A high-efficiency exhaust gas treatment system and process

A high-efficiency technology for waste gas treatment, applied in gas treatment, separation methods, dispersed particle separation and other directions, can solve the problems of PM2. The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

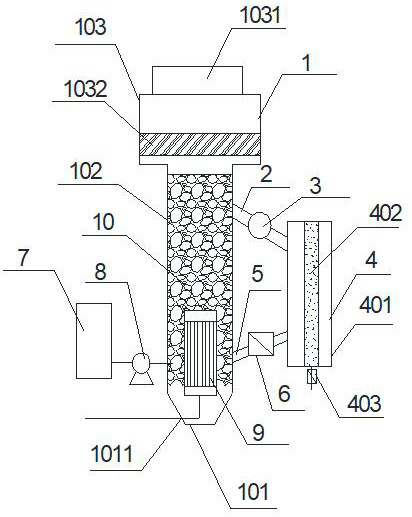

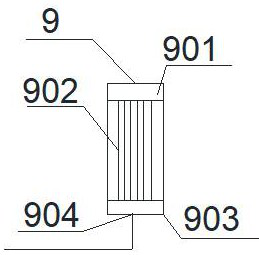

[0023] Such as figure 1 As shown, a high-efficiency waste gas treatment system includes a slurry bed 1, an overflow pipe 2, an overflow pump 3, a liquid-solid separator 4, a return pipe 5, a return valve 6, a chemical storage tank 7, a chemical dosing pump 8, Exhaust gas distributor 9, molecular sieve 10, said slurry bed 1 and liquid-solid separator 4 are equipped with heating and heat preservation devices outside; said slurry bed 1 includes lower bed body 101, middle bed body 102, expansion section 103, said One end of the overflow pipe 2 is connected to the upper part of the middle bed body 102, and the other end is connected to the upper part of the liquid-solid separator 4. A gas outlet 1031 is opened on the top of the enlarged section 103, and a mist eliminator 1032 is installed inside. One of net demister, particle packing demister or we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com