Patents

Literature

33results about How to "Continuous and efficient processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

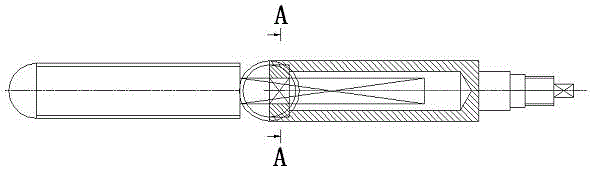

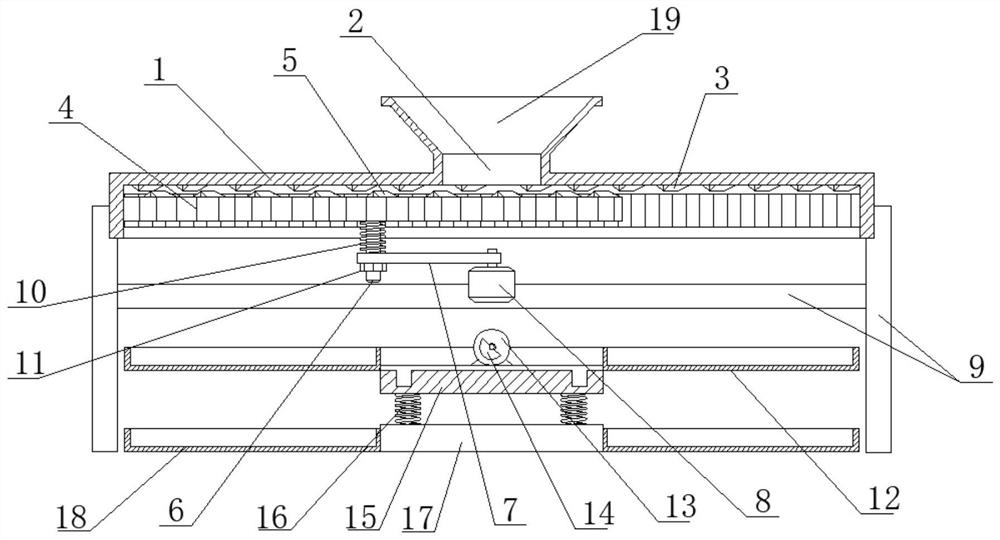

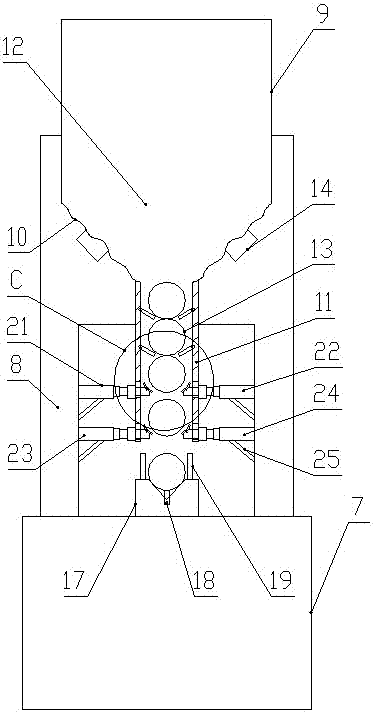

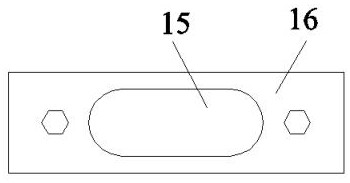

Automatic feeding numerical control lathe

InactiveCN105798332AAvoid shockPrevent flying outMetal working apparatusNumerical controlMaterial storage

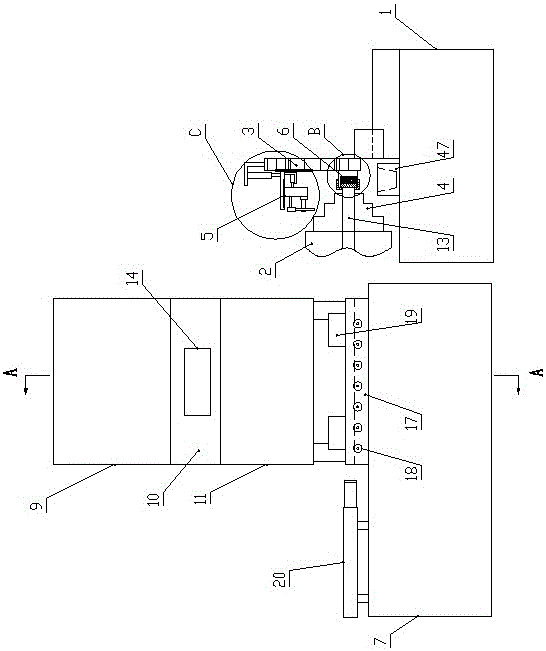

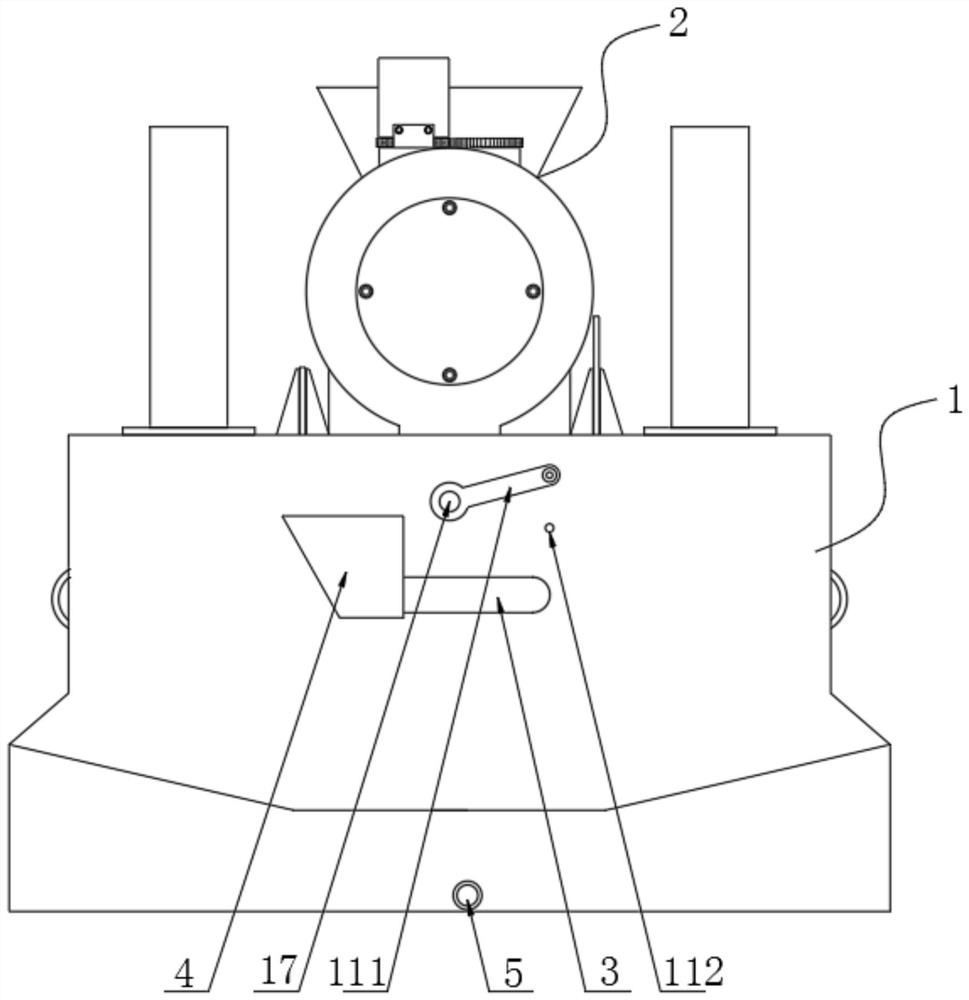

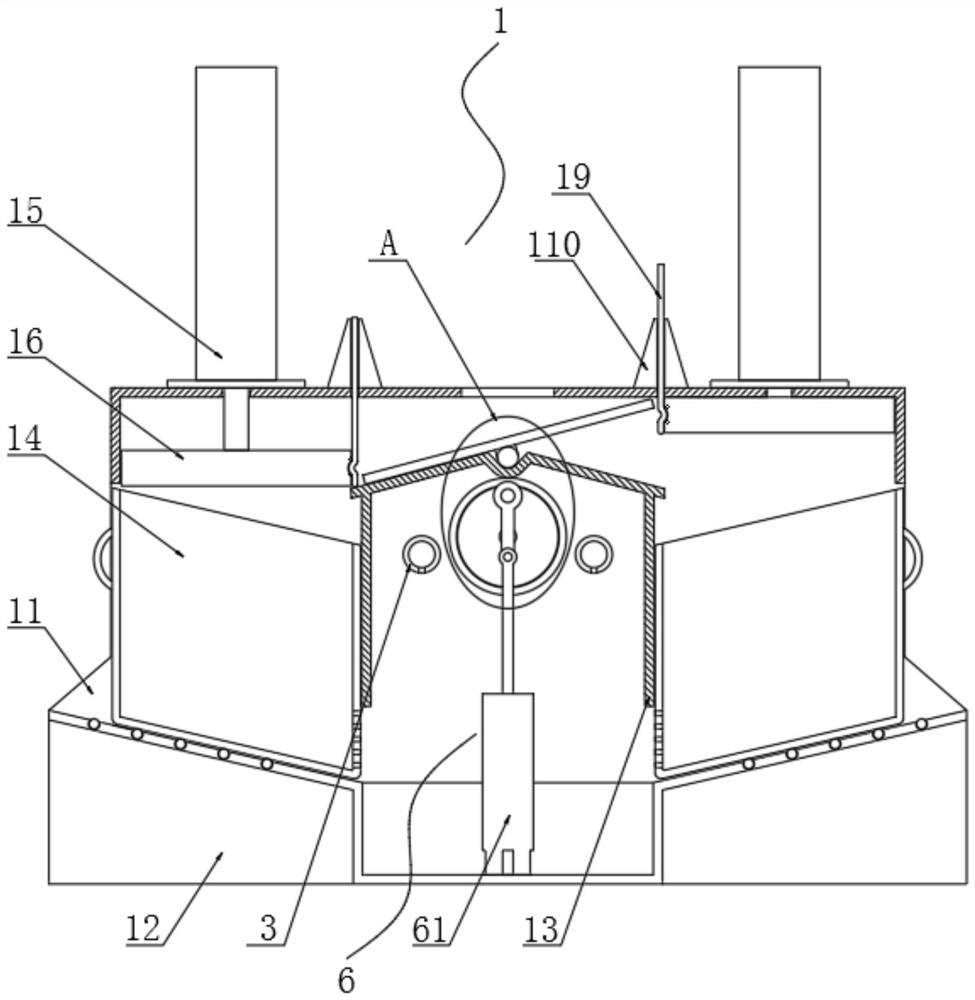

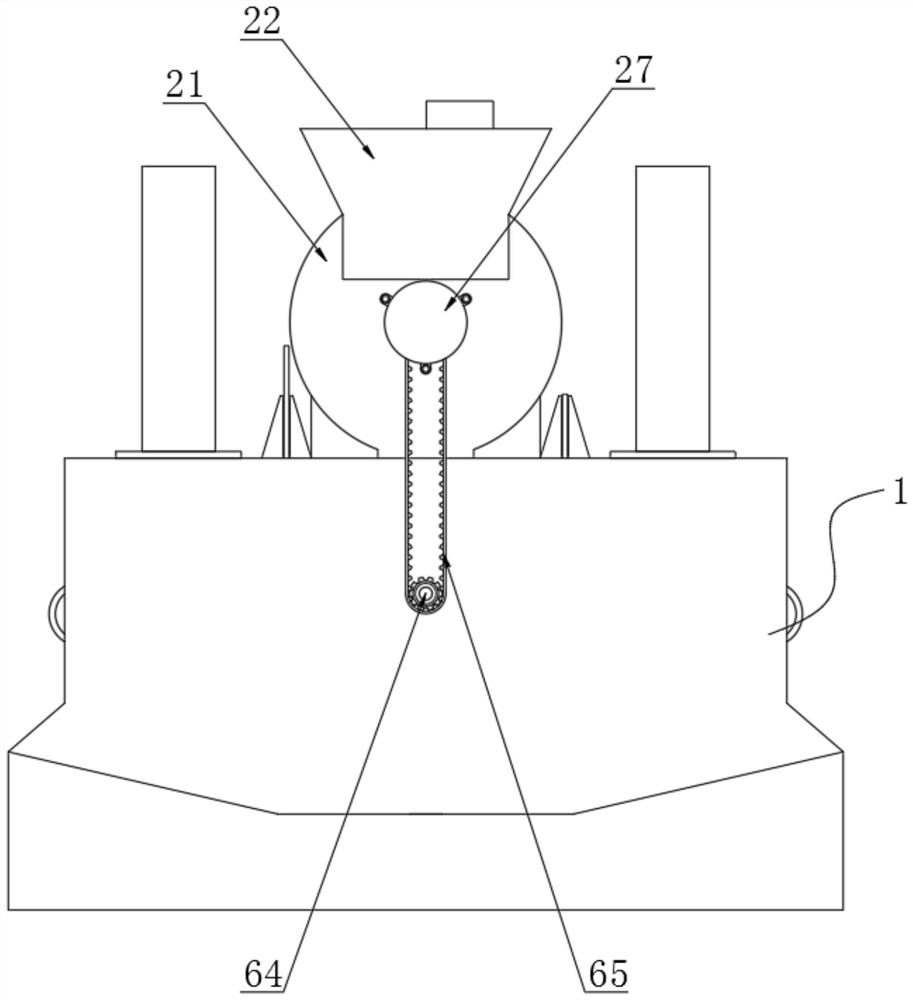

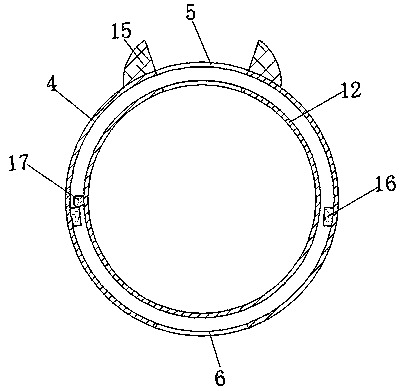

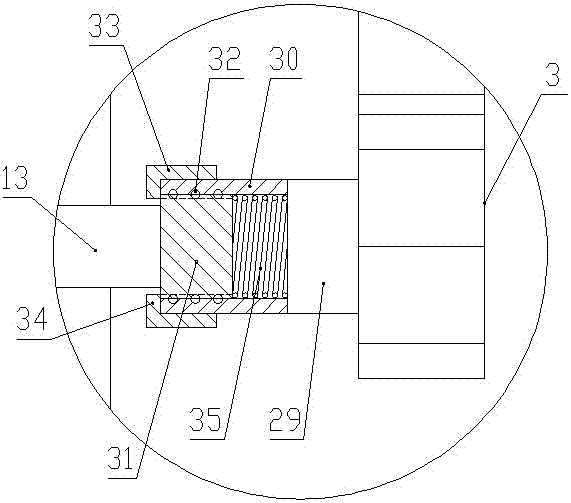

The invention discloses an automatic feeding numerical control lathe. The automatic feeding numerical control lathe comprises a lathe body, wherein a hollow spindle is arranged on the lathe body; a sliding rail is arranged on the lathe body along the front and back horizontal direction; a knife rest is slidably arranged on the sliding rail; a hollow chuck is axially and fixedly connected to the front end of the hollow spindle; a cutting mechanism and an electromagnetic adsorption mechanism are arranged on the knife rest; an automatic feeding device is arranged behind the lathe body; the automatic feeding device comprises a material box base; a material box support is fixedly connected onto the material box base; a material storage box, a corrugated pipe elastic joint and a discharging box are sequentially arranged on the material box support from top to bottom in a fixed manner; a vibration motor is arranged on the outer wall of each of the left and right sides of the corrugated pipe elastic joint; a material baffle mechanism is arranged on the lower part of the discharging box; and a material pushing base which is right blow the discharging box is fixedly connected onto the upper surface of the material box base. The automatic feeding numerical control lathe is simple and convenient for operation, high in automatic degree and stable in work; automatic feeding can be realized; non-cutting time is effectively shortened; cutting can be performed rapidly; and the working efficiency is improved.

