Saw blade edging equipment for metal cutter machining

A technology for cutting tools and saw blades, which is applied in the field of saw blade cutting equipment for metal cutting tool processing, can solve the problem of low efficiency of manual grinding, and achieve the effect of saving manpower and preventing rust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

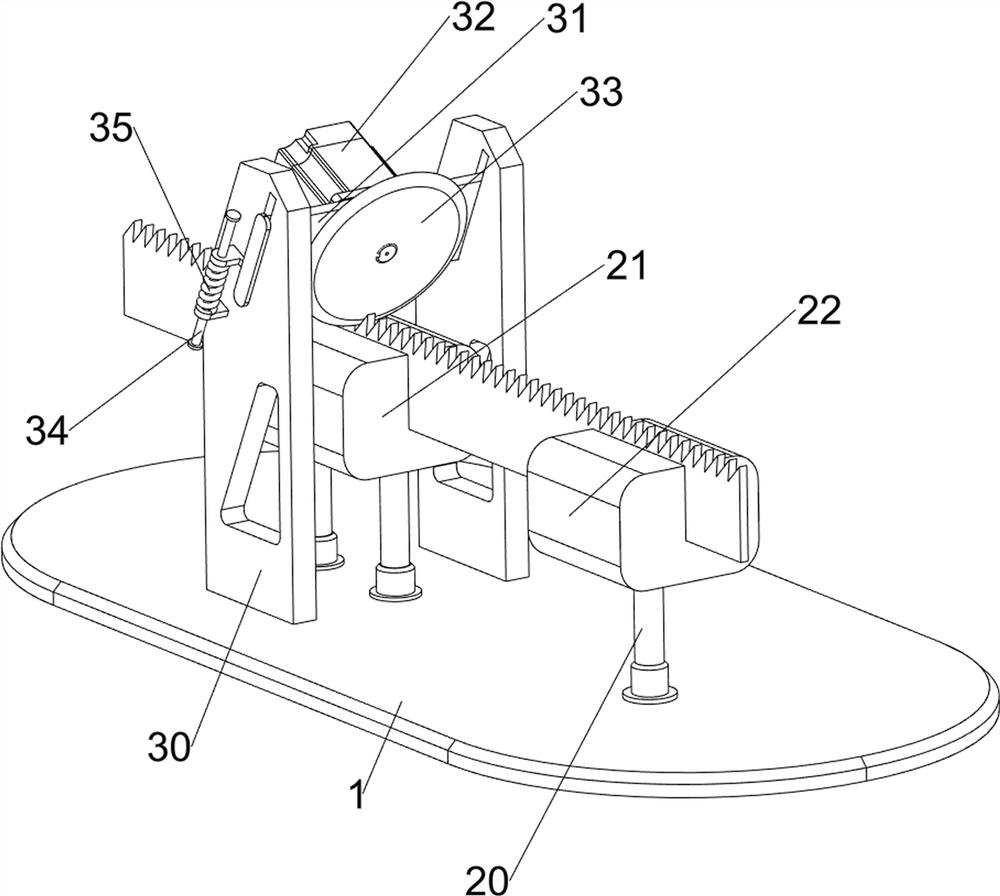

[0059] A saw blade sharpening device for metal tool processing, such as figure 1 As shown, it includes a bottom plate 1 , a fixing mechanism 2 and a cutting mechanism 3 , the top of the bottom plate 1 is provided with a fixing mechanism 2 , and the left side of the top of the bottom plate 1 is provided with a cutting mechanism 3 .

[0060] Such as figure 2 As shown, the sharpening mechanism 3 includes a first mounting plate 30, a slide plate 31, a first motor 32, a grinding wheel 33, a limit rod 34 and a first spring member 35, and the left side of the top of the base plate 1 is symmetrically provided with the first mounting plate 30, a slide plate 31 is slidably connected between the first mounting plates 30, a first motor 32 is provided on the slide plate 31, a grinding wheel 33 is connected to the output shaft of the first motor 32, and limit rods are slidingly provided on the outside of the first mounting plate 30 34 , the sliding plate 31 is connected to the limit rod 3...

