Coal mine U-shaped steel support stress-bearing monitoring and early warning device

A force monitoring and early warning device technology, applied in mining devices, mining equipment, shaft equipment, etc., can solve the problems of inaccurate monitoring values and unequal roadway walls, avoid position changes, prevent roadway accidents, and facilitate fixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

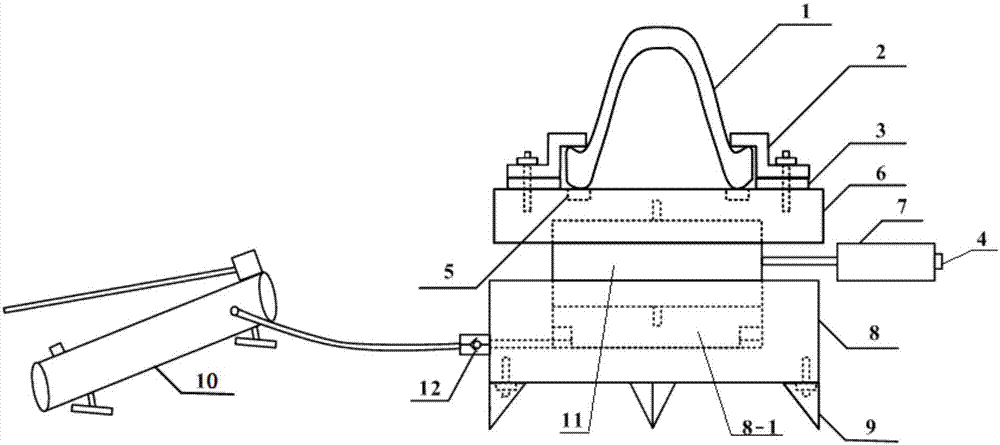

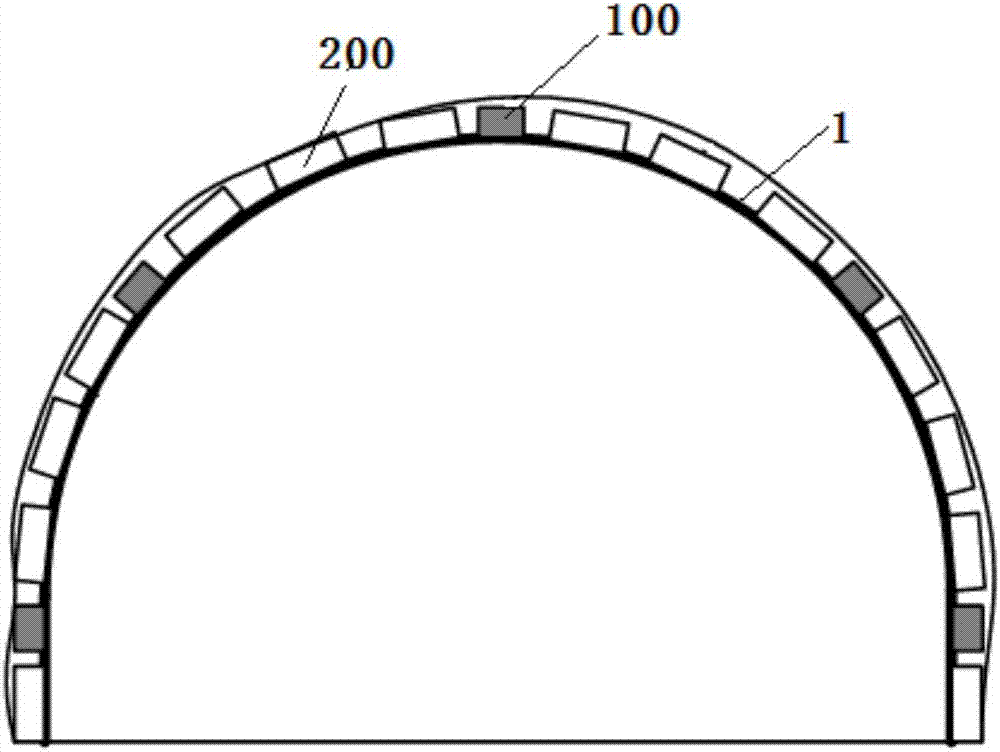

[0018] like figure 1 and figure 2 As shown, the coal mine U-shaped steel support force monitoring and early warning device of this embodiment includes a connecting device and a monitoring device. The connecting device includes a base 6, a Z-shaped presser foot piece 2 and a magnet 5, and the support foot of the U-shaped steel support 1 passes through The Z-type presser foot piece 2 is installed on the base 6, and is attracted with the magnet 5 arranged in the base 6; the Z-type presser foot piece 2 is connected with the base 6 by bolts; the monitoring device includes a pressure sensor 11, Processor 7 and sound and light alarm 4, one side of the pressure sensor 11 is embedded in the base 6, and is electrically connected to the processor 7; the processor 7 receives and displays the data transmitted by the pressure sensor 11 and measures The data is compared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com