3D printing powder transfer device, 3D printer and using method

A 3D printing and transfer device technology, applied in the field of additive manufacturing, can solve the problems of poor powder blowing effect, small blowing range, and unable to blow powder, etc., to achieve good blowing effect, simple structure, and anti-oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

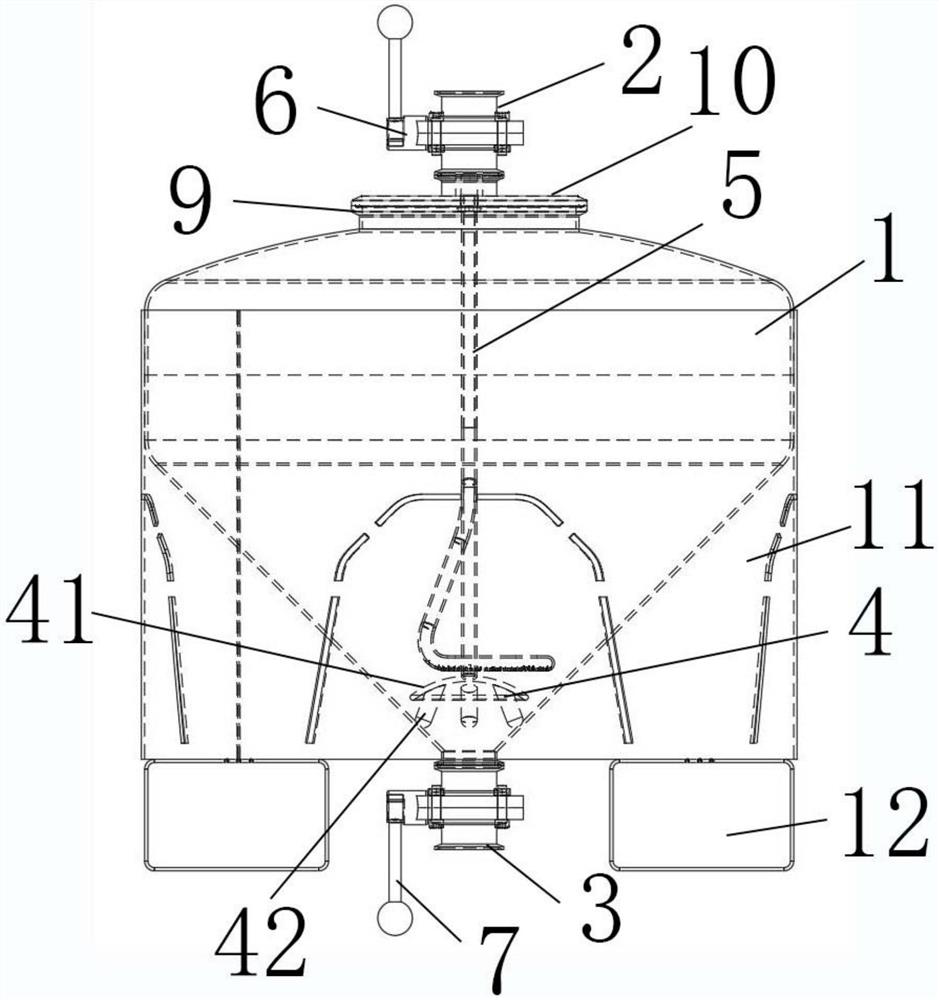

[0047] Such as Figure 1-Figure 3 As shown, an anti-oxidation and anti-blocking 3D printing powder transfer device, including

[0048] The powder storage bin 1 is used to store 3D printing powder, the top of the powder storage bin is provided with a powder inlet 2, and the bottom end is provided with a powder outlet 3, and the 3D printing powder in the powder storage bin flows from the powder inlet to the powder outlet ;

[0049] Buffer device 4, the buffer device is located at the bottom inside the powder storage bin;

