clamping plate; the movable type digital clamping plate is characterized by comprising a substrate, a supporting mechanism, a limiting mechanism, a displacement sensor, visual sensors, and a controller, wherein the substrate is arranged on the surface of the tested vehicle body through the supporting mechanism and the limiting mechanism in a stretching over mode; the supporting mechanism is used for supporting and positioning the substrate; the limiting mechanism is used for limiting the relative position of the substrate and the tested vehicle body; the displacement sensor is used for measuring a preset measuring point of the tested vehicle body; the visual sensors are arranged at the left end and the right end inside the substrate, and are used for measuring the edges of the two sides of the tested vehicle body; the controller is arranged on the upper surface of the substrate and is connected with the displacement sensor and the visual sensors and is used for receiving and processing data obtained by the displacement sensor and the visual sensors. Automatic, high-precision, high speed, digitization, networking and other demands in measurement of the outline deviation of the vehicle body in the train production process can be met.

Owner:SHANGHAI JIAO TONG UNIV

Coal mine U-shaped steel support stress-bearing monitoring and early warning device

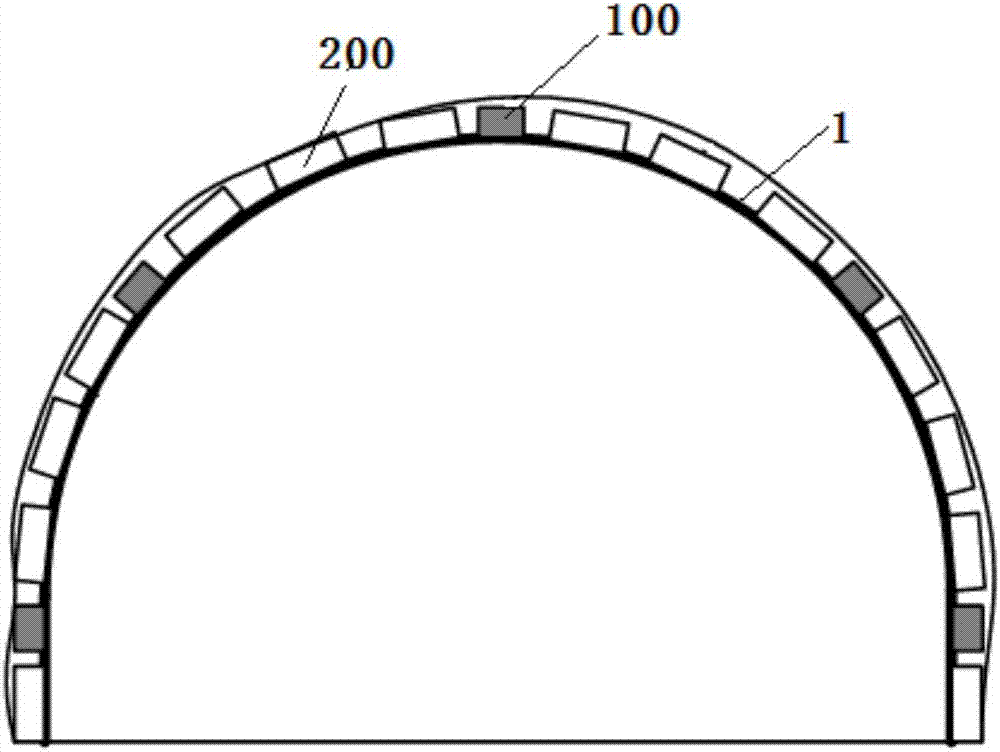

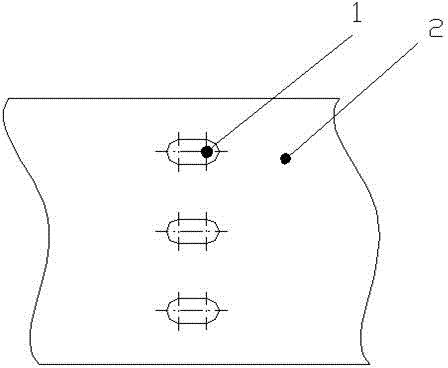

PendingCN107339124AAvoid location changesGuaranteed location consistencyMining devicesUnderground chambersMining engineeringStress sensors

The invention relates to a coal mine U-shaped steel support stress-bearing monitoring and early warning device. The coal mine U-shaped steel support stress-bearing monitoring and early warning device comprises a connecting device and a monitoring device, the connecting device comprises a base, Z-shaped foot pressing sheets and magnets, support feet of a U-shaped steel support is installed on the base through the Z-shaped foot pressing sheets and attracted to the magnets arranged in the base; the monitoring device comprises a pressure sensor, a processor and an audible and visual warner, one side of the pressure sensor is arranged in the base in an embedded mode, and the pressure sensor is electrically connected with the processor; and the audible and visual warner is connected with the processor and sends out warning signals. According to the coal mine U-shaped steel support stress-bearing monitoring and early warning device, the magnets are adopted to be fixed with the U-shaped steel support, so that the situation that the position changes in the installation process is avoided; the foot pressing sheets are utilized to limit the U-shaped steel support, so that the situation that the monitoring device and the steel support slide relatively in the stress bearing process of the steel support is prevented; the pressure sensor is externally connected to the processor and comparing with prewarning value is conducted, so that the warning signals are sent out timely; and bases are provided for reinforced supporting, and roadway accidents are effectively prevented from happening.

Owner:SHANDONG UNIV OF SCI & TECH

High-strength plate rolling and on-line cutting method

The invention relates to a processing technology of plate pressing sectional materials, in particular to a high-strength plate rolling and a on-line cutting method. According to the technology, the method includes the steps of decoiling coil stock, flattening the coil stock, roll forming, straightening sectional materials and cutting on-line. The method is characterized in that a step of automatic punching is added between the step of flattening the coil stock and the step of roll forming, the step of automatic punching is used for punching a row of holes in boards, when the rolling formed sectional materials are cut in the punching location, cutting force bearing points can be reduced by more than one thirds, the cutting stress is reduced, and the cutting deformation is reduced. The method mainly solves the technical problem that in the prior art fracture is prone to occur during cutting on-line and the cutting deformation of the rolling sectional materials is large, previous parking cutting of the plate rolling with high strength being changed into on-line synchronous cutting can be achieved, and the production efficiency of production lines can be improved. In addition, by means of positioning cutting, the consistency of on-line punching locations is guaranteed, the production efficiency and the use ratio of the plate rolling with high strength are effectively improved.

Owner:SHANGHAI YINGHUI TECH DEV

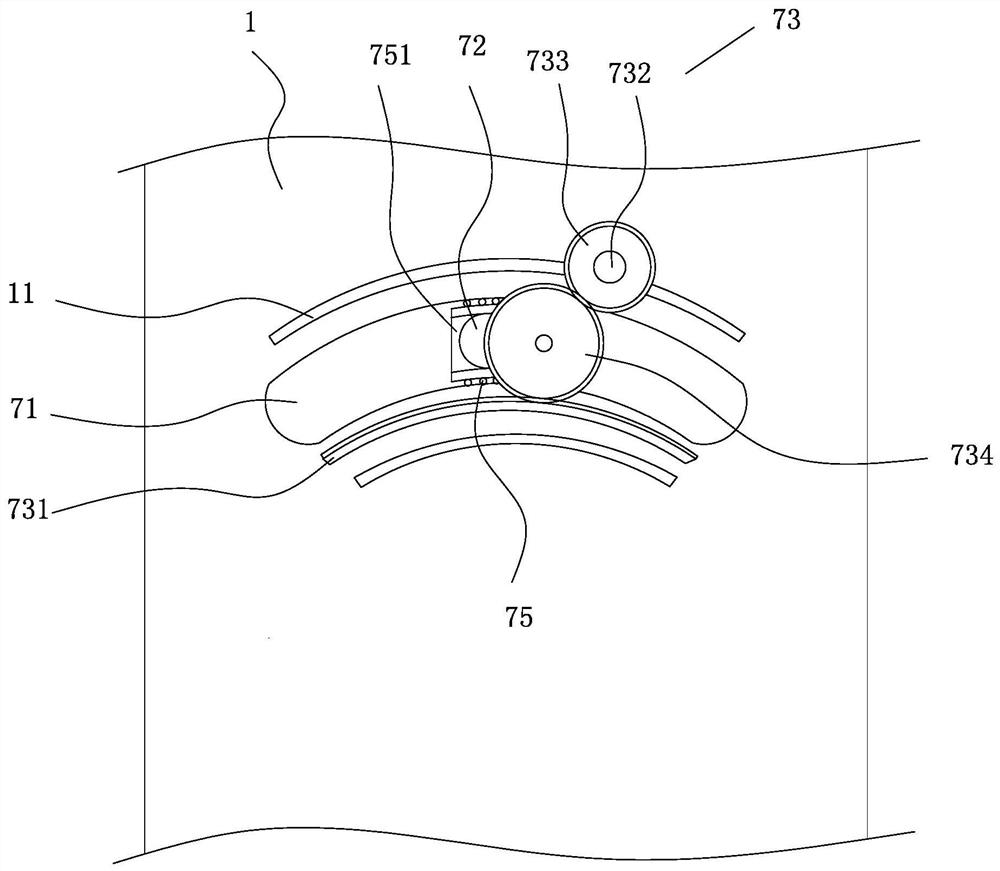

Automatic tension correction system for flexible material in supply process and correction method thereof

