Positioning system for spliced wooden door production

A positioning system and wooden door technology, applied in the direction of wood processing appliances, manufacturing tools, etc., can solve problems such as time-consuming and labor-intensive, and achieve the effect of ensuring processing efficiency and efficient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

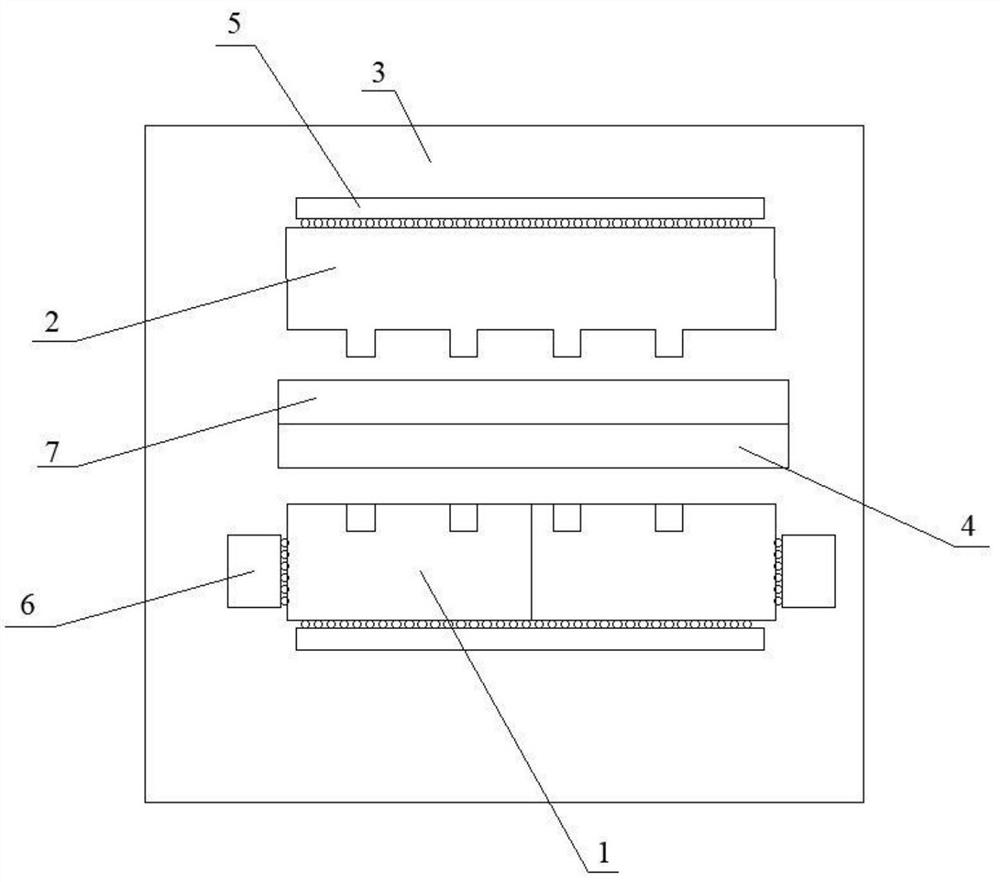

[0021] Please also refer to Figure 1-Figure 2 , this embodiment provides a positioning system for the production of assembled wooden doors. The positioning system for the production of assembled wooden doors is mainly used to solve the problem of time-consuming and labor-consuming manual assembly in the prior art. This system is already in the stage of actual use.

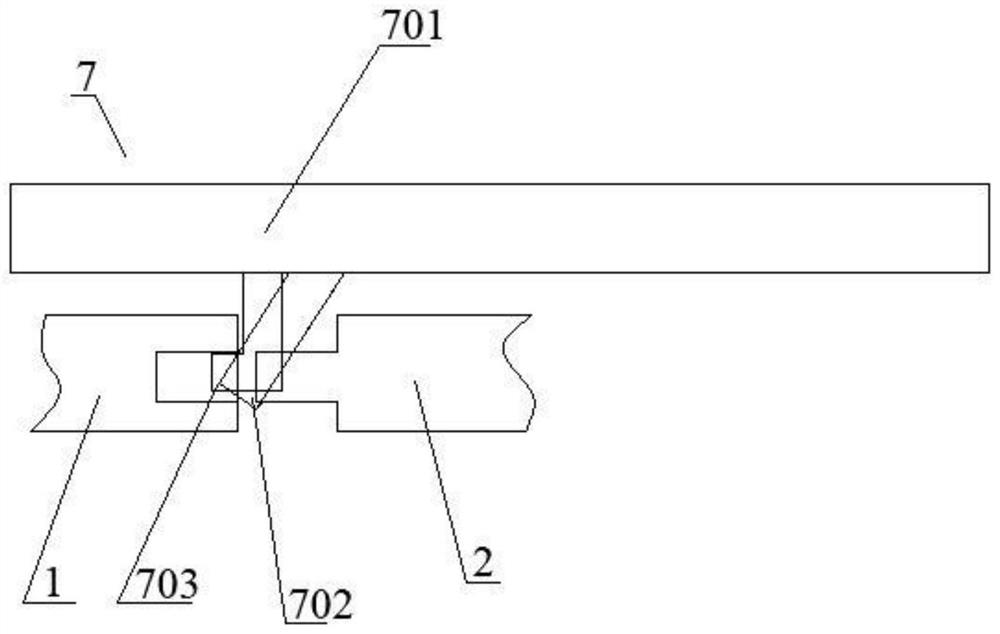

[0022] This application provides a positioning system for the production of assembled wooden doors. The system includes workpieces to be spliced, a placing table 3, a gluing assembly 4, a clamping assembly, and a positioning assembly 7. The workpieces to be spliced include a perforated wooden board 1 and a combined wooden board 2. There are splicing blocks on the splicing wooden board 2, and mounting holes corresponding to the splicing blocks are opened on the perforated wooden board 1, the workpieces to be spliced are placed on the placement table 3, and the clamping assembly is located on the Referring to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com