Owner:HUANGHE S & T COLLEGE

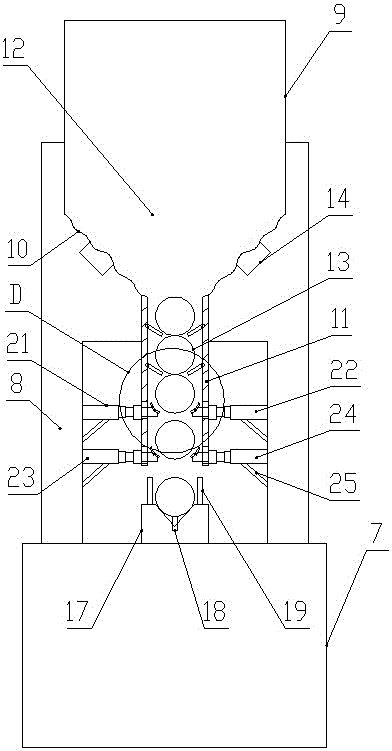

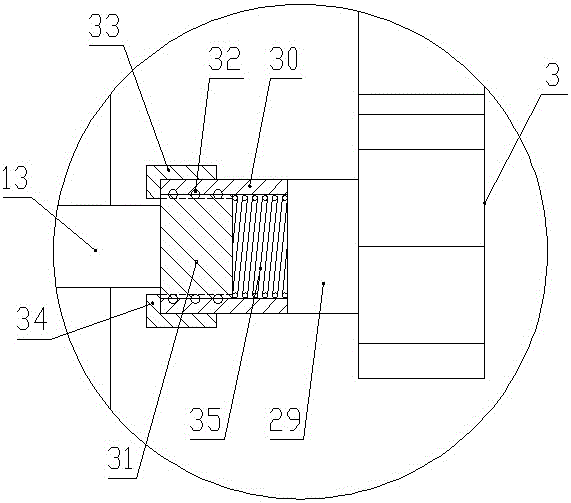

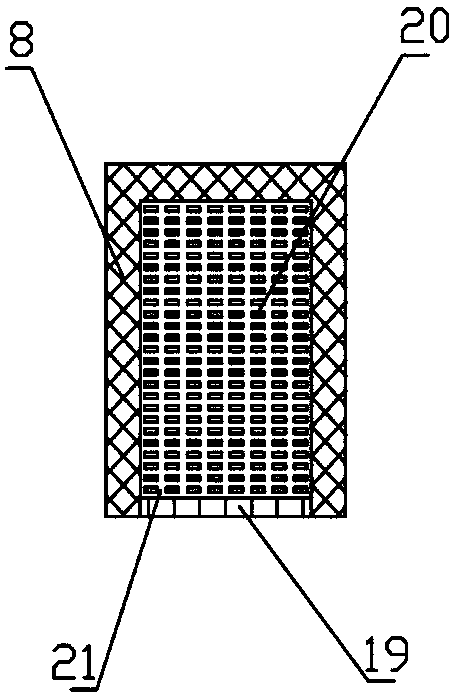

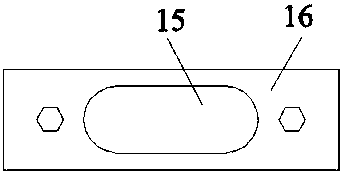

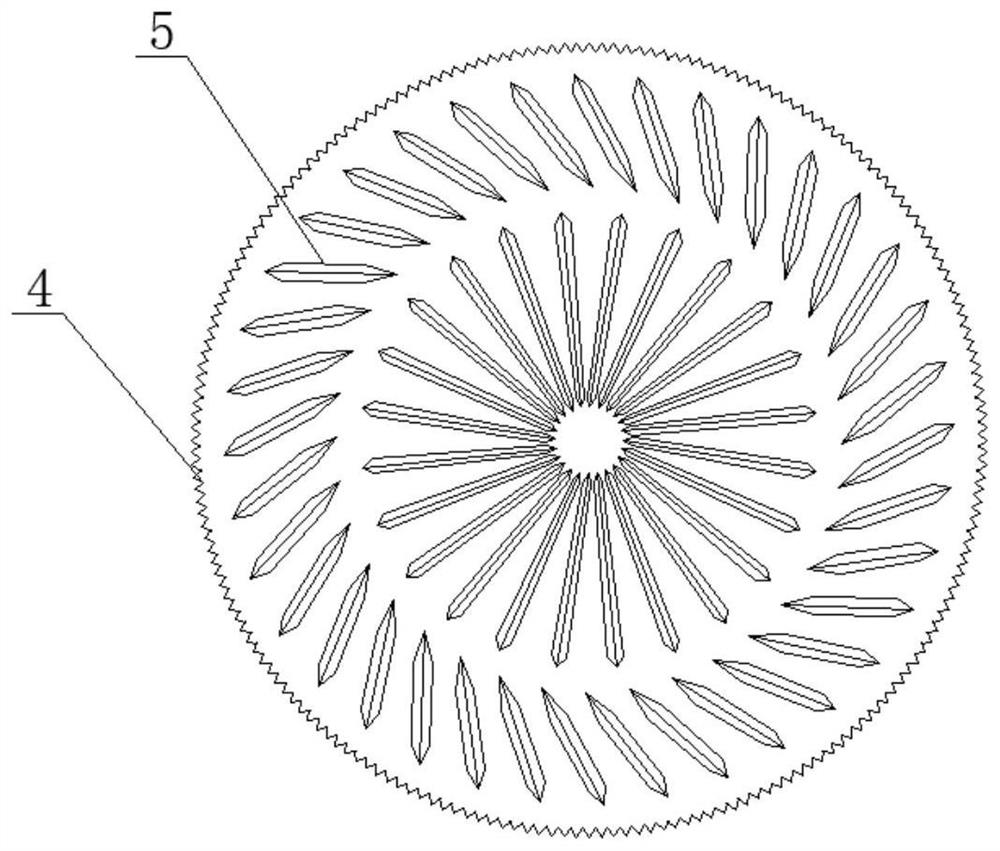

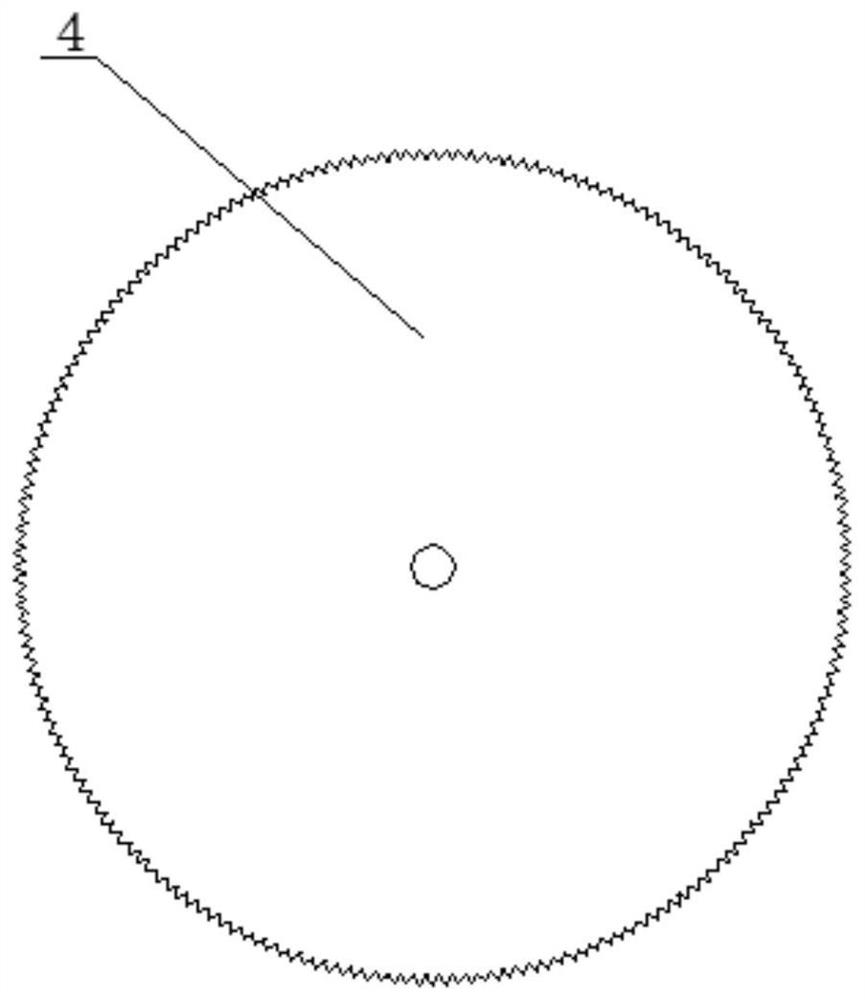

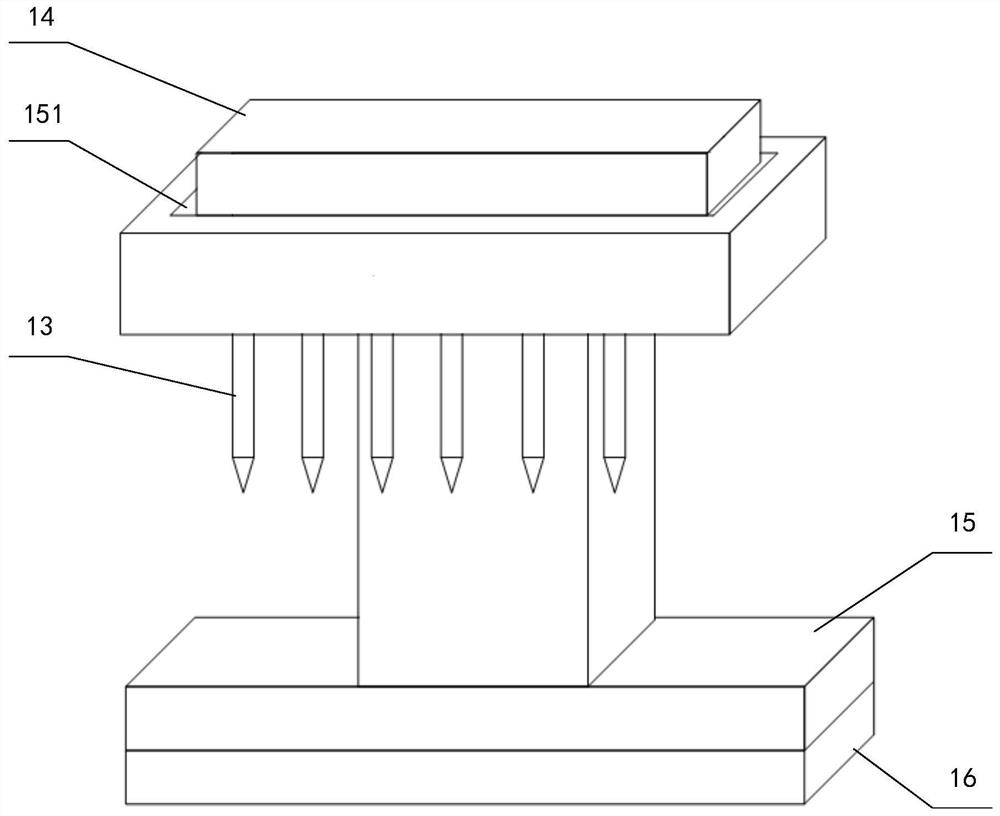

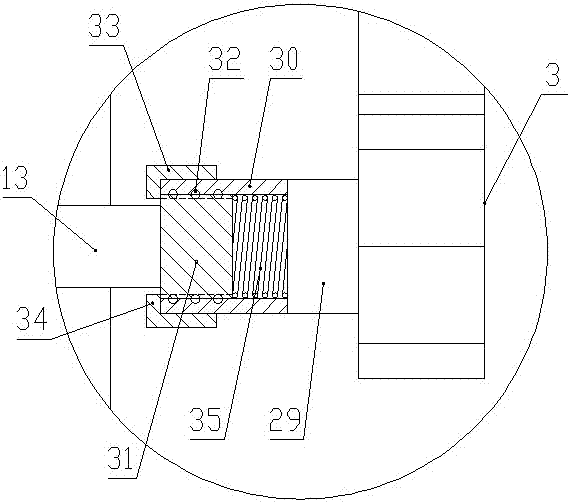

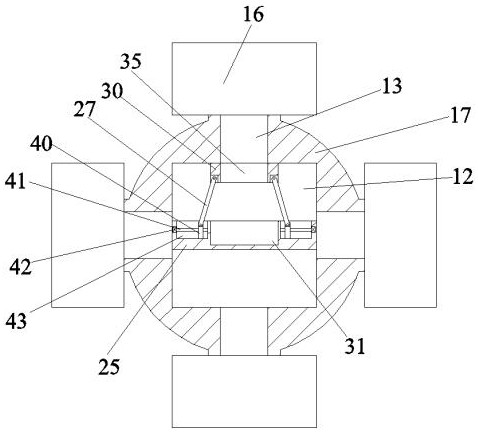

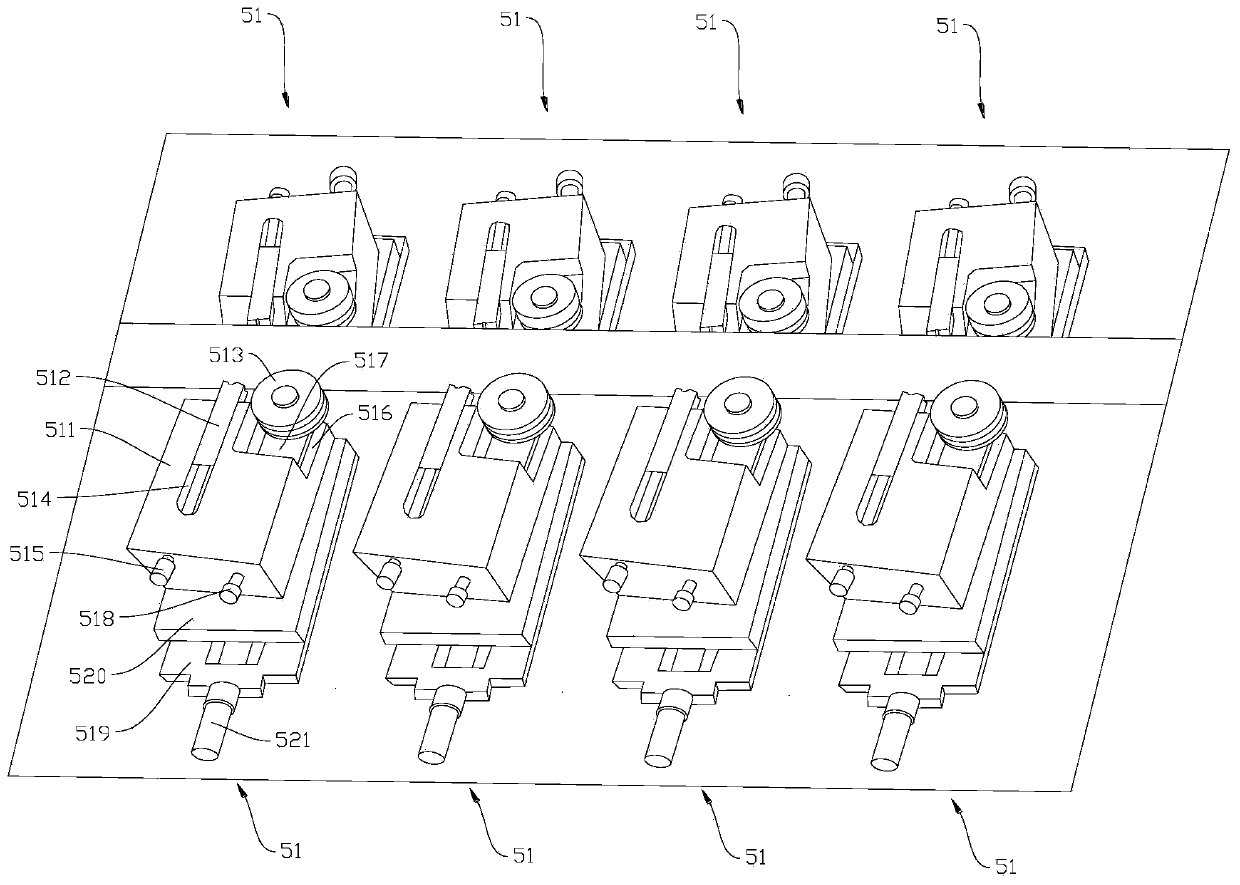

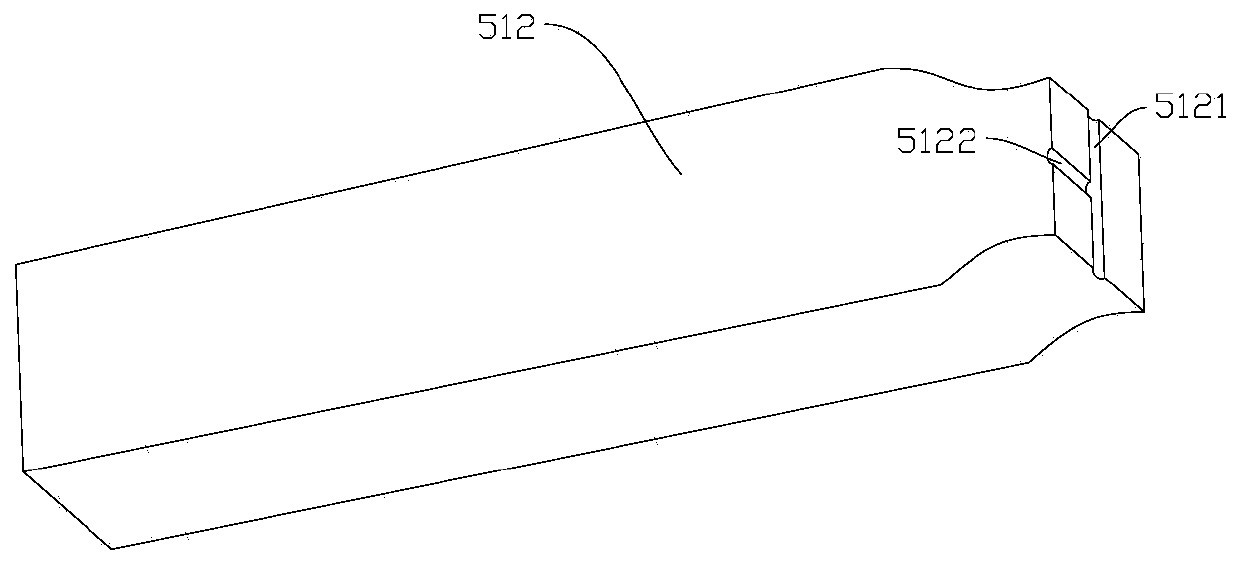

Single-point integral mould

InactiveCN105537410AHigh strengthContinuous and efficient processingShaping toolsEngineeringDrive motor

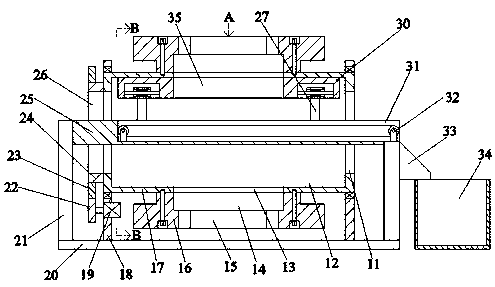

The invention relates to a single-point integral mould, and belongs to the field of mechanical engineering. The single-point integral mould consists of a plurality of single-point type supporting mechanisms, an upper supporting plate, a lower supporting plate, a vertical plate and a drive motor; each single-point type supporting mechanism is composed of a spiral up-down moving type ejector rod and a fixed type rotary drive handle; the single-point type supporting mechanisms are arranged in the form of a square matrix and a circular matrix at certain spacing to form a mould; a hole with inner threads is processed in the upper supporting plate; and a light hole is formed in the lower supporting plate. The mould enables the ejector rod to spirally ascend on the upper supporting plate through the motor and the rotation drive handle, so that different molded surfaces are formed. The single-point integral mould has the advantages that curved parts with different shapes can be continuously and efficiently processed; and meanwhile, curved surface of large boards can be processed, so that solid mould processing is avoided, and the cost for processing the curved parts with different shapes is saved.

Owner:JILIN UNIV

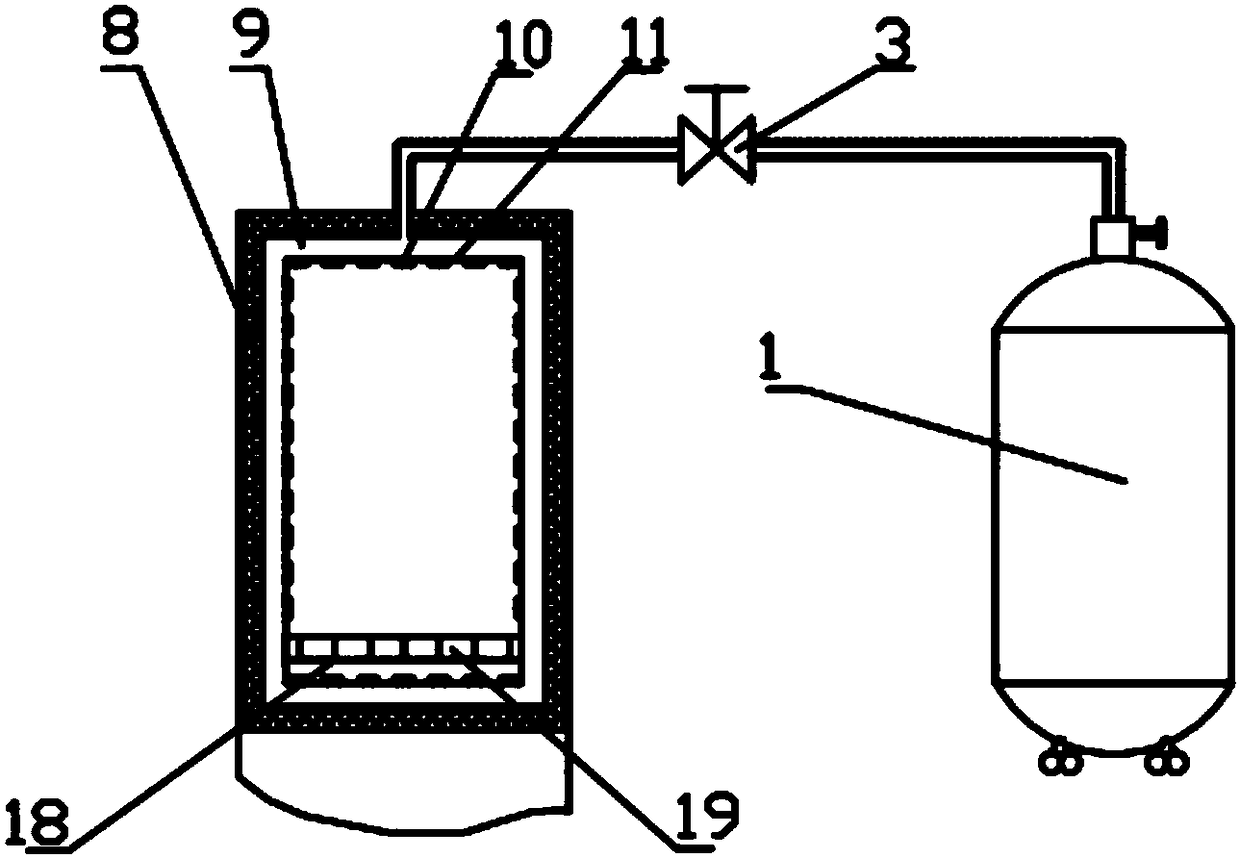

Deep cooling treatment device and method

The invention provides a deep cooling treatment device and method. The device comprises a box for conducting deep cooling treatment on a to-be-treated workpiece. The box is provided with a gas inlet and a main gas outlet. Hot gas enters the box through the gas inlet, and gas in the box is discharged through the main gas outlet. An annular liquid inlet groove surrounding the side wall of the box isarranged between the gas inlet and the main gas outlet of the box, and is used for conveying low-temperature media into the box. Gas at the gas inlet end in the box penetrates the plane where the annular liquid groove is located and is discharged through the main gas outlet. According to the provided deep cooling treatment device and method, the redundant cooling capacity in the box can be blowntowards the main gas outlet along with flowing of gas to directly conduct pre-cooling on the to-be-treated workpiece, continuous cooling capacity recycling is achieved, the cooling capacity can be sufficiently and completely recycled, energy consumption can be reduced, and the deep cooling treatment efficiency is improved. In addition, temperature returning and tempering treatment can be directlyand continuously conducted on the to-be-treated workpiece, and the treatment process is continuous and efficient.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

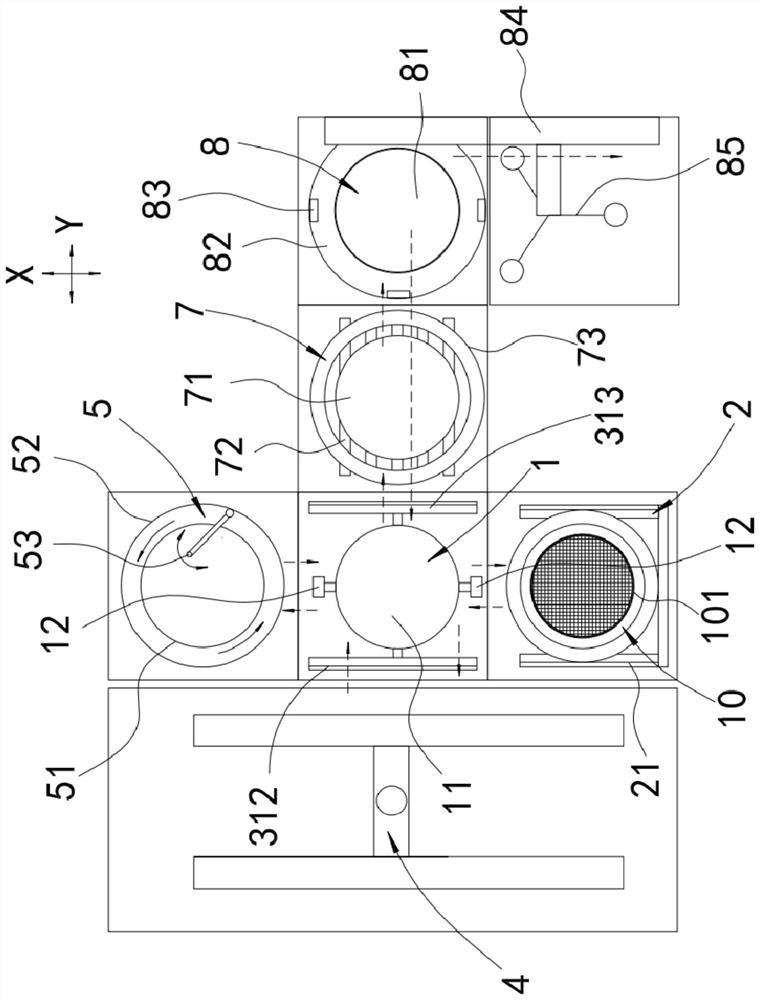

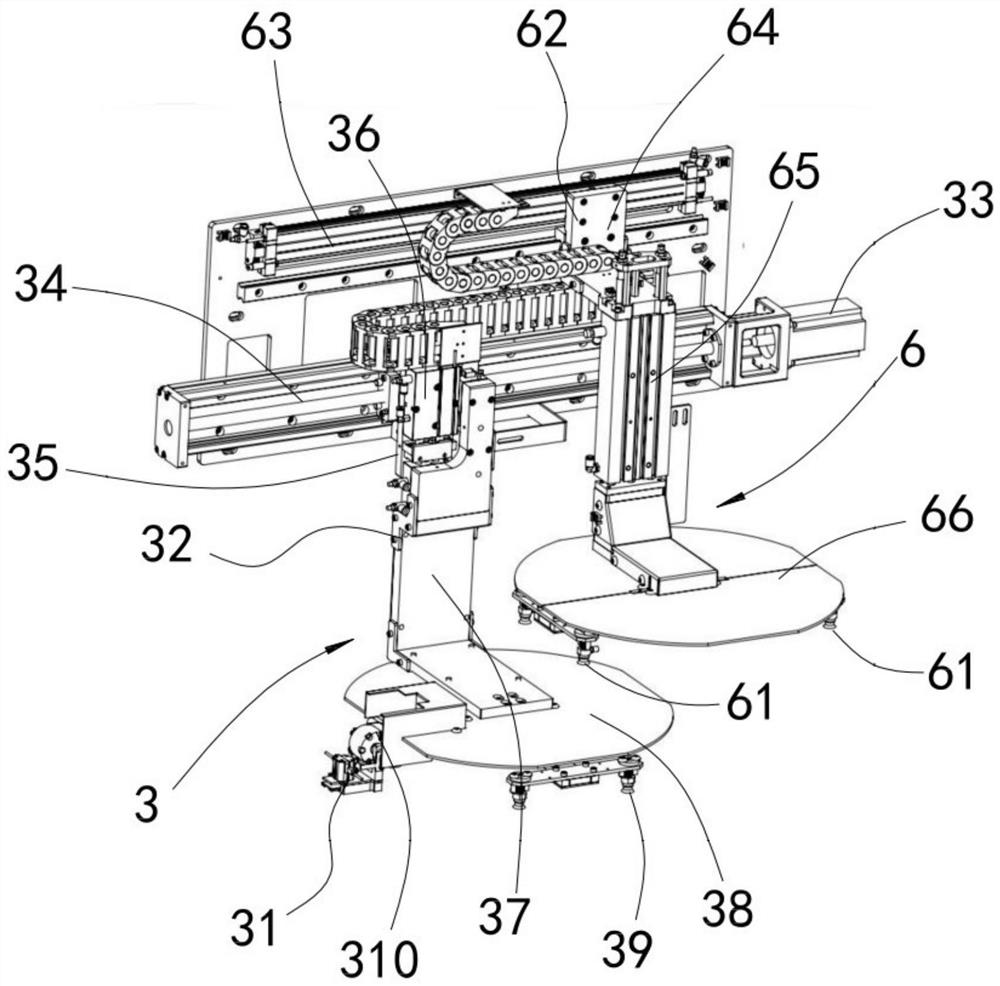

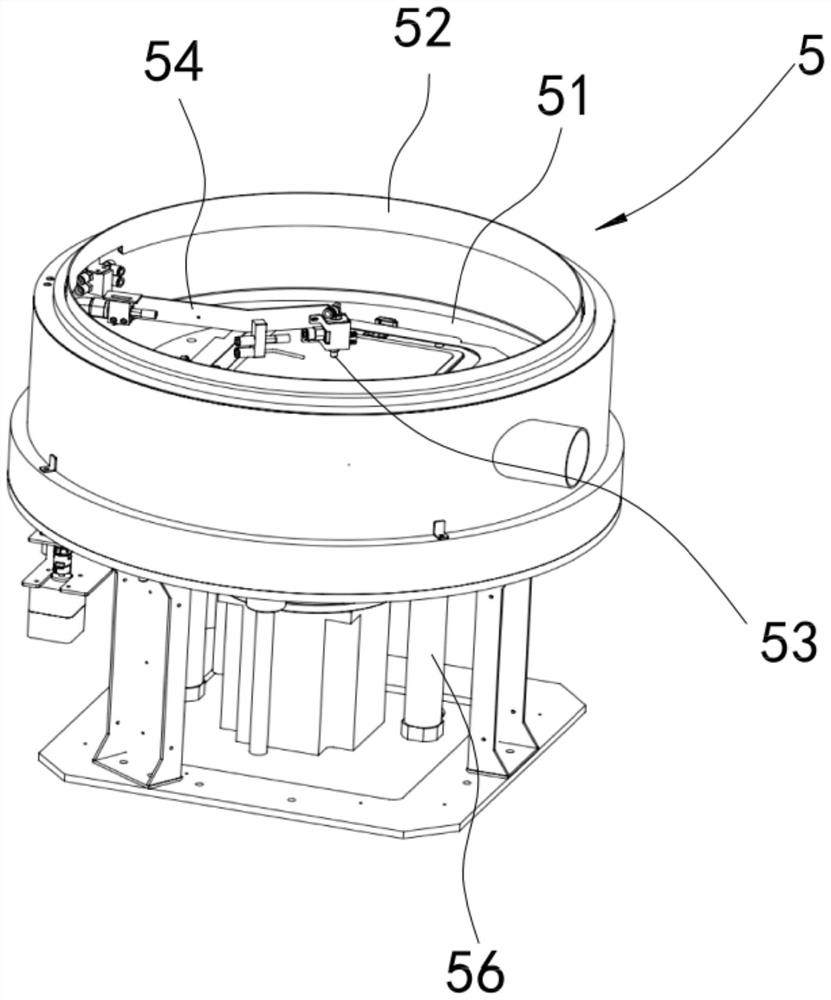

Wafer processing method and wafer processing device

ActiveCN114582713AGuaranteed positioning accuracyGuaranteed location consistencySolid-state devicesSemiconductor/solid-state device manufacturingWaferThin membrane

The invention discloses a wafer processing method and a wafer processing device.According to the wafer processing method, cleaning and UV dispergation are carried out on a wafer after girdling, the influence of cutting chippings and a glue layer on the surface of a thin film on subsequent ring taking can be effectively avoided, ring taking can be guaranteed, and before each action of girdling, UV dispergation and ring taking, ring taking can be carried out in a one-to-one manner; according to the technical scheme, the wafer is positioned through a set of centering mechanism, the position precision and consistency of the wafer at the positions of ring cutting, UV dispergation and ring taking can be effectively ensured, the ring cutting precision and the stable implementation of ring taking can be ensured, and the whole process of feeding, ring cutting, cleaning, UV dispergation, ring taking and discharging can be automatically realized through a set of automatic equipment, so that the production efficiency is improved, and the production cost is reduced. The automation degree is high, manual intervention is not needed, and continuous and efficient machining can be achieved.