InactiveCN111891807AAutomatic tension controlGuaranteed location consistencyTelevision system detailsColor television detailsTextile printerControl engineering

The invention relates to an automatic tension correction system for a flexible material in a supply process and a correction method thereof. The automatic tension correction system for the flexible material in the supply process is an automatic tension correction system arranged in a KN95 mask machine and comprises a front tensioning mechanism driving system connected with a front tensioning mechanism and used for driving the tensioning force of the front tensioning mechanism, a rear tensioning mechanism driving system connected with a rear tensioning mechanism and used for driving the tensioning force of the rear tensioning mechanism, an image acquisition system which is arranged between a seal printing mechanism and the rear tensioning mechanism, and an upper computer which is arranged on one side and connected with the image acquisition system, the front tensioning mechanism driving system and the rear tensioning mechanism driving system through wires. The upper computer receives images collected by the image acquisition system and controls the front tensioning mechanism driving system and the rear tensioning mechanism driving system to drive the tensioning force of the corresponding front tensioning mechanism and the tensioning force of the corresponding rear tensioning mechanism according to the mask cloth tightness degree reflected by the images. According to the automatic tension correction system for the flexible material in the supply process, the manual maintenance frequency is reduced, and the labor intensity is reduced.

Owner:天津容大机电科技有限公司

PVC carpet punching die

PendingCN108189146AImprove punching efficiencyGuaranteed location consistencyMetal working apparatusPunchingEngineering

The invention discloses a PVC carpet punching die. The PVC carpet punching die includes an upper die seat, positioning holes, a punching device and a convex mold core, wherein the positioning holes are formed in the upper die seat, a positioning groove hole is formed on the front portion of the positioning holes, and a concave mold core is arranged on the side face of the positioning groove hole.The concave mold core, far away from the positioning groove hole, is provided with the punching device. The punching device includes connecting bolt holes, a cutter upper support protective cover, a supporting spring, a telescopic rod, a heating ring cutter and an upper supporting rod. The PVC carpet punching die has the beneficial effects that a PVC carpet can be positioned, the position consistency of holes is guaranteed, and a cutter head is heated and punched, so that the PVC carpet can be quickly punched, incisions have no barbs, the attractiveness of the appearance of the PVC carpet is improved; and after punching, waste can be extruded out of the cutter head through the springs, the continuous work of the cutter head is ensured, and the punching efficiency of the PVC carpet is improved.

