Fast-assembly zero-point positioning device and method for automatic assembly of optical element

An optical element, zero-point positioning technology, applied in workpiece clamping devices, manipulators, program-controlled manipulators, etc., can solve problems such as quality and safety risks, optical path occlusion, and inability to meet high-precision assembly requirements, and achieve diversified operation methods. Fast and precise positioning, high consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

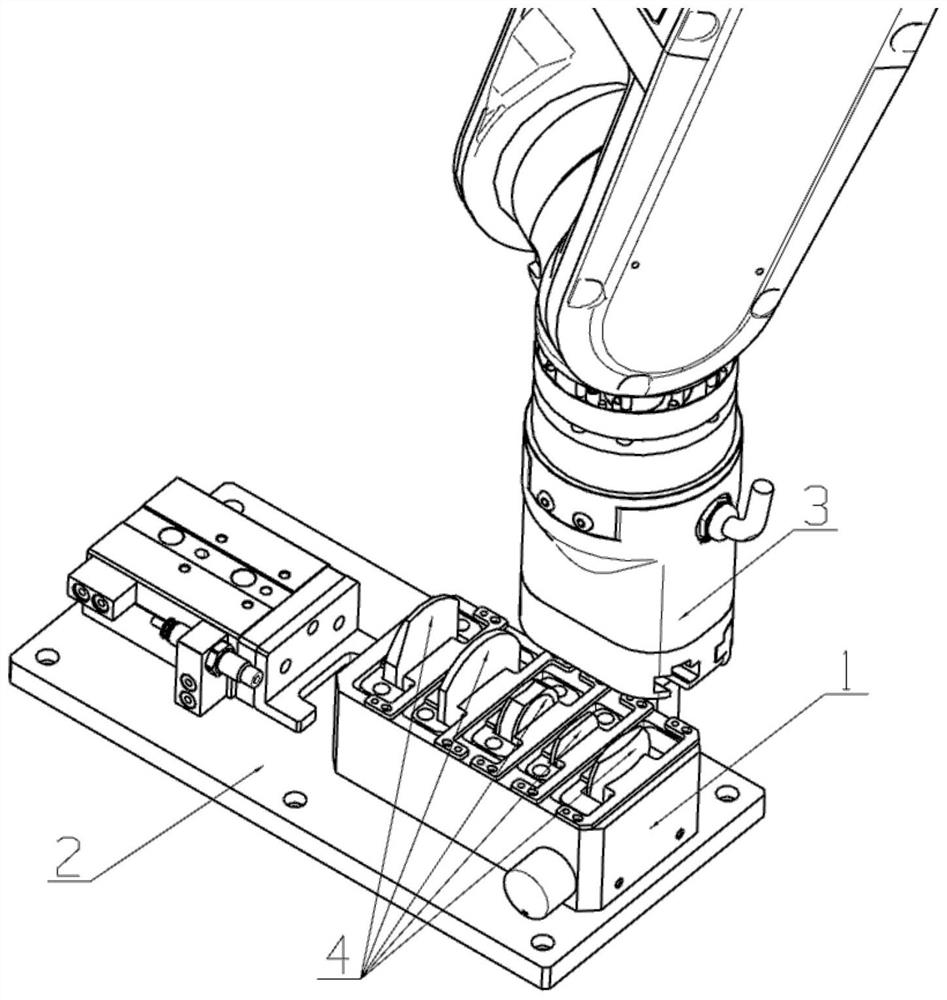

[0065] enter Figure 1-Figure 10 As shown, a quick assembly zero point positioning device for automatic assembly of optical components is characterized in that the device includes a parts tray 1 , a parts tray positioning and opening assembly 2 , and a clamping assembly 3 .

