Automatic tool setting device for numerical control external thread grinder

A technology of automatic tool setting and external thread, which is applied in the direction of automatic control devices, feeding devices, metal processing machinery parts, etc., can solve the problems of poor consistency in the position accuracy and size accuracy of the processed workpiece, is cumbersome, and is not conducive to labor protection. Consistency, improved accuracy and efficiency, beneficial to the effect of safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] An embodiment is described below in conjunction with the accompanying drawings to further illustrate the present invention.

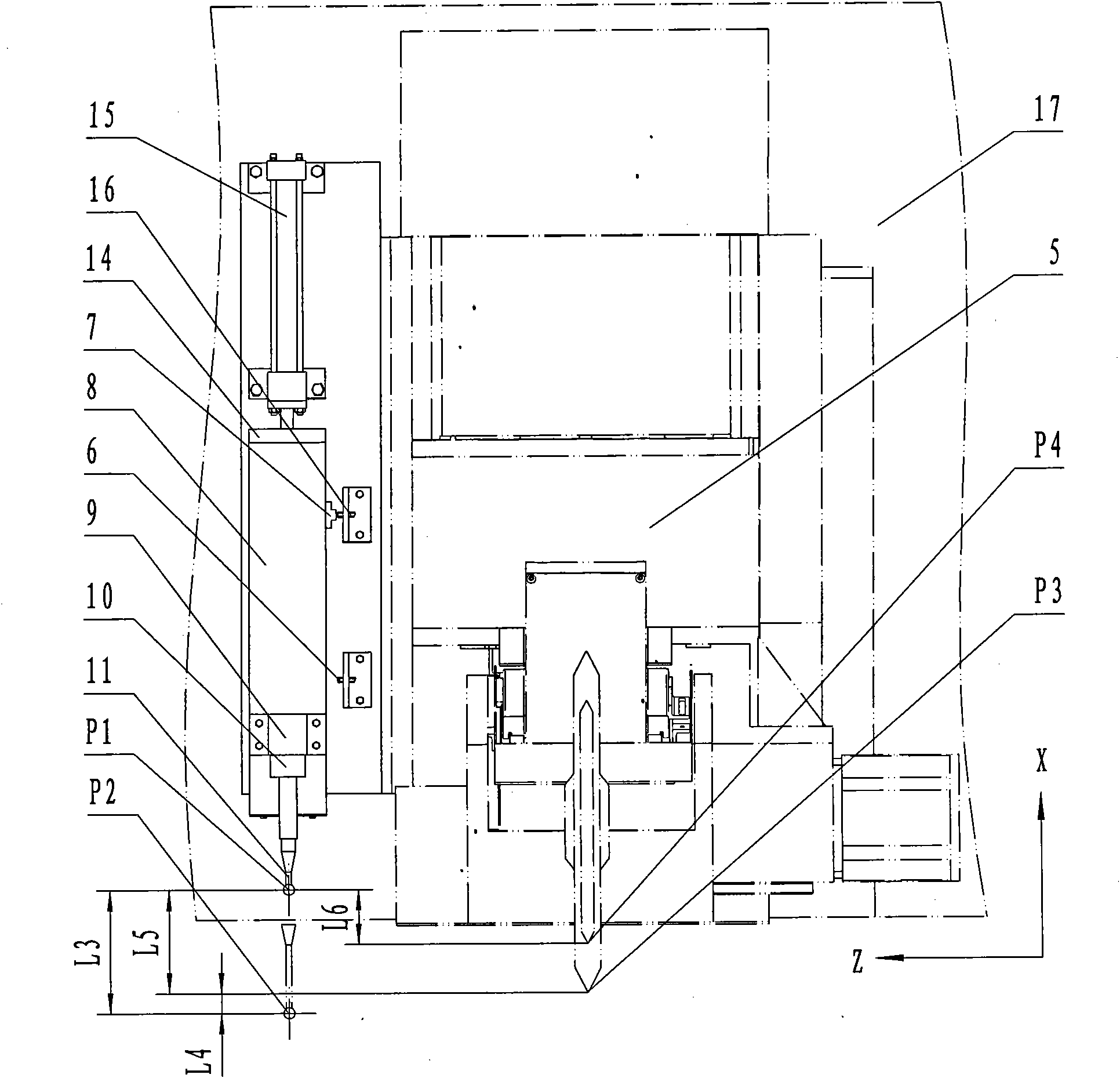

[0036] Example: Automatic tool setting device for SK7450×100 large-scale CNC thread grinder, SK7450×100 processing screw length 10m, grinding diameter Φ60~Φ200mm

