Structure and method for supplementing lithium to lithium ion battery based on lithium silicide composite material

A technology of lithium-ion batteries and composite materials, which is applied in the structural field of lithium-ion battery supplementation based on lithium silicide composite materials, can solve problems such as difficulties in large-scale industrial production, complex battery design, and large short-circuit of batteries, and achieve process equipment and Low environmental requirements, easy scale production, and improved cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

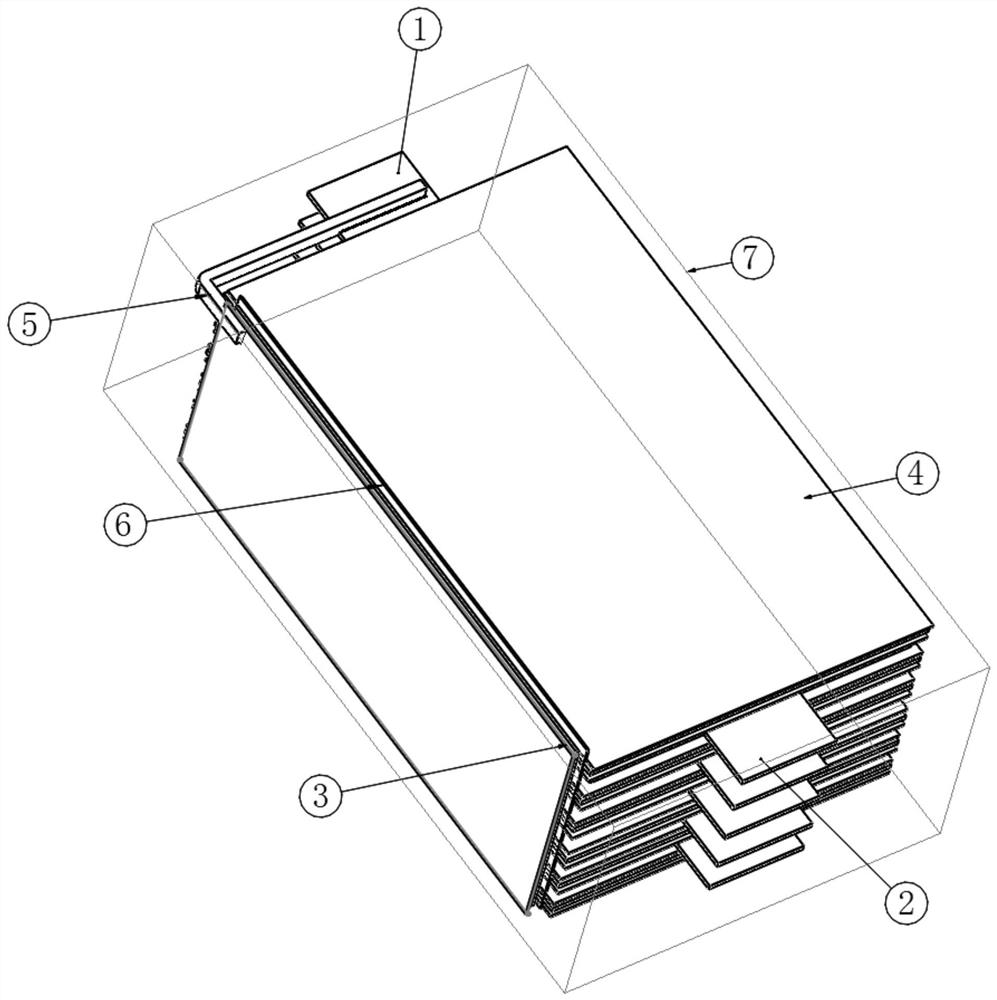

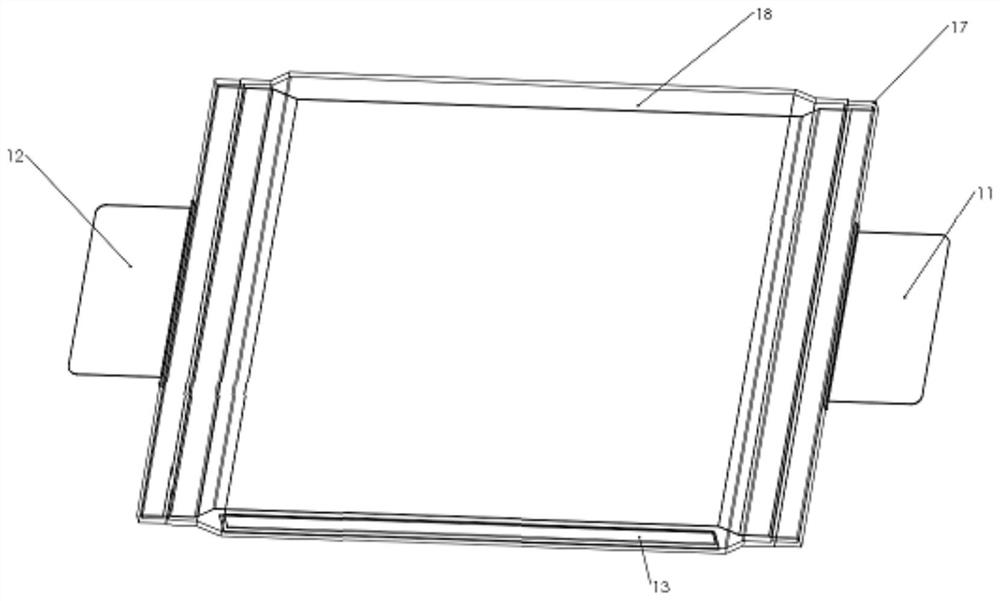

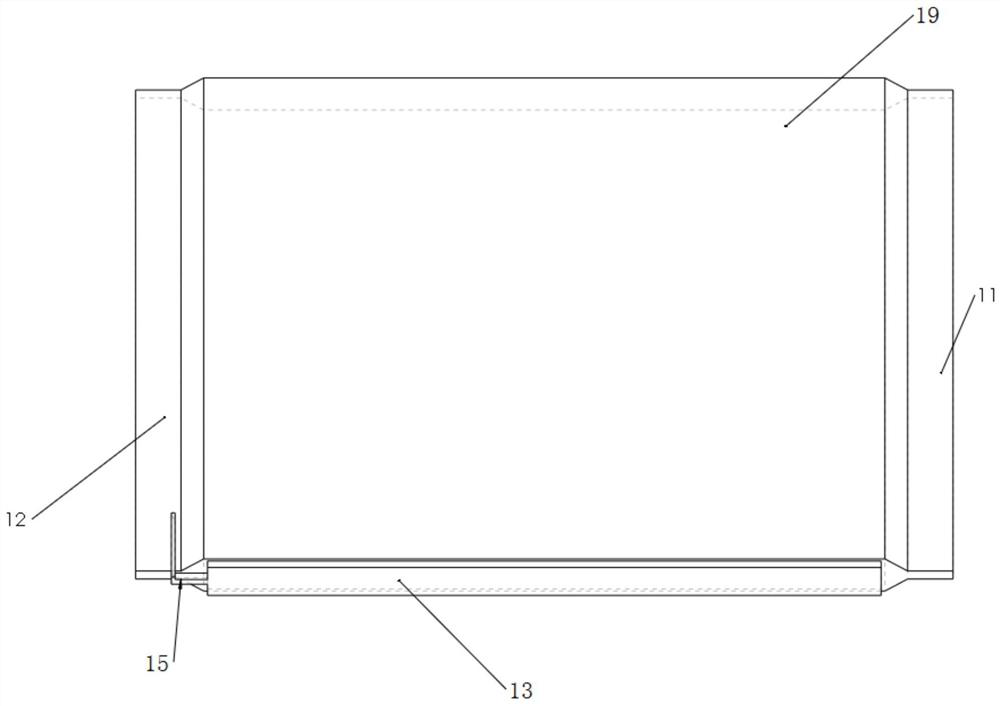

Embodiment 1

[0101] This implementation provides a method for supplementing lithium in a lithium-ion battery. In this embodiment, the capacity of the lithium-ion battery is a 25Ah coiled battery, with lithium iron phosphate as the positive electrode, artificial graphite as the negative electrode, and copper foil as the current collector; The lithium composite material is made into pole pieces of a certain size through homogenization, coating, and slitting. After the separator is wrapped, the pole piece is placed at the bottom of the lithium-ion battery, and the copper foil of the lithium silicide pole piece is connected to the negative electrode current collector. Package, inject electrolyte, and let stand. Using a small current of 0.01C for the first formation, the first charge capacity is 27.2Ah, the discharge capacity is 26.5Ah, and the first coulombic efficiency is 97.4%, which is 5.6% higher than the first coulombic efficiency (91.8%) of the battery without lithium supplementation. In...

Embodiment 2

