Template-free preparation method of modified hollow silicon microspheres

A silicon microsphere, template-free technology, applied in the direction of silicon, active material electrodes, structural parts, etc., can solve the problems of cumbersome preparation process, low Coulombic efficiency, large specific surface area of hollow silicon nanospheres, etc., achieve simple and safe process, improve Coulombic efficiency, the effect of reducing volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Add nano-silicon particles and polyethylene to deionized water, and ultrasonically vibrate for 10min at 40kHZ to obtain a dispersion; wherein, the particle diameter of nano-silicon particles is 100nm; the mass ratio of deionized water, nano-silicon particles and polyethylene is 180:20:1.

[0040] (2) Utilize a peristaltic pump to pass the dispersion into the reaction tank of an ultrasonic atomization device, and perform ultrasonic atomization under the action of pressure-sensitive ceramics to obtain atomized droplets; wherein, the atomization is carried out under a nitrogen atmosphere, and the atomization The gas flow rate is 150mL / min.

[0041] (3) Under a nitrogen atmosphere, pass the atomized liquid droplets into a high-temperature reaction furnace, pyrolyze them at 500°C for 0.5h, and recover the samples with a rear-end liquid-phase tail gas collection device to obtain a modified hollow silicon microsphere .

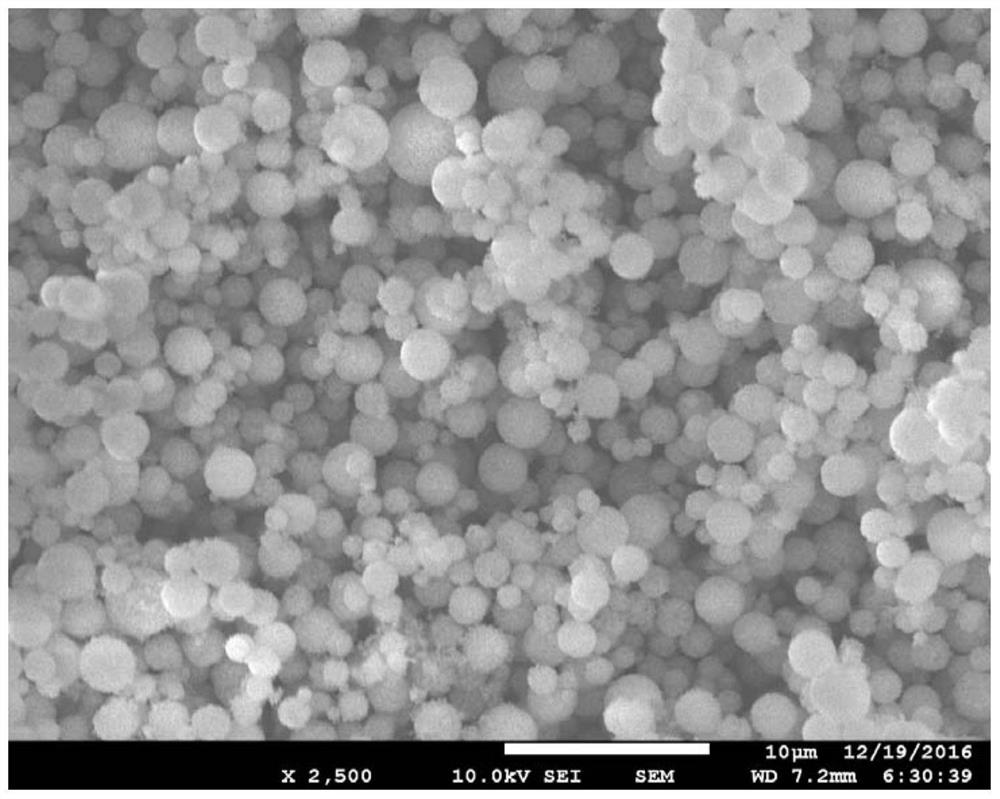

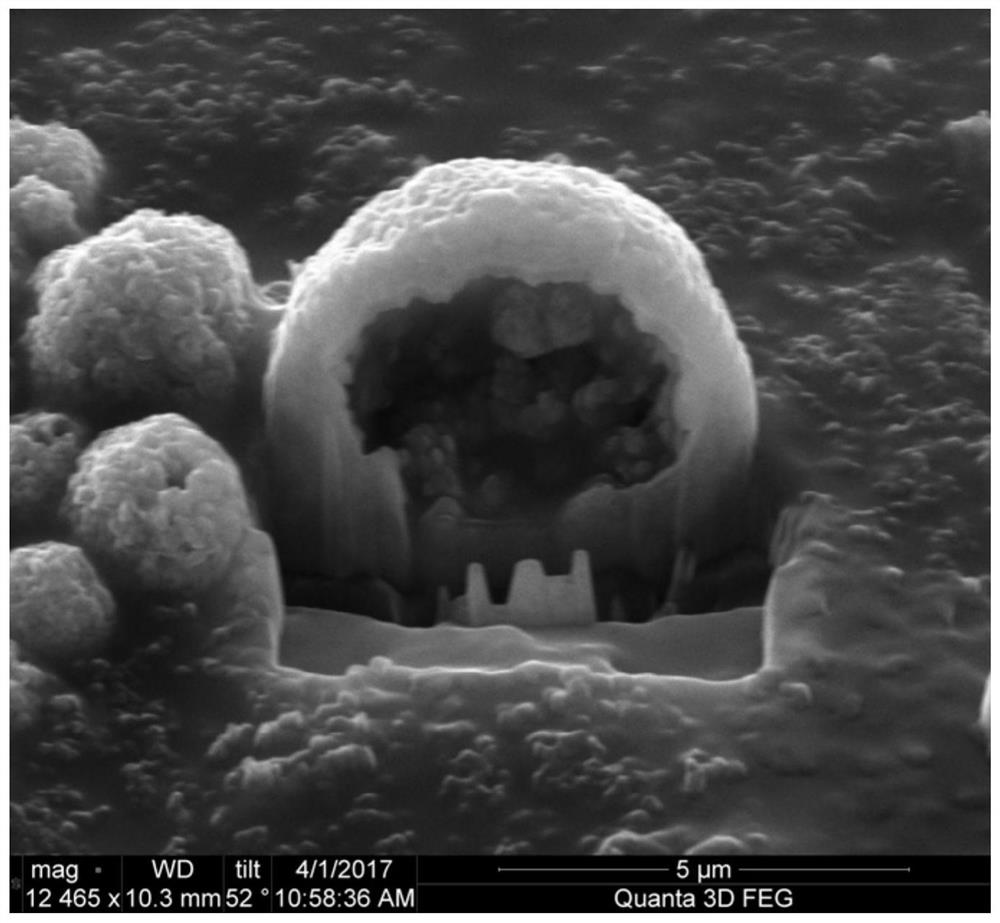

[0042] The SEM test results of the final product a...

Embodiment 2

[0045] (1) Add nano-silicon particles and polypropylene to deionized water, and ultrasonically vibrate for 10 minutes at 40kHZ to obtain a dispersion; wherein, the particle diameter of nano-silicon particles is 200nm; the mass ratio of deionized water, nano-silicon particles and polyethylene is 90:10:1.

