Lithium battery diaphragm for power battery and preparation method thereof

A technology for lithium battery separators and power vehicles. It is applied in the direction of batteries, lithium batteries, battery pack components, etc. It can solve the problems of battery combustion, hole generation, and size shrinkage, so as to improve heat shrinkage resistance, thermal stability, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

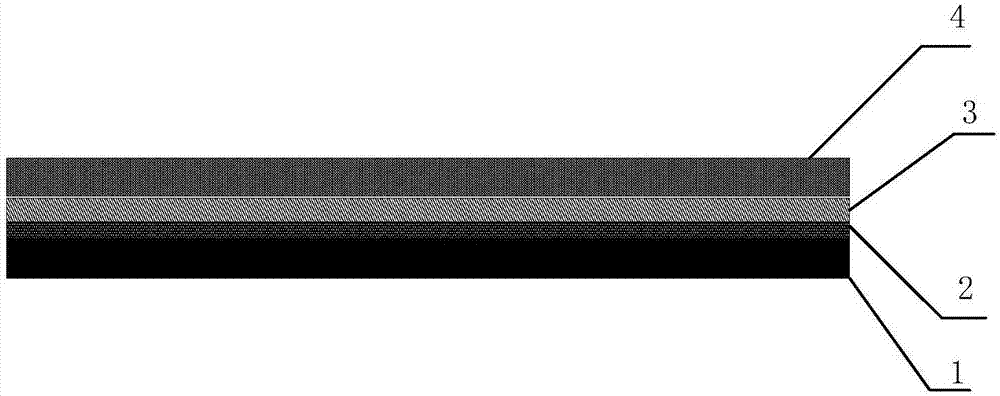

[0046] Such as figure 1 The lithium battery separator for power vehicles shown has four layers, which are base film 1, nano flame retardant layer 2, electrospun nanofiber layer 3 and thermal closure layer 4 from bottom to top, wherein base film 1 is PET nuclear pore membrane with a thickness of 5 μm to 20 μm, the nano flame retardant layer 2 is a flame retardant ceramic slurry with a thickness of 0.5 μm to 10 μm, the electrospun nanofiber layer 3 is 2 μm to 5 μm in thickness, and the thermal closure layer 4 is made of 5 μm to 10 μm in thickness High temperature resistant epoxy resin. Among them, the etched pore diameter of the PET nuclear pore membrane is 0.1 μm to 1.0 μm, and the density is 1×10 5 ~5×10 6 / cm 2 . The polymer material of the electrospun nanofiber layer is polyacrylonitrile, polyimide or polyvinylidene fluoride.

preparation Embodiment 1

[0047] Preparation Example 1: Preparation of Lithium Battery Diaphragm for Power Vehicles

[0048] The preparation of step (1) PET nuclear pore membrane

[0049] Using a heavy ion accelerator to provide a window energy of 10MeV / u 86 K r 26+ The ions were irradiated to the PET film, the scanning current was 120nA, and then the irradiated PET nuclear pore film was chemically etched. The etching solution was an aqueous solution of sodium hydroxide with a concentration of 1M, the etching temperature was set at 70°C, and the etching time was 30 Minutes, after etching and cleaning with deionized water, the PET nuclear pore membrane layer was obtained.

[0050] Step (2) coating flame retardant ceramic slurry

[0051] The raw material formula of the flame-retardant ceramic slurry is calculated in parts by weight:

[0052] 0.05 parts of vinyltrimethoxysilane, 10 parts of nano-titanium dioxide, 5 parts of melamine polyphosphate, 30 parts of dimethylacetamide, 2 parts of styrene-but...

preparation Embodiment 2

[0062] Preparation Example 2: Preparation of Lithium Battery Diaphragm for Power Vehicles

[0063] The preparation of step (1) PET nuclear pore membrane

[0064] Using a heavy ion accelerator to provide a window energy of 50MeV / u 86 K r 26+ The ions were irradiated to the PET film, the scanning current was 200nA, and then the irradiated PET nuclear pore film was chemically etched. The etching solution was a sodium hydroxide aqueous solution with a concentration of 1M, the etching temperature was set at 90°C, and the etching time was 30 Minutes, after etching and cleaning with deionized water, the PET nuclear pore membrane layer was obtained.

[0065] Step (2) coating flame retardant ceramic slurry

[0066] The raw material formula of the flame-retardant ceramic slurry is calculated in parts by weight:

[0067] 3 parts of vinyltrimethoxysilane, 40 parts of nano silicon dioxide, 30 parts of melamine polyphosphate, 50 parts of solvent, 10 parts of polyacrylic acid, 2 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com