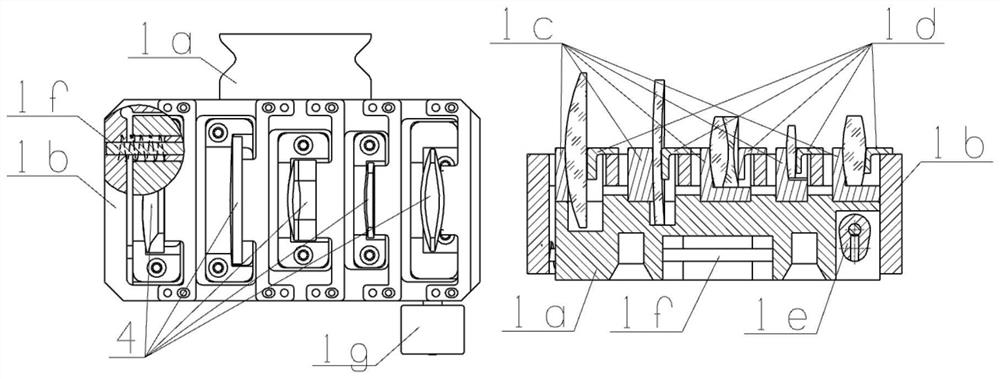

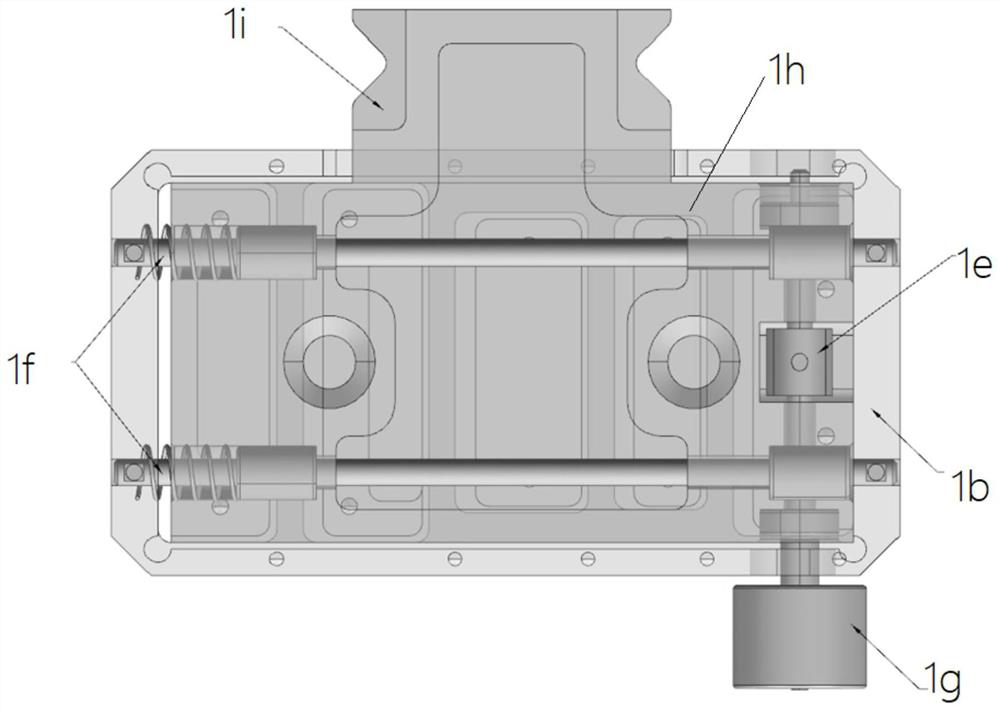

[0066] Parts tray 1 is composed of tray 1a, housing 1b, positioning piece 1c, locking piece 1d, cam 1e, spring slider 1f, and hand wheel 1g; the tray is T-shaped, including tray main body 1h and tray clamping arm 1i. A plurality of slots for placing optical components to be assembled are sequentially provided on the tray main body 1h along the length direction. The contact surface between the positioning piece 1c and the optical element 4 to be assembled is a positioning surface, which is used to ensure the installation position of the optical element 4 to be as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com