[0046] (2) Utilize a peristaltic pump to pass the dispersion into the reaction tank of an ultrasonic atomization device, and perform ultrasonic atomization under the action of pressure-sensitive ceramics to obtain atomized droplets; wherein, the atomization is carried out under a nitrogen atmosphere, and the atomization The gas flow rate is 100mL / min.

[0047](3) Under a nitrogen atmosphere, pass the atomized liquid droplets into a high-temperature reaction furnace, pyrolyze them at 500°C for 0.5h, and recover the samples with a rear-end liquid-phase tail gas collection device to obtain a modified hollow silicon microsphere .

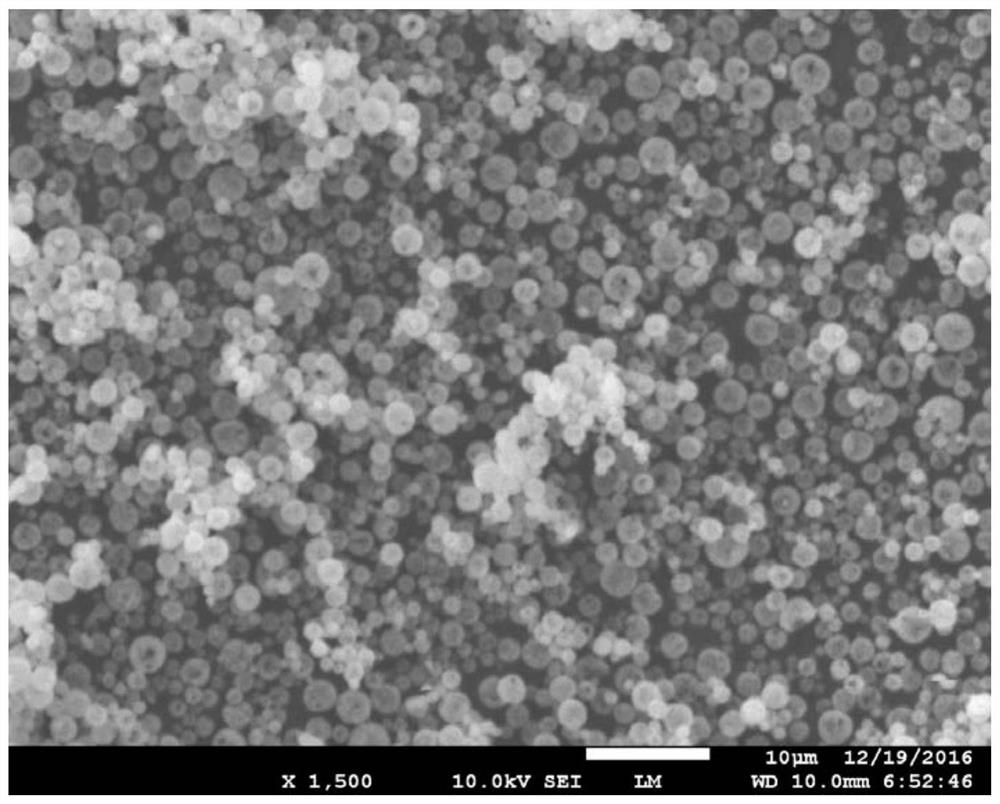

[0048] The SEM test results of the final produ...

Embodiment 3

[0051] (1) Add nano-silicon particles and polypropylene to deionized water, and ultrasonically vibrate for 10 minutes at 40kHZ to obtain a dispersion; wherein, the particle diameter of nano-silicon particles is 300nm; the mass ratio of deionized water, nano-silicon particles and polyethylene is 260:25:1.

[0052] (2) Utilize a peristaltic pump to pass the dispersion into the reaction tank of an ultrasonic atomization device, and perform ultrasonic atomization under the action of pressure-sensitive ceramics to obtain atomized droplets; wherein, the atomization is carried out under a nitrogen atmosphere, and the atomization The gas flow rate is 200mL / min.

[0053] (3) Under a nitrogen atmosphere, pass the atomized liquid droplets into a high-temperature reaction furnace, pyrolyze them at 500°C for 0.5h, and recover the samples with a rear-end liquid-phase tail gas collection device to obtain a modified hollow silicon microsphere .

[0054] The SEM test results of the final pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com