Automatic tension correction system for flexible material in supply process and correction method thereof

An automatic calibration, flexible material technology, applied in the parts of the TV system, thin material processing, winding strips, etc., can solve the problems of difficult adjustment and high maintenance frequency, to ensure position consistency, reduce labor intensity, The effect of reducing the frequency of manual maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The tension automatic correction system and correction method of the flexible material in the supply process of the present invention will be described in detail below with reference to the embodiments and drawings.

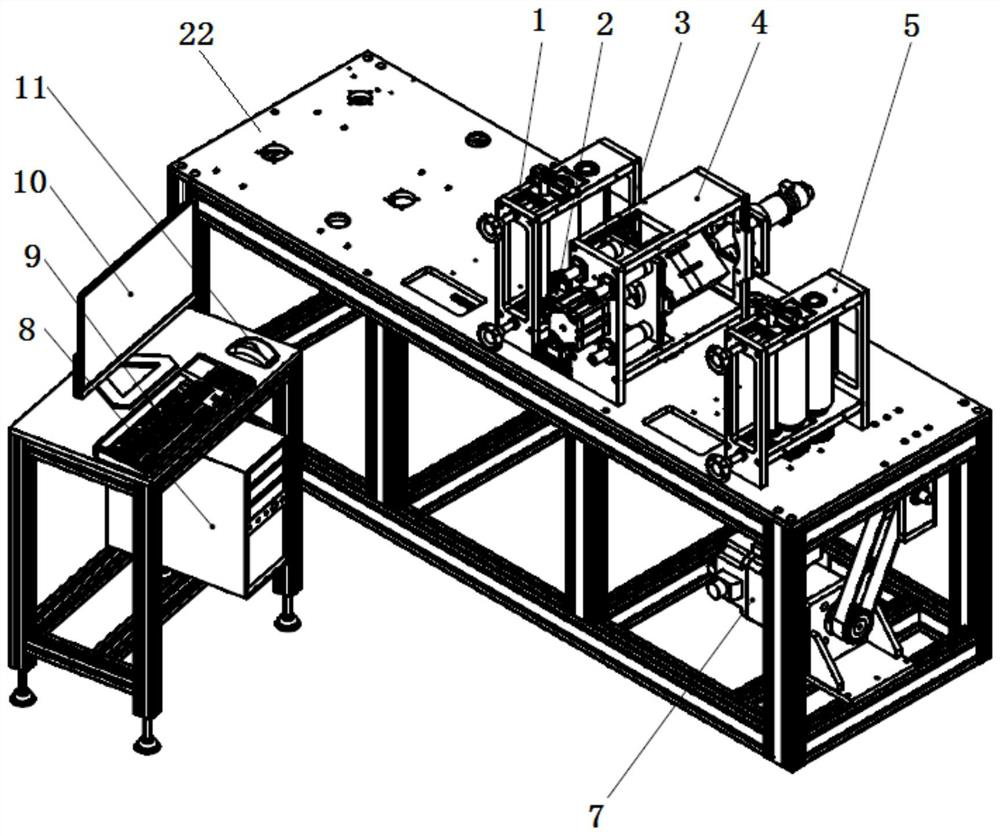

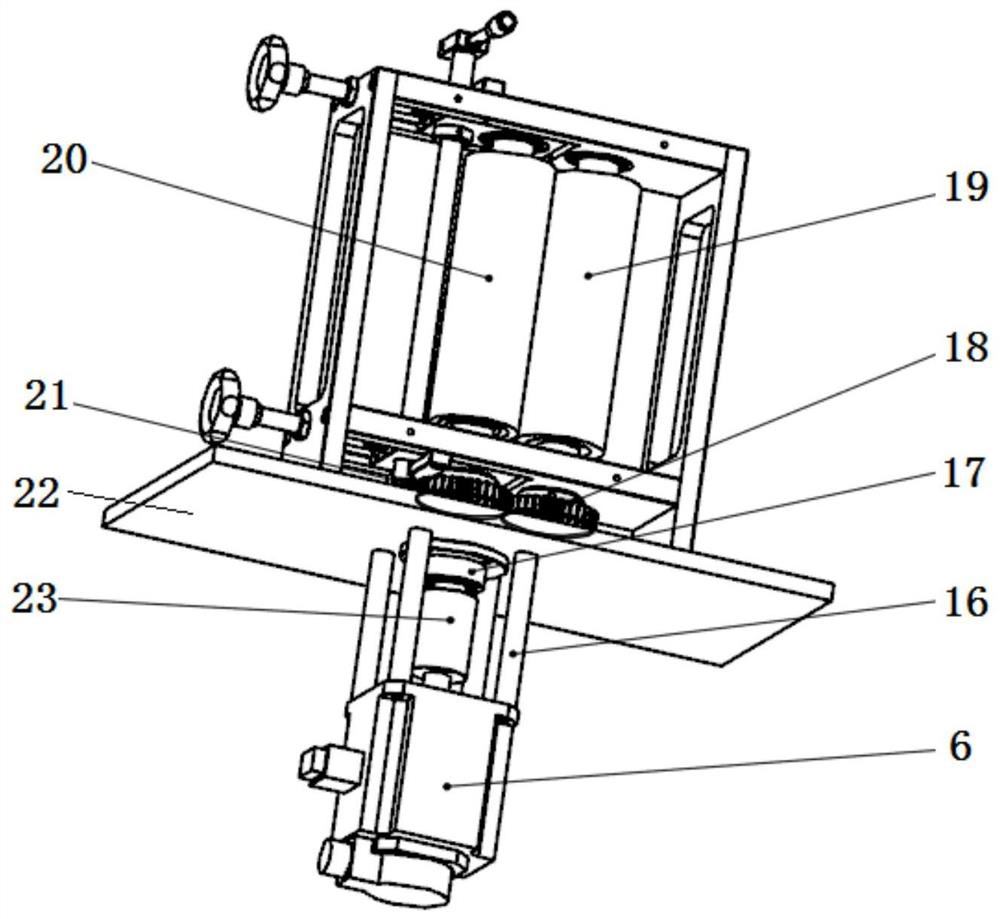

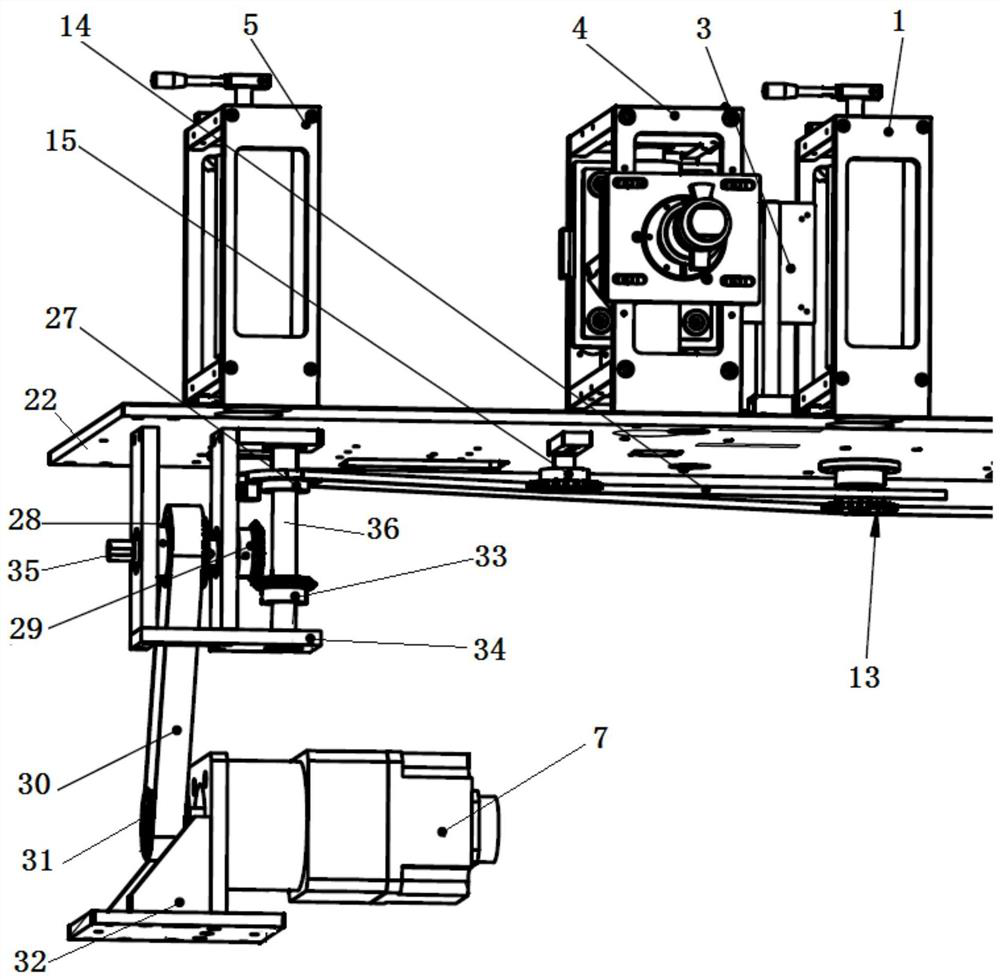

[0034] Such as figure 1 , figure 2 , image 3 As shown, the tension automatic correction system of the flexible material in the supply process of the present invention is an automatic tension correction system arranged in the KN95 mask machine, and it is characterized in that it includes the same front tension mechanism as the KN95 mask machine. 5 connected to drive the front tensioning mechanism driving system with 5 tensioning force of the front tensioning mechanism, connected to the rear tensioning mechanism 1 in the KN95 mask machine and used to drive the rear tensioning mechanism driving system of 1 tensioning force , the image acquisition system for collecting the image of the degree of tightness of the mask cloth 12 is arranged between the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com