Owner:JIANGSU JCA ELECTRONICS TECH CO LTD

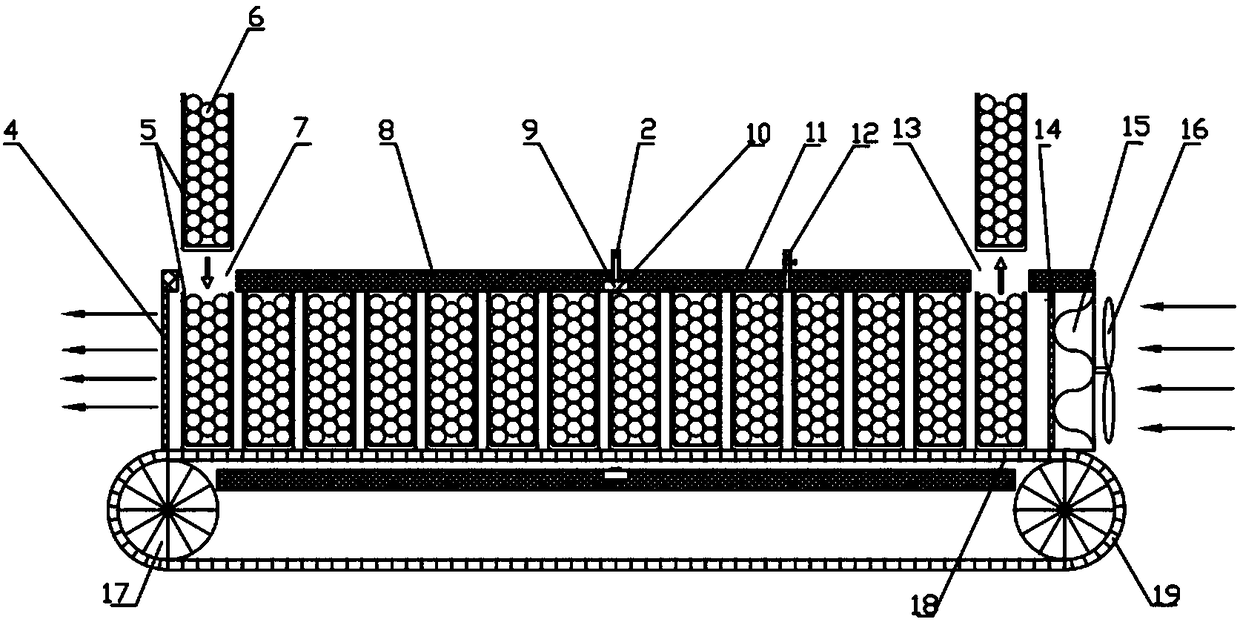

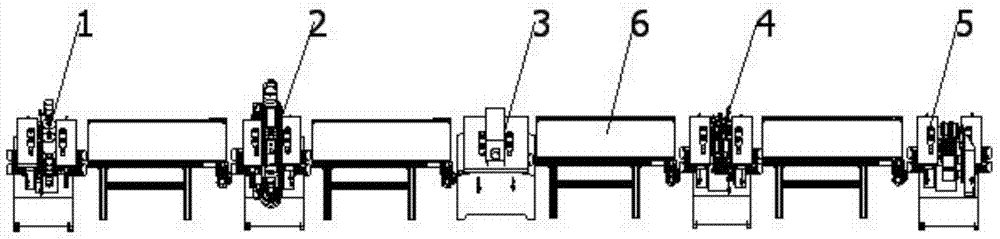

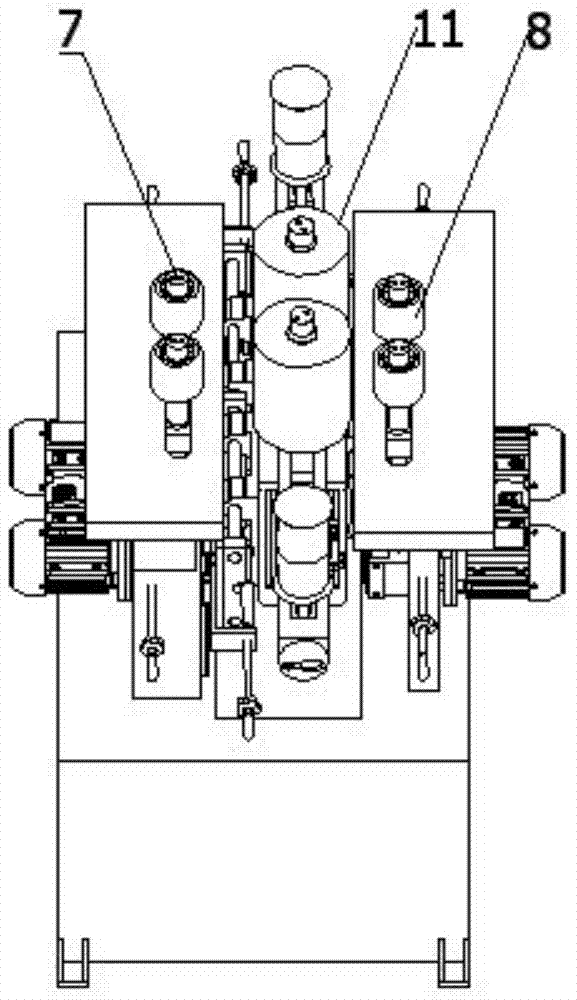

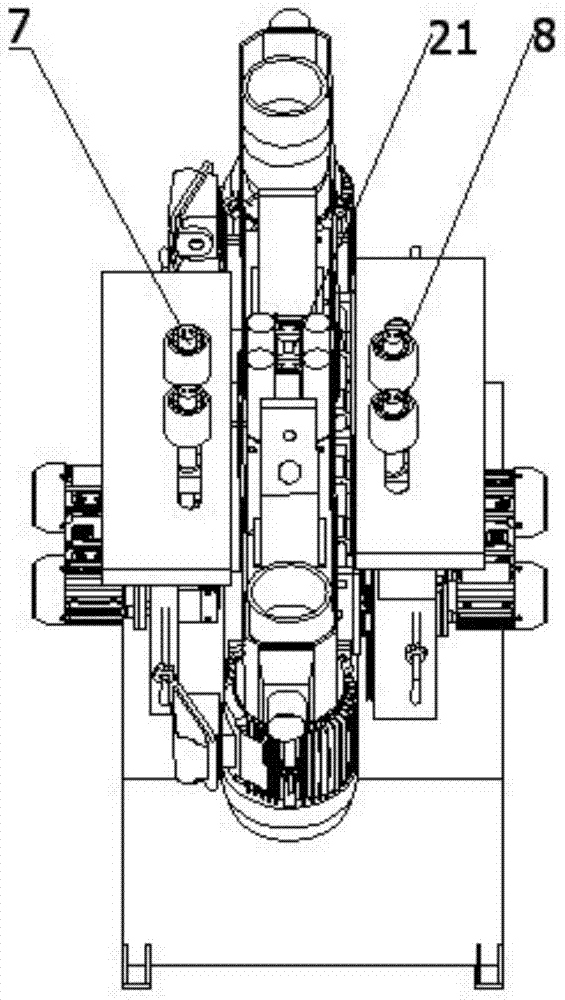

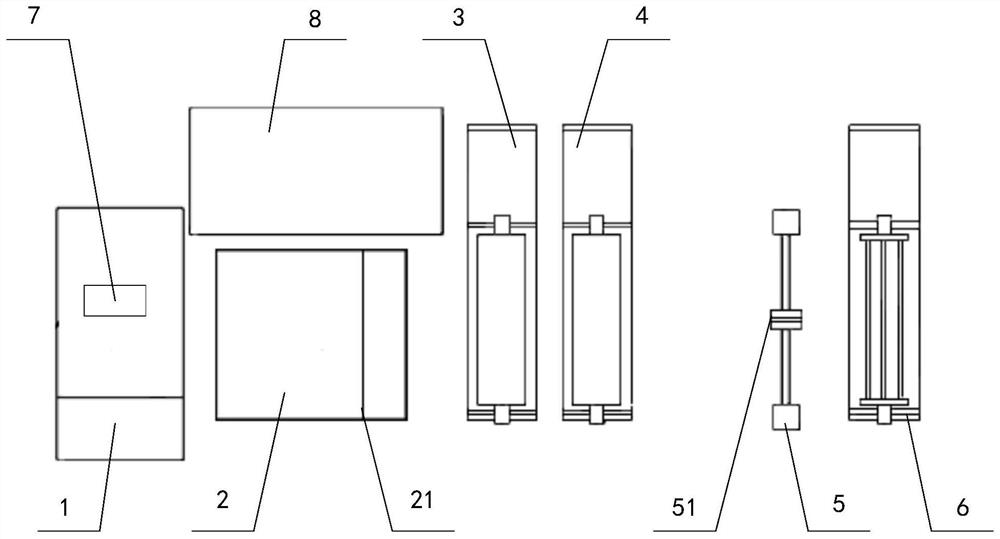

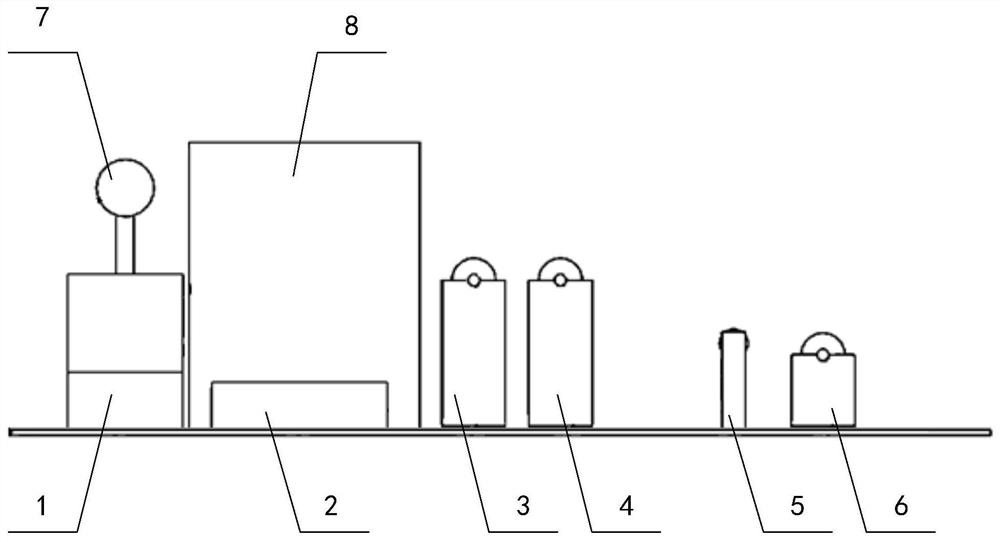

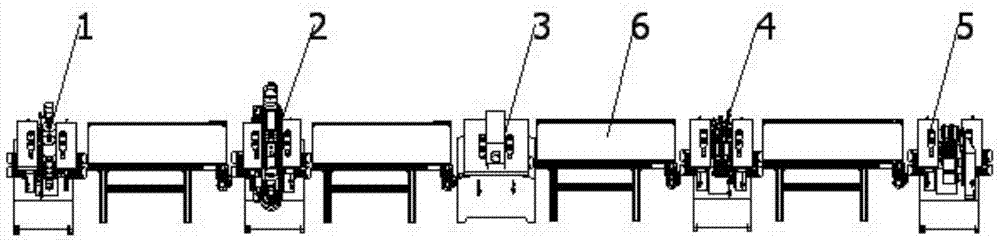

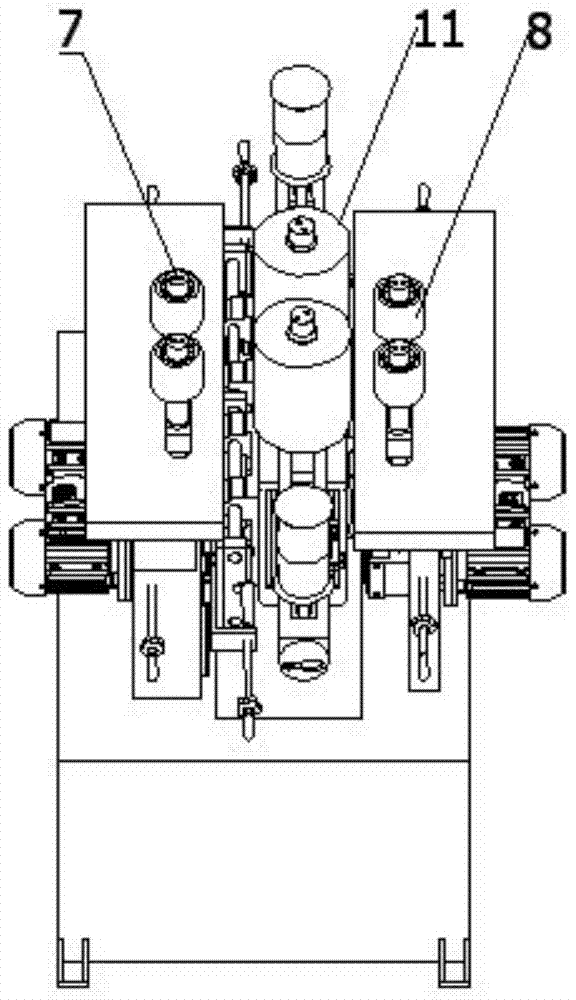

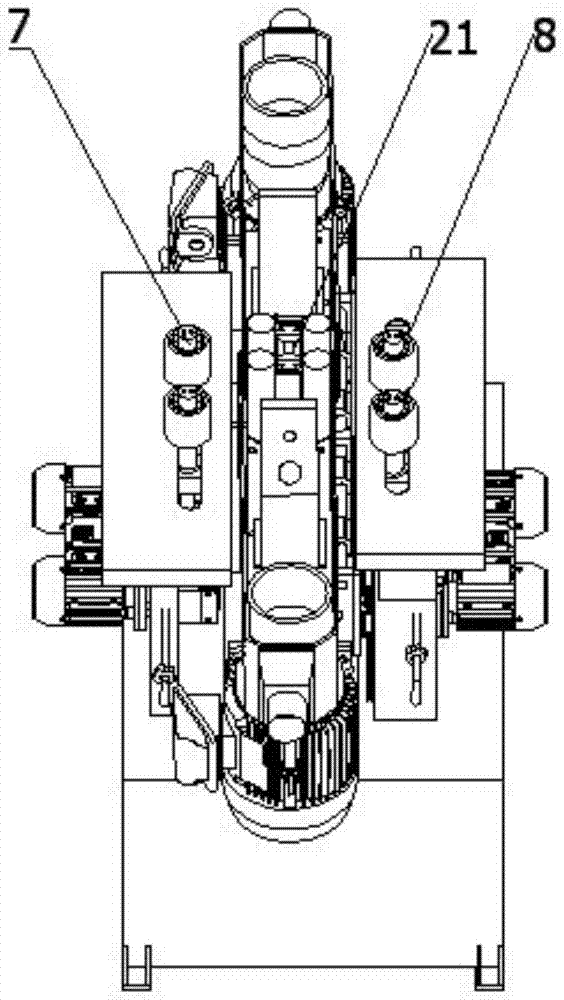

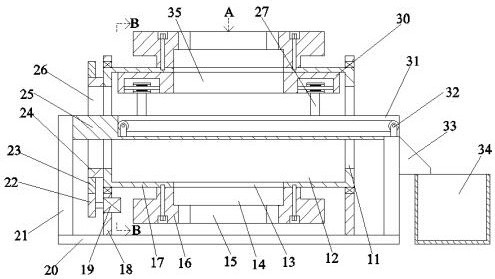

Sanding set

ActiveCN104259971AContinuous and efficient processingSimple structureGrinding machinesGrinding feedersStructural engineeringSander

The invention provides a sanding set comprising a double side roughing machine, a double side finishing machine, a chamfering machine, a left side and right side polisher, a top and bottom polisher and a plurality of conveying frames. The conveying frames are mounted among the double side roughing machine, the double side finishing machine, the chamfering machine, the left side and right side polisher and the top and bottom polisher and are used for conveying wood material. The sanding set is simple in structure and applicable to continuous efficient processing of irregular wood materials.