Owner:安吉艺科装饰材料科技有限公司

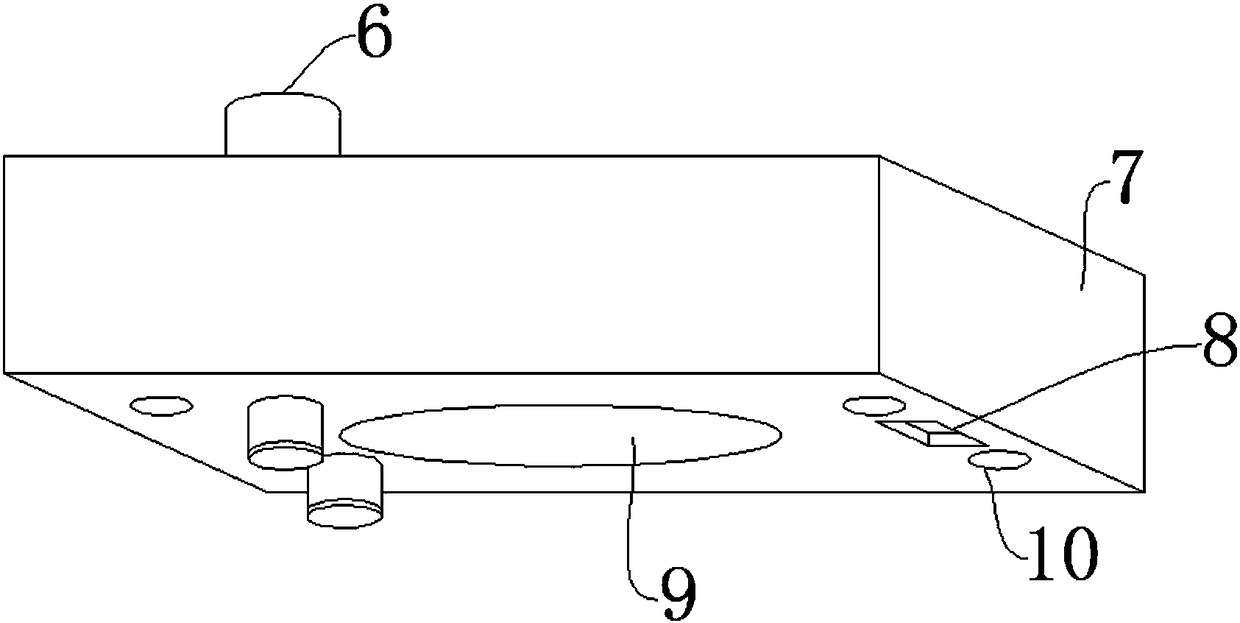

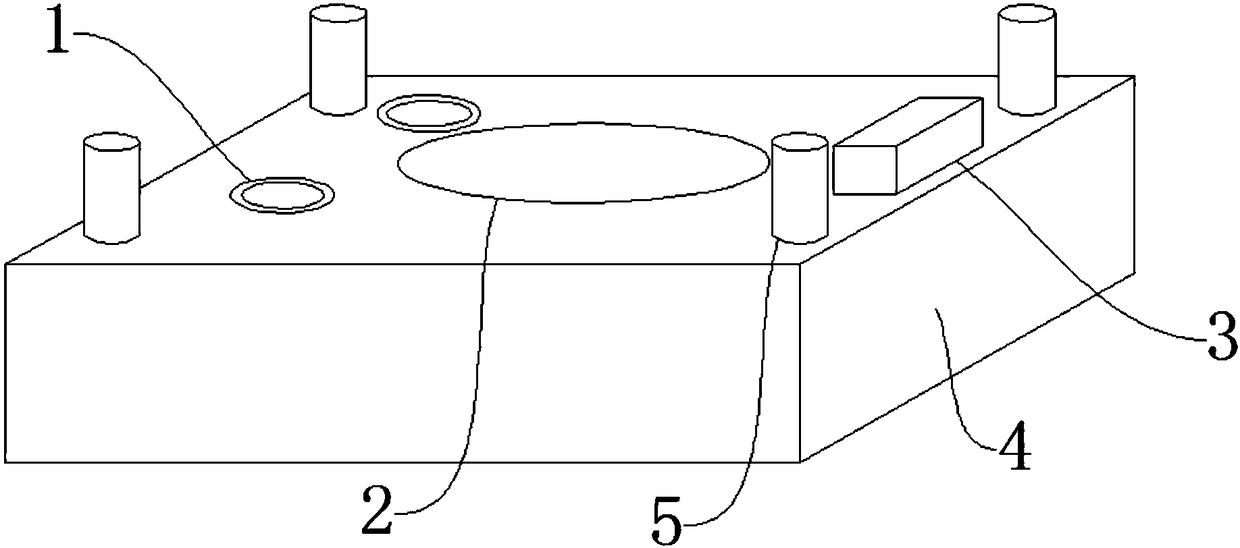

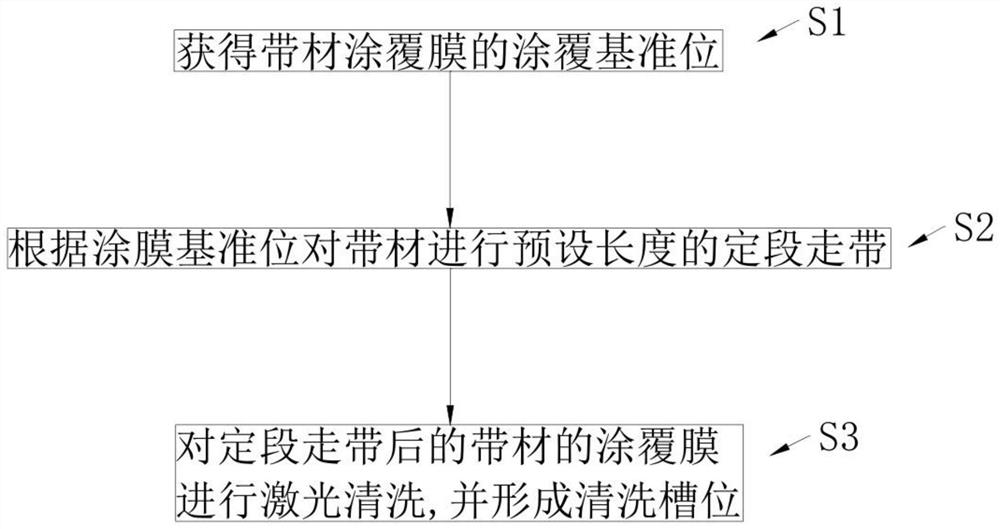

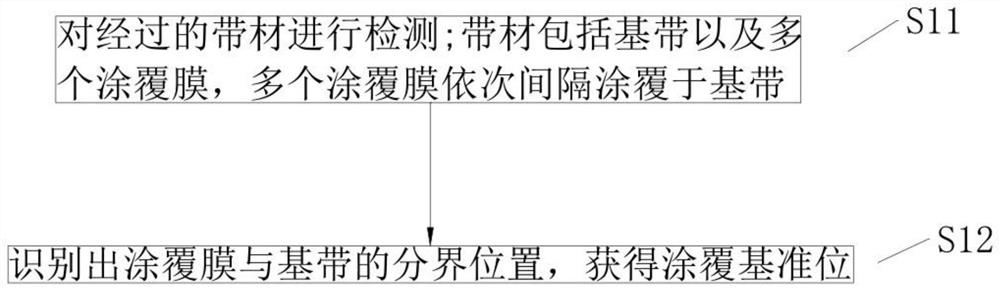

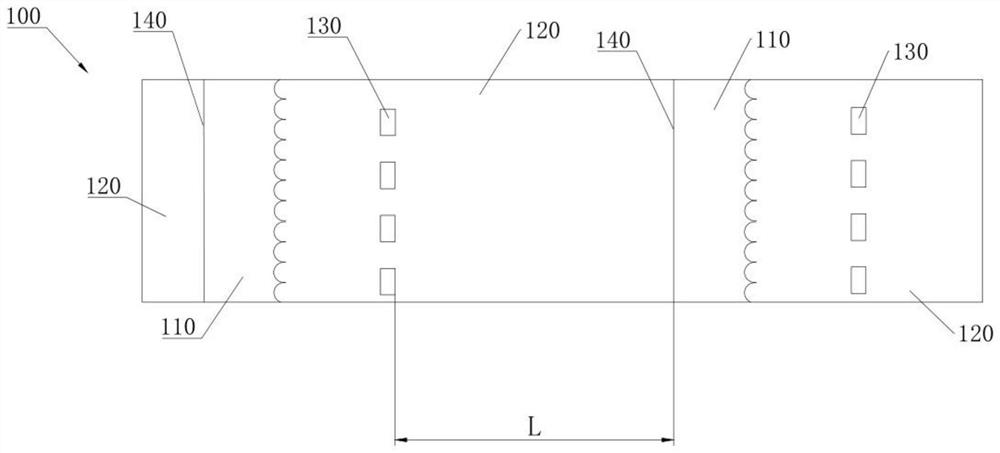

Laser cleaning method and device

ActiveCN111151515BAccurately determineGuaranteed location consistencyCleaning processes and apparatusPhysical chemistryEngineering

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

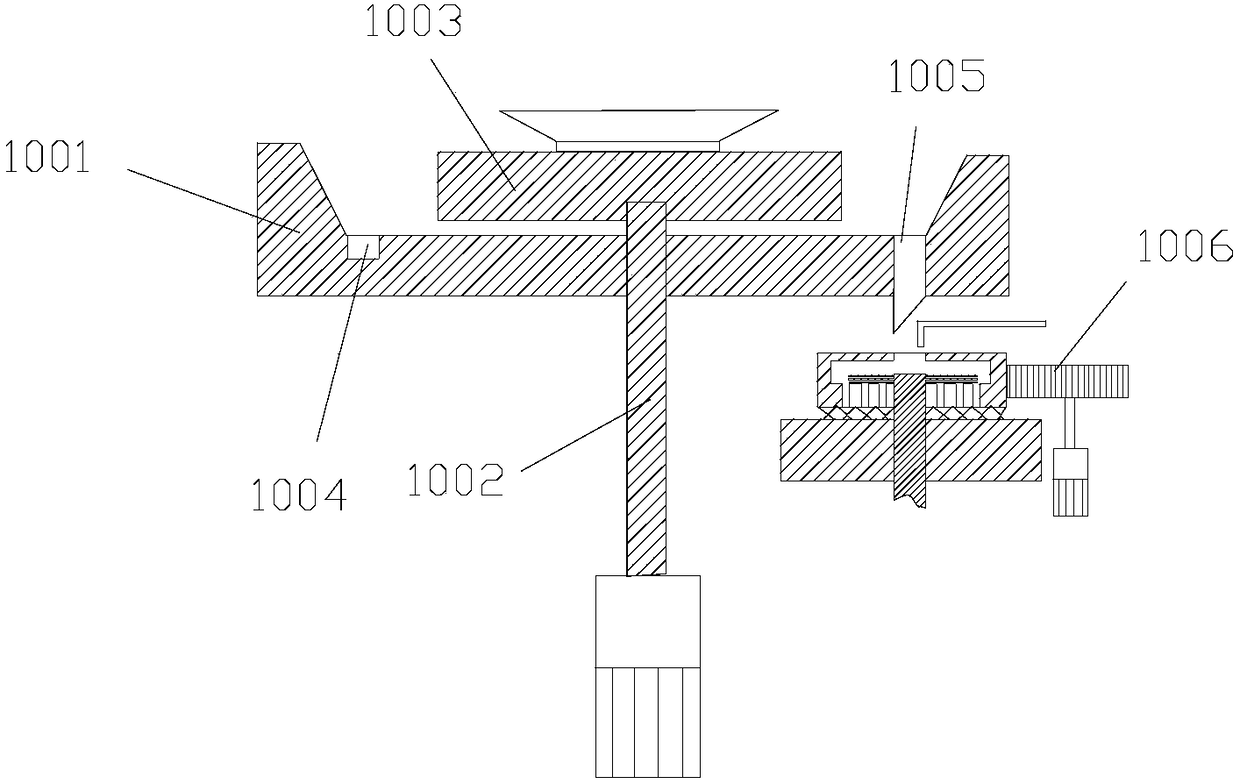

Tea cup production line, and method for producing tea cup by using production line

The invention discloses a tea cup production line sequentially comprising a blank making mechanism, a glazing mechanism, a glost kiln and an auxiliary glazing device from front to back according to aprocess flow. The blank making mechanism comprises a blank making table, a blank making rotary shaft and a blank making rotary plate; a circle of guiding chute is further formed in the blank making table; a grinding device is arranged under a discharge hole of the guiding chute; the glazing mechanism comprises a main rotary base and a hairbrush; a cup blank to be glazed is arranged on the main rotary base; the main rotary base rotates to drive the cup blank to be glazed to rotate; a bristle end of the hairbrush can be in abut-joint to the outer surface of the cup blank to be glazed; and the auxiliary glazing device comprises an auxiliary rotary base, a black glaze cup model, an auxiliary contact rod, an auxiliary batch type lifting mechanism, an auxiliary elastic device, an auxiliary batchtype pushing mechanism and an auxiliary clamping device. The invention further discloses a method for producing a tea cup by using the tea cup production line. The tea cup production line provided bythe invention has the advantages of high pug utilization rate, uniformity in glazing, and good glazing effect.

