Method for preparing strong-absorption antibacterial paper diaper

A kind of antibacterial paper, strong absorption technology, applied in the direction of absorbent pads, medical science, clothing, etc., can solve the problems of users' safety and health, itching and rash, damage to the skin protective layer, etc., to avoid itching and rash, Keep the skin dry and ensure the effect of safety and health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

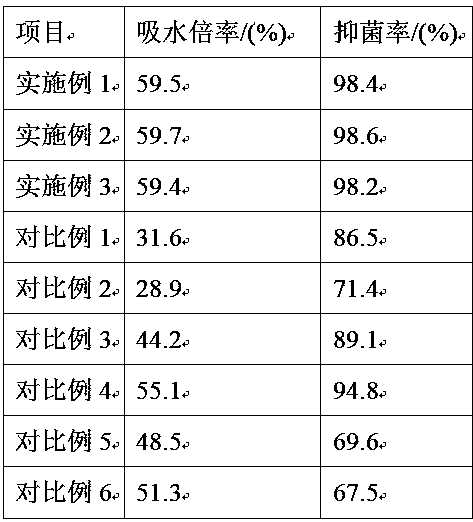

Examples

Embodiment 1

[0029] A method for preparing a strong absorption antibacterial diaper, comprising the following steps:

[0030] (1) Preparation of surface non-woven fabric: Mix the surface raw material fibers evenly, lay the net, and then perform spunlace reinforcement. The surface raw material fibers are composed of chitosan fibers, composite water-absorbing resin fibers, nano-antibacterial biological protein fibers and silk fibers. After the surface layer non-woven fabric contacts the urine, it can instantly avoid the itching and rash caused by the urine contacting the skin, and the surface layer non-woven fabric is obtained; the surface layer raw material fiber is composed of the following raw materials by weight: chitosan fiber 46 , composite water-absorbent resin fiber 40, nanometer antibacterial biological protein fiber 25, silk fiber 14; described composite water-absorbent resin fiber, adds microporous silica gel to the water-absorbent resin, vacuum heats until completely melted, heat ...

Embodiment 2

[0039] A method for preparing a strong absorption antibacterial diaper, comprising the following steps:

[0040] (1) Preparation of surface non-woven fabric: Mix the surface raw material fibers evenly, lay the net, and then perform spunlace reinforcement. The surface raw material fibers are composed of chitosan fibers, composite water-absorbing resin fibers, nano-antibacterial biological protein fibers and silk fibers. After the surface layer non-woven fabric contacts the urine, it can instantly avoid the itching and rash caused by the urine contacting the skin, and the surface layer non-woven fabric is obtained; the surface layer raw material fiber is composed of the following raw materials in parts by weight: chitosan fiber 47 , composite water-absorbing resin fiber 41, nanometer antibacterial biological protein fiber 26, silk fiber 15; described composite water-absorbing resin fiber, adds microporous silica gel to the water-absorbing resin, heats in vacuum until completely m...

Embodiment 3

[0049] A method for preparing a strong absorption antibacterial diaper, comprising the following steps:

[0050] (1) Preparation of surface non-woven fabric: Mix the surface raw material fibers evenly, lay the net, and then perform spunlace reinforcement. The surface raw material fibers are composed of chitosan fibers, composite water-absorbing resin fibers, nano-antibacterial biological protein fibers and silk fibers. After the surface layer non-woven fabric contacts urine, it can instantly avoid itching and rash caused by urine contacting the skin, so as to obtain a surface layer non-woven fabric; the surface layer raw material fiber is composed of the following raw materials in parts by weight: chitosan fiber 48 , composite water-absorbent resin fiber 42, nanometer antibacterial biological protein fiber 27, silk fiber 16; described composite water-absorbent resin fiber, adds microporous silica gel to the water-absorbent resin, heats in vacuum until completely melted, heat pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com