Owner:江西英硕智能科技有限公司

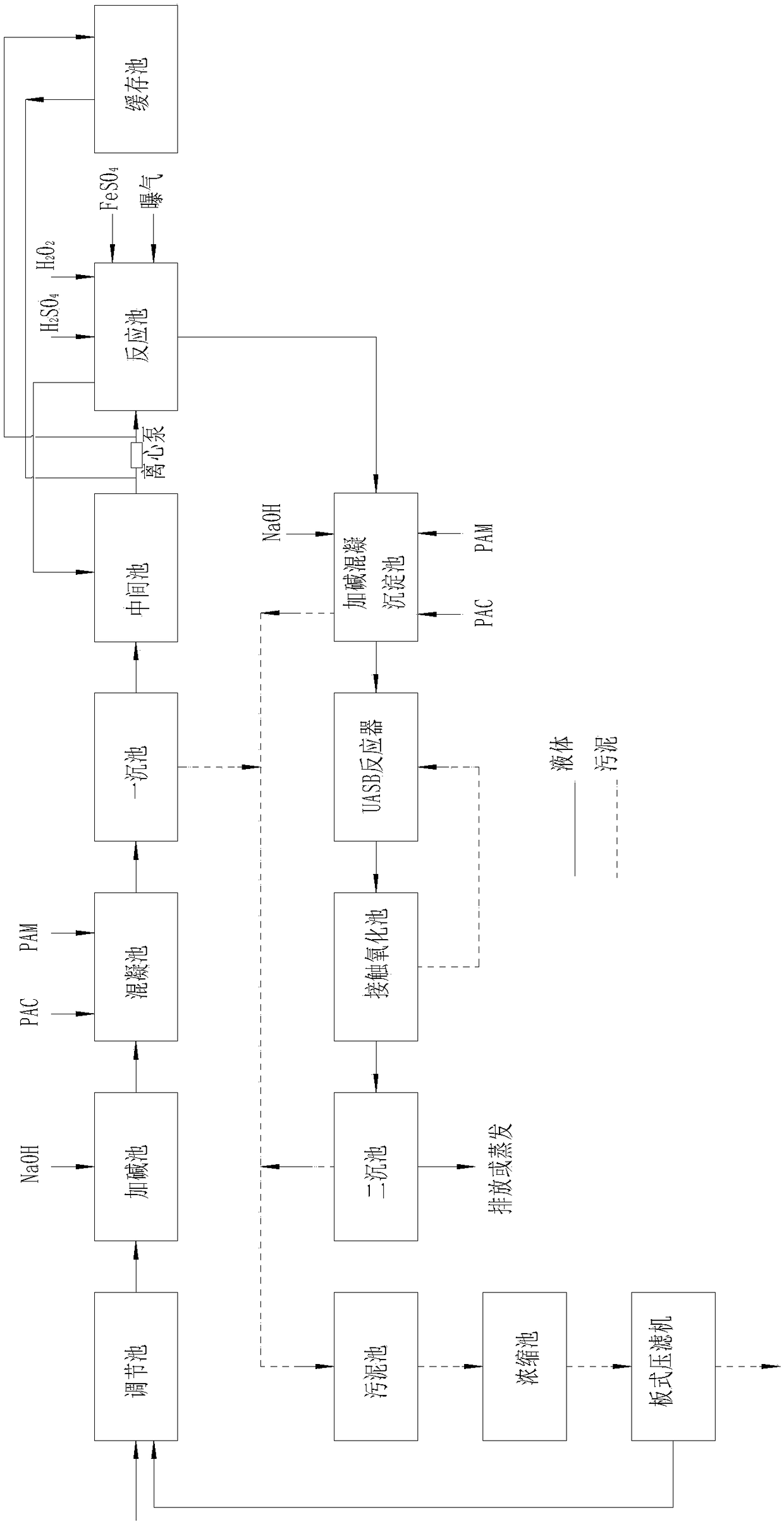

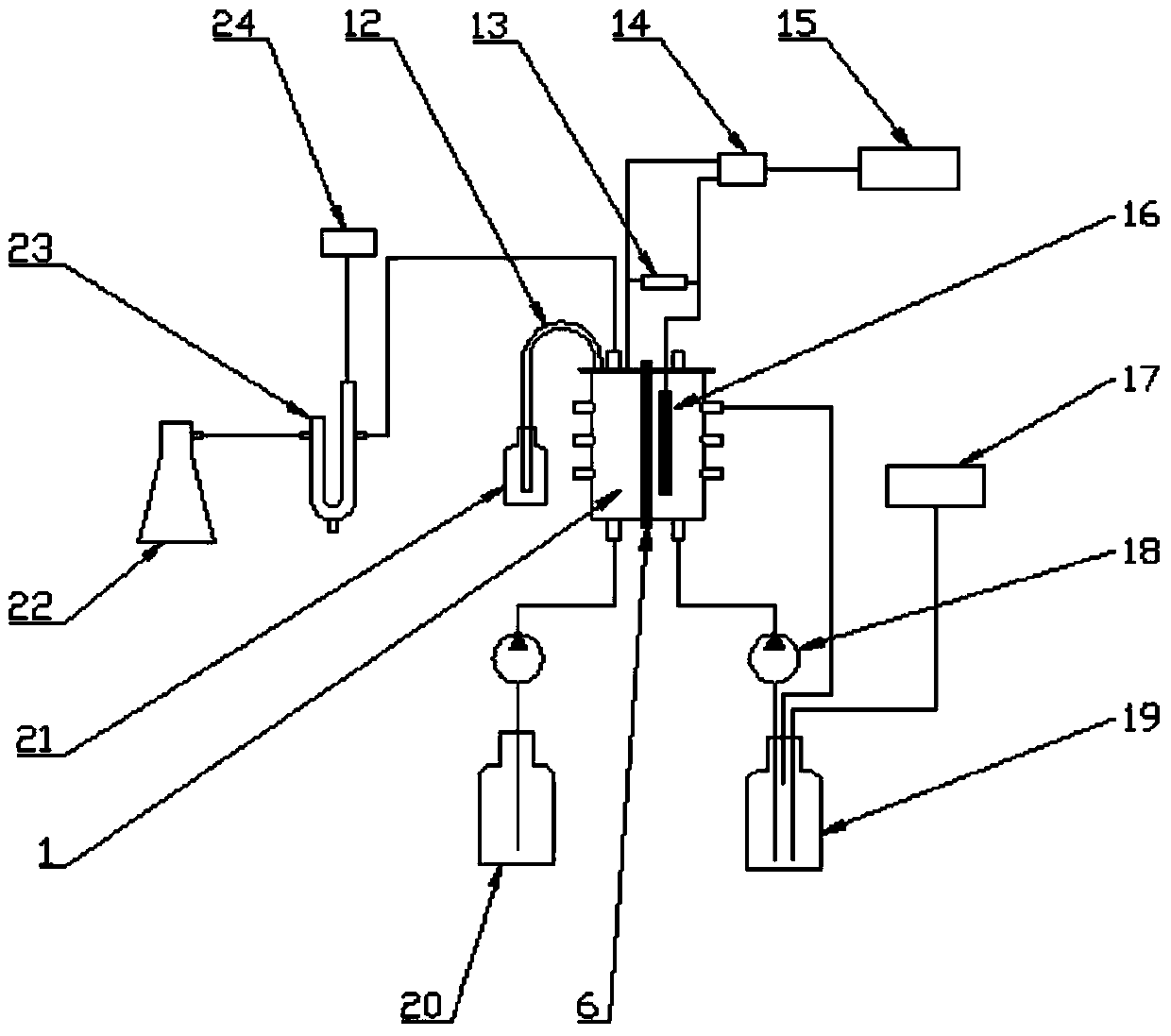

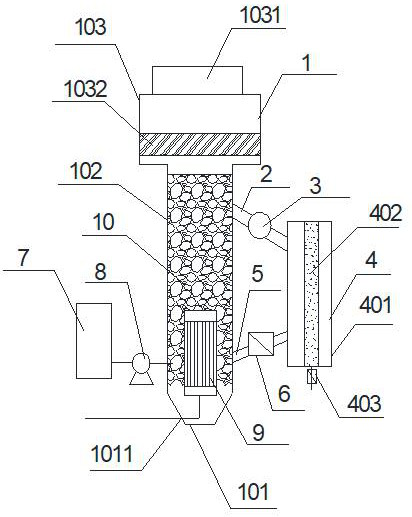

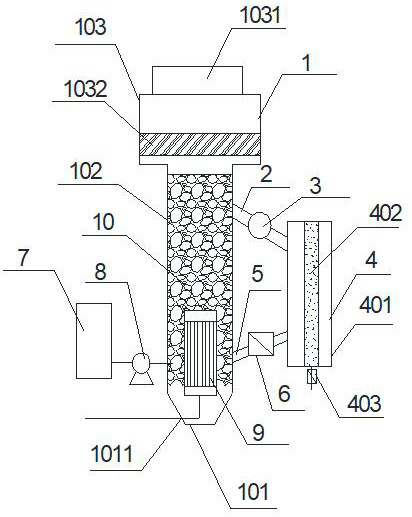

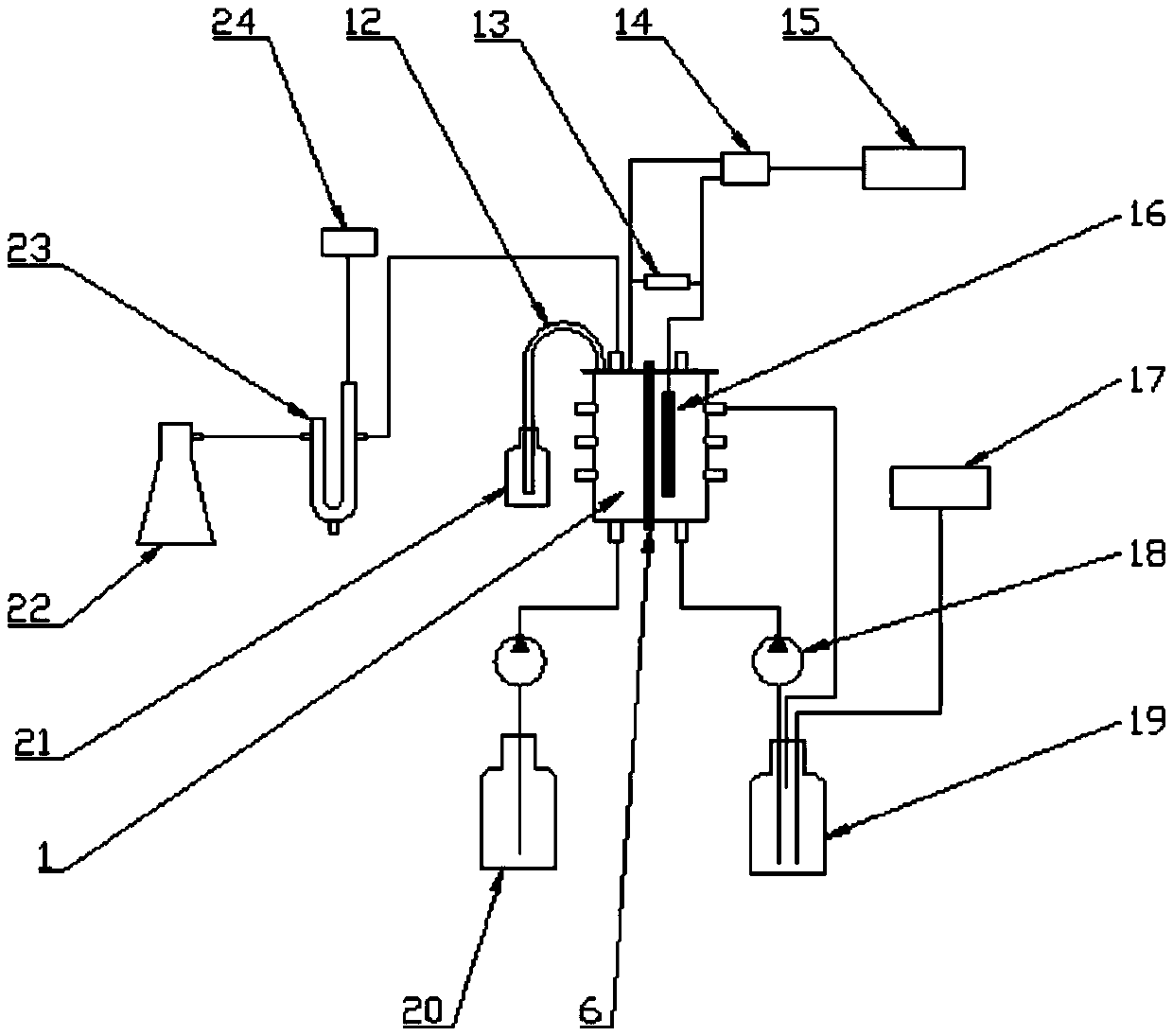

Microelectrolysis based advanced oxidation water treatment system and method

ActiveCN108439723AActive enoughAdd lessWater contaminantsTreatment with aerobic and anaerobic processesHigh concentrationElectrolysis

The invention discloses a microelectrolysis based advanced oxidation water treatment system and method. According to the water treatment system and method, iron-carbon micro-electrolysis and a fentonreaction are combined and fused into other sewage treatment technologies, iron / carbon granules are replaced conveniently, passivation of the iron / carbon granules is reduced, and then the sewage treatment effect is better. High-concentration COD sewage can be treated, and sewage containing organic matter difficult to biodegrade can also be treated.

Owner:张家港市清泉水处理有限公司

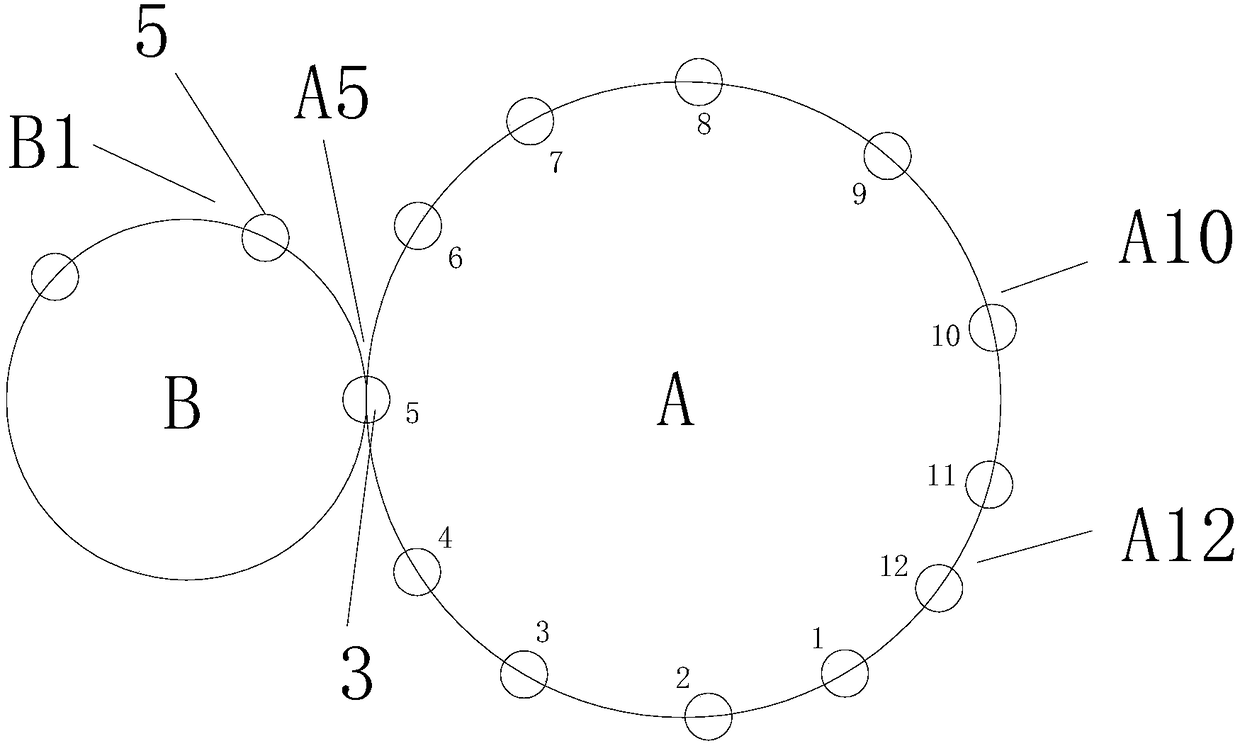

Bottom corner tube-type glass bottle making machine and bottom corner tube-type glass bottle manufacturing method thereof

ActiveCN108423975AContinuous and efficient processingGuaranteed uptimeGlass reforming apparatusGlass severing apparatusEngineeringTubes types

The invention relates to a bottom corner tube-type glass bottle making machine and a bottom corner tube-type glass bottle manufacturing method thereof. The bottom corner tube-type glass tube making machine comprises a part A and a part B, wherein the part A comprises a seat A which is fixedly arranged, wherein a turntable A revolves on the seat A to drive a glass tube on a clamp A to move sequentially at a bottom manufacturing preheating station, a bottom manufacturing cutting station, a bottom neck front heating station, a bottom neck preliminary processing station, a bottom neck rear heatingstation and a bottom neck forming station; the clamp A rotates so that the glass tube forms a bottle bottom corner in a bottom neck preliminary processing clamp and a bottom neck forming clamp; the part B comprises a seat B capable of revolving, a bottle receiving station and a bottle opening blow-through station, and a plurality of clamps B are arranged on the seat B; the clamp B of the bottle receiving station clamps the glass tube cut off from the bottom manufacturing cutting station of the part A, and then moves the glass tube to the bottle opening blow-through station of the part B, a blow-through nozzle is arranged on the bottle opening blow-through station vertically downward, and the blow-through nozzle blows through the upper end of the bottle moved to the bottle opening blow-through station to form a bottle opening.

Owner:江苏嘉佳药用玻璃制品有限公司

Environment-friendly solid waste treatment device

ActiveCN111804700APlay a screening effectGuaranteed screening effectDrying solid materials without heatTransportation and packagingDrive shaftWaste treatment

The invention relates to the technical field of waste treatment, and discloses an environment-friendly solid waste treatment device which comprises a filter press box and a crushing box fixedly connected to the top of the filter press box. The crushing box comprises an outer cylinder, the bottom of the outer cylinder is provided with a falling opening communicating with the top of the filter pressbox, the top of the back of the outer cylinder fixedly communicates with a feeding hopper, the front side and the rear side of an inner cavity of the outer cylinder are each rotatably connected witha rotary drum, a plurality of groups of material leakage grooves are formed in the surface of the rotary drum at equal intervals, and the inner side of the rotary drum is fixedly connected with a driving shaft through a tripod. According to the environment-friendly solid waste treatment device, the rotary drum which rotates continuously is arranged, so that the solid waste can be continuously brought to a high position to fall down, the solid waste can be repeatedly cut and crushed by a plurality of blades on two groups of tool holders, the solid waste can be effectively crushed into small blocks, the material leakage grooves on the surface of the rotary drum can also achieve a screening effect, the thorough crushing of the solid waste is guaranteed, the subsequent treatment is facilitated, and the treatment efficiency can be improved.

Owner:河北总友环保科技有限公司

Stamping die facilitating to blanking

The invention discloses a stamping die facilitating to blanking. The stamping die facilitating to blanking comprises vertical plates which are symmetrically arranged, wherein a rotary barrel is rotationally arranged in each vertical plate; an accommodating cavity is formed in each rotary barrel; a plurality of open grooves are formed in the end wall of each accommodating cavity in a communicationmanner; the open grooves communicate with an external space; inner cavities are formed in the end walls of the two sides of each accommodating cavity in a communication manner; the inner cavities aresymmetrically formed; and rotary devices driving the rotary barrels to rotate are arranged on the outer surfaces of the vertical plates and the rotary barrels. The equipment is simple in structure; easier blanking machining is realized by adopting the manner of replacing dies with different shapes and dimensions by means of rotating, and a lower die does not need to be manually replaced; and moreover, wastes are rapidly guided out of the equipment in a blanking process, and the lower die plays the role of structure enhancement during stamping for the equipment, so that the structure strength and reliability during continuous blanking of the die are effectively improved, and the life of the die is prolonged.

Owner:东莞市伟峰印刷有限公司

Traditional Chinese medicine preparation equipment and process

InactiveCN112916128AImprove processing efficiencyEasy to processPharmaceutical product form changeCocoaMedicinal herbsMechanical engineering

The invention discloses traditional Chinese medicine preparation equipment and process. The traditional Chinese medicine preparation equipment comprises a grinding type upper cover body, a medicinal material feeding opening, fixed grinding teeth, a movable grinding disc, movable grinding teeth, a grinding disc main shaft, a driving connecting rod, a driving rotating shaft and a support; traditional Chinese medicinal materials are placed in a feeding hopper, and the medicinal materials fall onto the movable grinding disc; medicinal materials are ground between the fixed grinding teeth and the movable grinding disc by starting the driving rotating shaft; the ground medicinal materials fall onto a screen device to be vibrated and screened; and the screened medicinal materials fall onto a medicinal material receiving disc to be collected, and grinding preparation processing of the traditional Chinese medicinal materials is completed. Compared with the prior art, according to the grinding device structure, grinding is conducted in a grinding mode, continuous grinding can be conducted, the processing efficiency is improved, medicinal materials obtained through grinding and processing can be processed to be finer, moreover, continuous screening is conducted after grinding, continuous efficient processing is achieved, it is guaranteed that the medicine effect of the medicinal materials is exerted, and application and popularization value is achieved.

Owner:HUAIHUA UNIV

PVA-containing desizing wastewater treatment method and treatment system

PendingCN108409022AImprove biodegradabilityEnables continuous processing operationsWater treatment compoundsWater contaminantsWater treatment systemFiltration

The invention discloses a PVA-containing desizing wastewater treatment method. The treatment method is characterized in that an acidic regulator is used for regulating the pH value of to-be-treated desizing wastewater to be 3-5, and then, the desizing wastewater is conveyed into an electromagnetic stirring type reactor; current is controlled to be 12-14A, and frequency is controlled to be 25-35 HZ, so that PVA is gathered to form polymer; the polymer is discharged from the electromagnetic stirring type reactor, and filtration is used for completing treatment on pollutant PVA in desizing wastewater. The obtained treatment method overcomes influences of PVA on wastewater treatment, avoids the treatment effect of wastewater in the presence of PVA, remarkably improves PVA removal efficiency, and effectively avoids the invalid influences caused by follow-up treatment steps as PVA removal efficiency is insufficient. A PVA-containing desizing wastewater treatment system is simple in structure, is low in investment and operation cost, is high in desizing wastewater treatment efficiency, and has remarkable application popularization value.