Owner:福建省东丰阁文化发展有限公司

Confirmation method for alignment achieved in wafer test

ActiveCN104422864BShorten test timeGuaranteed test qualityIndividual semiconductor device testingConfirmation testTester device

The invention discloses a method for confirming position alignment in a wafer test, comprising: 1) first specifying that the address Z of the memory area of the chip is the position for storing the mapping address, and the chip also includes a flag bit of the chip state; 2) In the first test process, the tester reads the chip position A information on the wafer from the probe station system, and writes the corresponding mapping relationship into the corresponding chip on the wafer through the tester; 3) In the second and subsequent process tests, compare the chip position A read by the probe station system with the position A' read from the target chip. If they are not the same, the tester will alarm; if they are consistent, continue follow-up tests. The invention avoids the situation that position alignment shifts in the multi-process test, saves the test time of the wafer, and guarantees the test quality of the wafer to the greatest extent.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

On-line Cutting Method of High-strength Sheet Rolling

The invention relates to a processing technology of plate pressing sectional materials, in particular to a high-strength plate rolling and a on-line cutting method. According to the technology, the method includes the steps of decoiling coil stock, flattening the coil stock, roll forming, straightening sectional materials and cutting on-line. The method is characterized in that a step of automatic punching is added between the step of flattening the coil stock and the step of roll forming, the step of automatic punching is used for punching a row of holes in boards, when the rolling formed sectional materials are cut in the punching location, cutting force bearing points can be reduced by more than one thirds, the cutting stress is reduced, and the cutting deformation is reduced. The method mainly solves the technical problem that in the prior art fracture is prone to occur during cutting on-line and the cutting deformation of the rolling sectional materials is large, previous parking cutting of the plate rolling with high strength being changed into on-line synchronous cutting can be achieved, and the production efficiency of production lines can be improved. In addition, by means of positioning cutting, the consistency of on-line punching locations is guaranteed, the production efficiency and the use ratio of the plate rolling with high strength are effectively improved.

Owner:SHANGHAI YINGHUI TECH DEV

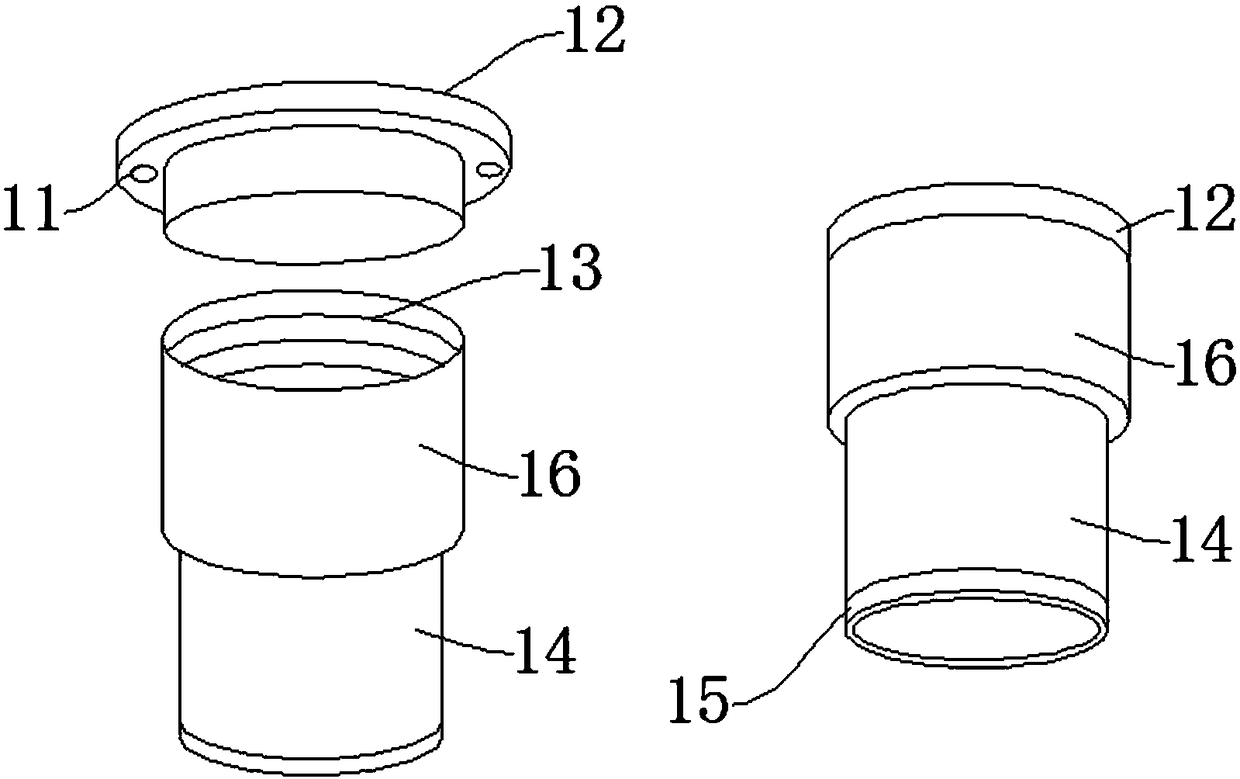

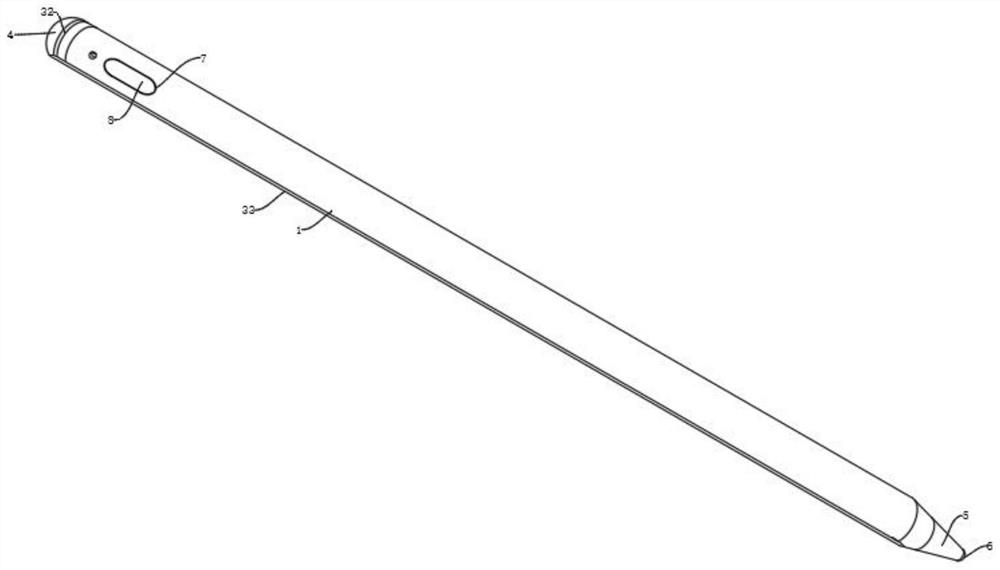

Active capacitance pen

PendingCN113885718AEasy to assembleImprove assembly efficiencyInput/output processes for data processingCapacitanceStructural engineering

The invention discloses an active capacitance pen. The active capacitance pen comprises a pen body, wherein a refill lower cover is placed on an inner wall of the pen body; a refill upper cover is placed on the inner wall of the pen body; one side of the refill lower cover is matched with one side of the refill upper cover; the inner wall of the pen body is matched with an outer wall of the refill upper cover; an outer wall of the refill lower cover is matched with the inner wall of the pen body; one end of the pen body is connected with a pen point in a threaded and sleeved mode; one end of the pen body is provided with a threaded groove; one end of the pen point is fixedly connected with a threaded rod; and an inner wall of the threaded groove is matched with an outer wall of the threaded rod. According to the invention, by inserting a pen tail cap into one end of the pen body, an upper clamping block is clamped into an inner wall of an upper clamping groove, and a lower clamping block is clamped into an inner wall of a lower clamping groove, so that the pen tail cap is assembled; the pen body passes through the pen tail cap, so that the refill upper cover and the refill lower cover are installed and fixed; and assembling is convenient, and the assembling efficiency is effectively improved.

Owner:深圳市凯润科技有限公司

High-speed edge sealing device for KN95 mask

ActiveCN112641160AIncrease powerReduce contact timeProtective garmentClothes making applicancesUltrasonic weldingStructural engineering

The invention relates to the field of mask machines, in particular to a high-speed edge sealing device for a KN95 mask. The high-speed edge sealing device mainly solves the problem of low production efficiency of a KN95 mask machine in the prior art. The device comprises a rack, a support, a knife roll base, a knife roll, two bearing seats and three ultrasonic welding joints, wherein the knife roll base is fixedly arranged on the rack; the two axial ends of the knife roll are arranged on the knife roll base through bearing pedestals respectively; the three ultrasonic welding joints are arranged on the support and distributed on the peripheral side of the knife roll; a transmission device enabling the three ultrasonic welding joints to rotate around the central axis of the knife roll is arranged between the rack and the support; and a calibration device for keeping the three ultrasonic welding joints to realize edge sealing operation on the same mask in sequence is arranged on the rack.

