Method for preparing positive plate of lithium-iron button battery

A battery positive electrode and iron buckle technology, applied in the direction of electrode manufacturing, etc., can solve the problems that the battery processing performance needs to be further improved, and achieve the effects of improving the consistency of internal resistance, improving capacity, and improving mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

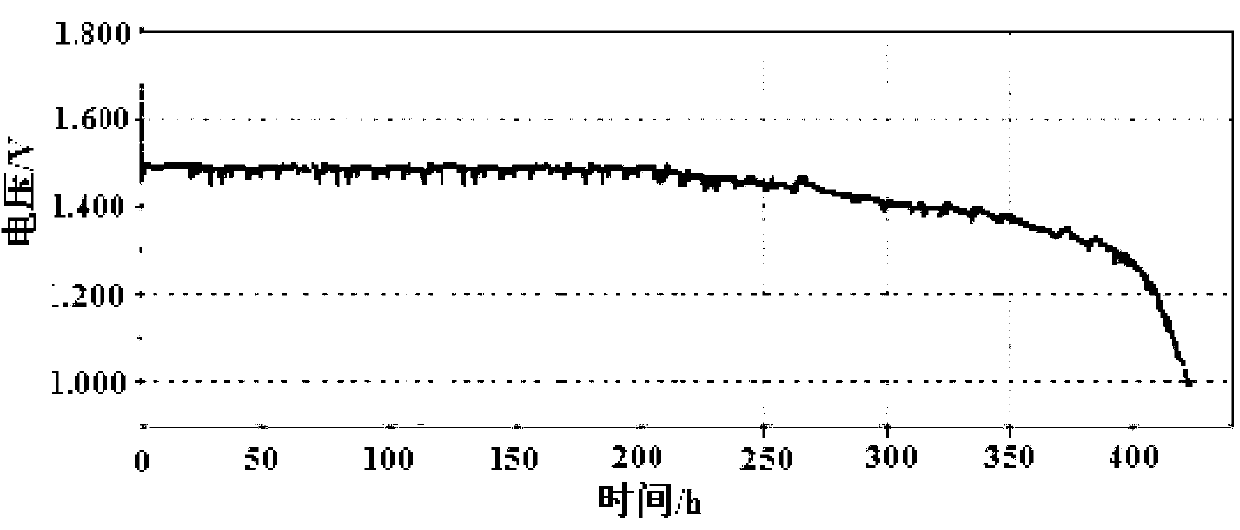

Image

Examples

Embodiment 1

[0019]First, the high-temperature pretreated iron disulfide cathode material was put into a ceramic ball mill for ball milling, the diameter of the ball was 3 cm, the mass ratio of iron disulfide to the ball was 1:5, the rotation speed was 100 r / min, and the ball milling time was 3 h. After passing through a 150-mesh sieve, the sieved iron disulfide and conductive carbon Super-p are added to a ceramic ball mill at a mass ratio of 96:1 for ball milling. The diameter of the ball is 3 cm, and the mass ratio of powder to ball is 1:7. , Speed: 100r / min, ball milling time 1h. Pass through a 150 mesh sieve. Add the mixture of iron disulfide and conductive agent into the mixing bucket of the planetary mixer, add the pre-prepared deionized water boiling at 100°C, and stir rapidly. The mass ratio of deionized water to powder is 1.5:1, and the revolution Speed 20±1r / min, rotation 1500±50r / min, stirring time 0.5h, then add PTFE solution (polytetrafluoroethylene) (concentration 60%), th...

Embodiment 2

[0021] First, the high-temperature pretreated iron disulfide cathode material was put into a ceramic ball mill for ball milling, the diameter of the ball was 3 cm, the mass ratio of iron disulfide to the ball was 1:5, the rotation speed was 100 r / min, and the ball milling time was 3 h. After passing through a 150 mesh sieve, the sieved iron disulfide, the conductive agent acetylene black, and the conductive agent conductive graphite KS-6 are added to a ceramic ball mill at a mass ratio of 96:0.5:1 for ball milling. The diameter of the ball is 3 cm. The ball mass ratio is 1:8, the rotational speed: 100r / min, and the ball milling time is 2h. Pass through a 150 mesh sieve. Add the mixture of iron disulfide and conductive agent into the mixing bucket of the planetary mixer, add the pre-prepared deionized water boiling at 100°C, and stir rapidly. The mass ratio of deionized water to powder is 2:1, and the revolution Speed 20±1r / min, rotation 1500±50r / min, stirring time 1h, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com