Owner:BOTOU DAHUA ENG CO LTD

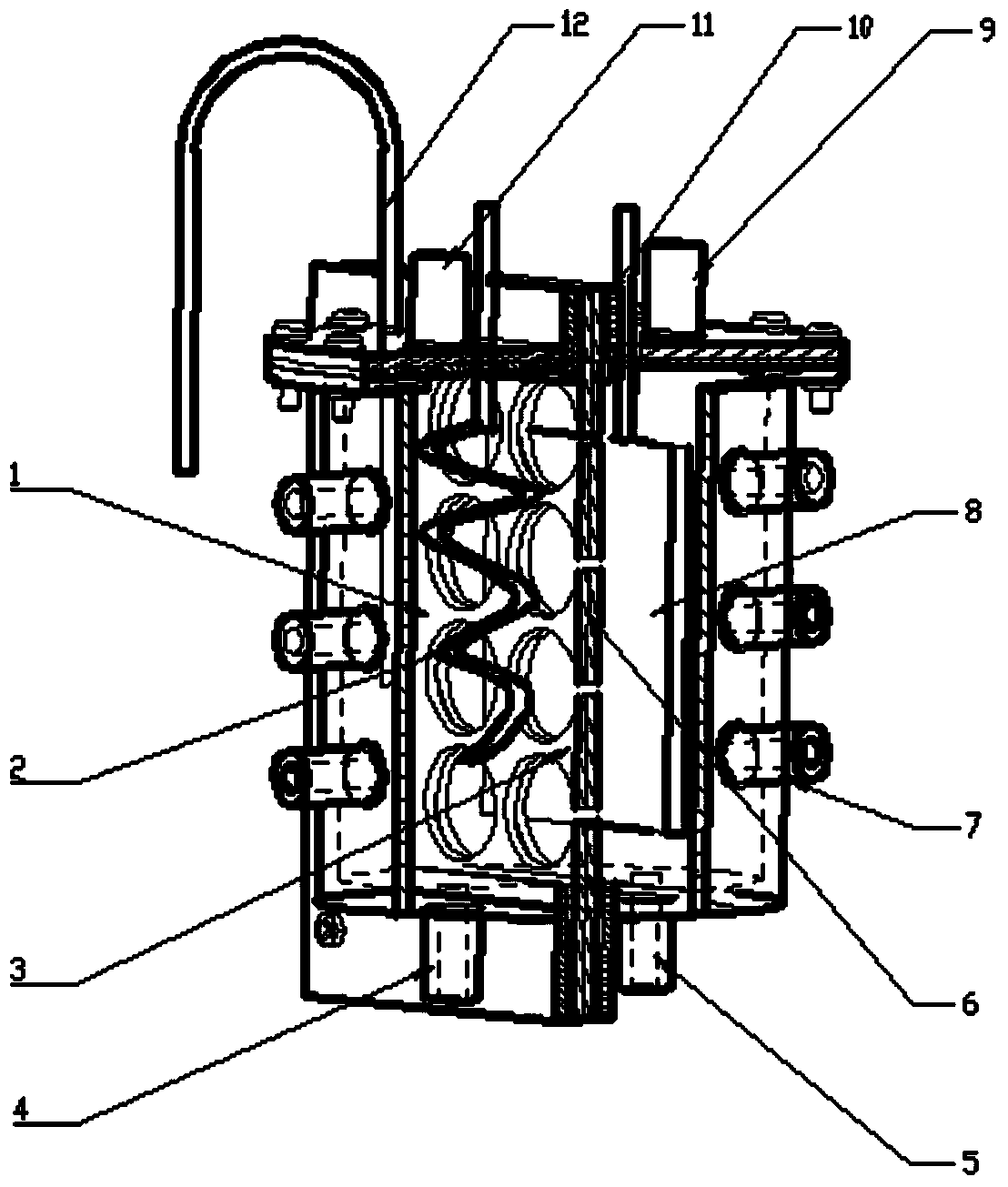

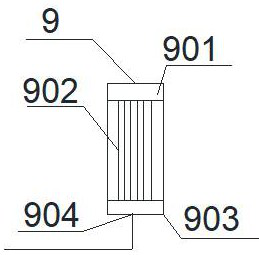

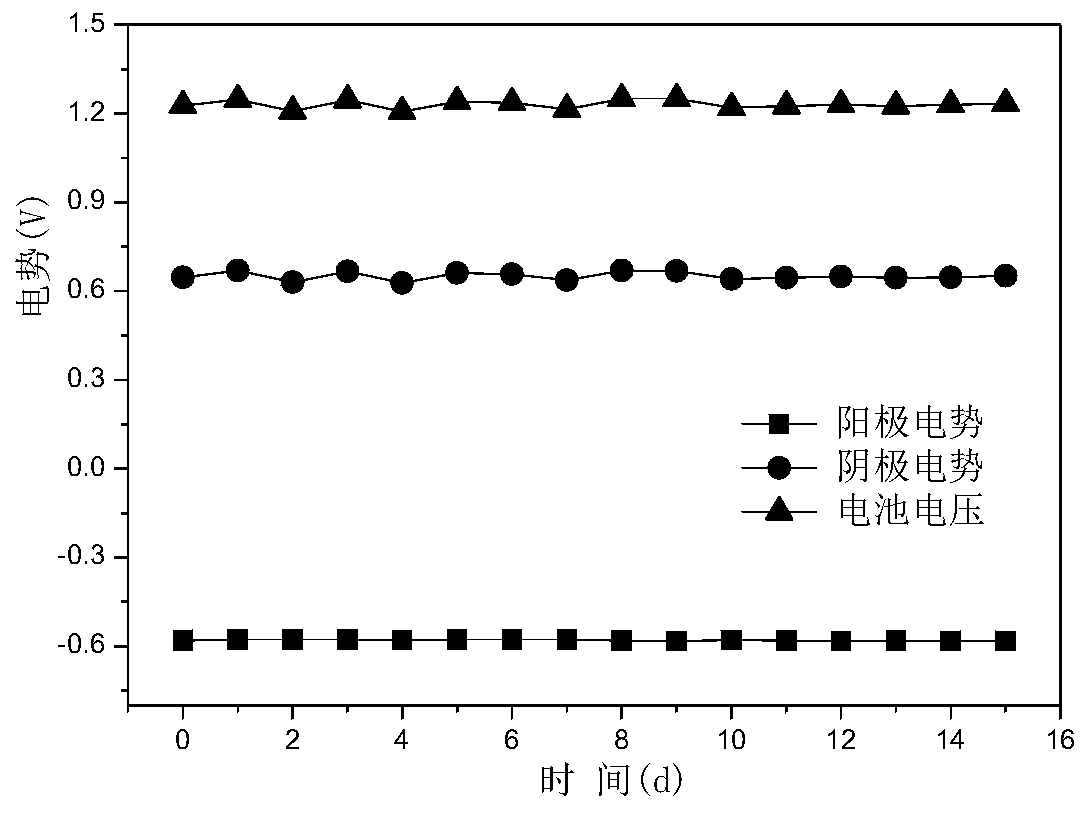

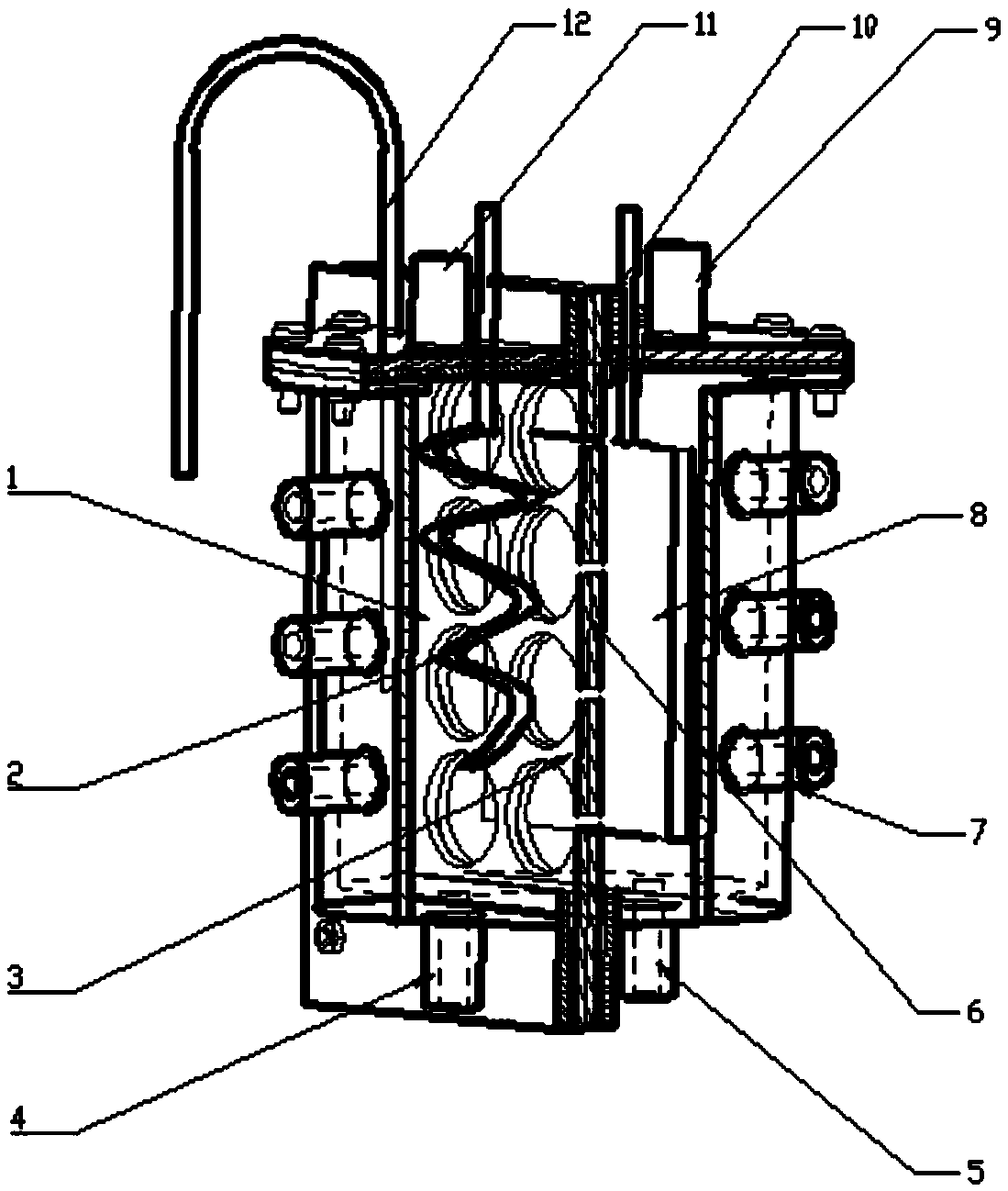

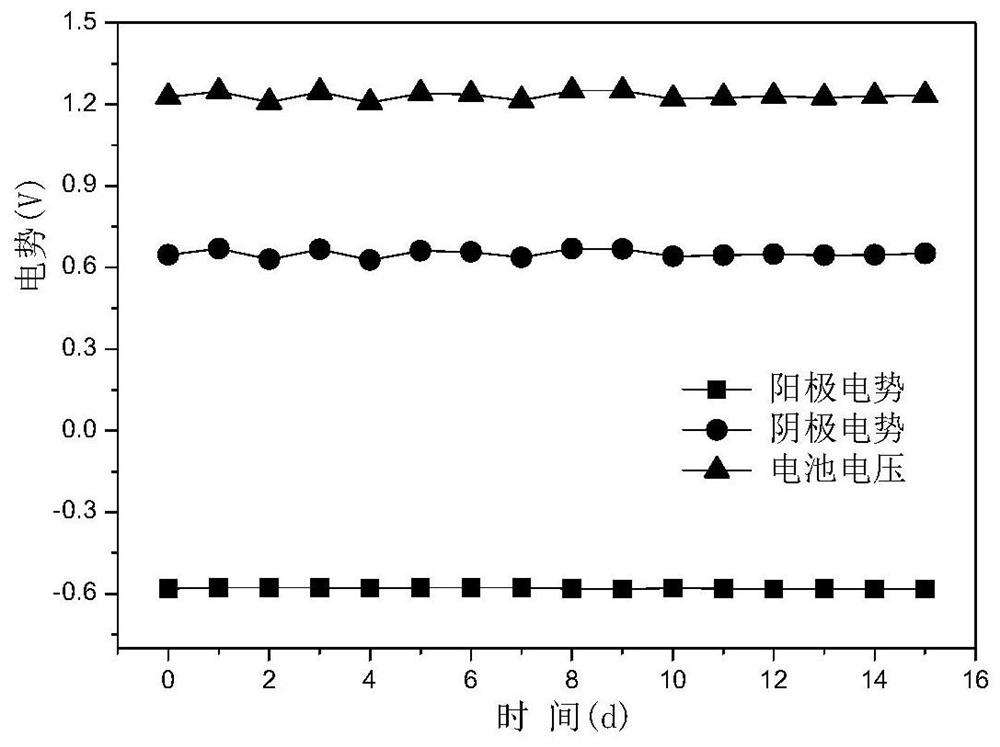

Carbon nanotube carrier type microbial electrochemical device for continuously treating sewage and generating power

ActiveCN103811792AContinuous and efficient processingEasy to operateCell electrodesWater contaminantsCarbon nanotubeSilica gel

The invention discloses a carbon nanotube carrier type microbial electrochemical device for continuously treating sewage and generating power, belonging to the technical field of sewage treatment of microbial fuel cells. The microbial electrochemical device comprises an anode chamber and a cathode chamber, wherein the anode chamber is uniformly filled with carbon nanotubes which serve as anodes and microbial carriers; organic sewage and anaerobic digested sludge are inoculated, the anode chamber and the cathode chamber are sealed by a silicone pad, and an anaerobic environment is formed in the anode chamber; a water outlet of the anode chamber is connected with a three-phase separator. According to the device, the anode chamber is filled with the carbon nanotubes to form a packed bed reactor, the device is easy to operate and free of any catalyst, sewage can be continuously and efficiently treated by a continuous and unconventional batched treatment manner, and when the organic load is 4g COD.L<-1>.d<-1> and the hydraulic retention time is 16 hours, the sewage removal rate can be about 90 percent. Moreover, the three-phase separator is added to the water outlet of the anode chamber, so that the problems of blockage and difficulty in maintenance caused by outflow of carbon particle materials are solved.

Owner:CHINA AGRI UNIV

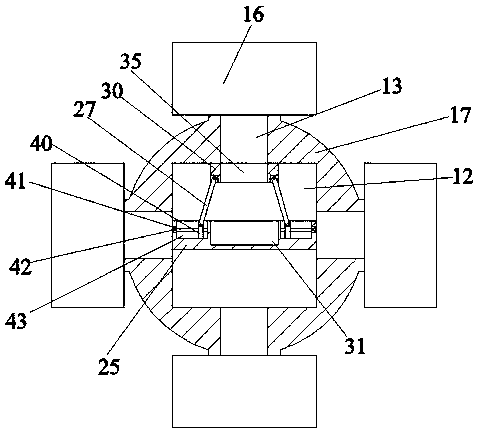

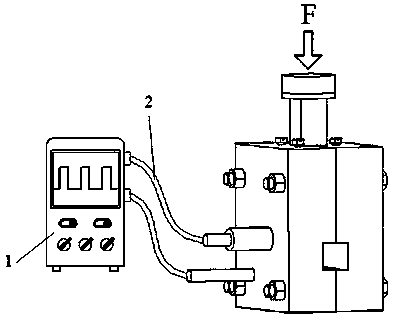

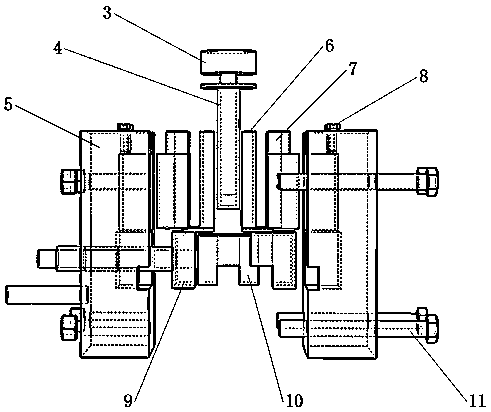

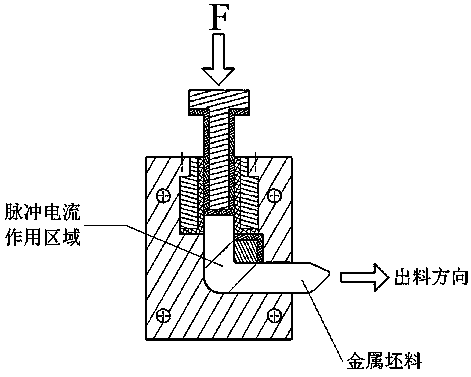

Pulse current assisted equal-diameter angular extrusion equipment and method

InactiveCN110479785AImprove plastic deformation abilityAvoid wrinklesExtrusion diesWrinkle skinMetallic materials

The invention relates to pulse current assisted equal-diameter angular extrusion equipment and method, and belongs to the field of metal material processing. An inner corner module insulation bushinginsulates an inner corner conductive module from the rest of a mold; a male mold insulating sleeve and a longitudinal channel insulation bushing are arranged so that it can be ensured that a metal blank is insulated from a male die pressing rod and a female mold longitudinal channel; the inner corner conductive module and a combined type female mold sleeve are connected to two poles of a pulse power supply correspondingly; the metal blank is in contact with inner and outer corners in the deformation process to be connected into a circuit, and blanks at the corners participate in conduction; and the pulse power supply should have the good adjustment performance, and the temperature of blanks in a deformation zone is controlled by adjusting pulse current parameters in the extrusion processing procedure. Pulse current is used for replacing traditional mold heating, plastic deformation of the metal blanks at the corners is used for assistance, wrinkles and cracks are prevented, the yield is improved, energy consumption is saved, and continuous and efficient processing is achieved; and the overheating growth of crystal grains is effectively suppressed, uniform and fine grains are obtained, and the strength and plasticity are greatly improved.

Owner:JILIN UNIV

Efficient waste gas treatment system and process

ActiveCN113082977AHigh catalytic activityContinuous and efficient processingGas treatmentDispersed particle separationMolecular sieveReflux valve

The invention provides an efficient waste gas treatment system and process, the efficient waste gas treatment system comprises a slurry bed, an overflow pipe, an overflow pump, a liquid-solid separator, a return pipe, a return valve, a medicament storage tank, a dosing pump, a waste gas distributor and a molecular sieve; wherein the slurry bed comprises a lower bed body, a middle bed body and an expansion section, one end of the overflow pipe is connected with the upper part of the middle bed body, and the other end of the overflow pipe is connected with the upper part of the liquid-solid separator; one end of the return pipe is connected with the lower part of the liquid-solid separator, the other end of the return pipe is connected with the lower part of the middle bed body, the return valve is positioned on the return pipe, the inlet end of the dosing pump is connected with the medicament storage tank, and the outlet end of the dosing pump is connected with the middle bed body; the waste gas distributor is positioned in the middle bed body and comprises an upper seal head, a perforated pipe, a lower seal head and a gas inlet, wherein the perforated pipe is located between the upper sealing head and the lower sealing head, and the slurry bed is filled with the molecular sieve. According to the efficient waste gas treatment process, the waste gas can be in full contact with the treatment agent, gaseous pollutants in the waste gas can be efficiently removed without generation of secondary pollutants such as PM2.5.