Owner:QUANZHOU HANWEI MACHINERY MFG

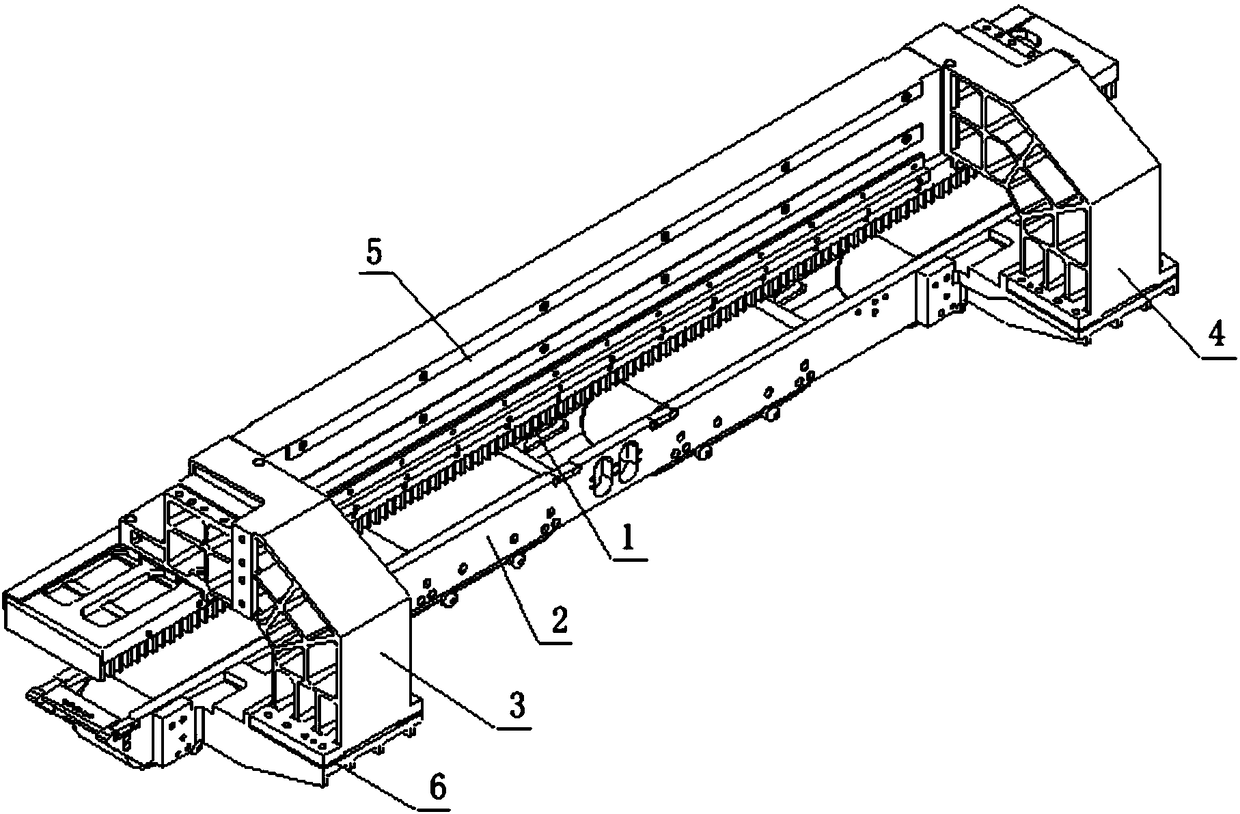

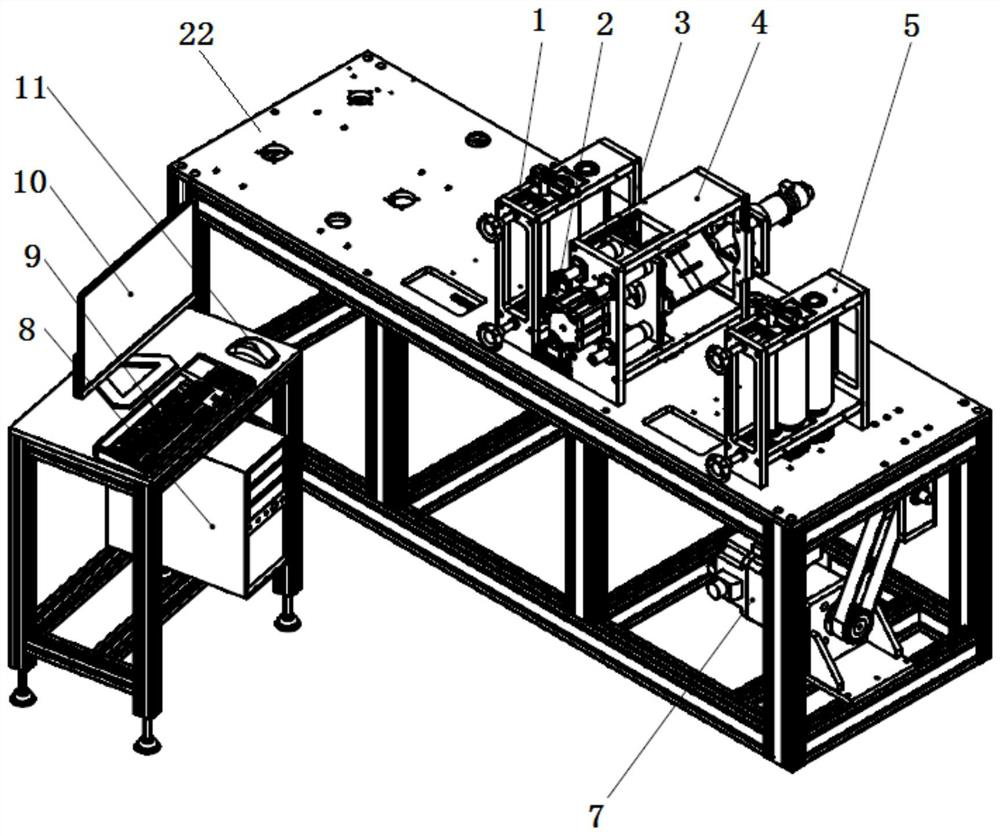

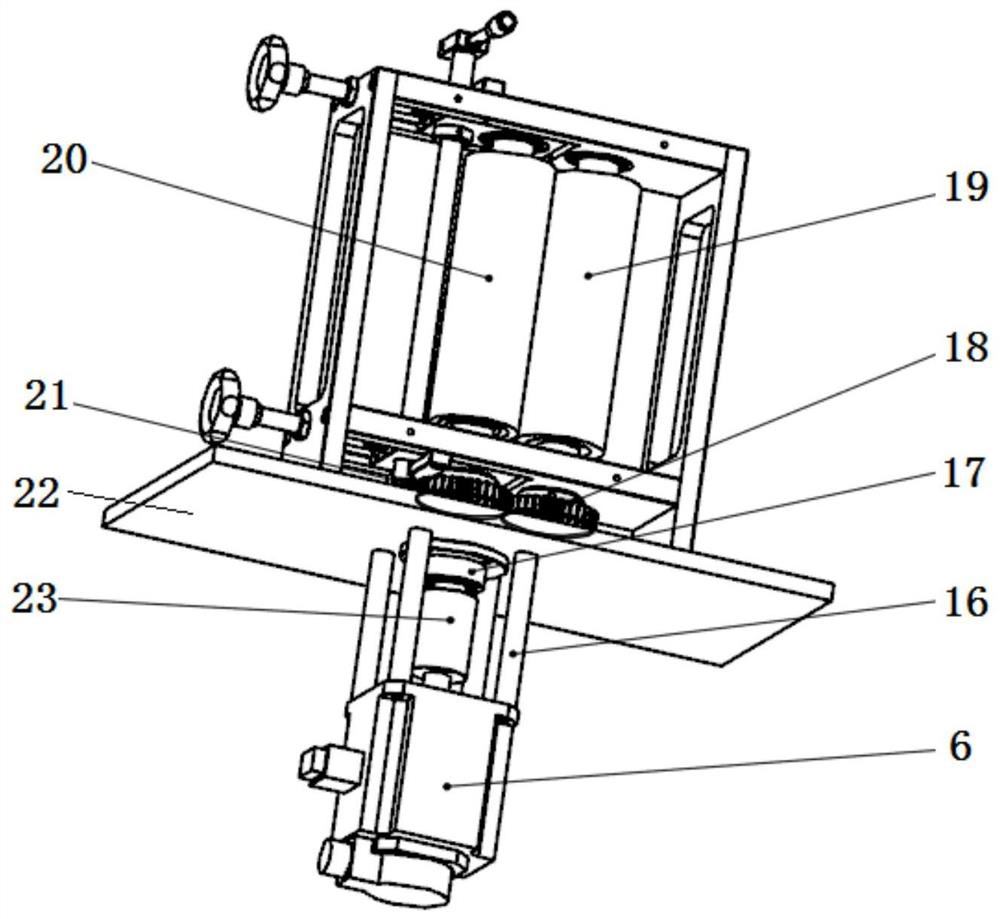

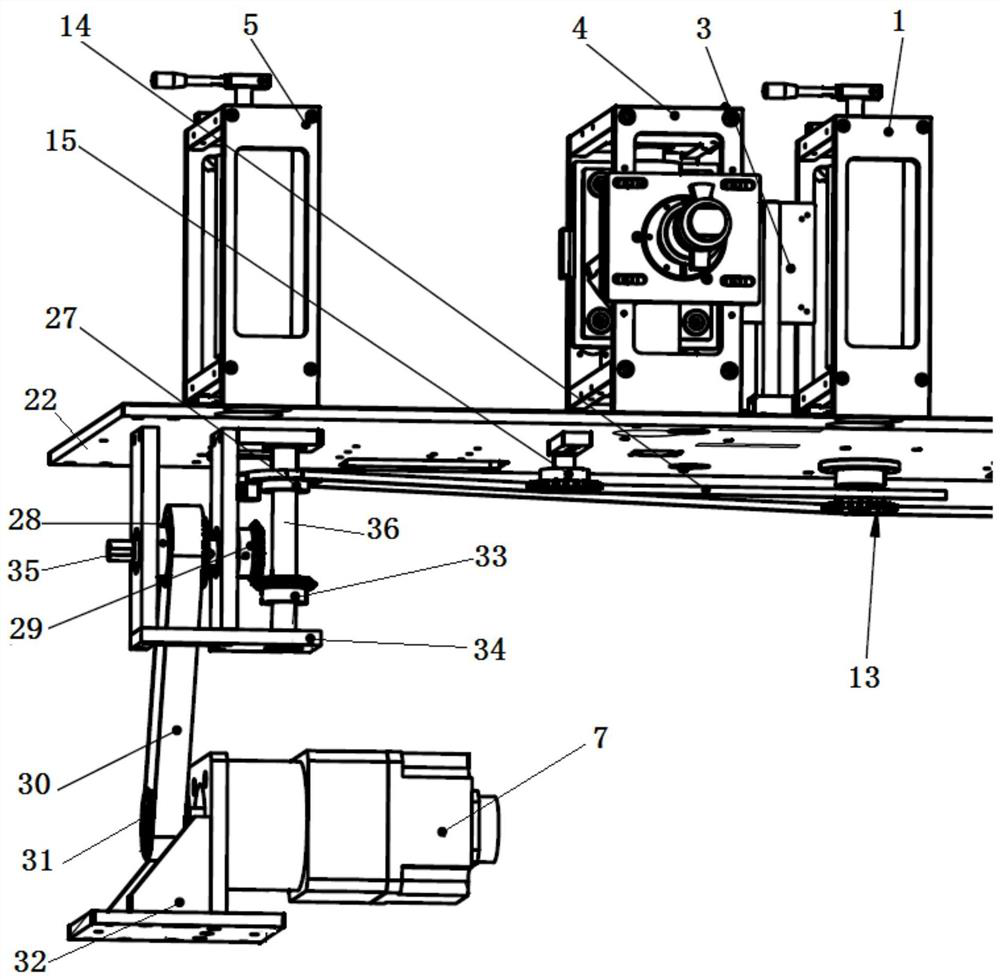

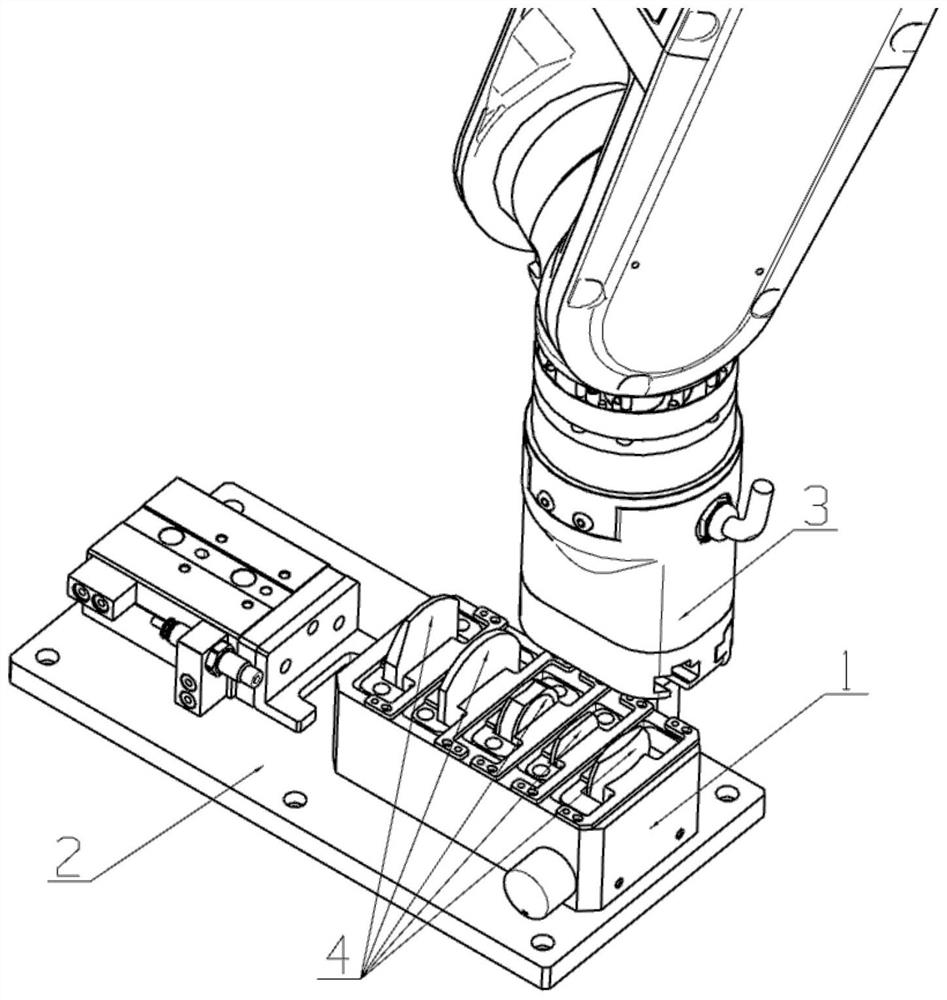

A material reciprocating transfer device and method thereof

ActiveCN103863818BShorten the working cycleGuaranteed location consistencyCharge manipulationConveyor partsEngineeringTransfer mechanism

The invention discloses a material reciprocating transferring device and method. The material reciprocating transferring device comprises a transferring mechanism arranged between the material position of a material device and the machining position of a machining device. The transferring mechanism is movably connected with a downward fetching mechanism. The material reciprocating transferring device further comprises a primary locating mechanism located below the middle section of the transferring mechanism. Materials are fed for the first time and for the second time. When fetched for the first time, the materials move from the material position to the primary locating mechanism. When fetched for the second time, the materials move from the primary locating mechanism to the machining position. The primary locating mechanism is adopted, so that a work piece is roughly located at the material position; due to the locating function of the primary locating mechanism, the materials can be accurately placed at the machining position and can be accurately machined. The transferring mechanism adopts two mechanical arms moving linearly for feeding materials, so that the transferring period of the work piece is greatly shortened, and production efficiency is improved. The material reciprocating transferring device is suitable for the application environment with large distance between the material position and the machining position.

