Method for extracting hydroxytyrosol from olive fruits

A technology of hydroxytyrosol and olive fruit, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of cumbersome extraction process and low extraction efficiency of hydroxytyrosol, and prevent oxidative denaturation and reduce production costs. The effect of low cost, simple method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

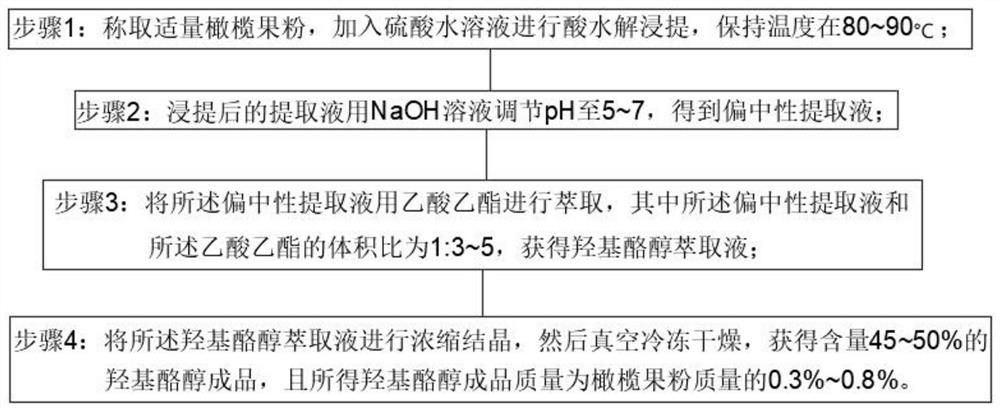

[0030] Step 1: Select clean and undamaged olive fruit raw materials for depitting, crushing, and drying to obtain olive fruit powder. Weigh 10 kg of olive fruit powder, add 30 L of sulfuric acid aqueous solution with a concentration of 0.6 mol / L for acid hydrolysis and extraction, and keep the temperature at 80 °C, while leaching, a stirrer is used to continuously stir to improve the leaching efficiency.

[0031] Step 2: The pH of the leached extract is adjusted to 5 with 1 mol / L NaOH solution to obtain a neutral extract.

[0032] Step 3: Extract the partial neutral extract with ethyl acetate for 3 times, wherein the volume ratio of the partial neutral extract to the ethyl acetate is 1:3 to obtain the hydroxytyrosol extract.

[0033] Step 4: Concentrate and crystallize the hydroxytyrosol extract, then vacuum freeze-dry at -25°C for 24 hours to obtain a finished product with a content of 45% hydroxytyrosol, and the quality of the finished product is 0.3% of the mass of the oliv...

Embodiment 2

[0035] Step 1: Select clean and undamaged olive fruit raw materials for depitting, crushing, and drying to obtain olive fruit powder. Weigh 10 kg of olive fruit powder, add 33 L of sulfuric acid aqueous solution with a concentration of 0.5 mol / L for acid hydrolysis and extraction, and keep the temperature at 83 °C, while leaching, a stirrer is used to continuously stir to improve the leaching efficiency.

[0036] Step 2: The pH of the extracted extract after leaching is adjusted to 6 with 1 mol / L NaOH solution to obtain a neutral extract.

[0037] Step 3: Extract the partial neutral extract with ethyl acetate for 3 times, wherein the volume ratio of the partial neutral extract to the ethyl acetate is 1:4 to obtain the hydroxytyrosol extract.

[0038] Step 4: Concentrate and crystallize the hydroxytyrosol extract, and then vacuum freeze-dry at -25°C for 30 hours to obtain a finished product of hydroxytyrosol with a content of 47%, and the quality of the finished product of hydr...

Embodiment 3

[0040] Step 1: Select clean and undamaged olive fruit raw materials for depitting, crushing, and drying to obtain olive fruit powder. Weigh 10 kg of olive fruit powder, add 37 L of sulfuric acid aqueous solution with a concentration of 0.4 mol / L for acid hydrolysis and extraction, and keep the temperature at 87 °C, while leaching, a stirrer is used to continuously stir to improve the leaching efficiency.

[0041] Step 2: The pH of the extracted extract after leaching is adjusted to 7 with 1 mol / L NaOH solution to obtain a neutral extract.

[0042] Step 3: extracting the neutral extract with ethyl acetate for 4 times, wherein the volume ratio of the partial neutral extract to the ethyl acetate is 1:4 to obtain a hydroxytyrosol extract.

[0043] Step 4: Concentrate and crystallize the hydroxytyrosol extract, and then vacuum freeze-dry at -25°C for 36 hours to obtain a finished product of hydroxytyrosol with a content of 48%, and the quality of the finished product of hydroxytyro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com