Embodiment 2

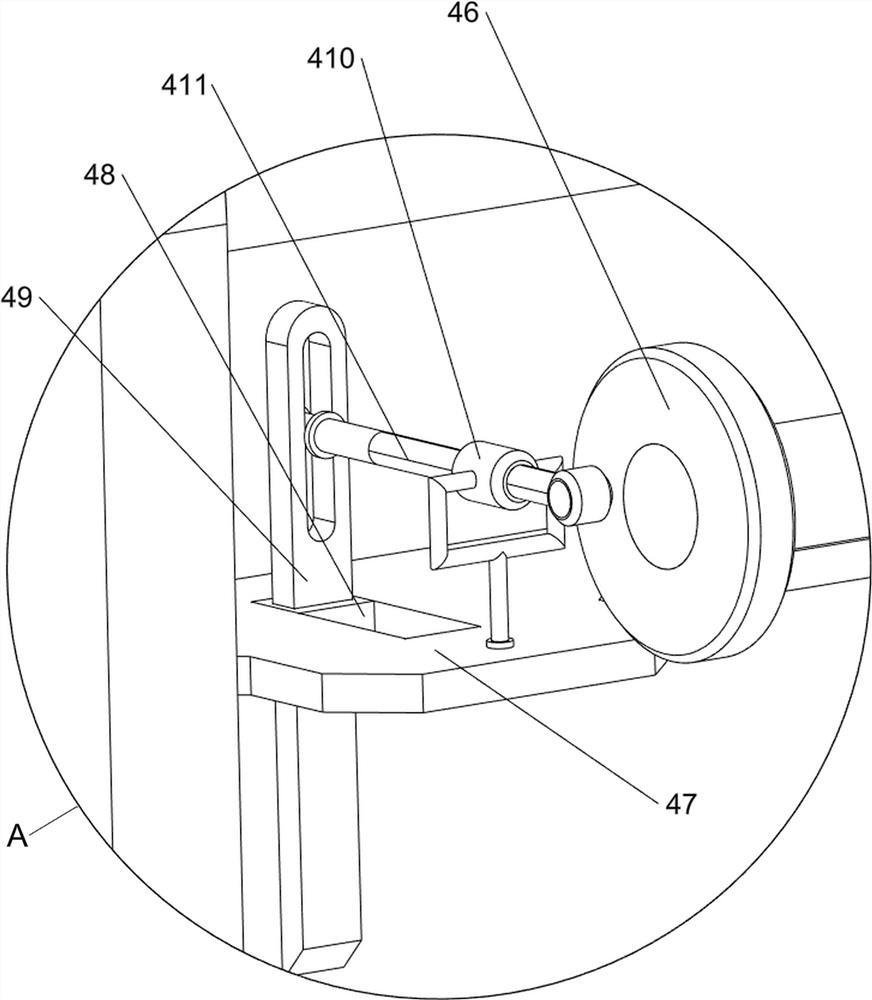

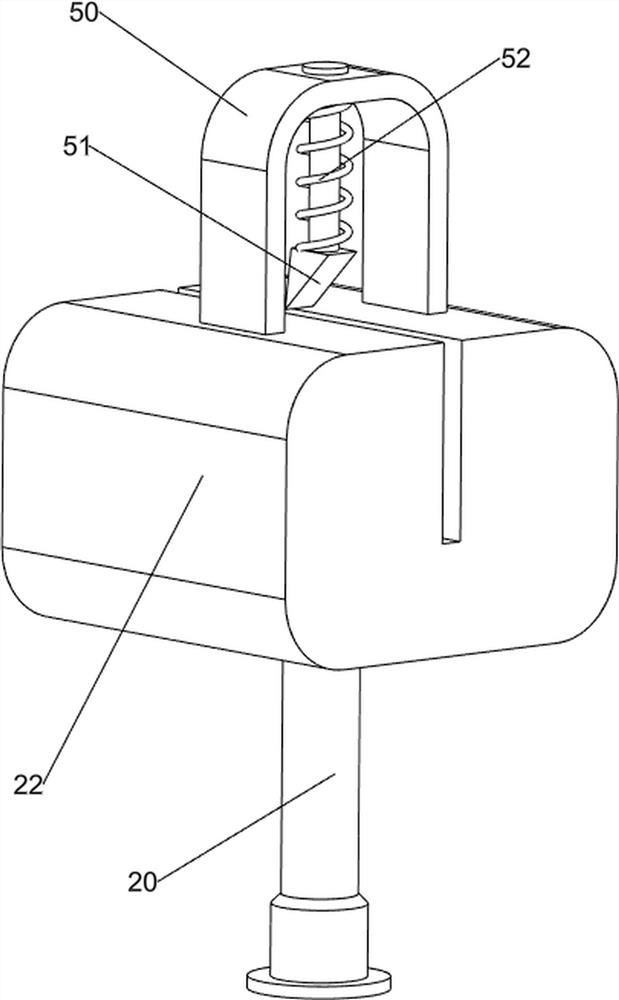

[0064]On the basis of Example 1, such as image 3 and Figure 4 As shown, a propulsion mechanism 4 is also included, and the propulsion mechanism 4 includes a second mounting plate 40, a second motor 41, a rotating shaft 42, a pulley set 43, a turret 44, a cam 45, a runner 46, a third mounting plate 47, Slider 48, first push rod 49, fixed frame 410 and second push rod 411, base plate 1 top right rear side are provided with second motor 41, base plate 1 top right side is provided with second mounting plate 40 symmetrically front and rear, rear side The second mounting plate 40 is rotatably provided with a rotating shaft 42, and a pulley group 43 is connected between the rotating shaft 42 and the output shaft of the second motor 41, and a turret 44 is rotationally connected between the second mounting plate 40, and the rear side of the rotating shaft 42 is arranged There is a cam 45, the turret 44 cooperates with the cam 45 and the limit rod 34, the front side of the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com