Material reciprocating transferring device and method

A transfer device, reciprocating technology, applied in the direction of conveyor objects, transportation and packaging, furnaces, etc., can solve the problems of lower product yield, large labor force, pattern deviation, etc., to improve production efficiency, save operating time, and shrink The effect of the transfer cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

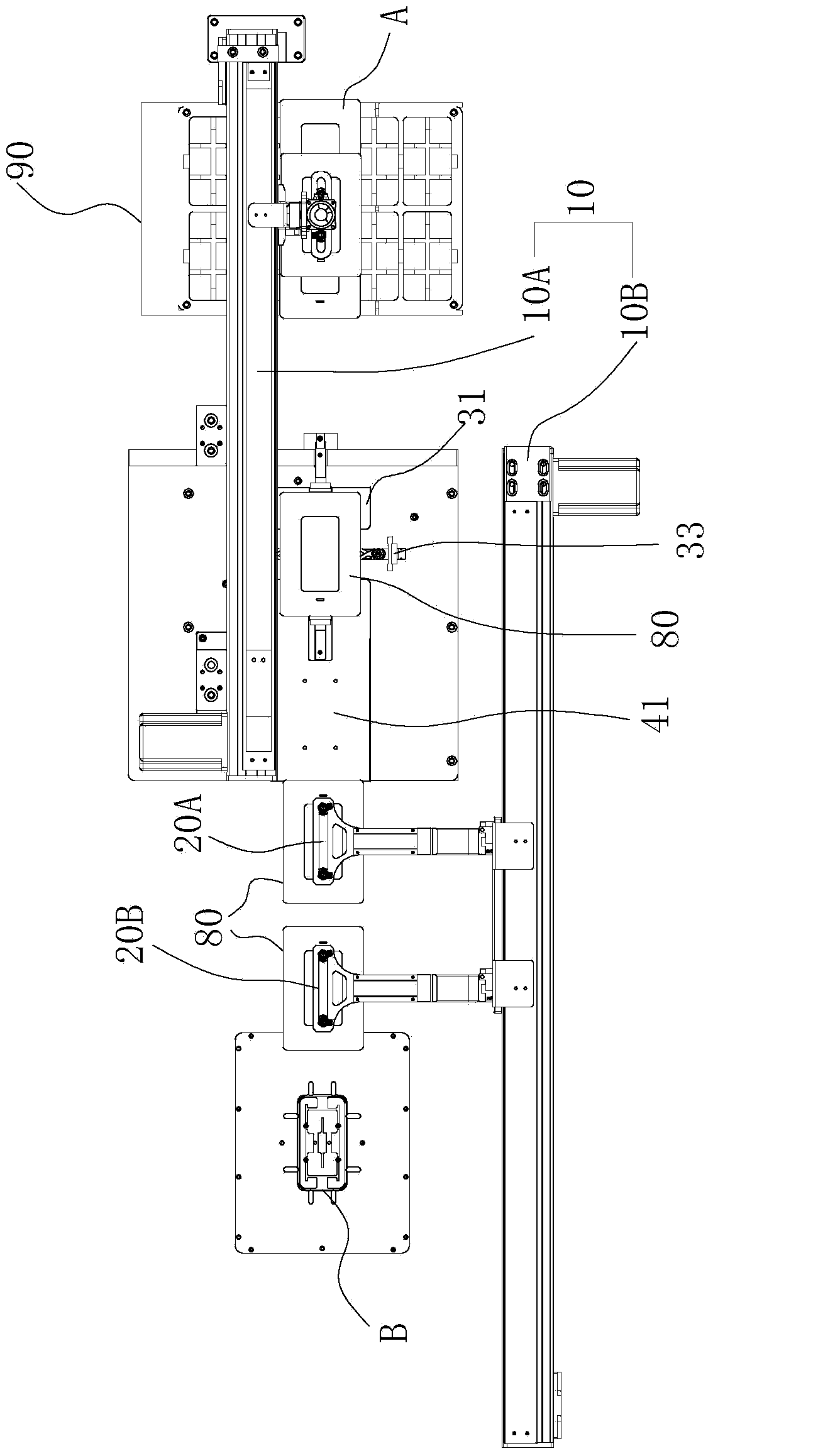

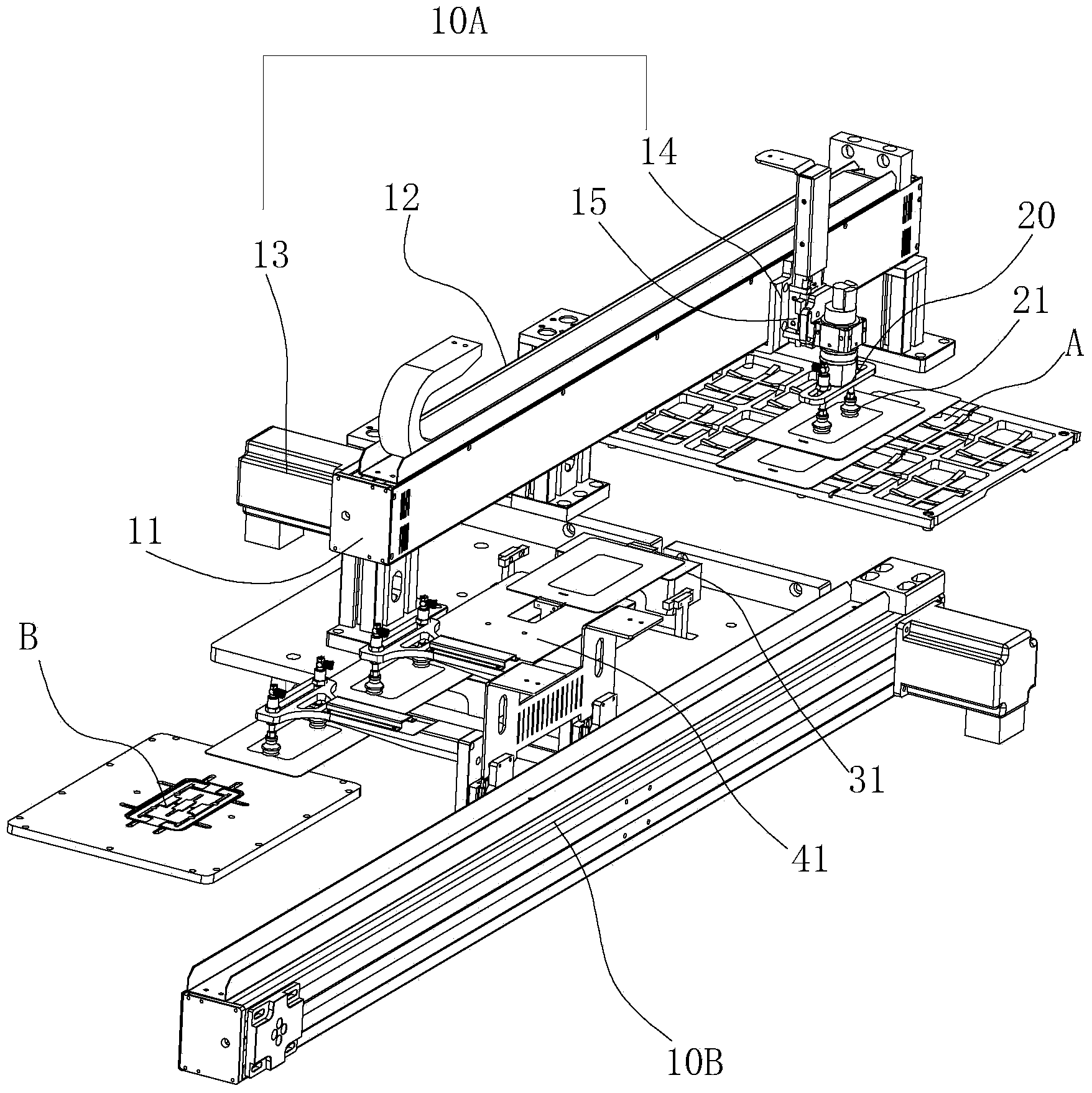

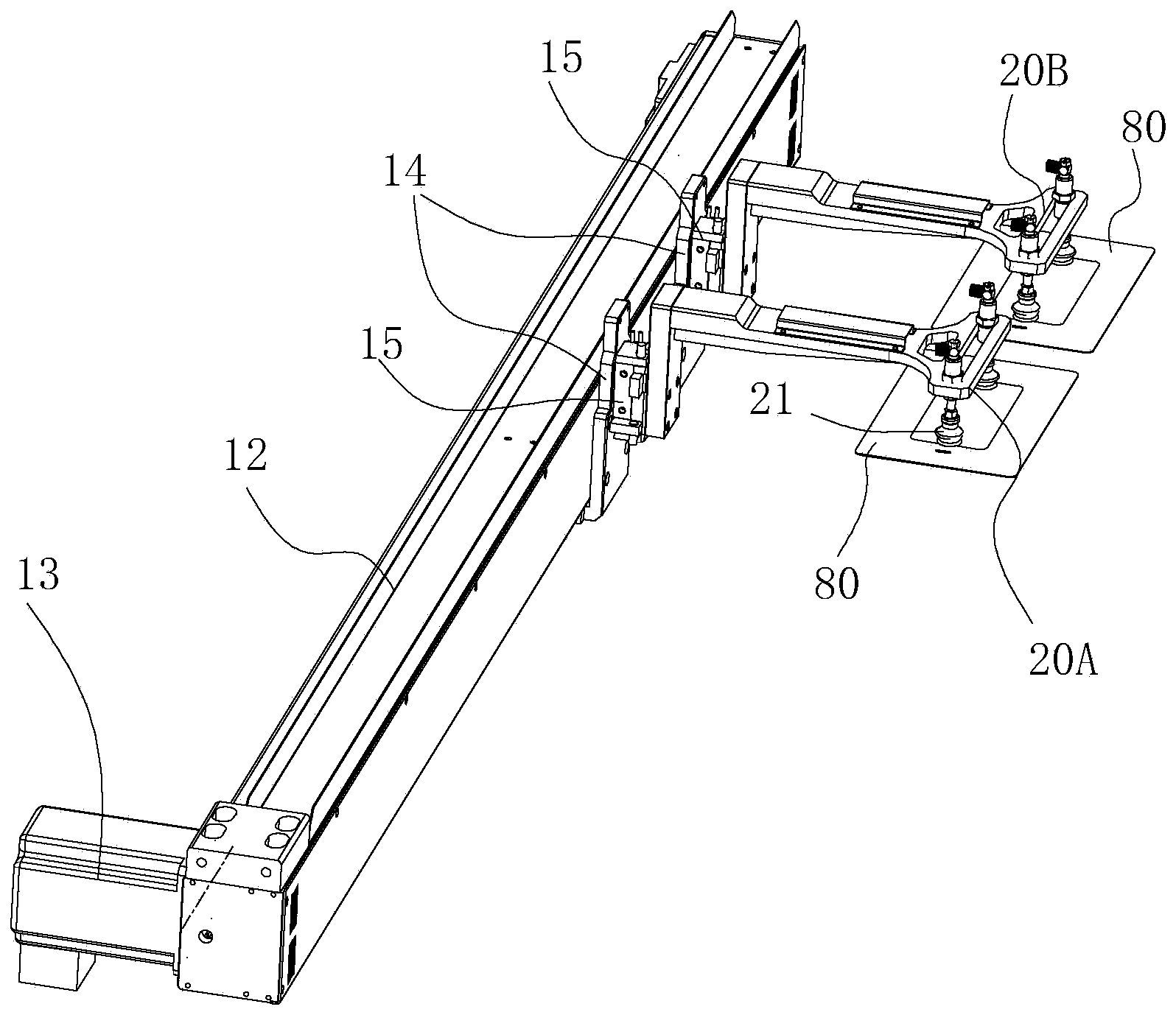

[0040] Such as Figure 1-5As shown, a material reciprocating transfer device of the present invention, the transfer device is arranged between the material device and the processing device, including a transfer mechanism 10 arranged between the material position A of the material device and the processing position B of the processing device, The transfer mechanism 10 is movably connected with a downward retrieving mechanism 20, and also includes a primary positioning mechanism 30 (also called a secondary positioning mechanism) located below the middle section of the transfer mechanism 10. The feeding of the glass plate (that is, the workpiece) includes the first For the first feeding and the second feeding, the first retrieving is fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com