Metal plate machining chamfering equipment

A sheet metal and corner technology, applied in the field of sheet metal processing chamfering equipment, can solve the problems of insecurity, uneven sides of sheet metal raw materials, and easy scratching of air-conditioning rack accessories, so as to improve accuracy, Process continuous and efficient, quality-assured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the technical solution of this embodiment will be described in detail below in conjunction with the accompanying drawings. The following embodiments are only used to illustrate the technical solution of this embodiment more clearly, so they are only examples, and should not be used to limit the protection scope of this embodiment.

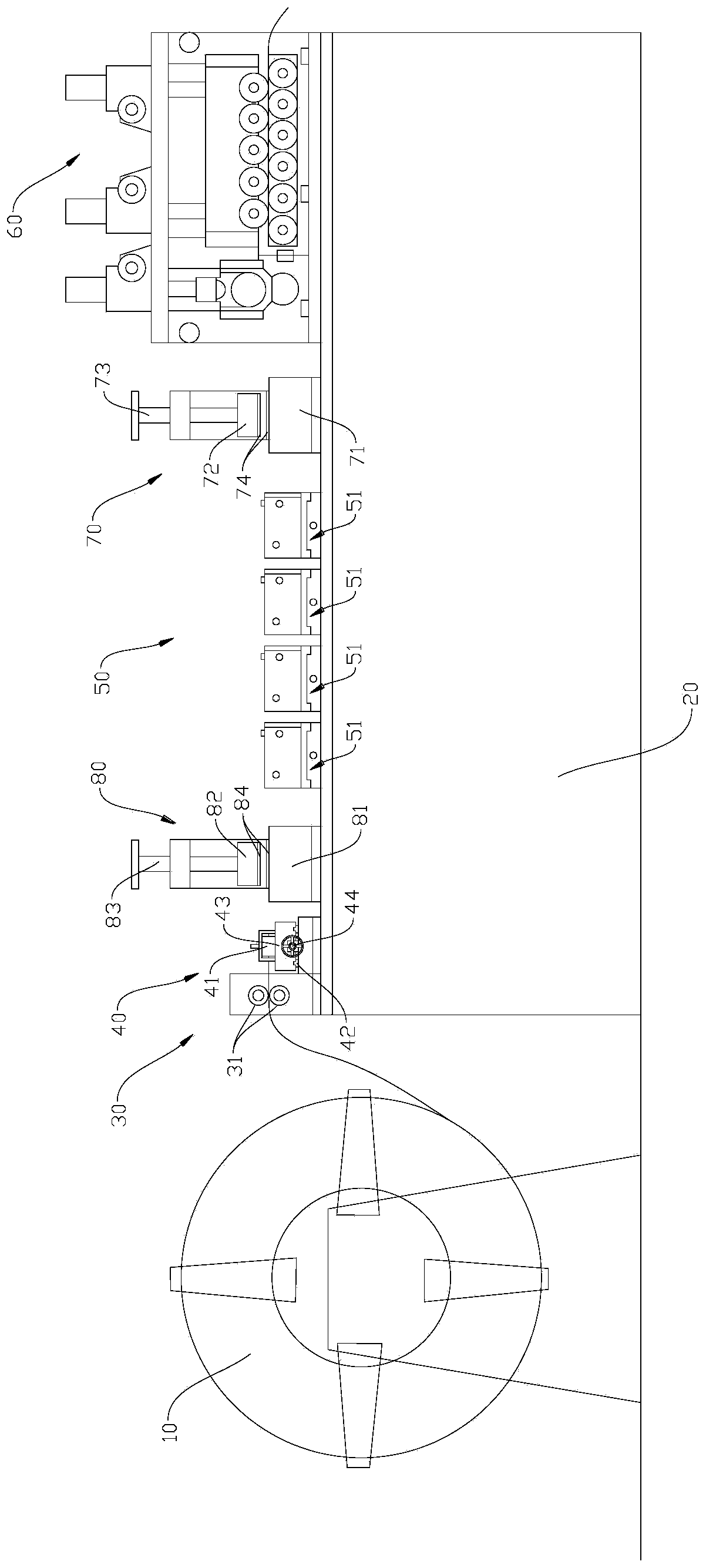

[0021] Such as Figure 1-Figure 3 As shown, the embodiment of the present invention provides a sheet metal processing chamfering equipment, including a discharge rack 10 and a frame 20, the discharge frame 10 leads the sheet metal to the frame 20, and the frame 20 is sequentially provided with an introduction mechanism 30. A limit mechanism 40, a chamfering mechanism 50 and a pulling mechanism 60 for pulling sheet metal.

