Inert gas protection platform for micro forging and rolling composite additive manufacturing system

An inert gas and additive manufacturing technology, applied in the field of additive manufacturing, can solve problems such as the ability to isolate air, improve production efficiency and production quality, meet the needs of production and use, and prevent oxidative denaturation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

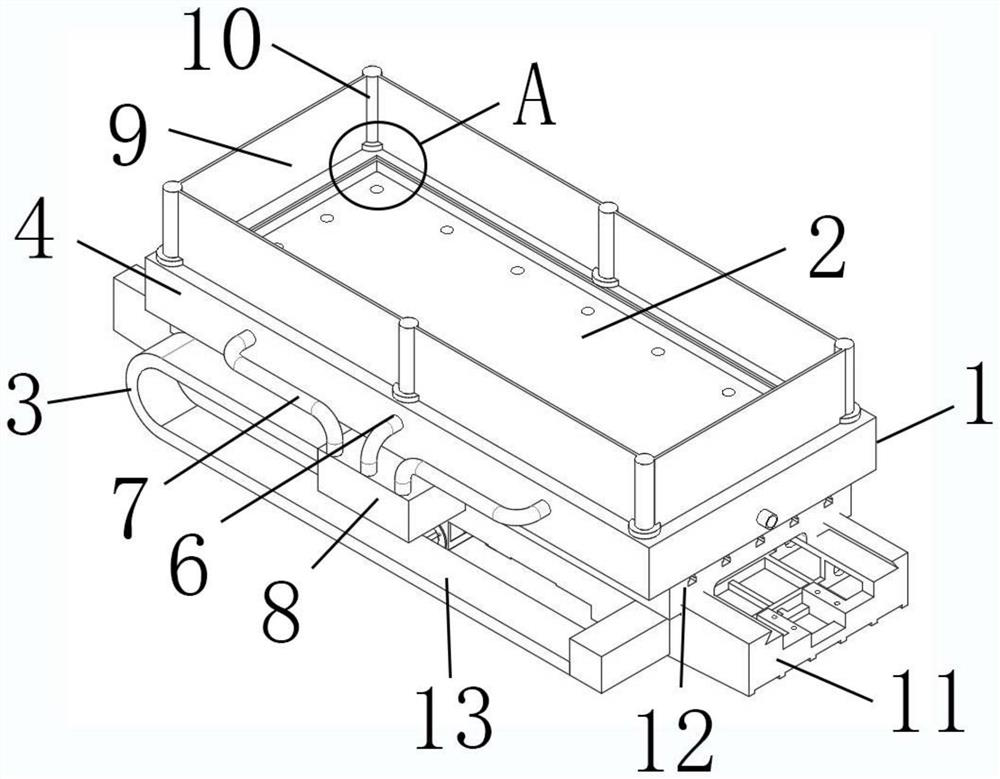

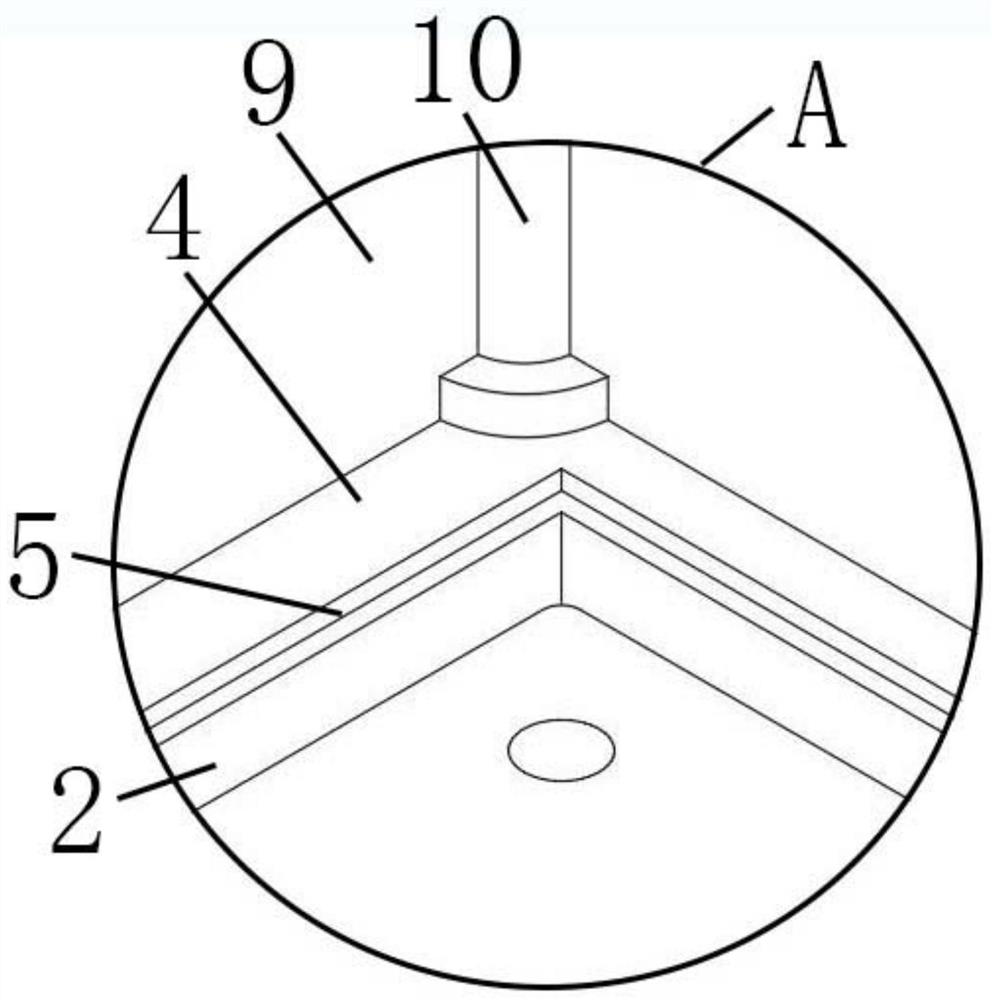

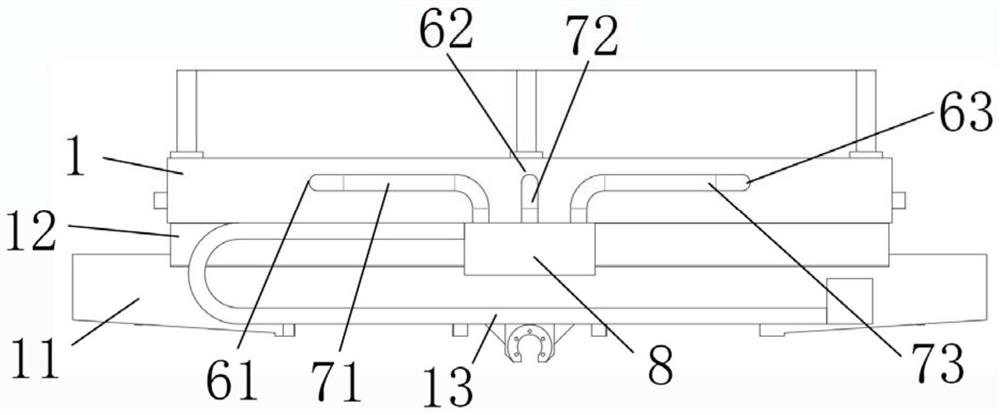

[0045] Such as Figure 1-Figure 3 As shown, an inert gas protection platform for a micro-forging composite additive manufacturing system includes a platform as a whole 1, and the platform as a whole includes a printing substrate 2, a gas transmission device and a heating substrate 3 located below the printing substrate, An integrated frame 4 is provided on the periphery of the printing substrate and the heating substrate, and an annular air outlet groove 5 is provided between the integrated frame and the printing substrate, and between the integrated frame and the heating substrate. One side of the integrated frame is provided with several inert gas inlets 6 communicating with the annular gas outlet groove, and the gas transmission device and each inert gas inlet are connected through gas distribution pipes 7 .

[0046] Further, gaps are provided between the integrated frame and each side of the printing substrate, and between the integrated frame and each side of the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com