Preparation method of high-efficiency negative active material for lithium ion secondary battery

A negative electrode active material and lithium-ion battery technology, applied in the direction of secondary batteries, battery electrodes, circuits, etc., can solve the problems of not being suitable for large-scale production, not effectively improving the first effect, affecting Coulombic efficiency, etc., and achieving excellent electrochemical performance Effects of cycle stability, inhibition of SEI film formation, and improvement of Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

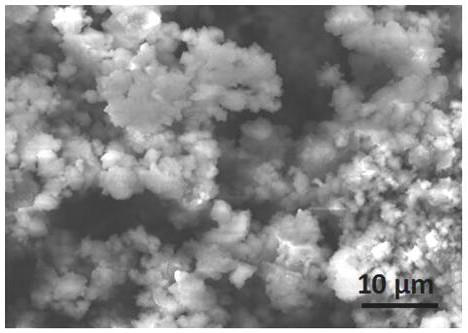

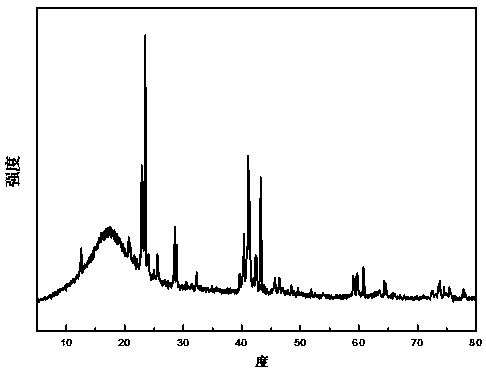

Image

Examples

Embodiment 1

[0043] Lithium-ion battery of the present invention can be prepared by the following method:

[0044] (1) Li 4.4 Preparation of Si:

[0045] The pre-milled silicon powder and shredded lithium flakes were mixed and placed in a zirconia ball mill jar at a molar ratio of 1:4.4, and cyclohexane was added as a lubricant, and high-energy ball milled on a planetary ball mill at a speed of 450 rpm for 15 hours. (The ball used is made of stainless steel) The material ratio is 100:1 to obtain nano-scale Li 4.4 Si material.

[0046] (2) Preparation of silicon / graphite / carbon composite negative electrode material:

[0047] (1) Put the above pre-milled silicon powder and pre-milled graphite in a ceramic ball mill tank according to the mass ratio of 25:55, and mix them in a high-energy ball mill on a planetary ball mill at a speed of 400 rpm for 5 hours. The material ratio of the balls (the balls used are made of ceramic materials) is 10:1, get silicon / graphite composite material.

[0...

Embodiment 2

[0062] (1) Li 4.4 Preparation of Si:

[0063] The silicon powder after pre-ball milling and the shredded lithium flakes are mixed in a zirconia ball mill jar according to a molar ratio of 1:5.2, and n-hexane is added as a lubricant, and high-energy ball milling is carried out on a planetary ball mill at a speed of 400rpm for 10h, and the balls ( The ball used is made of stainless steel) with a material ratio of 80:1 to obtain nanoscale Li 4.4 Si material.

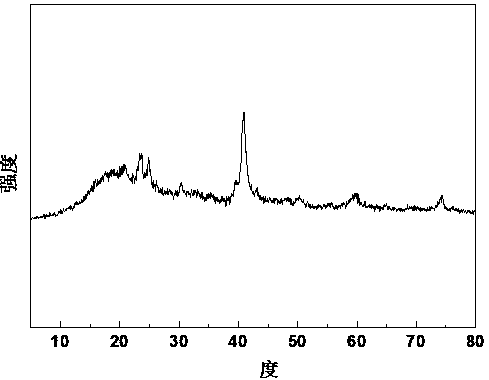

[0064] Li prepared above 4.4 XRD patterns of Si and figure 2 similar.

[0065] (2) Preparation of silicon / graphite / carbon composite negative electrode material:

[0066] (1) Put the above pre-milled silicon powder and pre-milled graphite in a ceramic ball mill tank according to the mass ratio of 30:50, and mix them in a high-energy ball mill on a planetary ball mill at a speed of 450rpm for 10 hours. The material ratio of the balls (the balls used are ceramic materials) is 20:1, to obtain a silicon / graphite composite...

Embodiment 3

[0078] (1) Li 4.4 Preparation of Si:

[0079] The silicon powder after the pre-ball milling and the shredded lithium flakes are mixed and placed in a zirconia ball mill jar according to a molar ratio of 1:5.8, and toluene is added as a lubricant, and high-energy ball milling is performed on a planetary ball mill at a speed of 500rpm for 20h, and the balls (used The ball is made of stainless steel) The material ratio is 120:1, and the nano-scale Li 4.4 Si material.

[0080] Li prepared above 4.4 XRD patterns of Si and figure 2 similar.

[0081] (2) Preparation of silicon / graphite / carbon composite negative electrode material:

[0082] (1) Put the above pre-milled silicon powder and pre-milled graphite in a ceramic ball mill tank at a mass ratio of 15:75, and mix them with a high-energy ball mill on a planetary ball mill at a speed of 350rpm for 5 hours. The material ratio of the balls (the balls used are ceramic materials) is 15:1, to obtain silicon / graphite composites. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com