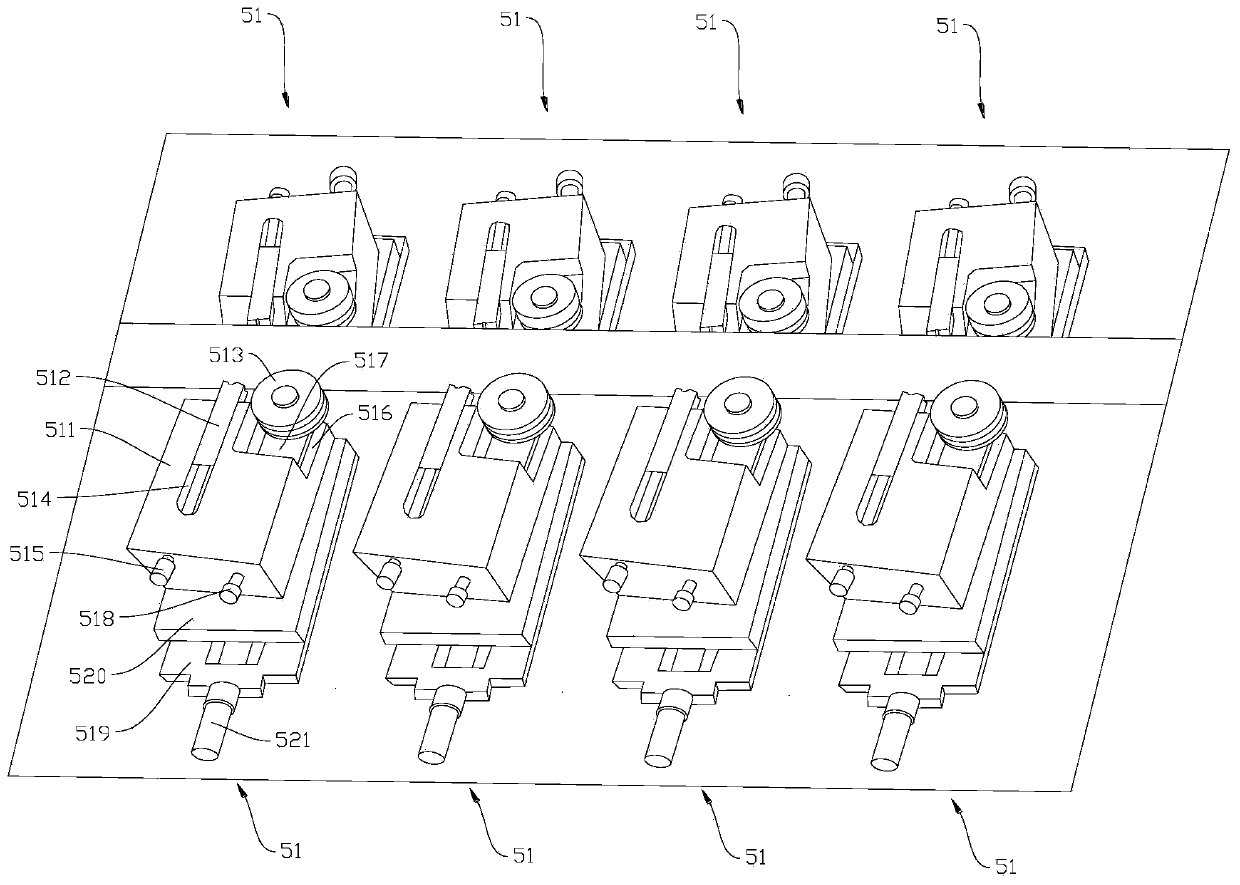

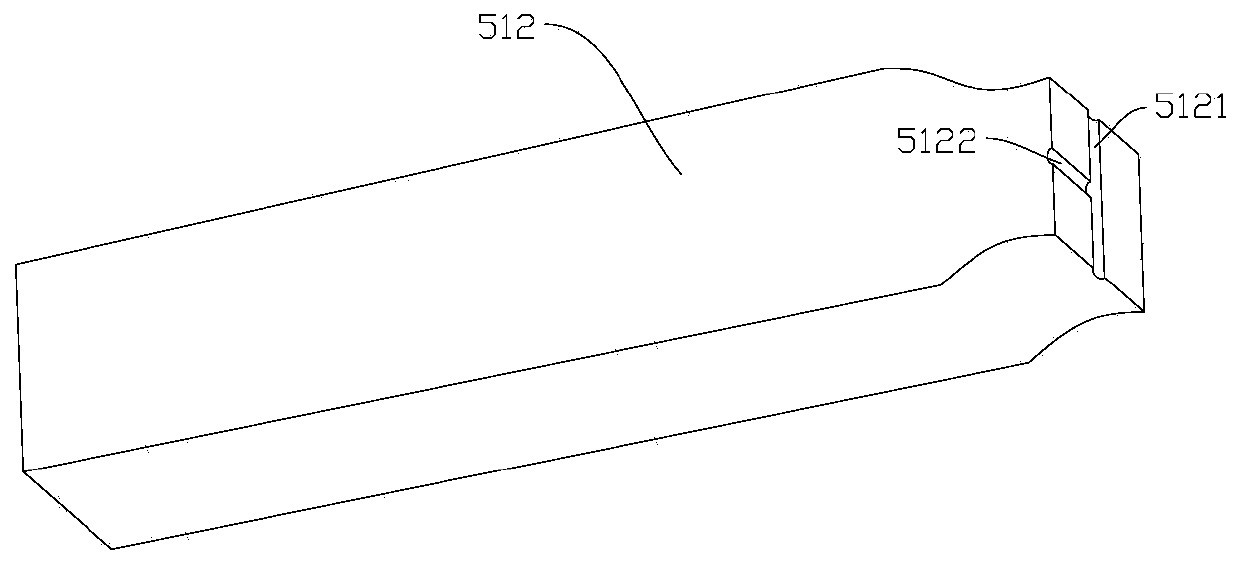

[0022] The introduction mechanism 30 includes a pair of flat nip rollers 31 respectively clamped on the upper and lower sides of the sheet metal. The limit mechanism 40 includes a pair of first limit wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com