Owner:湖南三兴精密工业股份有限公司

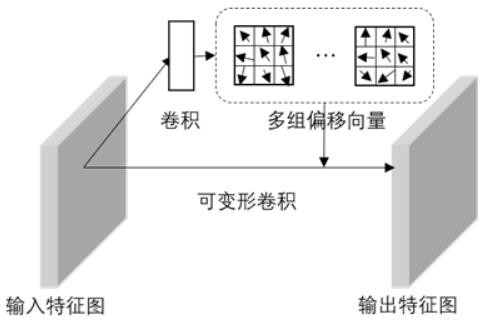

Deformable convolution method and device and storable medium

PendingCN114708468AEnhance expressive abilityMitigating the Risks of FittingCharacter and pattern recognitionNeural architecturesData setAlgorithm

The invention discloses a deformable convolution method and device and a storage medium. The deformable convolution method comprises the following steps of 1, performing conventional convolution on an input feature map to obtain offset vectors of multiple groups of sampling point coordinates; 2, extracting the features of the shifted sampling points from the input feature map for the coordinates of each group of sampling points, and performing weighted summation by using a convolution kernel to obtain the output features of each group; and step 3, averaging the convolution output features of each group to obtain a final output feature. According to the method, through multiple groups of sampling points, the expression capability of deformable convolution is enhanced, the position consistency of channels of convolution input features is ensured, and experiments on a target detection data set COCO prove that the target detection performance is effectively improved.

Owner:NANJING UNIV +1

Fast-assembly zero-point positioning device and method for automatic assembly of optical element

ActiveCN114290268AGuaranteed quick assembly zero point positioningHigh precisionProgramme-controlled manipulatorGripping headsEngineeringMechanical engineering

The invention designs a quick-assembly zero-point positioning device and method for automatic assembly of an optical element for quick tray assembly, zero-point positioning and pickup on-line of the optical element in an automatic optical machine assembly and adjustment process. The technical problems that according to a traditional automatic optical element assembling method, light path shielding is likely to be caused, the high-precision assembling requirement cannot be met, and quality safety risks exist are solved. According to the invention, fast-assembly zero-point positioning in the automatic assembly process of the optical element can be realized without light blocking, with high precision, high consistency, high stability and high safety; the optical elements can be quickly and nondestructively inserted and locked by the part disc, and the position precision of the optical elements on the part disc is ensured; the part disc positioning and opening assembly ensures the consistency of the placement positions of the part discs each time and loosens locking pieces on the part discs; the clamping assembly is used for clamping the part disc and stably clamping the optical element without light blocking.

Owner:中航洛阳光电技术有限公司

Digital card board with positioning compensation function and its measuring method

ActiveCN108344382BStable and reliable relative position relationshipGuaranteed location consistencyUsing optical meansElectricityMeasurement point

The invention provides a digital card board with a positioning compensation function and a measuring method of the digital card board. The digital card board comprises a substrate, a positioning mechanism, displacement sensors, vision sensors and a controller; the substrate straddles the surface of a tested vehicle body through the positioning mechanism; the positioning mechanism is located belowthe substrate and is used for supporting the substrate and defining the relative positions of the substrate and the tested vehicle body; the displacement sensors are mounted inside the substrate, arevertical to a surface where preset measurement points of the tested vehicle body are located, and are used for measuring the preset measurement points of the tested vehicle body; the vision sensors are located at two sides of the substrate and are used for measuring the edges of the two sides of the tested vehicle body; and the controller is installed in the substrate, is electrically connected with the displacement sensors and the vision sensors and is used for receiving and processing data measured by the displacement sensors and the vision sensors. The digital card board of the invention has high positioning precision and high measuring speed. With the digital card board adopted, the contour deviation of the vehicle body can be measured in real time at a production site.