Owner:江苏舒源空调制造有限公司

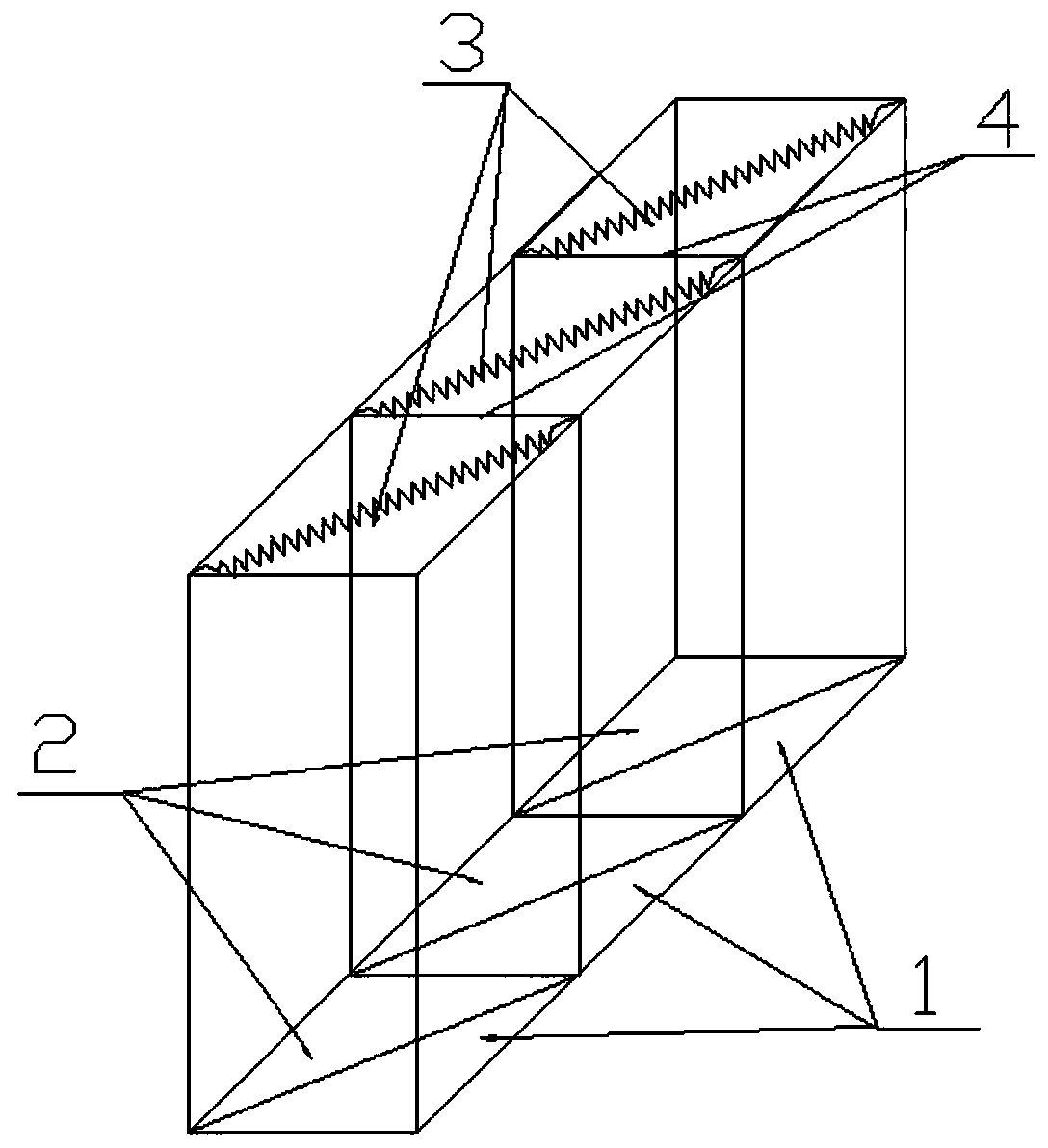

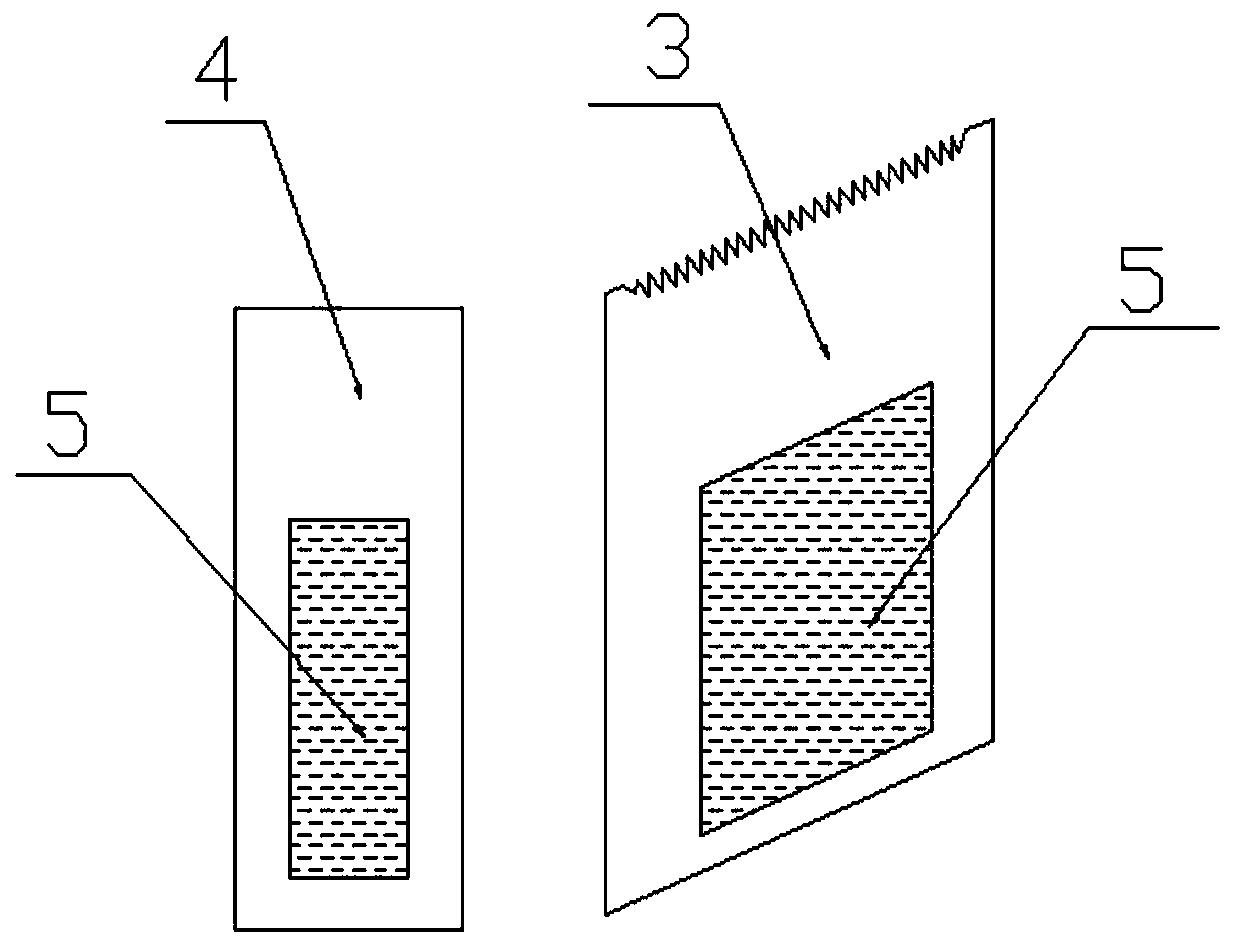

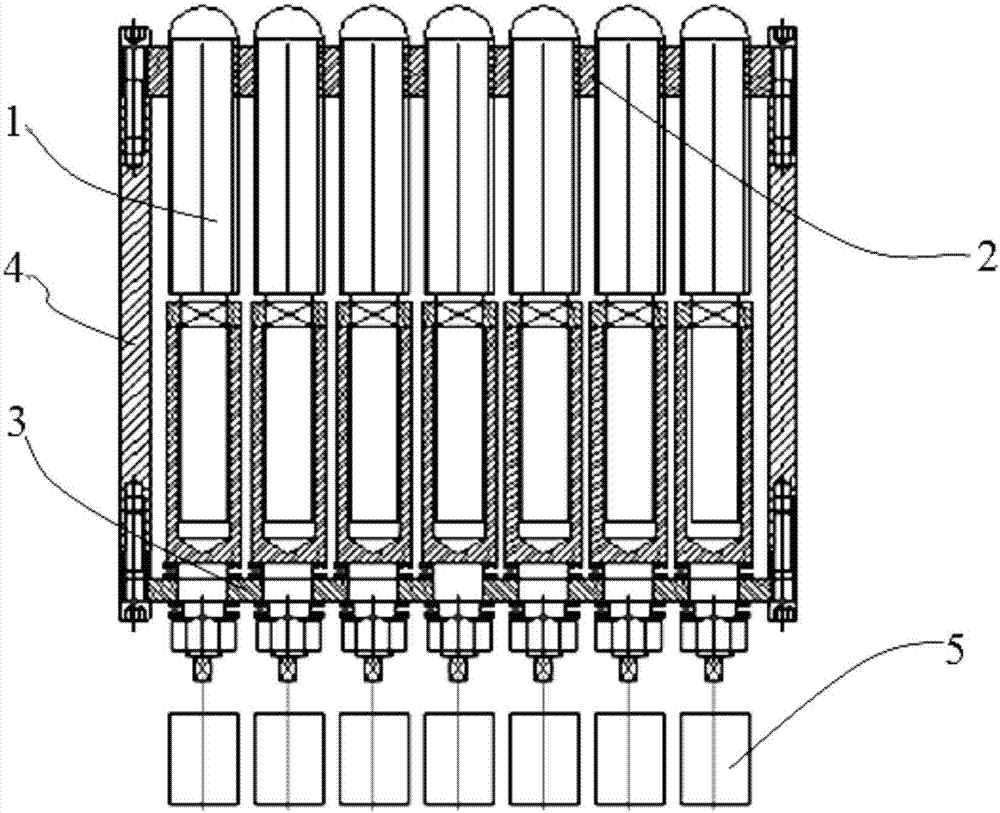

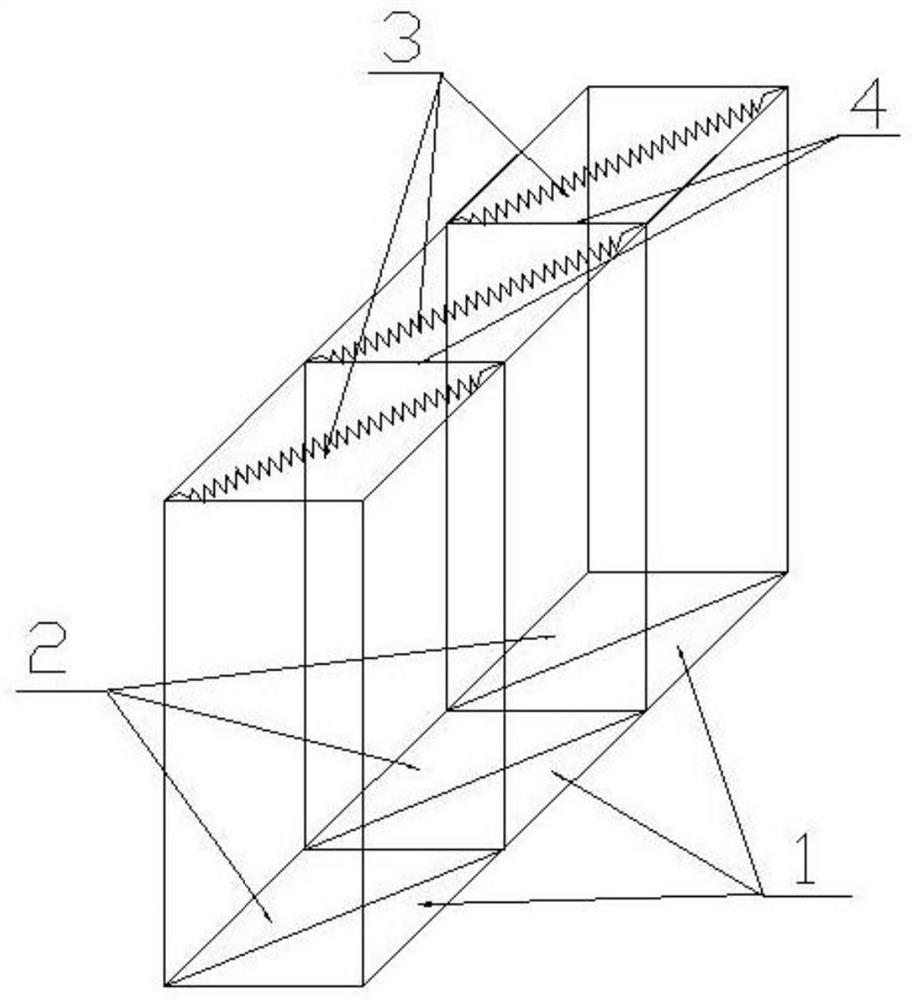

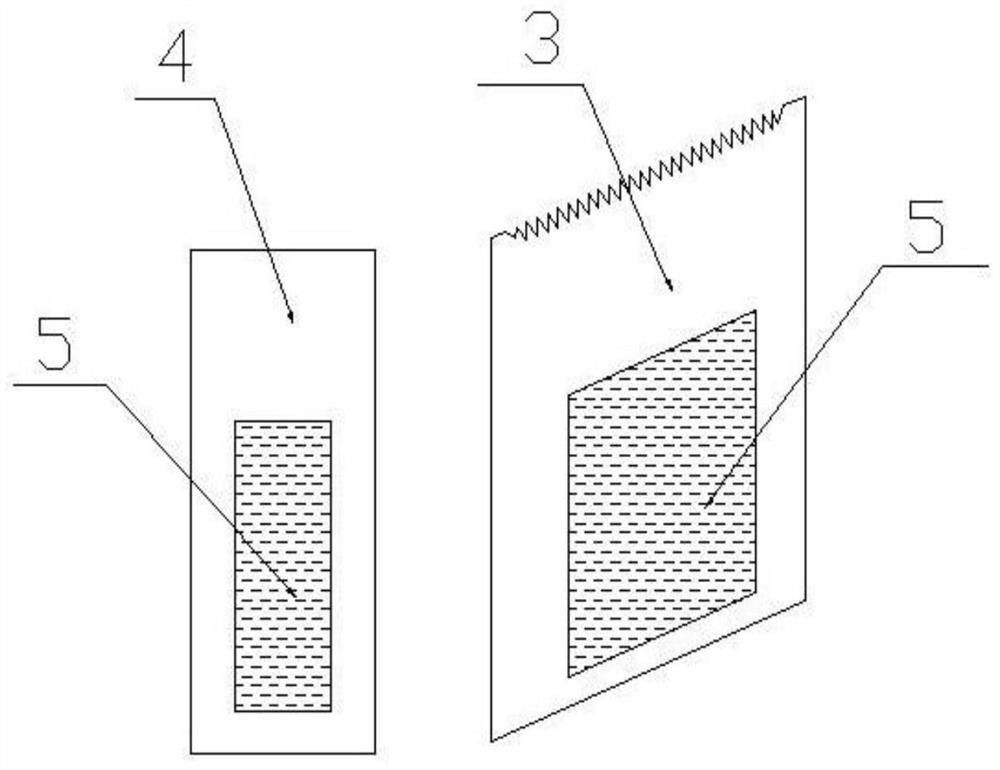

Integral multistage microorganism fuel battery pack

ActiveCN110323478AReduce spacingImprove transfer efficiencyTreatment by combined electrochemical biological processesWater contaminantsMicrobial fuel cellMicroorganism

The invention relates to an integral multistage microorganism fuel battery pack. The integral multistage microorganism fuel battery pack is formed by serially connecting a plurality of same cubical battery monomers; each battery monomer comprises an anode chamber and a cathode chamber; the anode chamber and the cathode chamber are separated along the diagonal lines of the battery monomers; a proton exchange diaphragm is arranged between the anode chamber and the cathode chamber; a medium inside the anode chamber and the cathode chamber of every two adjacent battery monomers is conveyed continuously, and the proton exchange diaphragm is arranged between the anode chamber and the cathode chamber. According to the integral multistage microorganism fuel battery pack, a conventional microorganism fuel battery structure design is broken, the anode chamber and the cathode chamber of a multistage MFC are nested and fused mutually, the distance between the anode chamber and the cathode chamberis reduced obviously, and the internal resistance of the system is reduced to the maximum extent. Bidirectional interconnecting transfer of protons is formed between adjacent single-stage MFCs, the transmission path cross sections of protons between the anode chamber and the cathode chamber are greatly expanded, and the proton transfer efficiency can be promoted obviously.

Owner:YANTAI UNIV

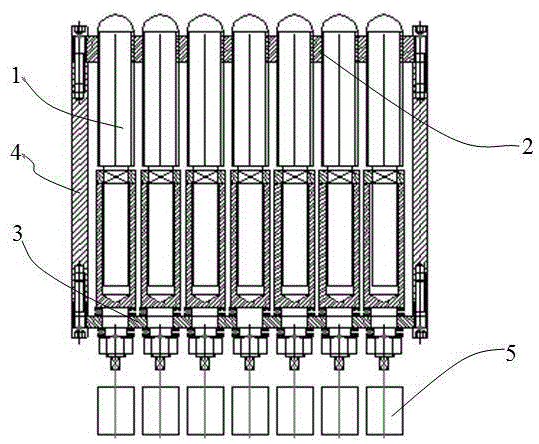

Biological fiber continuous forming equipment

PendingCN113715291AHigh strengthContinuous and efficient processingCoatingsContinuous productionManufacturing engineering

The invention discloses biological fiber continuous forming equipment. The equipment comprises an extrusion device, a solidification device, a drying device, a collection device and a beam combining device, the beam combining device can be arranged between the drying device and the collection device, the extrusion device is used for continuously extruding multiple strands of fiber filaments, then solidification bath contained in the solidification device is used for solidifying the immersed fiber filaments, then, the fiber filaments after solidification are dried by using the drying device, and the multi-strand fiber filaments are combined by using the beam combining device, so that the strength of the fiber filaments is improved; and finally, the rotating collection device is used for collecting the fiber filaments, the devices are sequentially arranged, continuous production is achieved, and therefore, high-strength biological fibers can be continuously and efficiently processed.

Owner:TSINGHUA UNIV

A single point integrated mold

InactiveCN105537410BHigh strengthContinuous and efficient processingShaping toolsDrive motorEngineering

The invention relates to a single-point integral mould, and belongs to the field of mechanical engineering. The single-point integral mould consists of a plurality of single-point type supporting mechanisms, an upper supporting plate, a lower supporting plate, a vertical plate and a drive motor; each single-point type supporting mechanism is composed of a spiral up-down moving type ejector rod and a fixed type rotary drive handle; the single-point type supporting mechanisms are arranged in the form of a square matrix and a circular matrix at certain spacing to form a mould; a hole with inner threads is processed in the upper supporting plate; and a light hole is formed in the lower supporting plate. The mould enables the ejector rod to spirally ascend on the upper supporting plate through the motor and the rotation drive handle, so that different molded surfaces are formed. The single-point integral mould has the advantages that curved parts with different shapes can be continuously and efficiently processed; and meanwhile, curved surface of large boards can be processed, so that solid mould processing is avoided, and the cost for processing the curved parts with different shapes is saved.

Owner:JILIN UNIV

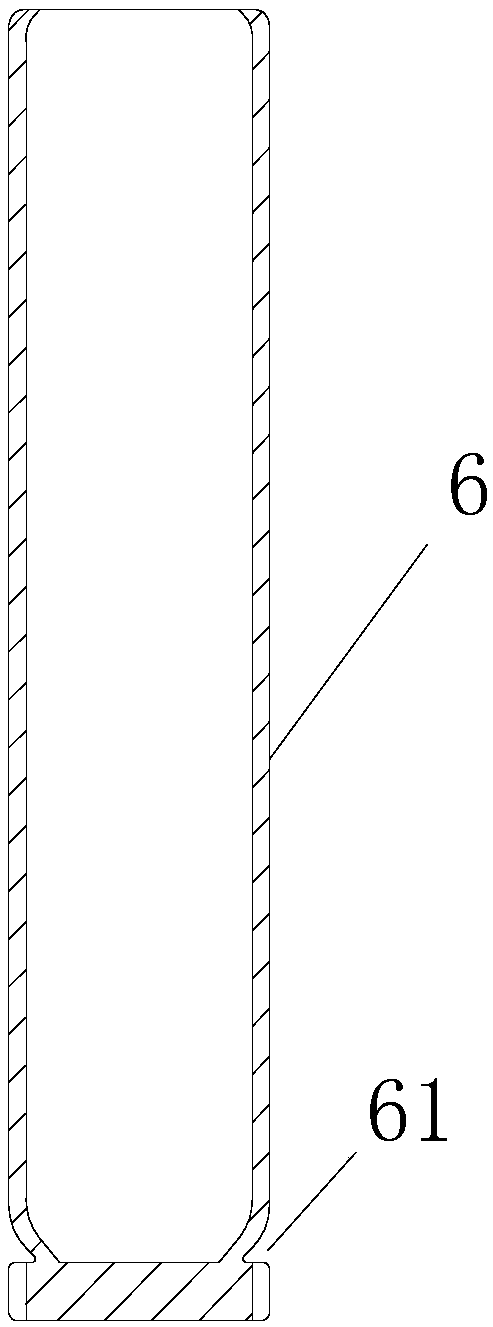

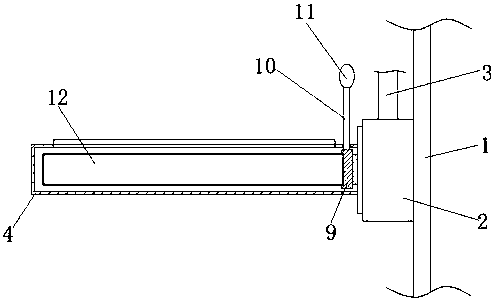

Powdered activated carbon adding device for landfill leachate tail water treatment

PendingCN110498472ASolve the troublesome problem in the recycling and replacement processRecycling and replacement process is quick and easyWater/sewage treatment by sorptionContaminated groundwater/leachate treatmentFlocculationActivated carbon

The invention relates to the technical field of landfill leachate treatment, in particular to a powdered activated carbon adding device for landfill leachate tail water treatment. The device comprisesa sliding mounting base and a sliding rail, the sliding rail is vertically arranged along the tank wall of a neutralization flocculation tank, the sliding mounting seat in sliding fit is disposed onthe sliding rail, one side of the sliding mounting seat far from the sliding rail is equipped with an outer cylinder and an inner cylinder, the top of the outer cylinder is equipped with an inlet, thebottom of the outer cylinder is equipped with an outlet, the inner cylinder is located inside the outer cylinder, the inner cylinder is equipped with a long and straight through-hole along the lengthdirection of the cylinder body, and activated carbon is added into the inner cylinder through the inlet on the outer cylinder and the through-hole on the inner cylinder. The device provided by the invention solves the problem of troublesome replacement process of activated carbon during adding of powdered activated carbon into the neutralization flocculation tank, makes the activated carbon replacement process faster and more convenient, saves time, ensures continuous and efficient landfill leachate tail water treatment, and the treatment process is obviously optimized.

Owner:SHENYANG ACAD OF ENVIRONMENTAL SCI

A high-efficiency exhaust gas treatment system and process

ActiveCN113082977BHigh catalytic activityContinuous and efficient processingGas treatmentDispersed particle separationMolecular sieveReflux valve

The invention provides a high-efficiency exhaust gas treatment system and process, including a slurry bed, an overflow pipe, an overflow pump, a liquid-solid separator, a return pipe, a return valve, a chemical storage tank, a chemical dosing pump, an exhaust gas distributor, and a molecular sieve , the slurry bed includes a lower bed body, a middle bed body, and an expansion section. One end of the overflow pipe is connected to the upper part of the middle bed body, and the other end is connected to the upper part of the liquid-solid separator. The overflow pump is located on the overflow pipe, and one end of the return pipe is connected to the liquid-solid separator. The lower part of the solid separator is connected, and the other end is connected with the lower part of the middle bed body. The return valve is located on the return pipe. The upper head, the porous pipe, the lower head, the air inlet, the porous pipe is located between the upper head and the lower head, and the molecular sieve is filled in the slurry bed. The waste gas of the high-efficiency waste gas treatment process of the present invention can be fully contacted with the treatment agent, can efficiently remove gaseous pollutants in the waste gas, and will not produce secondary pollutants such as PM2.5 dust.