[0103] A method for replenishing lithium in a lithium-ion battery is provided in this implementation. In this embodiment, the capacity of the lithium-ion battery is a 25Ah winding battery, with lithium iron phosphate as the positive electrode, and 650mAh / g of silicon carbon and graphite composite materials as the negative electrode. Copper foil is the current collector; the lithium silicide composite material is made into pole pieces of a certain size through homogenization, coating, and slitting. Connected to the negative electrode current collector, packaged, injected with electrolyte, and left to stand for the first week of formation with a small current of 0.01C. The first week’s charge capacity is 27.6Ah, discharge capacity is 25.8Ah, and the first Coulombic efficiency is 93.4%, which is higher than that of batteries without lithium supplementation. Efficiency (80.5%) increased by 12.9% in the first week.

Embodiment 3

[0105] A method for supplementing lithium in a lithium-ion battery provided by this implementation. In this embodiment, the capacity of the lithium-ion battery is a 25Ah laminated battery, with lithium nickel manganese oxide as the positive electrode, and 650mAh / g of silicon carbon and graphite composite material as the negative electrode. Copper foil is used as the current collector; the lithium silicide composite material is made into pole pieces of a certain size through homogenization, coating, and slitting. The foil and the negative electrode current collector are connected and conducted, packaged, injected with electrolyte, and left to stand. Using a small current of 0.01C for the first week of formation, the first week’s charge capacity is 30Ah, the discharge capacity is 27.2Ah, and the first-time Coulombic efficiency is 90.6%, which is 10.6% higher than the first-week efficiency (80%) of the battery without lithium supplementation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com