Owner:SHANGHAI JIAOTONG UNIV

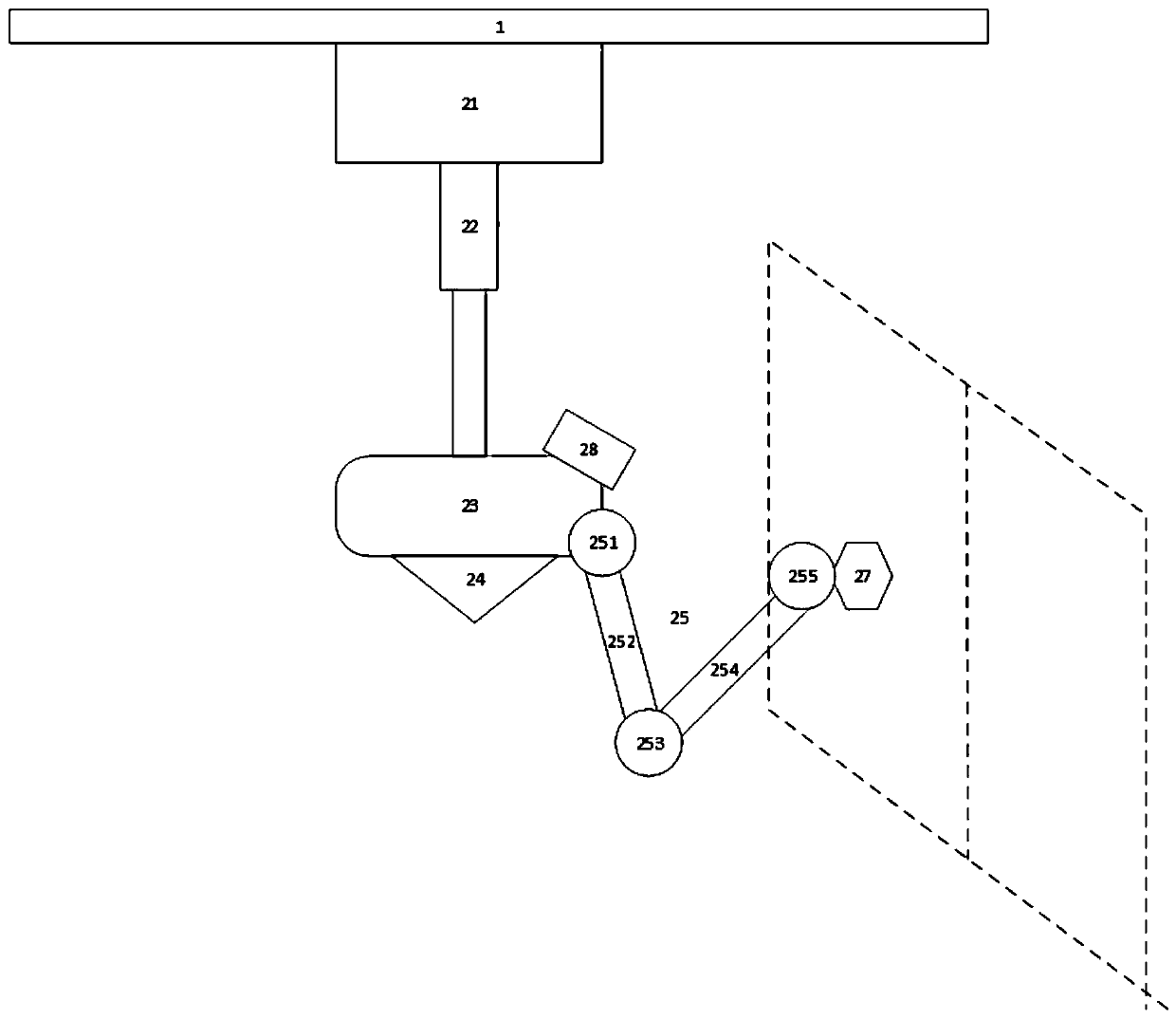

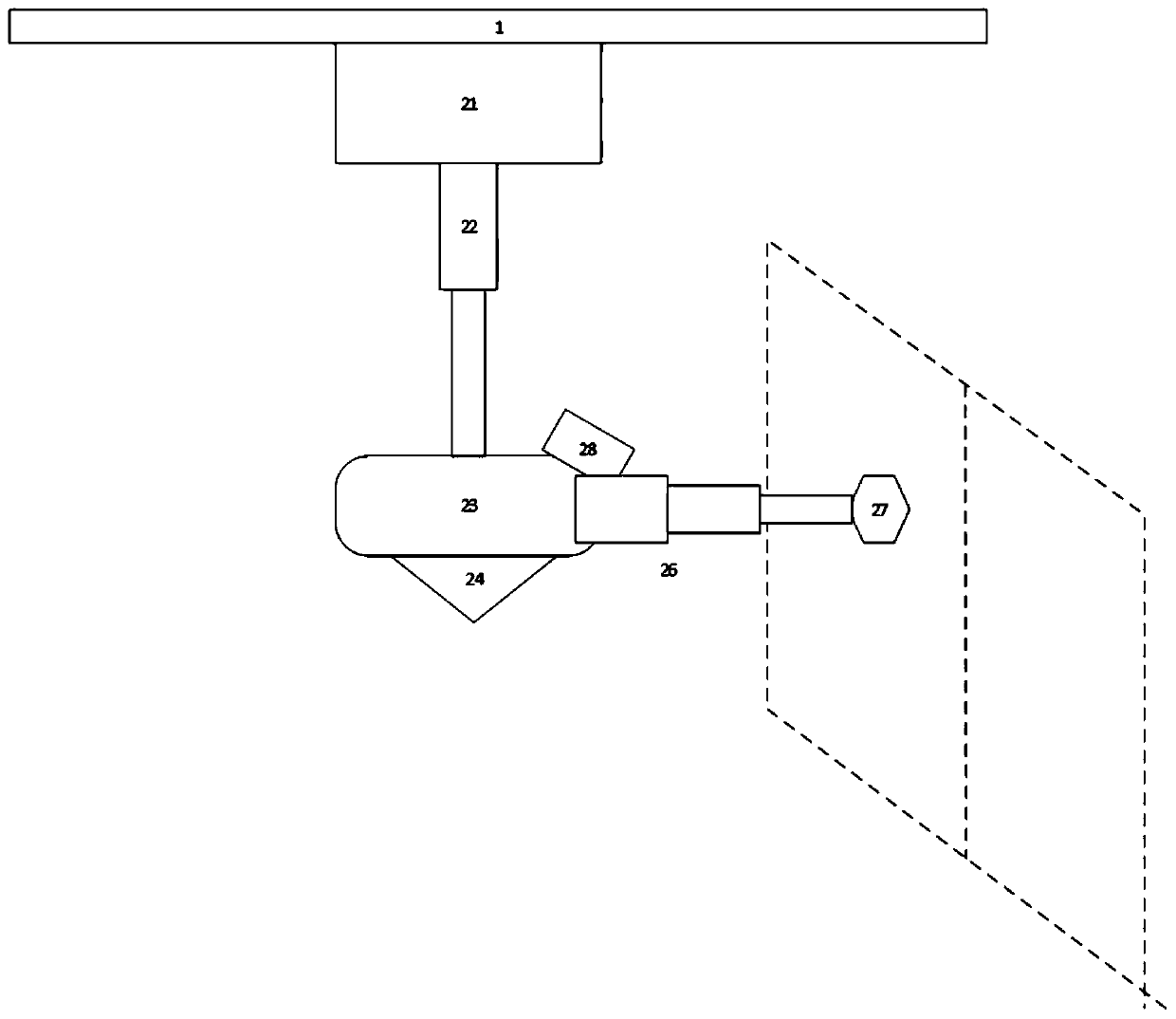

A partial discharge automatic detection device, system and method

ActiveCN107765145BExpand coverageExpand the field of viewTesting using optic methodsSimulationTesting equipment

The invention discloses a partial discharge automatic detection apparatus, system and method. The apparatus comprises a robot body; and an extension module and a control module that are arranged thereon. The robot body comprises a horizontal movement module and a vertical lifting movement module which enable the extension module to move in a horizontal direction and a vertical direction respectively. The extension module performs an action of extending outward relative to the robot body, and drives a detection module disposed at the tail end of the extension module to move according to a control instruction sent by the control module until the detection module is attached to the surface of a detected device. The robot body is provided with an auxiliary positioning module thereon to mark the surface of the detected device, and the control module corrects the movement trajectory of the extension module according to the deviation between the marked point and a target point, so as to realize the automatic detection of the partial discharge of the position of each target point. According to the invention, the problems and defects can be discovered in time and the resulting huge loss canbe avoided.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

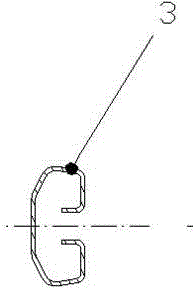

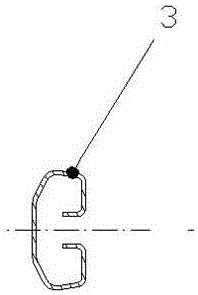

A pressing arm type bending center feeding mechanism

ActiveCN111545660BGuaranteed pressing forceGuaranteed location consistencyMetal-working feeding devicesPositioning devicesStructural engineeringReducer

The invention relates to the technical field of bending equipment, in particular to a pressing arm type bending center feeding mechanism, which includes a C-shaped pressing arm, and two free ends of the C-shaped pressing arm are respectively provided with a swing arm mechanism, a lifting mechanism, a pressure bearing mechanism and a rotating mechanism, a sliding mechanism is set under the C-shaped pressing arm; the swinging arm mechanism is a crank slider mechanism driven by a swing arm servo motor, and the lifting mechanism is connected to the bottom of the crank slider mechanism, and can be fixed on the C-shaped pressing arm along the The lifting slide rail on the arm realizes lifting and moving, and the finale shaft carrier is connected to the vertically arranged finale shaft through the finale shaft bearing; the rotating mechanism is arranged under the pressure-bearing mechanism, and drives the pressure-bearing plate in the pressure-bearing mechanism to rotate. The invention adopts the crank connecting rod structure to realize the compression of the plate, ensures the pressing force of the plate, and improves the accuracy of the pressing position and the moving position; adopts the mutual cooperation of the pressure bearing plate support seat, the first pillar and the second pillar The structure reduces the bearing pressure of the rotary reducer and prolongs the service life of the rotary reducer.

Owner:青岛艾特智能装备有限公司

A method for manufacturing a high-precision tension cable-net unit of a mesh antenna

ActiveCN107986115BEasy to prepareImprove operational consistencyAntenna supports/mountingsWire toolsCable netLinear displacement

A manufacturing method of a high-precision tension cable net unit of a mesh antenna comprises the following steps that firstly, a moving datum (4) on a linear displacement executing mechanism (2) is adjusted to be zero, and the distance between a fixed datum (3) and the moving datum (4) is calibrated through a theodolite test system; secondly, one end of a tension cable is manufactured to be a first fixed ring, and the fixed datum (3) is sleeved with the first fixed ring; thirdly, after the other end of the tension cable is used as a free end and folded in two, the part, folded in two, of thetension cable is sleeved with a compression connection terminal, and a moving ring is manufactured; fourthly, the moving datum (4) obtained in the first step is sleeved with the moving ring obtained in the third step, the free end of the tension cable is wound around a pretension loading device (6), and then tension is applied; fifthly, the linear displacement executing mechanism (2) is controlledto move, after the linear displacement executing mechanism (2) drives the moving datum (4) to move to a preset position, the compression connection terminal in the third step is tightly pressed, anda second fixed ring is manufactured.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

A high-voltage plug-in structure for quick-change battery packs for electric vehicles

ActiveCN104466069BConvenient for frequent replacementGuaranteed lifeCurrent conducting connectionsSmall-sized cells cases/jacketsElectrical batteryElectric vehicle

The invention discloses a high-voltage plug-in structure for a quick-change battery pack of an electric vehicle. . The high-voltage plug-in structure of the quick-change battery pack for electric vehicles invented, when there is a limited position deviation when the high-voltage plug-in contacts with the mating end, the high-voltage plug-in and its mating end are assembled through the guiding function of the guiding fillet of the conductive core to ensure assembly Smooth, in the future quick change, it is convenient to replace the battery frequently and ensure the life of its plug-in, so as to improve the efficiency of quick change, maintain good high-voltage circuit performance, reduce faults and avoid potential safety hazards; moreover, the high-voltage plug-in and adjacent electrical components After the connection, the contact core is still kept in the original free state to ensure position consistency.

Owner:奇瑞新能源汽车股份有限公司

A high-speed edge banding device for kn95 masks

ActiveCN112641160BIncrease powerReduce contact timeProtective garmentClothes making applicancesUltrasonic weldingEngineering

The invention relates to the field of mask machines, in particular to a high-speed edge banding device for KN95 masks, which mainly solves the problem of low production efficiency of KN95 mask machines in the prior art, including a frame, a bracket, a cutter roller base, a cutter roller, two a bearing seat and three ultrasonic welding joints, the base of the cutter roller is fixed on the frame, the axial ends of the cutter roller are respectively arranged on the base of the cutter roller through bearing seats, and the three ultrasonic welding joints are provided on the bracket, and distributed on the peripheral side of the knife roller, a transmission device is provided between the frame and the bracket to make the three ultrasonic welded joints rotate around the central axis of the knife roller, and the frame is provided with a holding A calibration device for three ultrasonic welding joints to perform edge sealing on the same mask in sequence.

Owner:QUANZHOU HANWEI MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com