Owner:江苏舒源空调制造有限公司

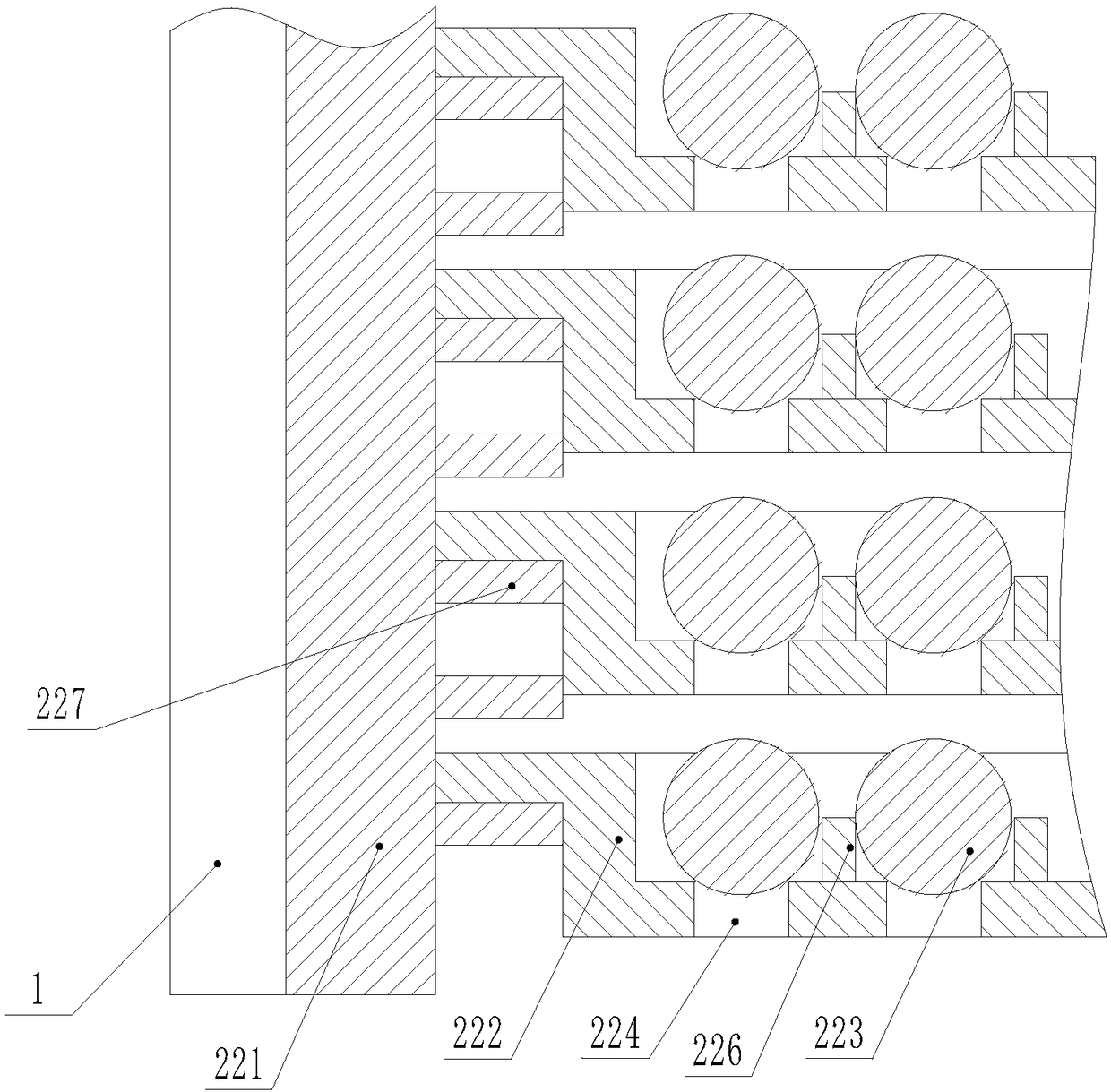

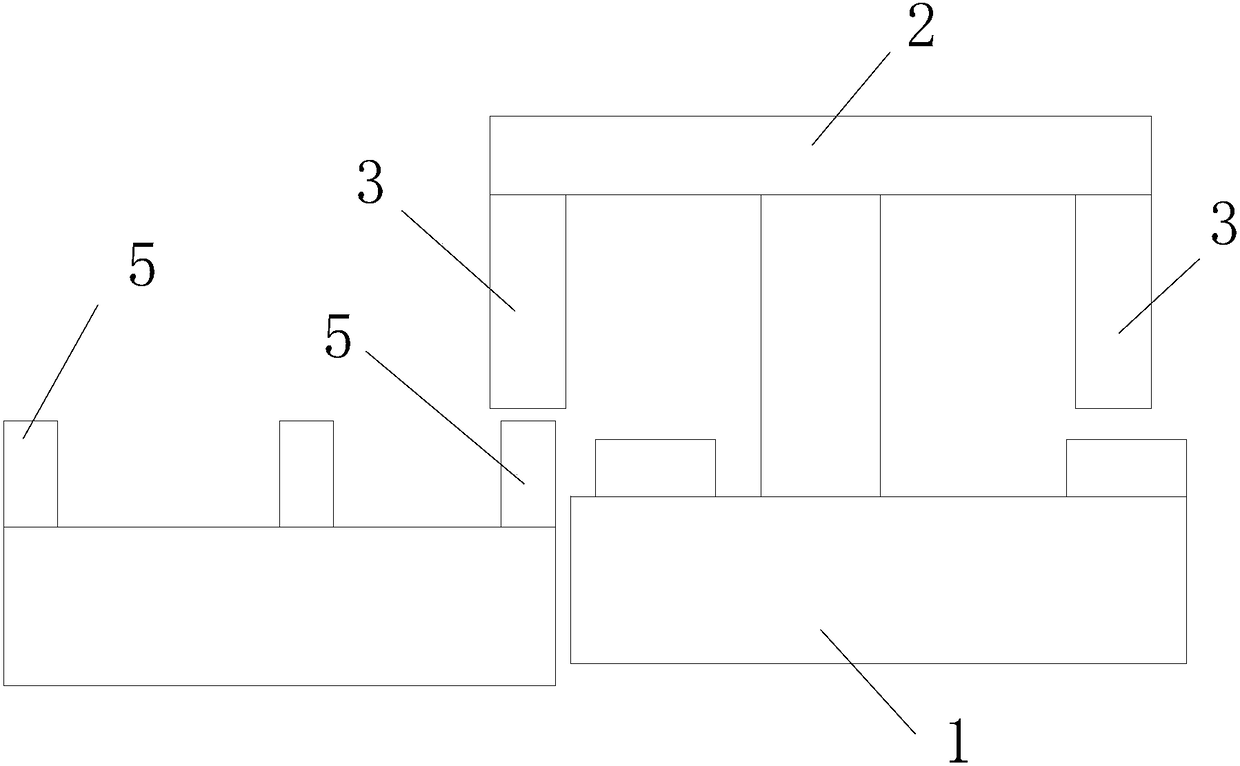

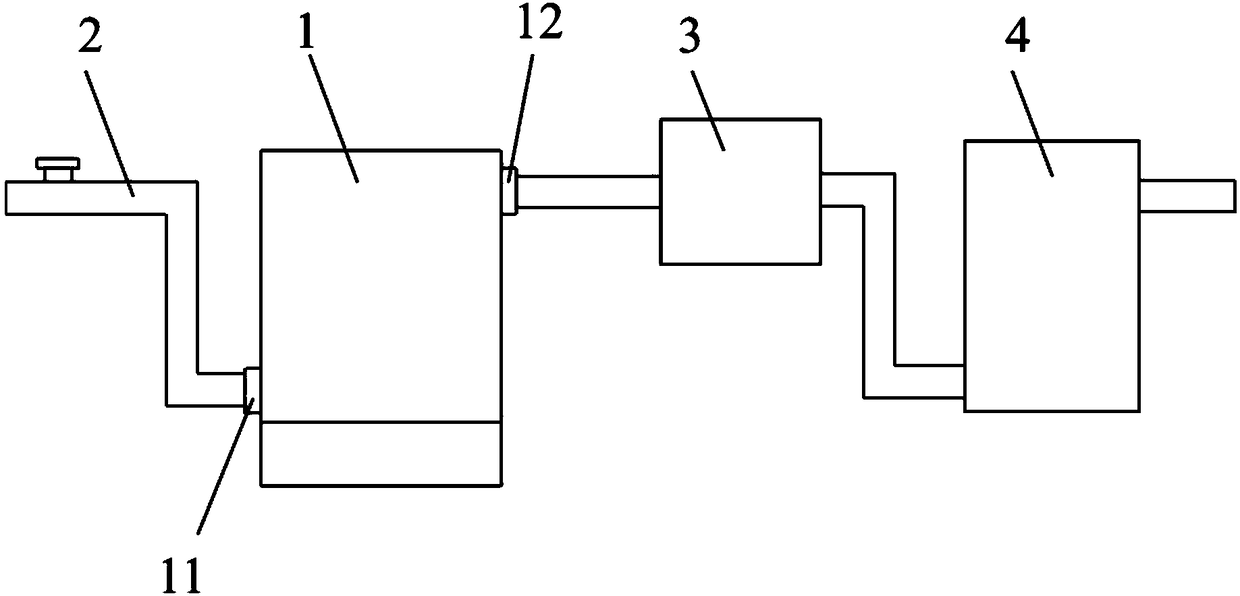

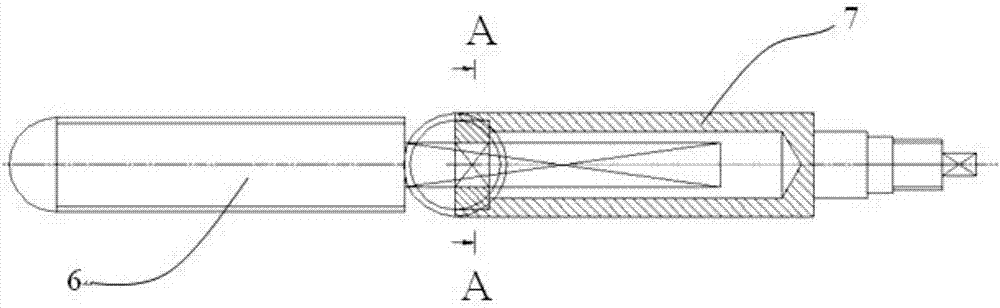

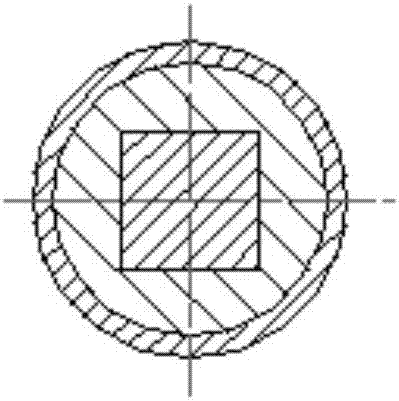

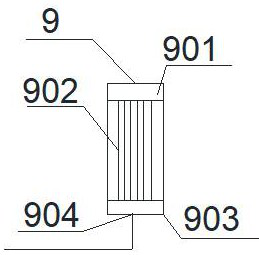

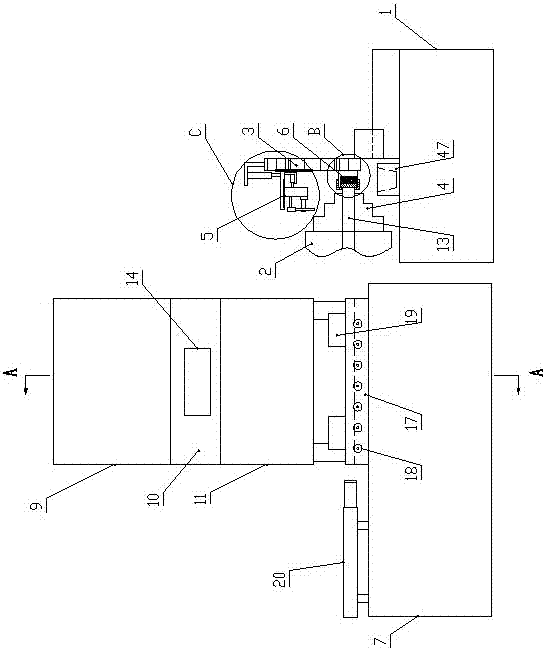

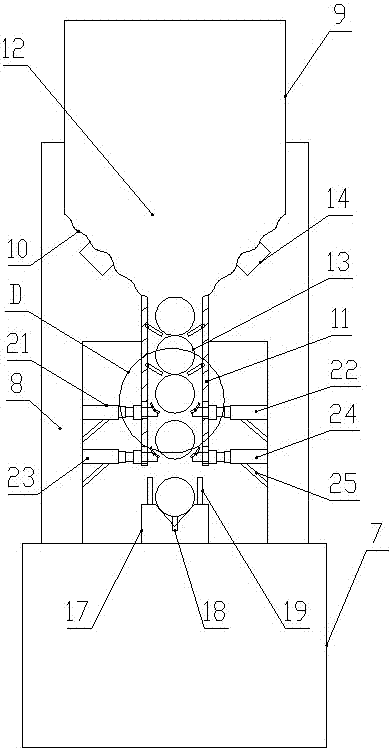

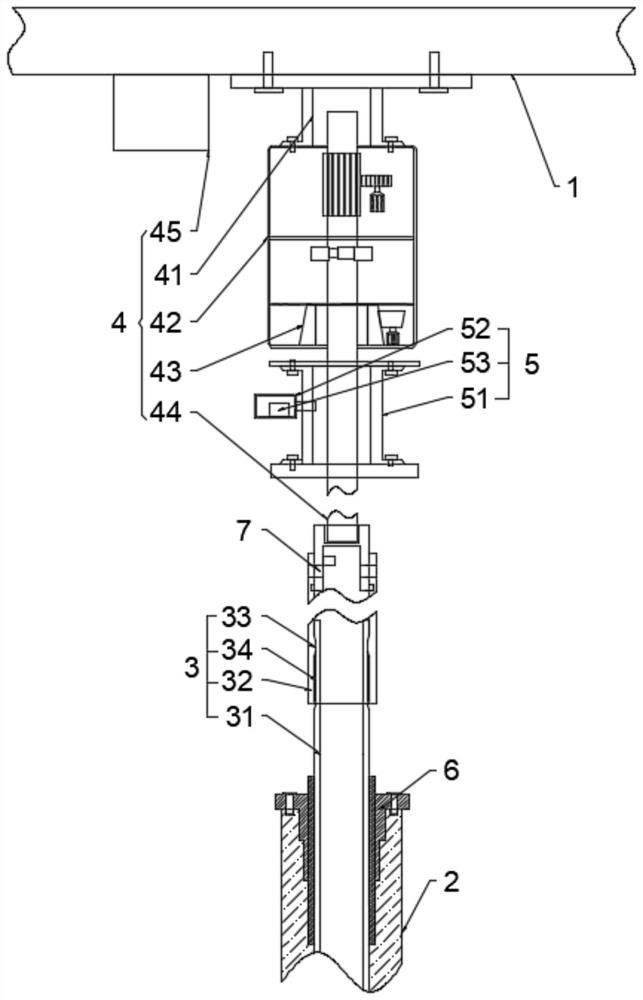

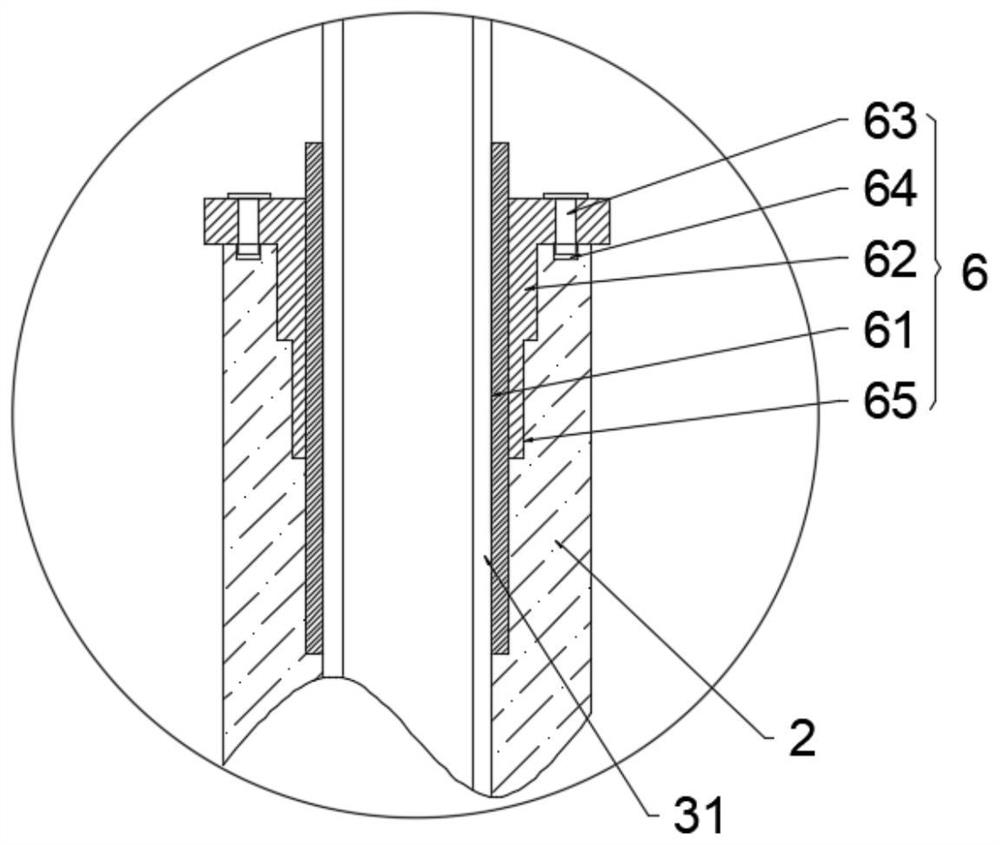

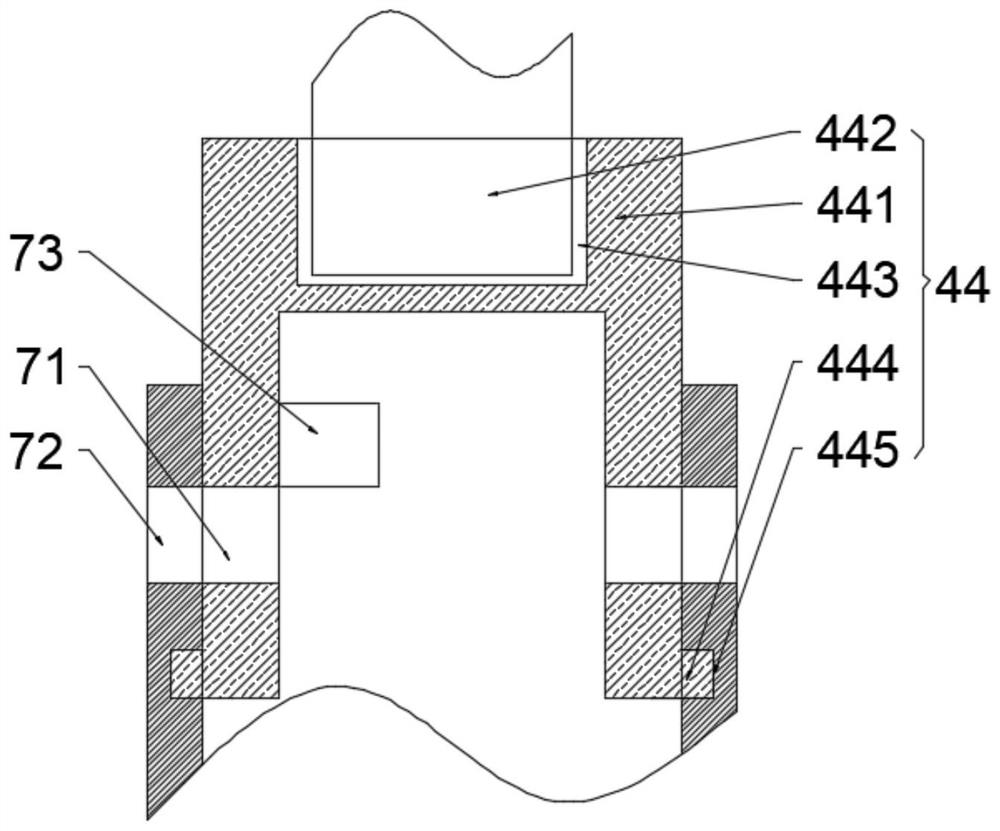

A CNC lathe with automatic loading for shaft parts

InactiveCN105798330BAvoid shockPrevent flying outTurning machinesPositioning apparatusEngineeringExpansion joint

The invention discloses a digital controlled lathe capable of conducting automatic loading and suitable for shaft parts. The digital controlled lathe comprises a lathe body, wherein the lathe body is provided with a hollow spindle, a sliding rail is arranged on the lathe body in the front and back horizontal direction, a knife rest is arranged on the sliding rail in a slidable manner, the front end of the hollow spindle is coaxially and fixedly connected with a hollow chuck, the knife rest is provided with an electromagnetic attraction mechanism, and an automatic loading device is arranged behind the lathe body; and the automatic loading device comprises a work bin base, the work bin base is fixedly connected with a work bin support, the work bin support is fixedly connected with a storage box, a corrugated pipe expansion joint and an unloading box from top to bottom in sequence, one vibration motor is arranged on the left outer wall of the corrugated pipe expansion joint, one vibration motor is arranged on the right outer wall of the corrugated pipe expansion joint, a stock stop is arranged on the lower portion of the unloading box, and the upper surface of the work bin base is fixedly connected with a material pushing base located under the unloading box. The digital controlled lathe is easy and convenient to operate, high in automation degree and stable in work, and can achieve automatic loading, effectively shorten the auxiliary time and improve the working efficiency.

Owner:HUANGHE S & T COLLEGE

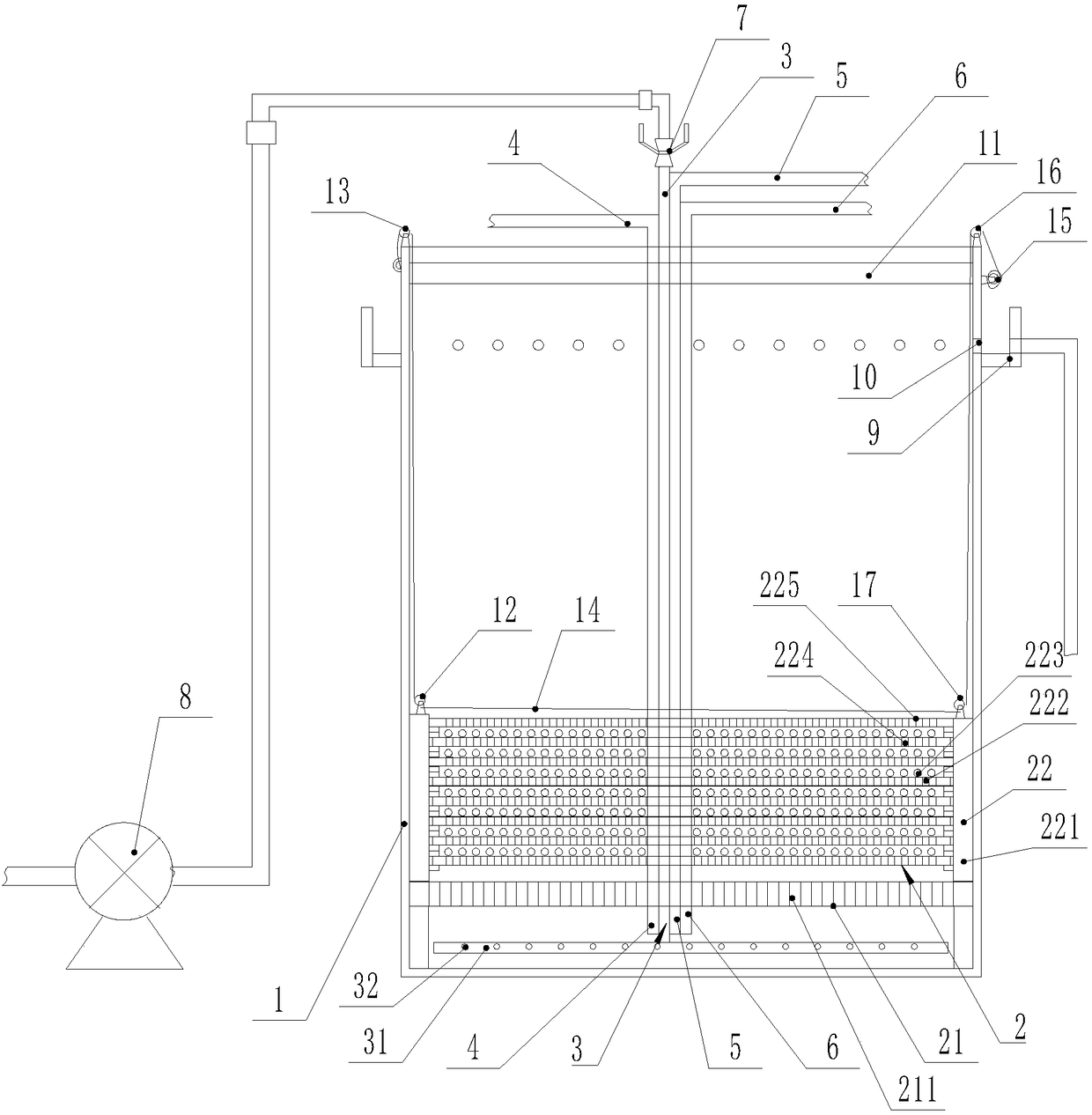

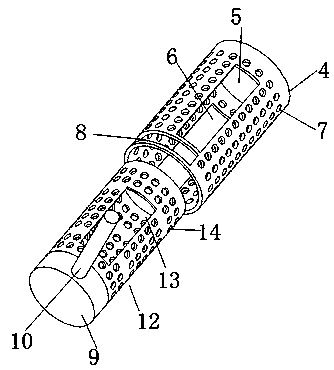

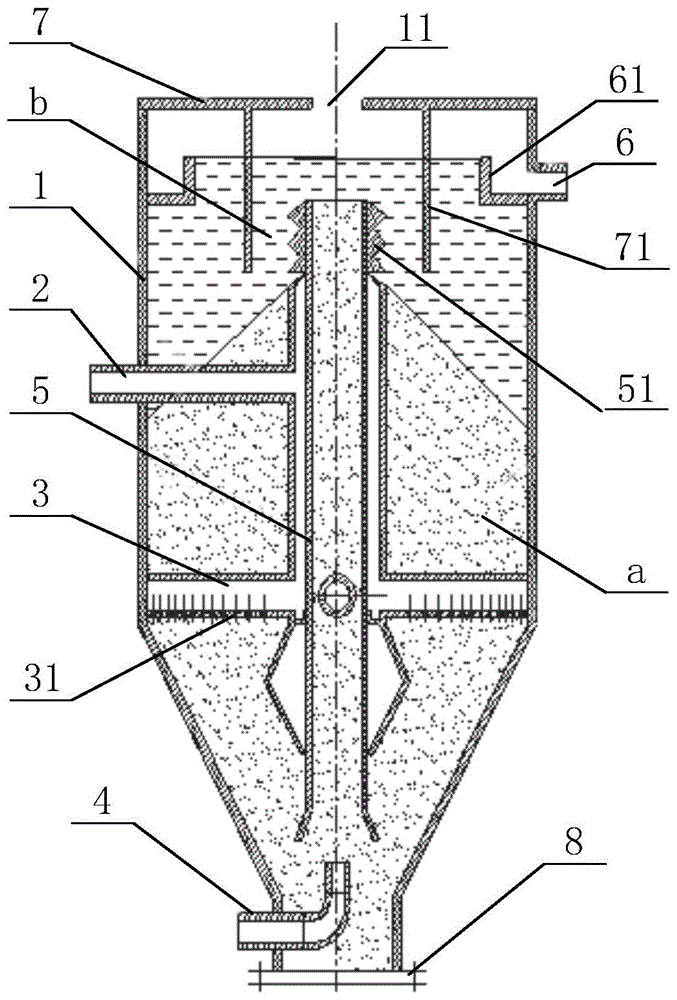

An internal circulation iron-carbon micro-electrolysis reactor

ActiveCN105036261BReduce energy consumptionReduce wearWater/sewage treatment using germicide/oligodynamic-processElectrolysisWater flow

The invention discloses an internal-circulation type iron-carbon micro-electrolysis reactor. The reactor structurally comprises a cylinder body (1), a water inlet pipe (2), a water distributor (3), an air inlet pipe (4) and an internal circulation pipe (5); waste water flows through the water inlet pipe (2) and the water distributor (3) in sequence and is dispersed into iron-carbon filler (a) which is located on the lower portion of the cylinder body (1), and in the process of being in contact with the iron-carbon filler (a), the waste water is purified unceasingly till post-purification water is formed and drained out of a water outlet (6) of the cylinder body; air enters the iron-carbon filler (a) at the bottom of the cylinder body (1) through the air inlet pipe (4), and aeration bubbles moving upward are formed; the aeration bubbles drive the iron-carbon filler (a) to pass through the internal circulation pipe (5) and be discharged into the post-purification water; the iron-carbon filler (a) keeps on being sedimentated till falling back to an accumulation bed of the iron-carbon filler (a), thereby an aeration cycle of the iron-carbon filler (a) is formed. It is thus clear that by means of the internal-circulation type iron-carbon micro-electrolysis reactor, the energy consumption is low, the abrasion is little, the operation is simple, and the waste water can be disposed in a continuous and highly-efficient mode.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

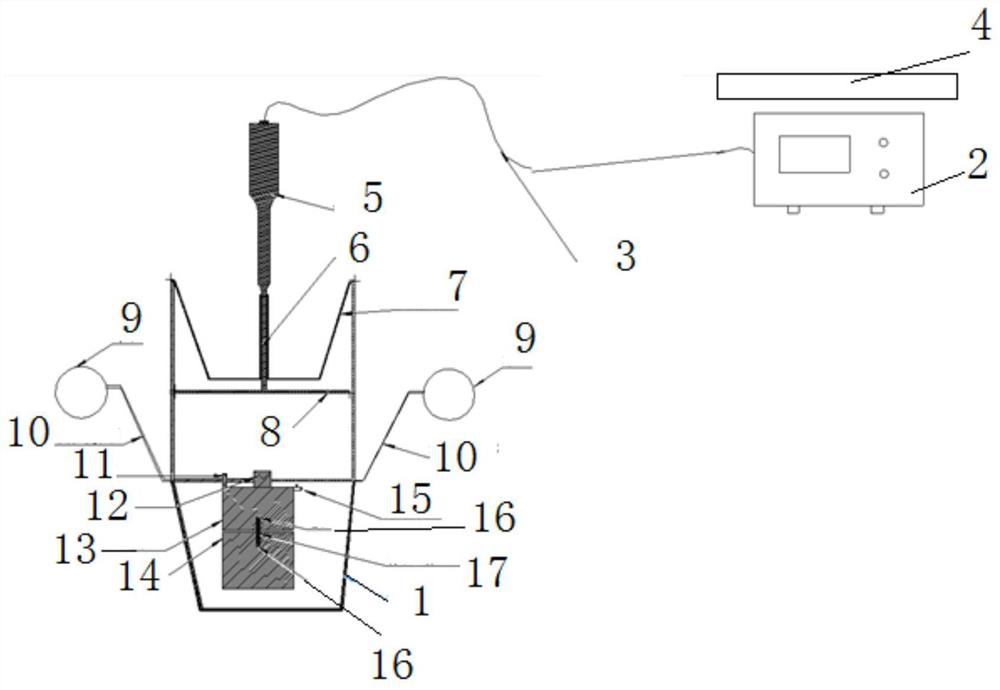

Ultrasonic water garbage treatment device

PendingCN112744969AAvoid cloggingSafe to useFatty/oily/floating substances removal devicesGeneral water supply conservationPhysicsWater circulation

The invention discloses an ultrasonic water garbage treatment device. A solar panel is mounted on an ultrasonic power supply, the ultrasonic power supply is electrically connected with an ultrasonic transducer through an ultrasonic power line, an ultrasonic amplitude-change pole penetrating through a garbage filter is connected to the ultrasonic transducer, an ultrasonic vibration plate is mounted below the ultrasonic amplitude-change pole, a rear cover is installed on one side of the garbage filter, a floating ball / cylinder connecting rod connected with a floating ball is installed on the rear cover, an impeller chamber and a water pump motor are installed in the rear cover, the water pump motor is in transmission connection with the impeller chamber through a rotor main part and a bearing connected with the outer side of the rotor main part in a sleeving mode, a function conversion valve is installed in the impeller chamber, and the impeller chamber is provided with a water inlet circulation port and a water outlet circulation port. The device is safe to use and the installation is convenient and fast. The device can continuously and efficiently process blue-green algae.