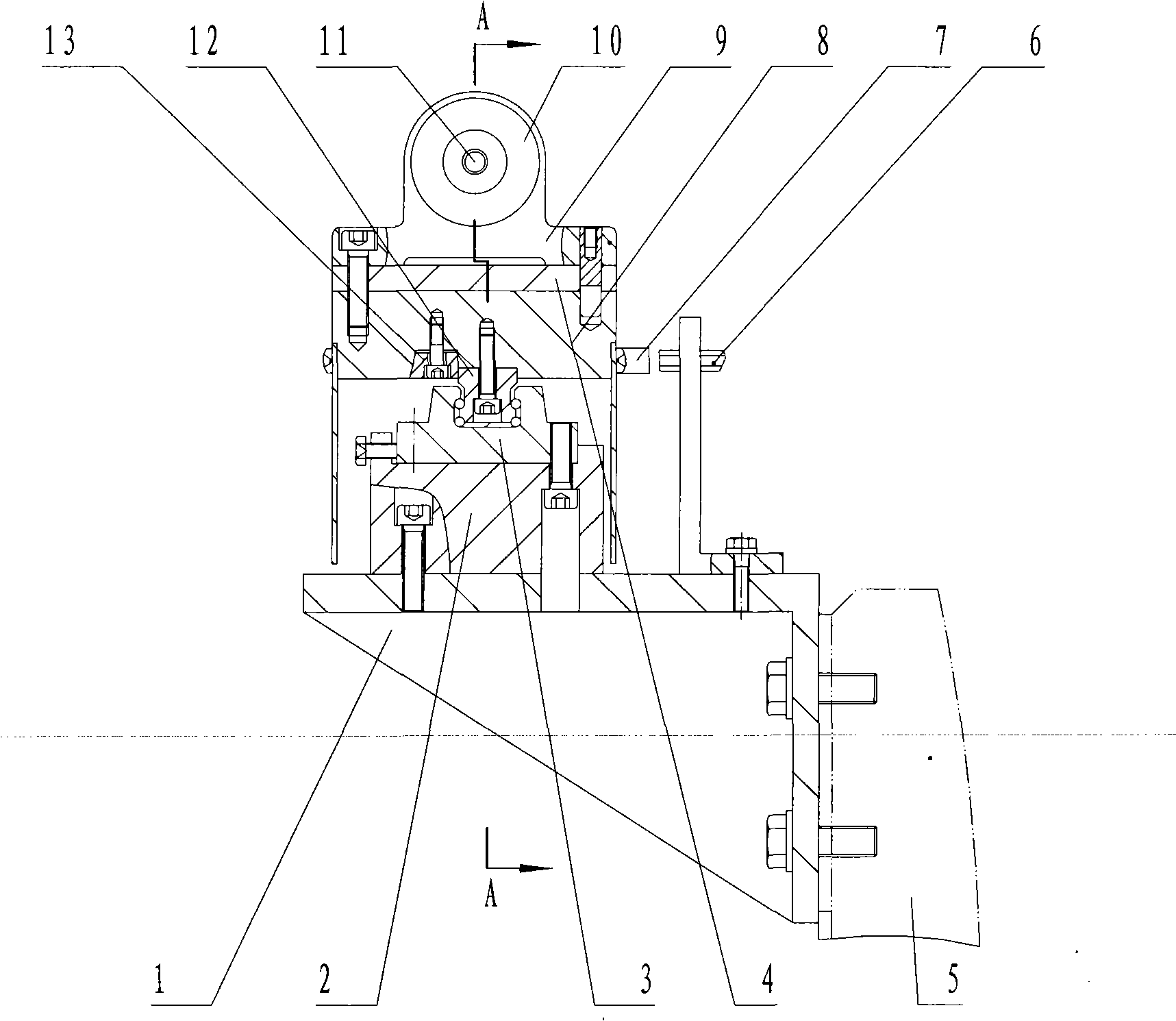

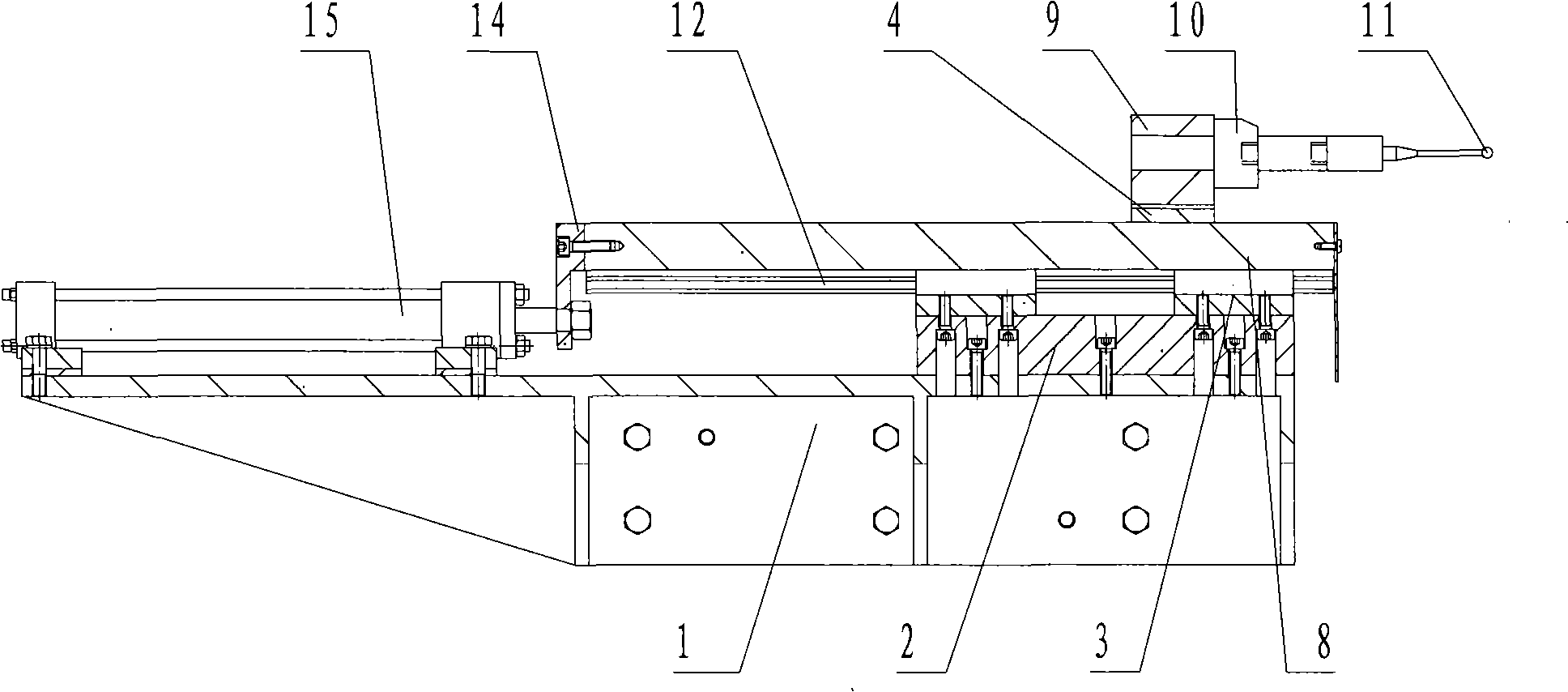

[0037] like figure 1 , figure 2 , image 3The automatic tool setting device of the CNC external thread grinder shown in this embodiment includes the CNC system of the machine tool, the lateral movement mechanism of the grinding wheel frame (X-axis digitally controlled movement mechanism), and the carriage longitudinal movement mechanism (Z-axis digitally controlled movement mechanism). The carriage 17 that moves in the Z coordinate direction is installed on the longitudinal guide rail at the rear of the machine tool, and the grinding wheel frame 5 that moves in the X coordinate direction is installed on the lateral guide rail of the carriage 17 . The functions of the numerical cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com