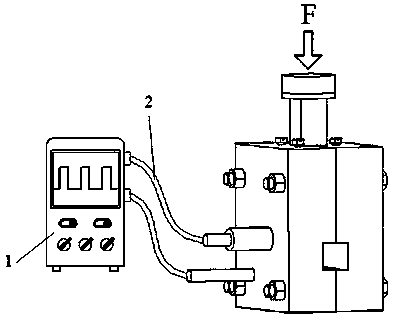

Pulse current assisted equal-diameter angular extrusion equipment and method

A technology of equal-diameter angular extrusion and pulse current, which is applied in the direction of metal extrusion dies, etc., can solve the problems that cannot be completely solved in the equal-diameter angular extrusion process, and achieve the effects of continuous and efficient processing, rapid heating, and improved strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

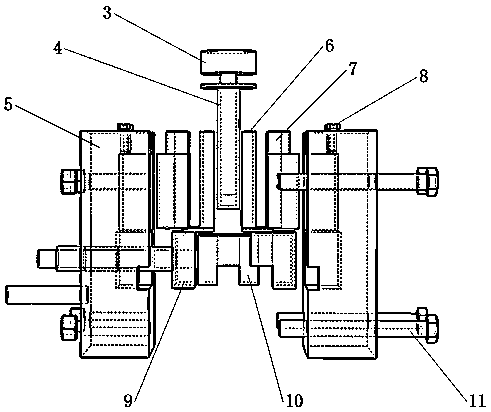

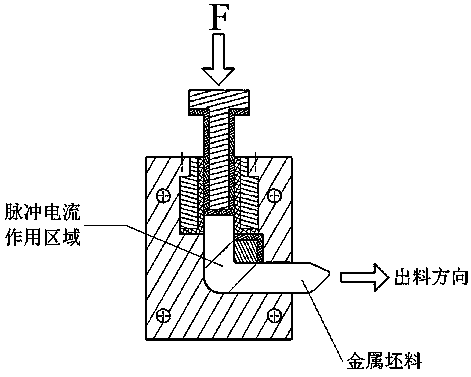

[0053] Taking the pulse current-assisted equal angular extrusion processing of AZ61 magnesium alloy billet as an example, the implementation of the patent is described in detail.

[0054] 1. Assemble the concave mold and punch of the equal diameter angular extrusion equipment according to the description of the above specific embodiment, and place the concave mold on the horizontal anvil of the press.

[0055] 2. Cut out a number of quadrangular prism-shaped blanks with a size of 16mm×16mm×70mm on the AZ61 magnesium alloy ingot that has undergone solution heat treatment, and fully polish the surface with sandpaper until the surface is smooth. After smearing the grease containing molybdenum disulfide on the surface of the blank, put the blank into the longitudinal channel of the die.

[0056] 3. Apply a layer of synthetic grease containing molybdenum disulfide on the outer surface of the insulating sleeve of the punch, and press the assembled punch into the die, so that the AZ6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com