Owner:江苏百航超声科技有限公司

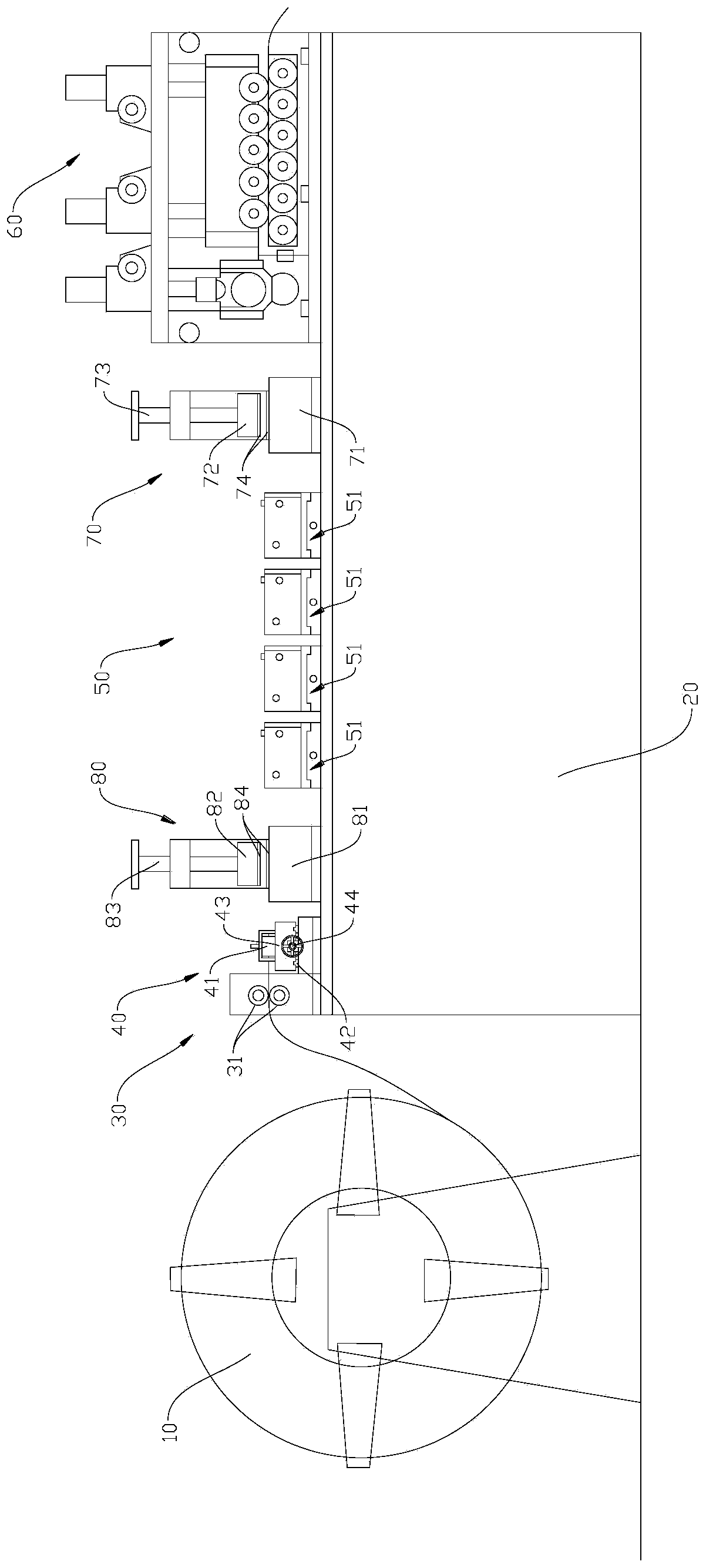

Complete sanding device

ActiveCN104259971BContinuous and efficient processingSimple structureGrinding machinesGrinding feedersPulp and paper industryDevice kit

The invention provides a sanding set comprising a double side roughing machine, a double side finishing machine, a chamfering machine, a left side and right side polisher, a top and bottom polisher and a plurality of conveying frames. The conveying frames are mounted among the double side roughing machine, the double side finishing machine, the chamfering machine, the left side and right side polisher and the top and bottom polisher and are used for conveying wood material. The sanding set is simple in structure and applicable to continuous efficient processing of irregular wood materials.

Owner:江西英硕智能科技有限公司

A stamping die with convenient blanking

ActiveCN110624995BDoes not affect normal workImprove structural strengthStripping-off devicesEngineeringWaste material

The invention discloses a stamping die facilitating to blanking. The stamping die facilitating to blanking comprises vertical plates which are symmetrically arranged, wherein a rotary barrel is rotationally arranged in each vertical plate; an accommodating cavity is formed in each rotary barrel; a plurality of open grooves are formed in the end wall of each accommodating cavity in a communicationmanner; the open grooves communicate with an external space; inner cavities are formed in the end walls of the two sides of each accommodating cavity in a communication manner; the inner cavities aresymmetrically formed; and rotary devices driving the rotary barrels to rotate are arranged on the outer surfaces of the vertical plates and the rotary barrels. The equipment is simple in structure; easier blanking machining is realized by adopting the manner of replacing dies with different shapes and dimensions by means of rotating, and a lower die does not need to be manually replaced; and moreover, wastes are rapidly guided out of the equipment in a blanking process, and the lower die plays the role of structure enhancement during stamping for the equipment, so that the structure strength and reliability during continuous blanking of the die are effectively improved, and the life of the die is prolonged.

Owner:东莞市伟峰印刷有限公司

A CNC lathe with automatic feeding

InactiveCN105798332BAvoid shockPrevent flying outMetal working apparatusNumerical controlEngineering

The invention discloses an automatic feeding numerical control lathe. The automatic feeding numerical control lathe comprises a lathe body, wherein a hollow spindle is arranged on the lathe body; a sliding rail is arranged on the lathe body along the front and back horizontal direction; a knife rest is slidably arranged on the sliding rail; a hollow chuck is axially and fixedly connected to the front end of the hollow spindle; a cutting mechanism and an electromagnetic adsorption mechanism are arranged on the knife rest; an automatic feeding device is arranged behind the lathe body; the automatic feeding device comprises a material box base; a material box support is fixedly connected onto the material box base; a material storage box, a corrugated pipe elastic joint and a discharging box are sequentially arranged on the material box support from top to bottom in a fixed manner; a vibration motor is arranged on the outer wall of each of the left and right sides of the corrugated pipe elastic joint; a material baffle mechanism is arranged on the lower part of the discharging box; and a material pushing base which is right blow the discharging box is fixedly connected onto the upper surface of the material box base. The automatic feeding numerical control lathe is simple and convenient for operation, high in automatic degree and stable in work; automatic feeding can be realized; non-cutting time is effectively shortened; cutting can be performed rapidly; and the working efficiency is improved.

Owner:HUANGHE S & T COLLEGE

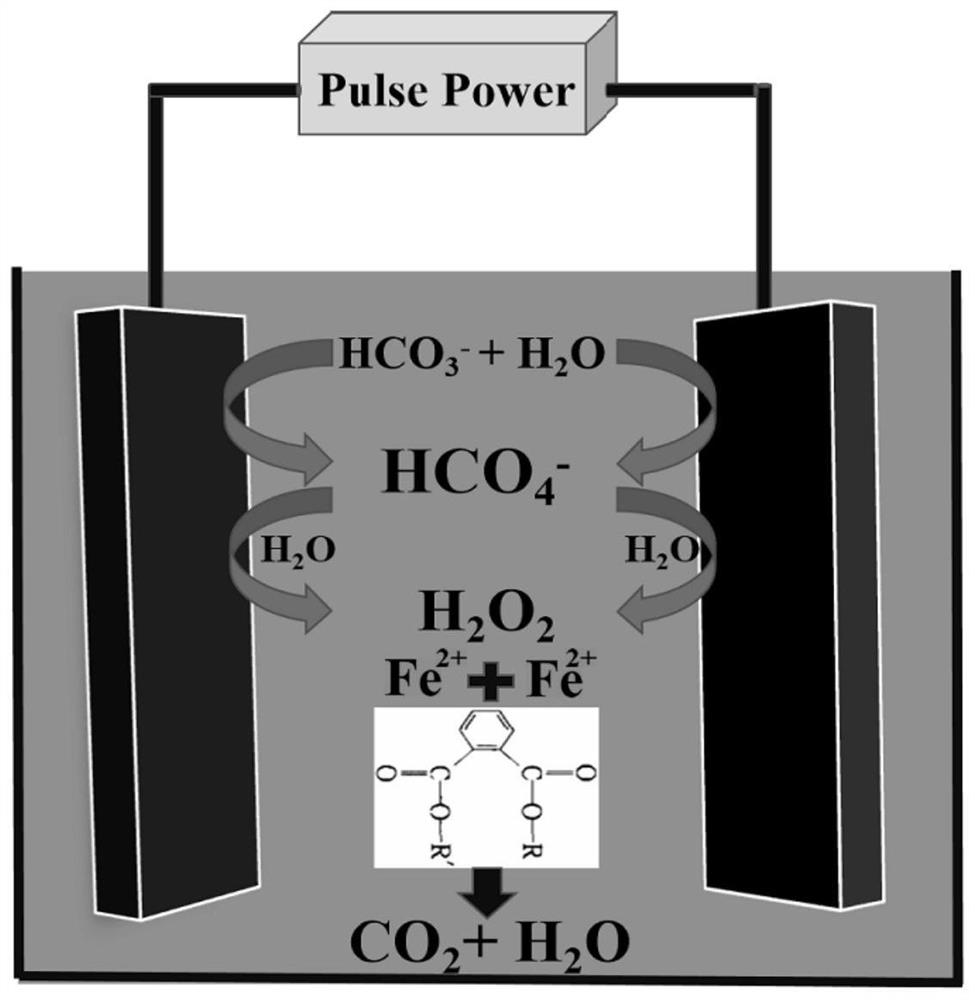

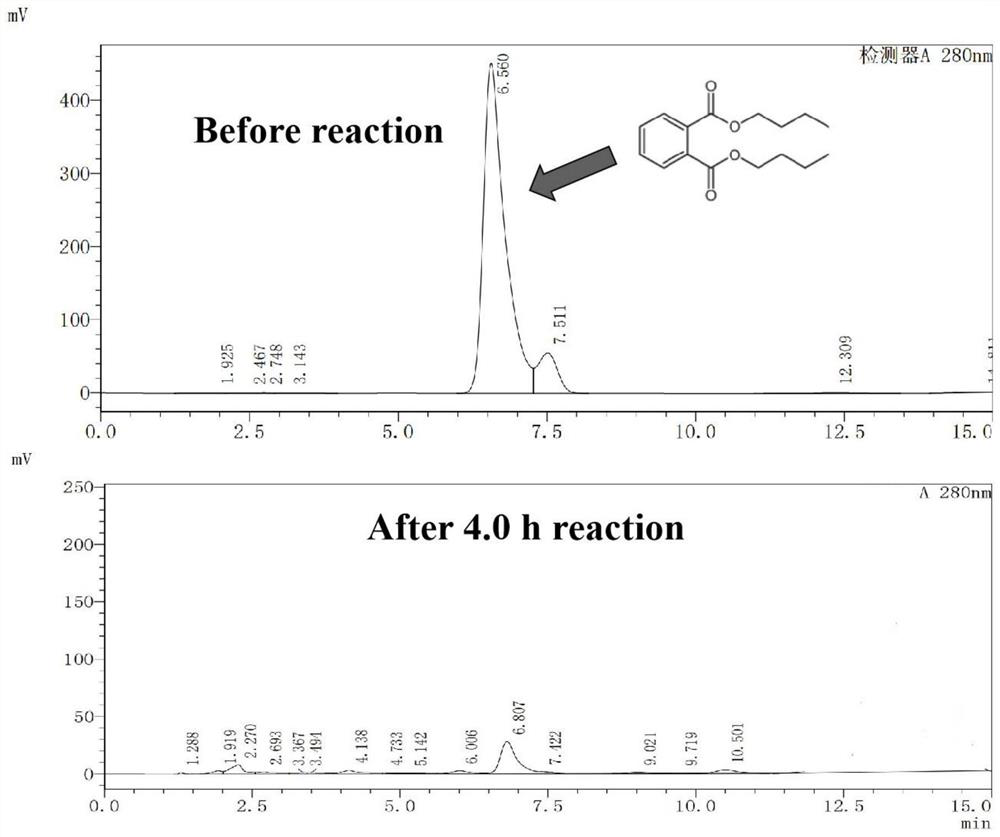

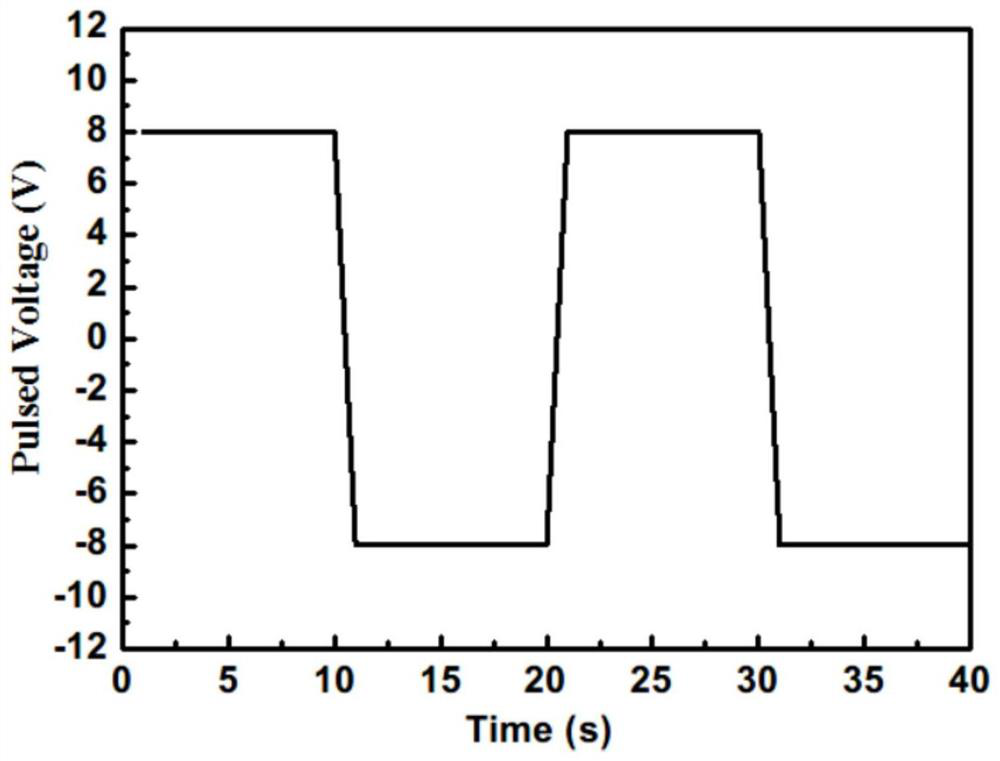

Method for repairing and treating phthalate-polluted soil through hydrogen peroxide produced through pulse electrochemistry

ActiveCN112872015AStrong oxidation abilityOvercoming inefficienciesContaminated soil reclamationSoil scienceEdaphic

The invention relates to a method for repairing and treating phthalate-polluted soil through hydrogen peroxide produced through pulse electrochemistry, and belongs to the technical field of soil repairing. The method specifically comprises the following steps: crushing the phthalate-polluted soil, adding the crushed phthalate-polluted soil into an aqueous solution containing bicarbonate radicals, uniformly conducting mixing, inserting two carbon electrodes, and then applying square-wave pulse voltage on the two carbon electrodes to carry out electrochemical remediation treatment. According to the method, air does not need to be introduced into the soil, a reaction electrode does not need to be periodically replaced, dissolved bicarbonate radicals in the soil are electrochemically activated, and mediated water is oxidized and converted into hydrogen peroxide, so that the phthalate-polluted soil is continuously and efficiently repaired and treated, and the method has the characteristics of simplicity, convenience, greenness and high efficiency.

Owner:CHONGQING RES ACAD OF ECO ENVIRONMENTAL SCI

Inner and outer cylinder combined structure and method for algae control deep well

ActiveCN113565074AImprove work efficiencyEasy accessWater cleaningMowersEnvironmental engineeringBiology

The invention discloses an inner and outer cylinder combined structure of an algae control deep well. The inner and outer cylinder combined structure comprises a mounting rack, a base cylinder, a combined cylinder mechanism, an adjusting device and a water level monitoring mechanism, one end of the mounting rack is fixedly mounted on the ground, the base cylinder is mounted and inserted in the water bottom, the combined cylinder mechanism is mounted in the base cylinder through a mounting assembly, the adjusting device is arranged on the mounting rack, the combined cylinder mechanism is connected to the mounting rack through the adjusting device, and a water inlet mechanism is arranged on the combined cylinder mechanism. The adjusting device is arranged on the mounting rack, the depth of the water inlet mechanism is electrically adjusted, the working efficiency of blue-green algae treatment is improved, the cross sectional area of a water inlet formed by the water inlet mechanism is adjusted, the continuity of blue-green algae treatment is guaranteed, aquatic plants are periodically cut by the water inlet mechanism, the aquatic plants are prevented from blocking the water inlet of the water inlet mechanism to hinder blue-green algae treatment, and continuous and efficient blue-green algae treatment is guaranteed.

Owner:中交(苏州)城市开发建设有限公司

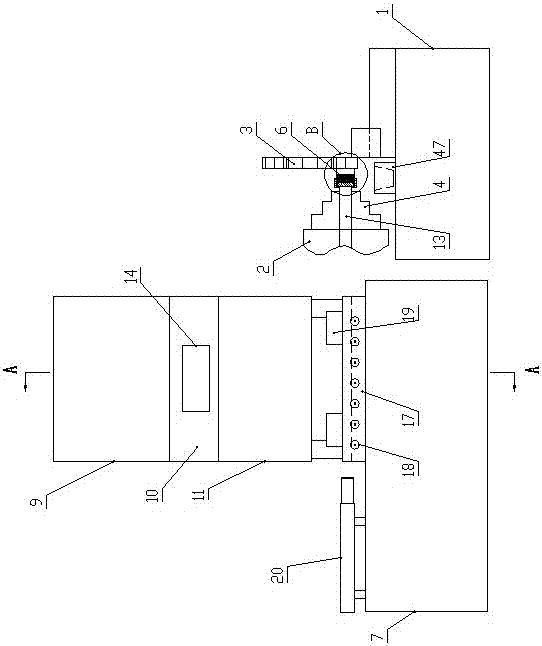

Metal plate machining chamfering equipment

PendingCN111250792AContinuous and efficient processingAccurate locationFeeding apparatusPositioning apparatusTool bitStructural engineering

The invention discloses metal plate machining chamfering equipment. The metal plate machining chamfering equipment comprises a discharging frame and a rack, a metal plate is led out to the rack through the discharging frame, and a lead-in mechanism, a limiting mechanism, a chamfering mechanism and a traction mechanism used for dragging the metal plate are sequentially arranged on the rack; the lead-in mechanism comprises a pair of flat clamping rollers which are clamped on the upper side and the lower side of the metal plate; the limiting mechanism comprises a pair of first limiting wheels clamped to the left side and the right side of the metal plate correspondingly; the chamfering mechanism comprises at least one pair of cutting assemblies symmetrically arranged on the two sides of the metal plate, each cutting assembly comprises a tool apron, a tool bit and a second limiting wheel, the tool aprons are installed on the rack, the tool bits are installed on the tool aprons, and the blade ends of the tool bits abut against the side edges of the metal plate to be used for cutting and chamfering of the side edges of the metal plate; and the second limiting wheels are arranged in frontof the tool bits and installed on the tool aprons, and the second limiting wheels abut against the side edges of the metal plate. According to the metal plate machining chamfering equipment, the sideedges of the metal plate can be chamfered continuously, efficiently and accurately.

Owner:谢秀林

Carbon nanotube-supported microbial electrochemical device for continuous sewage treatment and electricity generation

ActiveCN103811792BContinuous and efficient processingEasy to operateCell electrodesWater contaminantsPtru catalystCarbon nanotube

The invention discloses a carbon nanotube carrier type microbial electrochemical device for continuously treating sewage and generating power, belonging to the technical field of sewage treatment of microbial fuel cells. The microbial electrochemical device comprises an anode chamber and a cathode chamber, wherein the anode chamber is uniformly filled with carbon nanotubes which serve as anodes and microbial carriers; organic sewage and anaerobic digested sludge are inoculated, the anode chamber and the cathode chamber are sealed by a silicone pad, and an anaerobic environment is formed in the anode chamber; a water outlet of the anode chamber is connected with a three-phase separator. According to the device, the anode chamber is filled with the carbon nanotubes to form a packed bed reactor, the device is easy to operate and free of any catalyst, sewage can be continuously and efficiently treated by a continuous and unconventional batched treatment manner, and when the organic load is 4g COD.L<-1>.d<-1> and the hydraulic retention time is 16 hours, the sewage removal rate can be about 90 percent. Moreover, the three-phase separator is added to the water outlet of the anode chamber, so that the problems of blockage and difficulty in maintenance caused by outflow of carbon particle materials are solved.

Owner:CHINA AGRI UNIV

An integrated multi-stage microbial fuel cell stack

ActiveCN110323478BReduce spacingImprove transfer efficiencyTreatment by combined electrochemical biological processesWater contaminantsMicrobial fuel cellFuel cells

The invention relates to an integral multistage microorganism fuel battery pack. The integral multistage microorganism fuel battery pack is formed by serially connecting a plurality of same cubical battery monomers; each battery monomer comprises an anode chamber and a cathode chamber; the anode chamber and the cathode chamber are separated along the diagonal lines of the battery monomers; a proton exchange diaphragm is arranged between the anode chamber and the cathode chamber; a medium inside the anode chamber and the cathode chamber of every two adjacent battery monomers is conveyed continuously, and the proton exchange diaphragm is arranged between the anode chamber and the cathode chamber. According to the integral multistage microorganism fuel battery pack, a conventional microorganism fuel battery structure design is broken, the anode chamber and the cathode chamber of a multistage MFC are nested and fused mutually, the distance between the anode chamber and the cathode chamberis reduced obviously, and the internal resistance of the system is reduced to the maximum extent. Bidirectional interconnecting transfer of protons is formed between adjacent single-stage MFCs, the transmission path cross sections of protons between the anode chamber and the cathode chamber are greatly expanded, and the proton transfer efficiency can be promoted obviously.

Owner:YANTAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com