A kind of preparation method of high first-efficiency lithium-ion secondary battery negative electrode active material

A negative electrode active material and lithium-ion battery technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of not being suitable for large-scale production, not performing pre-lithiation, complex preparation process, etc., and achieve excellent electrochemical performance Cycle stability, high stability and cycle life, and the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

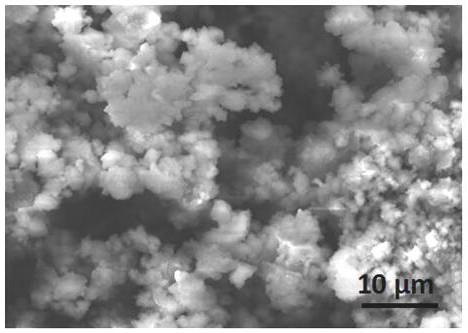

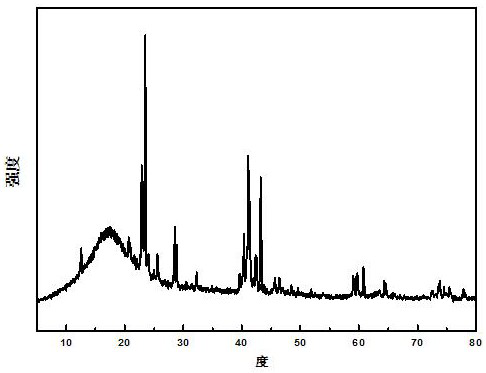

Image

Examples

Embodiment 1

[0043] Lithium-ion battery of the present invention can be prepared by the following method:

[0044] (1) Li 4.4 Preparation of Si:

[0045] The pre-milled silicon powder and shredded lithium flakes were mixed and placed in a zirconia ball mill jar at a molar ratio of 1:4.4, and cyclohexane was added as a lubricant, and high-energy ball milled on a planetary ball mill at a speed of 450 rpm for 15 hours. (The ball used is made of stainless steel) The material ratio is 100:1 to obtain nano-scale Li 4.4 Si material.

[0046] (2) Preparation of silicon / graphite / carbon composite negative electrode material:

[0047] (1) Put the above pre-milled silicon powder and pre-milled graphite in a ceramic ball mill tank according to the mass ratio of 25:55, and mix them in a high-energy ball mill on a planetary ball mill at a speed of 400 rpm for 5 hours. The material ratio of the balls (the balls used are made of ceramic materials) is 10:1, get silicon / graphite composite material.

[0...

Embodiment 2

[0062] (1) Li 4.4 Preparation of Si:

[0063] The silicon powder after pre-ball milling and the shredded lithium flakes are mixed in a zirconia ball mill jar according to a molar ratio of 1:5.2, and n-hexane is added as a lubricant, and high-energy ball milling is performed on a planetary ball mill at a speed of 400 rpm for 10 h, and the balls ( The ball used is made of stainless steel) with a material ratio of 80:1 to obtain nanoscale Li 4.4 Si material.

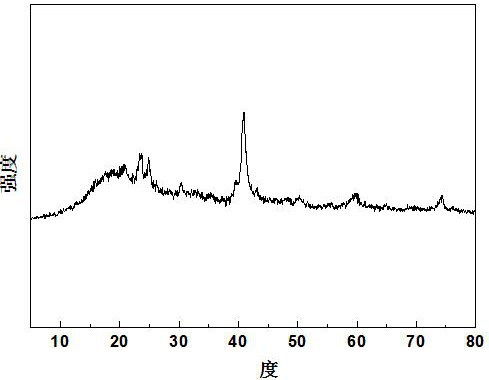

[0064] Li prepared above 4.4 XRD patterns of Si and figure 2 similar.

[0065] (2) Preparation of silicon / graphite / carbon composite negative electrode material:

[0066] (1) Put the above pre-milled silicon powder and pre-milled graphite in a ceramic ball mill tank according to the mass ratio of 30:50, and mix them in a high-energy ball mill on a planetary ball mill at a speed of 450rpm for 10 hours. The material ratio of the balls (the balls used are ceramic materials) is 20:1, to obtain a silicon / graphite composite...

Embodiment 3

[0078] (1) Li 4.4 Preparation of Si:

[0079] The silicon powder after the pre-ball milling and the shredded lithium flakes are mixed and placed in a zirconia ball mill jar according to a molar ratio of 1:5.8, and toluene is added as a lubricant, and high-energy ball milling is performed on a planetary ball mill at a speed of 500rpm for 20h, and the balls (used The ball is made of stainless steel) The material ratio is 120:1, and the nano-scale Li 4.4 Si material.

[0080] Li prepared above 4.4 XRD patterns of Si and figure 2 similar.

[0081] (2) Preparation of silicon / graphite / carbon composite negative electrode material:

[0082] (1) Put the above pre-milled silicon powder and pre-milled graphite in a ceramic ball mill tank at a mass ratio of 15:75, and mix them with a high-energy ball mill on a planetary ball mill at a speed of 350rpm for 5 hours. The material ratio of the balls (the balls used are ceramic materials) is 15:1, to obtain silicon / graphite composites. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com