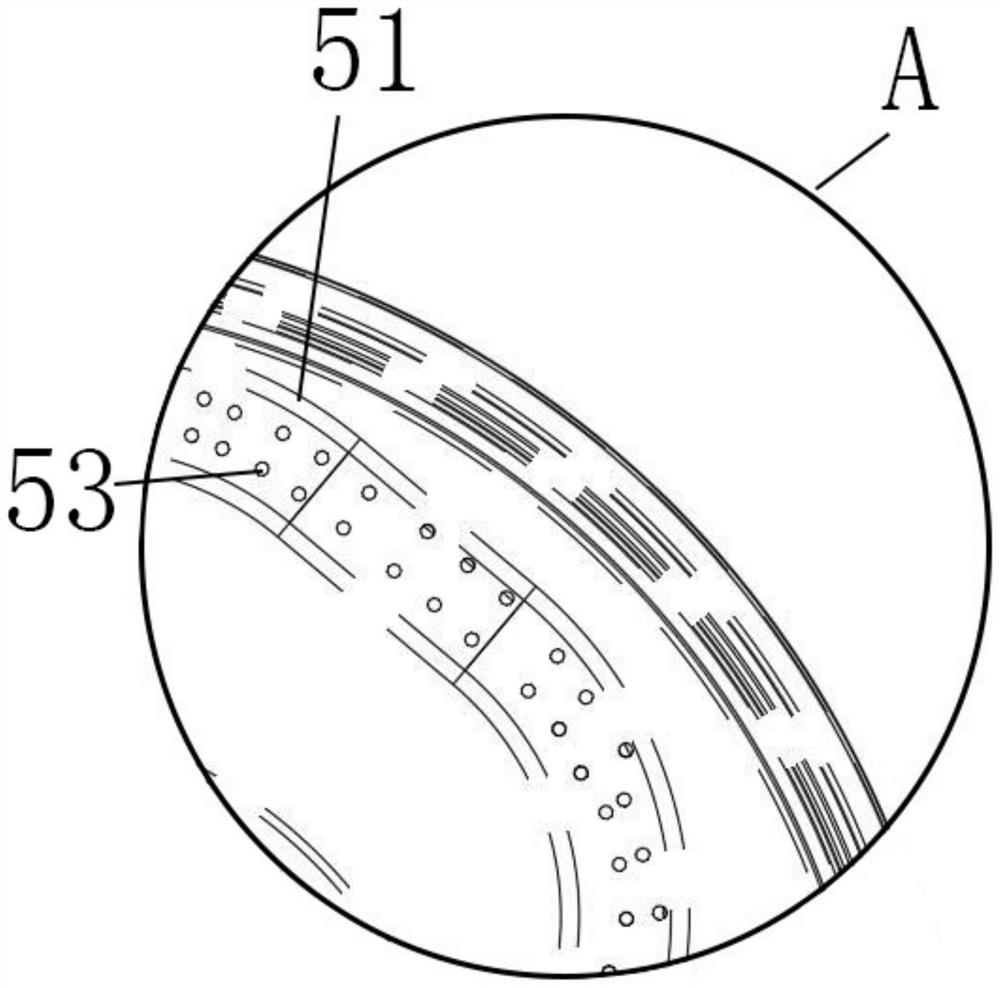

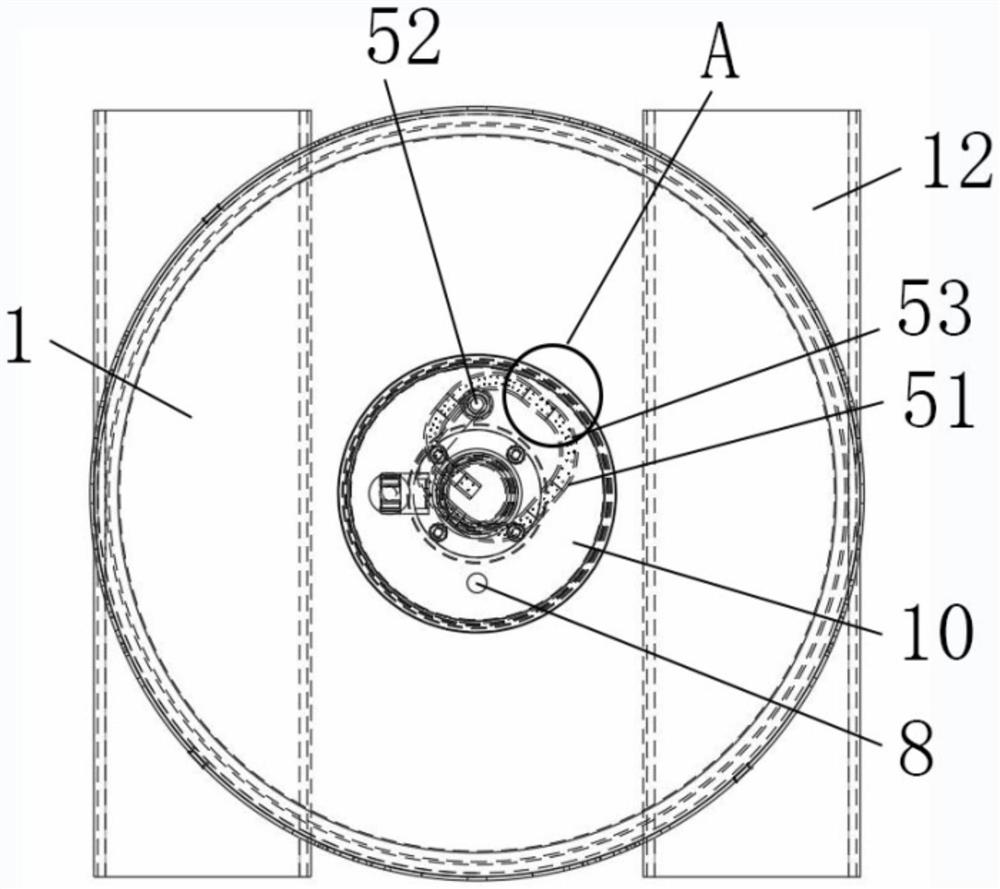

[0050] Gas inlet device 5; the gas inlet device is located inside the powder storage bin and one end is connected to the top of the powder storage bin, and the other end extends into the bottom of the powder storage bin and is located above the buffer device; the gas inlet The device is used to feed inert gas into the powder storage bin.

[0051] Further, the width of the powder storage bin gradually decreases from the end close to the powder inlet along th...

Embodiment 2

[0071] This embodiment is carried out on the basis of the first embodiment above, and the similarities with the above embodiment will not be repeated.

[0072] This embodiment mainly introduces an anti-oxidation and anti-clogging 3D printer compatible with Embodiment 1, including: a feeding device, a powder spreading device, and the anti-oxidation and anti-blocking 3D printing powder transfer device described in Embodiment 1. The powder inlet of the anti-oxidation and anti-blocking 3D printing powder transfer device is connected to the powder outlet of the feeding device, and the powder outlet of the anti-oxidation and anti-blocking 3D printing powder transfer device is connected to the powder spreading device. The powder inlet is connected.

[0073] Preferably, an inert gas supply device is included, and the inert gas supply device is connected to the inert gas inlet through a pipeline.

[0074] The method for using the 3D printer described in this embodiment includes the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com